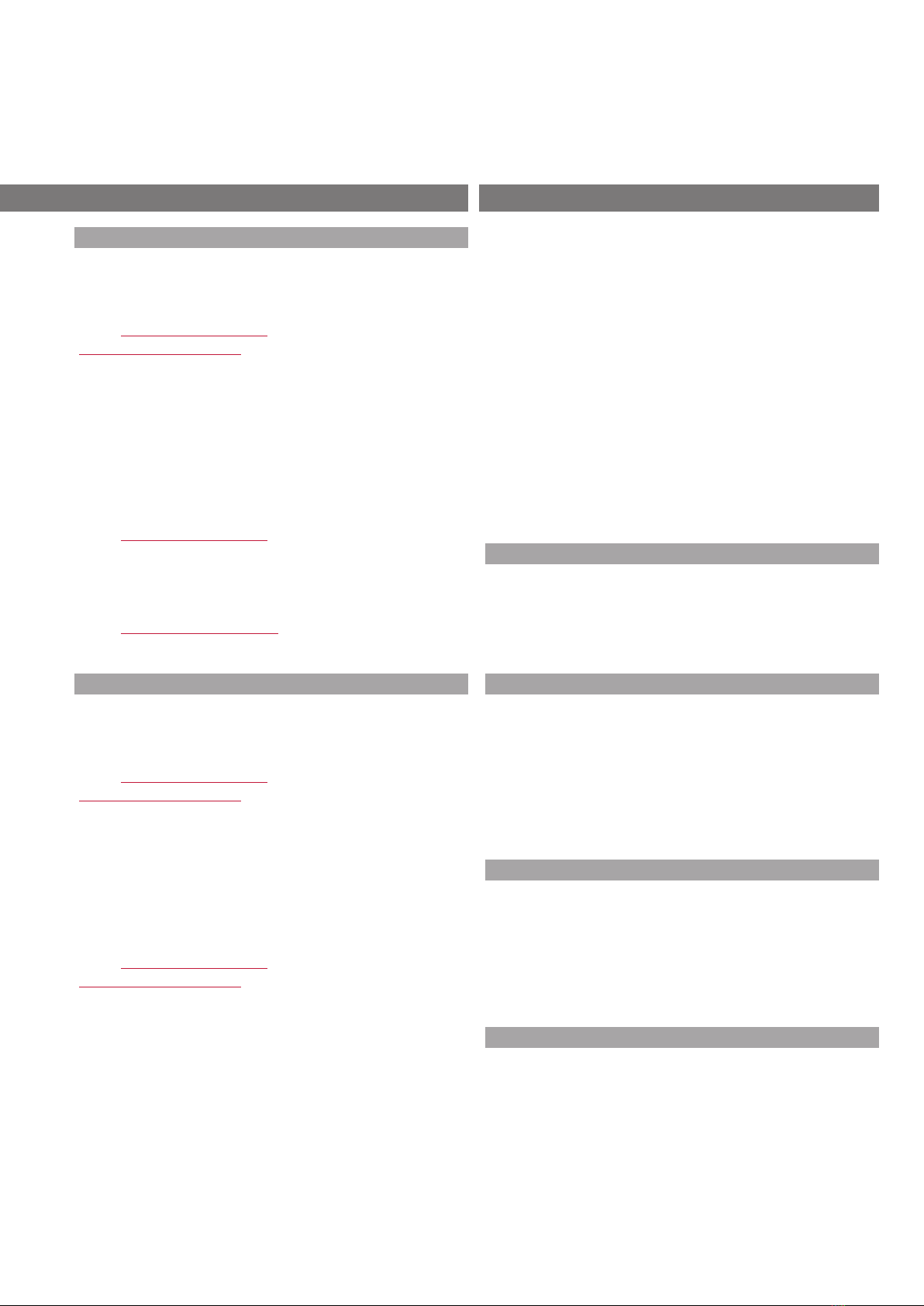

Table of contents

1. Contact information ........................................................................................................................................... 3

2. Terms and definitions ......................................................................................................................................... 3

3. Introduction..................................................................................................................................................... 5

3.1 Purpose and use of this manual ................................................................................................................................................................ 5

3.2 Used symbols and warnings ..................................................................................................................................................................... 5

4. Safety instructions............................................................................................................................................. 5

4.1 Intended use.............................................................................................................................................................................................. 5

4.2 Foreseeable misuse................................................................................................................................................................................... 6

4.3 Installation, commissioning and operation................................................................................................................................................ 6

5. Product overview .............................................................................................................................................. 6

