WARNING: READ BEFORE INSTALLATION

Fluid hammer and surges can destroy any pressure transmitter/transducer

and must always be avoided. A pressure snubber should be installed to

eliminate the damaging hammer effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as with

quick closing solenoid valves. Surges occur when flow is suddenly begun,

as when a pump is turned on at full power or a valve is quickly opened.

Liquid surges are particularly damaging to pressure transmitter/trans-

ducer if the pipe is originally empty. To avoid damaging surges, fluid

line should remain full (if possible), pumps should be brought up to

power slowly and valves operated slowly. To avoid damage from both

fluid hammer and surges, a surge chamber should be installed, and a

pressure snubber, such as Murphy PD-8100 Series (adjustable) or

PM6203 Series (fixed) call Murphy for details, should be installed on

every transmitter/transducer.

Symptoms of fluid hammer and surges damaging effects:

a. Pressure transmitter exhibits an output at zero pressure (large zero offset).

b. Pressure transmitter output remains constant regardless of pressure.

c. In severe cases, there will be no output.

Noise

For minimum noise susceptibility avoid running the transmitters/transduc-

ers cable in a conduit that contains high current AC power cables or igni-

tion loom on engine. Where possible avoid running the cable near induc-

tive equipment. Shielded cable is always recommended. Earth the shield

at one end only.

Mounting

CAUTION: THESE ARE PRECISION INSTRUMENTS.

DO NOT INSTALL IN ANY MANNER THAT CAN CAUSE

SIDE STRESS OR IS SUBJECT TO EXCESSIVE VIBRATION.

The transmitter/transducer requires no special mounting hardware and

can be mounted in any plane with negligible position error.

Although the unit can withstand substantial vibration without damage

or significant output effects, it is always good practice to mount the

transmitter where there is minimum vibration.

Apply Teflon tape/sealant to the pressure fittings threads before

installing. When tightening, apply a wrench to the hex wrench flats

located just above the pressure fitting. DO NOT tighten by using a

pipe wrench on the housing.

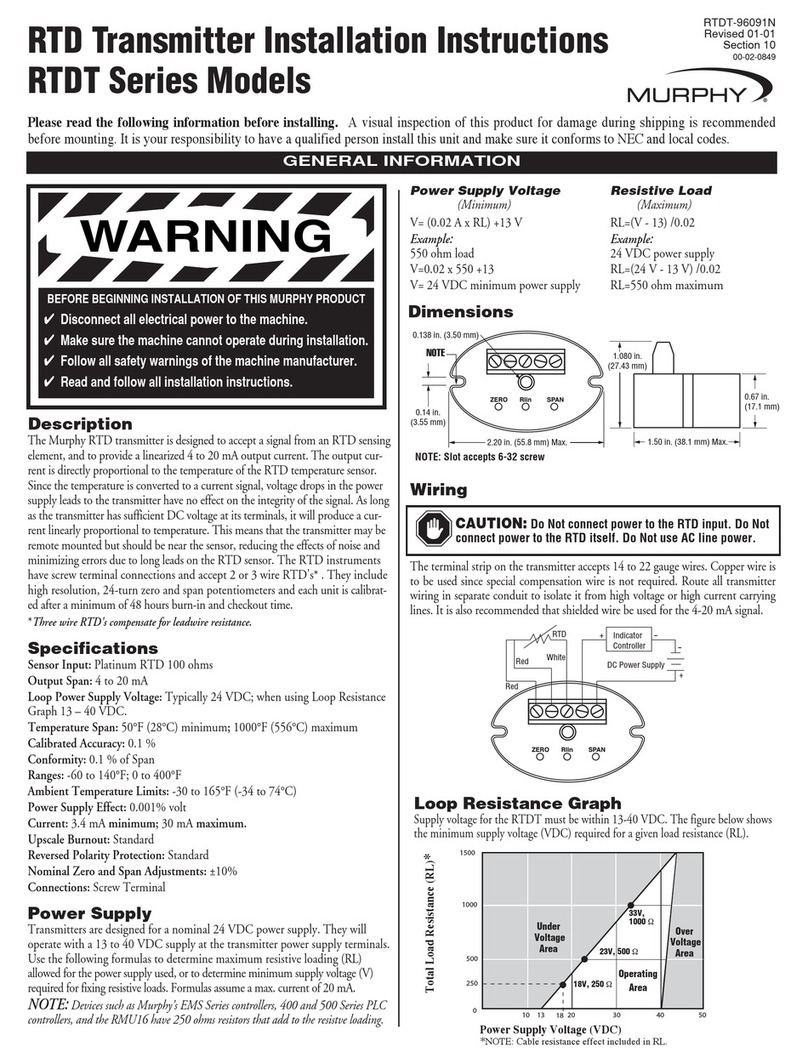

PXT Series Electrical Connections

Hold when attaching

to pressure source

Do NOT twist body

1/4 NPTF

2.08 in.

(53 mm)

7/8 Hex 316 Stainless

Steel Housing

2 in.

(51 mm)

2.30 in.

(58 mm)

2.30 in.

(58 mm)

.86 in.

(22 mm)

.866 A/F

1/2 NPTM

7/8 Hex 316 Stainless

Steel Housing

60 in. (1524 mm)

long cable-std.

.86 in.

(22 mm)

1.18 in. Dia.

(30 mm)

1/4 NPTF

1.18 in. Dia.

(30 mm)

.866 A/F

1/2 NPTM

60 in. (1524 mm)

long cable-std.

