PAGE 4 — JTN RIDE-ON TROWEL— OPERATION & PARTS MANUAL — REV. #5 (08/03/067)

JTN RIDE-ONTROWEL—TABLE OF CONTENTS

NOTE

Specificationsand

part numbersare

subjecttochange

withoutnotice.

MQ WHITEMAN JTN RIDE-ON

POWER TROWEL

Here's How to Get Help ............................................ 3

Table of Contents...................................................... 4

Training Checklist ...................................................... 5

Daily Pre-Operation Checklist................................... 6

Parts Ordering Procedures ....................................... 7

Safety Message Alert Symbols................................. 8

Rules For Safe Operation ....................................9-12

Operation and Safety Decals .................................. 13

Specifications (Trowel) ............................................ 14

Specifications (Engine) ........................................... 15

Engine Components (Honda) ................................. 16

Engine Components (Vanguard) ............................ 17

General Information................................................ 18

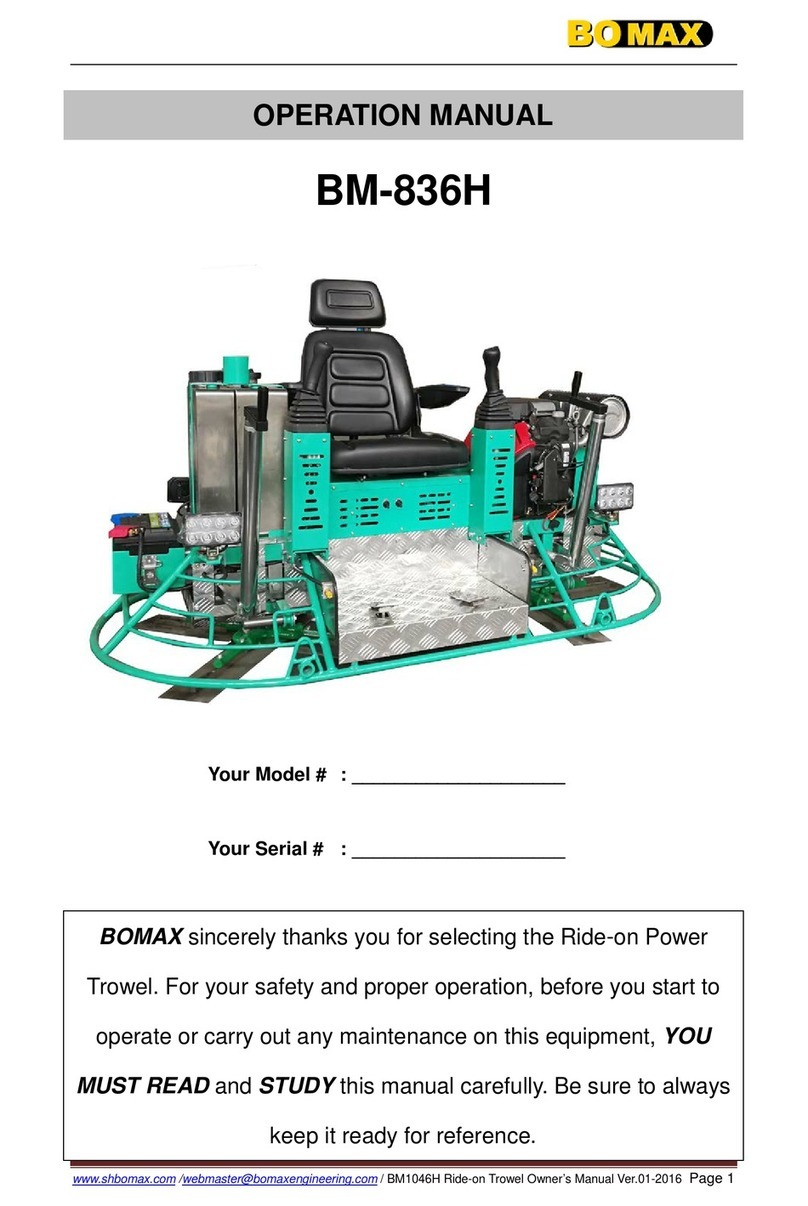

Controls and Indicators (Front)............................... 20

Controls and Indicators (Rear) ............................... 21

New Machine Set-up Instructions ........................... 22

Initial Start-up.....................................................23-25

Maintenance ......................................................26-32

Troubleshooting (Trowel) ...................................33-34

Troubleshooting (Engine)...................................35-36

Explanation od Code In Remarks Column.............. 37

Suggested Spare Parts........................................... 38

COMPONENT DRAWINGS

Nameplate and Decals.......................................40-41

Vanguard Engine and Clutch Assembly.............42-43

Honda Engine and Clutch Assembly .................44-45

Drive Assembly ..................................................46-47

Steering Assy. (LS) S/N 43489 & Below.............48-49

Steering Assy. (RS) S/N 43489 & Above............50-51

Steering Assy. (LS) S/N 43490-46645 ...............52-53

Steering Assy. (RS) S/N 43490-46645...............54-55

Steering Assy. (LS) S/N 46646~.........................56-57

Steering Assy. (RS) S/N 46645-61579...............58-59

Steering Assist Assy.S/N 61580 & Above..........60-63

Gearbox Pivot Assembly....................................64-65

Gearbox Assembly (Right-Side) ........................66-69

Gearbox Assembly (Left-Side)...........................70-73

Thrust Bearing Kit ..............................................74-75

4-Blade Spider Assembly (Left-Side).................76-77

4-Blade Spider Assembly (Right-Side) ..............78-79

Blades and Adjustment Fixture Assembly .........80-81

Twin Pitch Handle Assembly (RT/LT) .................82-83

Twin Pitch Tower Assembly (RT/LT) ...................84-85

Twin Pitch Miter Box Assembly ..........................86-87

Main Frame Assembly .......................................88-89

Seat Frame Assembly........................................90-91

Retardant Spray Tank Assy. S/N30058 & Below .. 92-93

Retardant Spray Tank Assy. S/N30059 & Above.. 94-95

Foot Pedal Assembly .........................................96-97

Throttle/Foot Pedal ............................................98-99

Battery Assembly ...........................................100-101

Lights Assembly .............................................102-103

Front Panel Assembly (Vanguard) .................104-105

Front Panel Assembly (Honda)).....................106-107

E-Z Mover & Lift Handle Assembly ................108-109

Wiring Diagram, Vanguard .............................110-111

Wiring Diagram, Honda..................................112-113

Terms and Conditions of Sale...............................114

Go to Discount-Equipment.com to order your parts