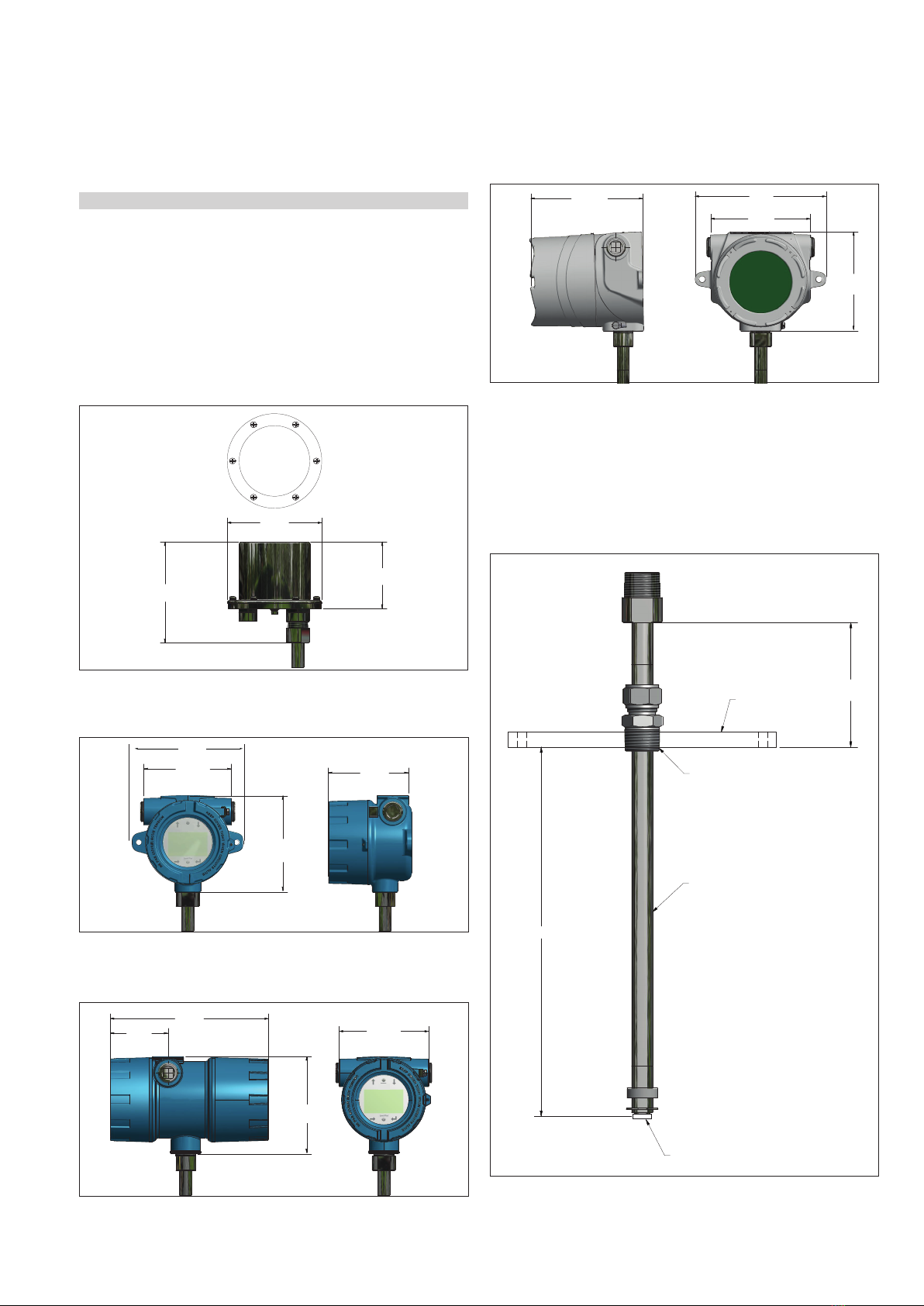

5.1 Components.............................................................................................................................................................................................. 7

5.2 Accuracy.................................................................................................................................................................................................... 8

5.3 Warranty.................................................................................................................................................................................................... 8

5.4 Storage...................................................................................................................................................................................................... 9