High Pressure Units

Isc 93 mA

La

Ca 0.12 F

3 mH

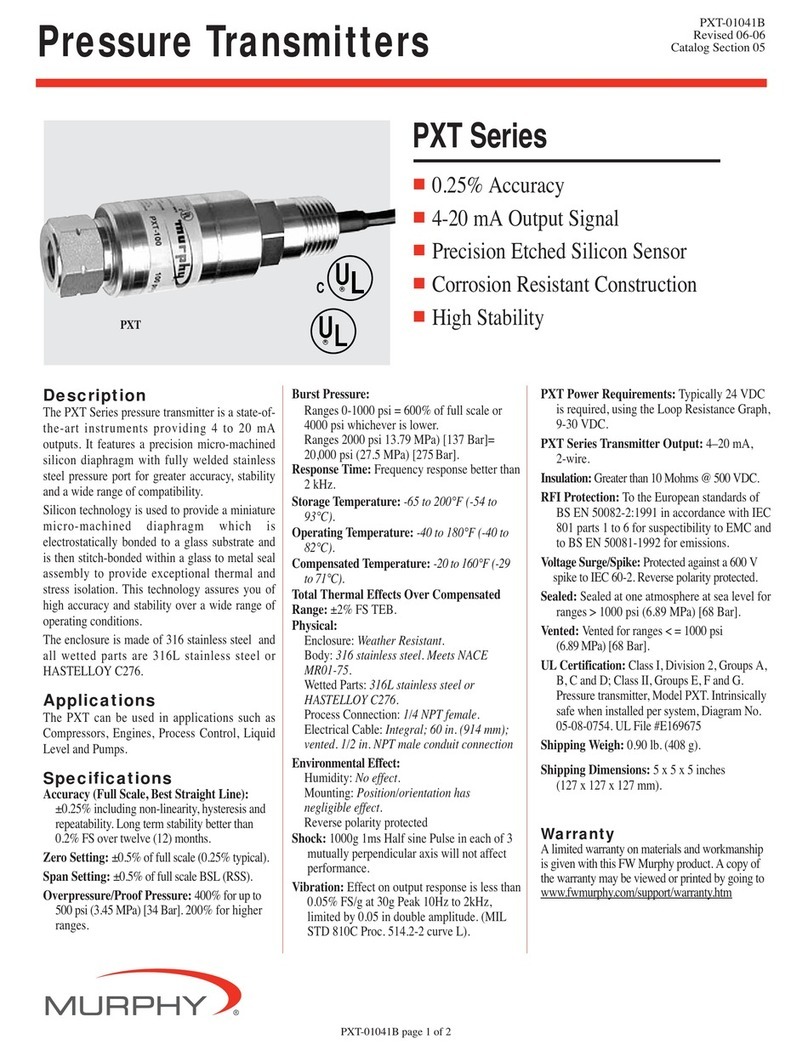

POWER BARRIER

Voc 28 V

USE THE FOLLOWING PARAMETERS IF CABLE

PARAMETERS ARE UNKNOWN.

CABLE CAPACITANCE: 60 pF/ft

µF)

HAZARDOUS AREA SAFE AREA

Class I, Groups A, B, C, D

Class II, Groups E, F, G

PXT SERIES

ALL INTRINSICALLY SAFE WIRING SHALL BE KEPT

SEPARATE FROM NON-INTRINSICALLY SAFE WIRING.

REFER TO ARTICLE 504 OF THE NATIONAL

ELECTRICAL CODE OR THE CANADIAN ELECTRICAL CODE.

TRANSMITTER ENTITY PARAMETERS

TERMINALS VMAX IMAX CI LI

POS - NEG 28 V 93 mA 0.11 F O.22 mH

BUSBAR

OUTPUT CURRENT MUST BE LIMITED BY A

RESISTOR SUCH THAT THE OUTPUT VOLTAGE

Vs CURRENT PLOT IS A STRAIGHT LINE

BETWEEN Voc AND Isc

BARRIER MUST BE INSTALLED AS

INSTRUCTED BY THE MANUFACTURER

SELECTED BARRIER INTRINSICALLY SAFE

CIRCUITS SHALL BE APPROVED FOR

CLASS I, II, III DIV 1 & 2, GROUPS A-G

TERMINATE BARRIER EARTH GROUND TO THE

GROUND BUS OF THE POWER DISTRIBUTION

PANEL. RESISTANCE TO GROUND MUST NOT

BE GREATER THAN 1 OHM

1

2

3

4

BARRIER NOTES

CONTROL EQUIPMENT

MUST NOT BE CONNECTED TO

EQUIPMENT WHICH USES OR

GENERATES MORE THAN

250 VRMS WITH RESPECT TO

EARTH GROUND

POWER

RETURN

V SUPPLY

EARTH GND

Vmax >= Voc

I max >= Isc

Ci + C cable =< Ca

Li + L cable =< La

CABLE INDUCTANCE: 0.2 µH/ft

(EX.L Cable=1000ft x 0.2 µH/ft=0.2mH)

INSTALLATION INSTRUCTIONS FOR CLASS I DIV 2

UNITS MEET CLASS I DIV 2 WHEN INSTALLED IN ACCORDANCE

WITH CLASS I DIV 2 METHODS. EITHER BY USING THE CONDUIT

AND GROUND CONNECTION PROVIDED OR BY INSTALLING IN A

SUITABLE ENCLOSURE ACCEPTABLE TO THE LOCAL AUTHORITY

HAVING JURISDICTION.

INSTALLATION INSTRUCTIONS FOR CLASS I DIV 1

µ

F

F

µ

FF