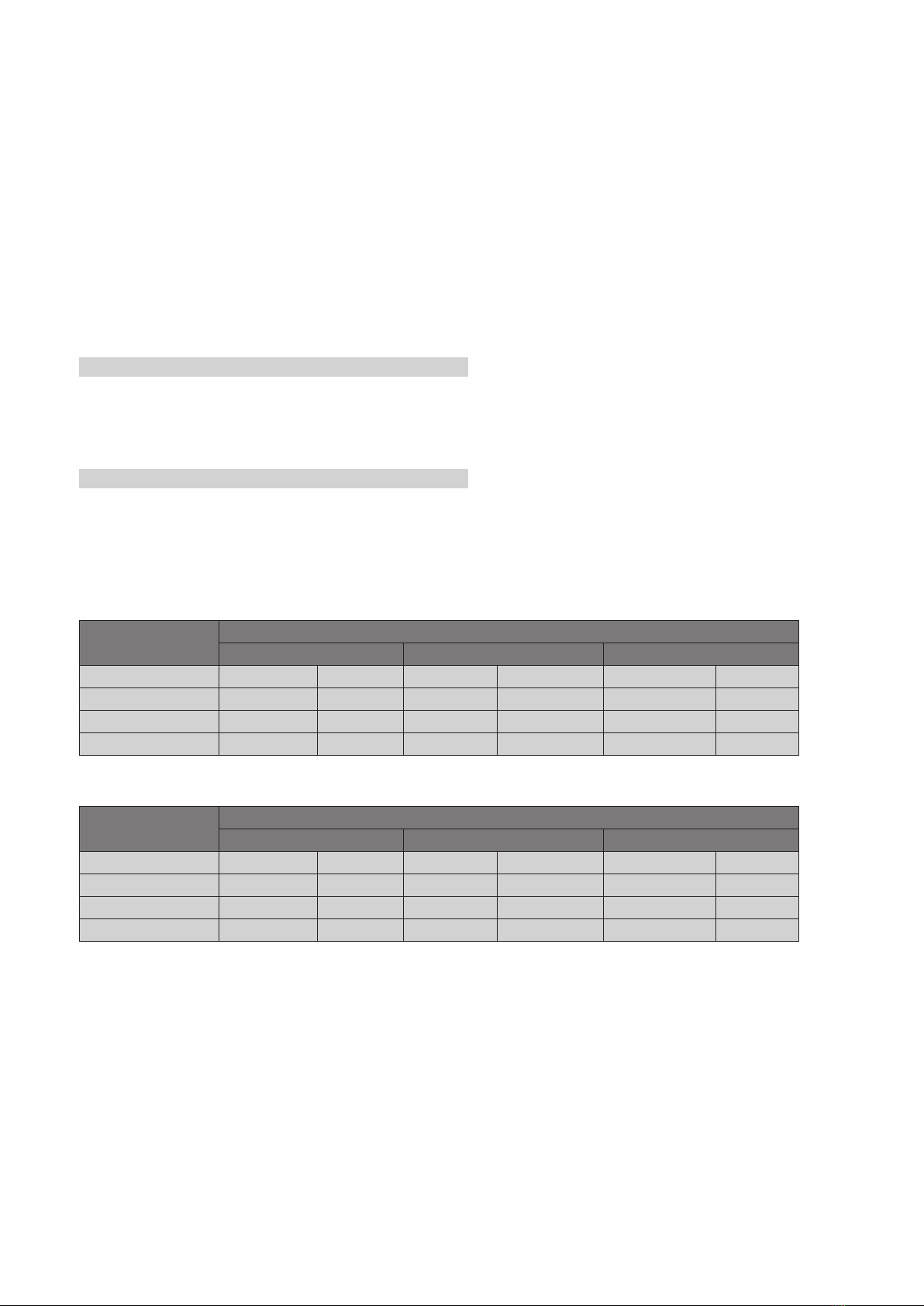

5.5 CRN Specifications.................................................................................................................................................................................... 9

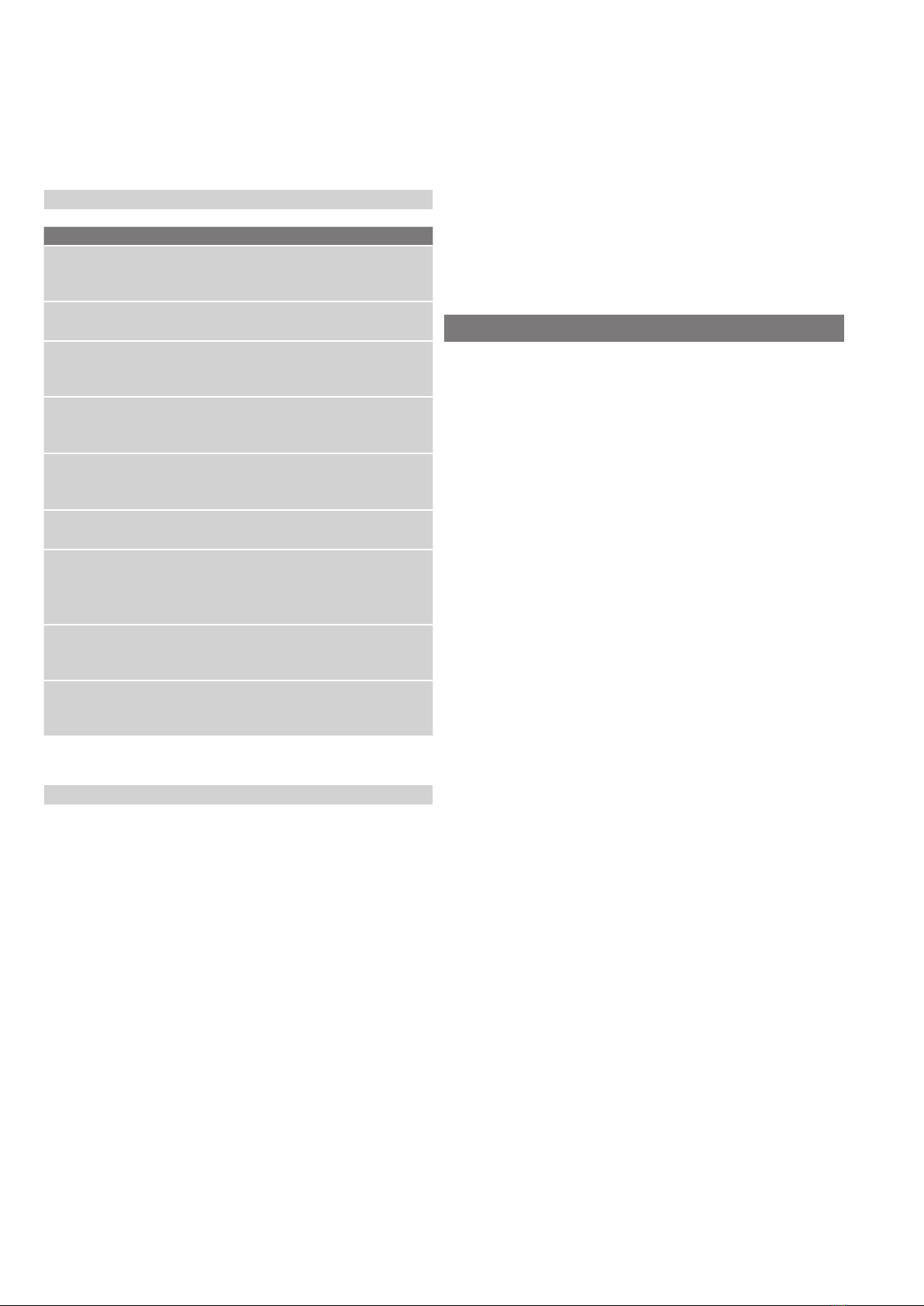

5.6 Model number identification.................................................................................................................................................................... 10

5.7 Technical data.......................................................................................................................................................................................... 12

6. Installation and mounting ...................................................................................................................................13

6.1 Training ................................................................................................................................................................................................... 13

6.2 Stilling wells and guide poles .................................................................................................................................................................. 13

6.3 Tools........................................................................................................................................................................................................ 13

6.4 Installation steps ..................................................................................................................................................................................... 13

6.5 Mounting................................................................................................................................................................................................. 13

7. Electrical connections........................................................................................................................................14

7.1 Basic information .................................................................................................................................................................................... 14

7.2 Safety recommendations......................................................................................................................................................................... 14

7.3 Industrial topologies................................................................................................................................................................................ 14

7.4 Cable recommendations.......................................................................................................................................................................... 15

7.5 Electrical conduit..................................................................................................................................................................................... 15

7.6 Grounding ............................................................................................................................................................................................... 15

7.7 Safety barriers......................................................................................................................................................................................... 16

8. Commissioning................................................................................................................................................17

8.1 Training ................................................................................................................................................................................................... 17

8.2 Tools........................................................................................................................................................................................................ 17

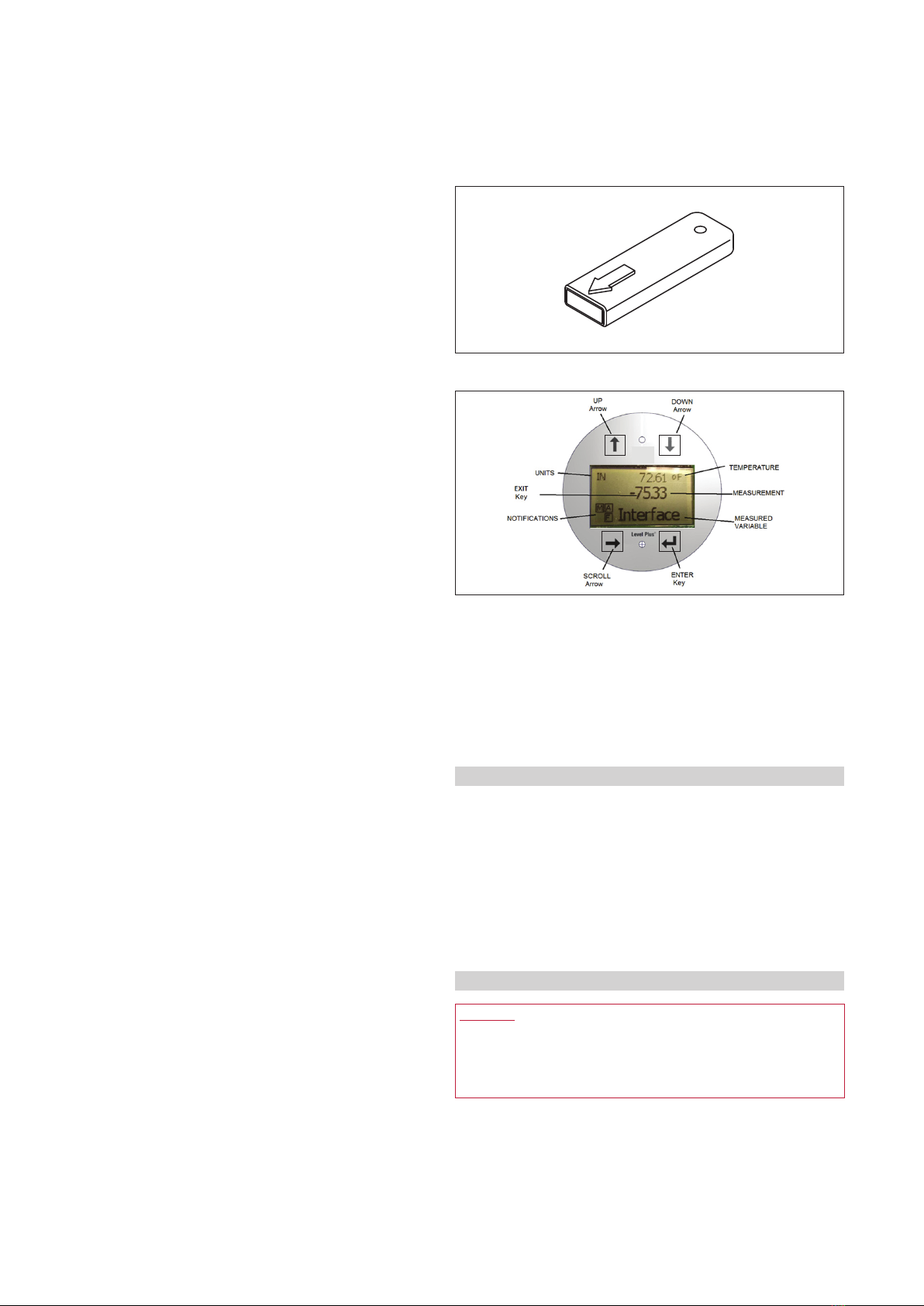

8.3 Setup software ........................................................................................................................................................................................ 17

8.4 Commissioning steps.............................................................................................................................................................................. 17

9. Maintenance...................................................................................................................................................17

9.1 Training ................................................................................................................................................................................................... 17

9.2 Tools........................................................................................................................................................................................................ 17

9.3 Inspection................................................................................................................................................................................................ 17

10. Repair.........................................................................................................................................................18

10.1 RMA policy............................................................................................................................................................................................ 18

10.2 Training ................................................................................................................................................................................................. 18

10.3 Tools...................................................................................................................................................................................................... 18

10.4 Setup software ...................................................................................................................................................................................... 18

10.5 Troubleshooting..................................................................................................................................................................................... 19

11. Spare parts ...................................................................................................................................................19

12. Interface ......................................................................................................................................................19

12.1 Modbus ................................................................................................................................................................................................. 19

12.2 DDA....................................................................................................................................................................................................... 19

12.3 HART®.................................................................................................................................................................................................. 19

13. Agency information .........................................................................................................................................20

13.1 Approvals overview ............................................................................................................................................................................... 20

13.2 Certificates ............................................................................................................................................................................................ 22

13.3 FM (NEC)............................................................................................................................................................................................... 22

13.4 FMC (CEC)............................................................................................................................................................................................. 33

13.5 ATEX and IECEx..................................................................................................................................................................................... 48