This appliance must be grounded. If it should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an

equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances. No adaptor should be used with this

appliance.

WARNING

Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician or service person if you are

in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the appliance – if it will not fit the outlet; have a proper outlet

installed by a qualified electrician.

120 V MODELS

This appliance is for use on a nominal 120 V circuit,

and has a grounded plug (figure 4). Make sure that the

appliance is connected to an outlet having the same

configuration as the plug. No adaptor should be used with

this appliance.

220 V/240 V MODELS

This appliance is for use on a circuit having a nominal rating more than 120V and

is factory-equipped with a specific cord and plug to permit connection to a proper

electric circuit. Make sure that the appliance is connected to an outlet having the

same configuration as the plug. No adaptor should be used with this appliance. If

the appliance must be reconnected for use on a different type of electric circuit,

the reconnections should be made by a qualified service personnel.

GrOundinG insTruCTiOns lOw VOlTaGe COnneCTiOns

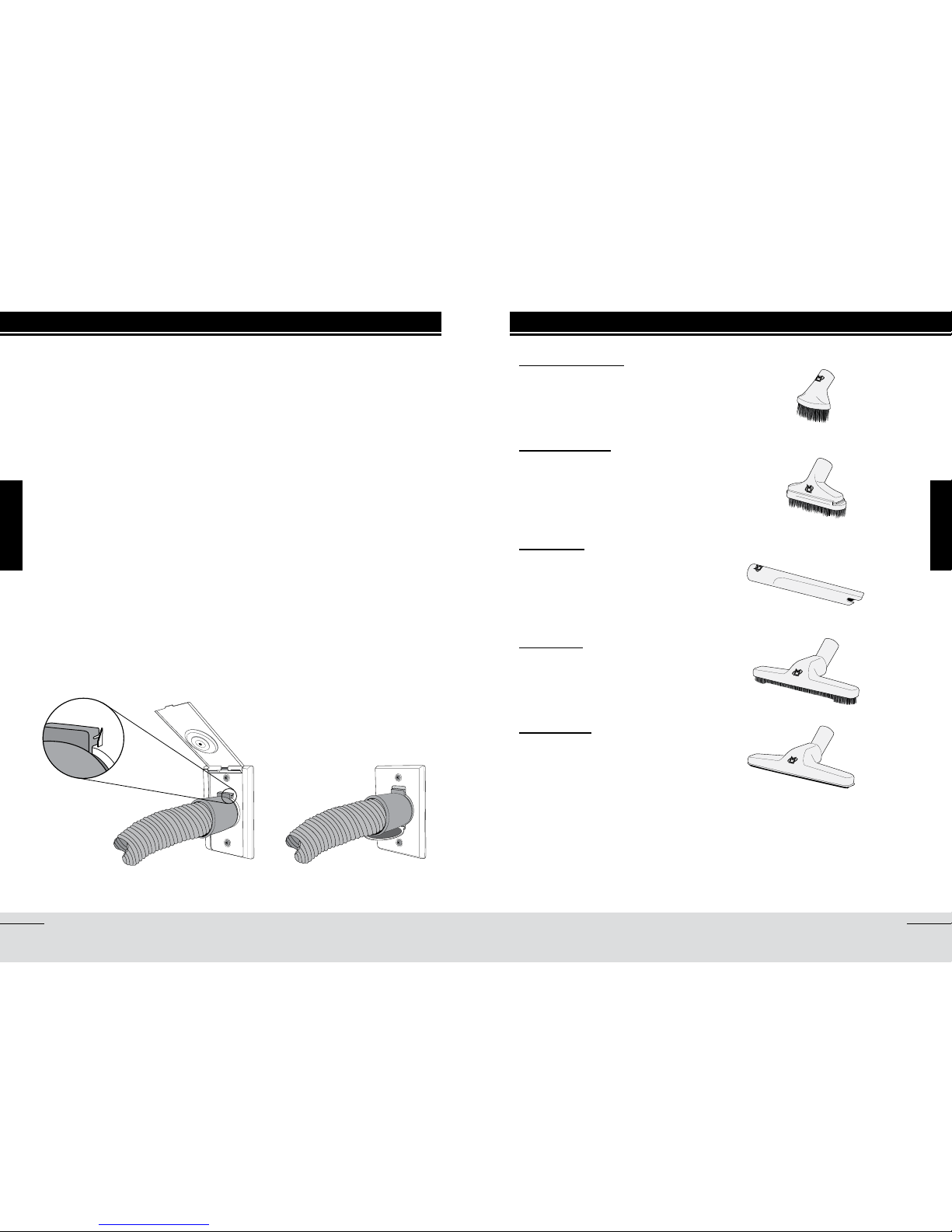

Connect the low voltage wires to the low

voltage inlet on your unit. To do so, simply

strip wires over 1/2 cm (1/4"), remove the

terminals from the low voltage inlet on the

unit, and proceed according to the types of

inlet and wire used.

STANDARD LOW VOLTAGE INLET

All types of wire

Twist the stranded wire to tighten the

loose strands together before proceeding.

Insert the wire into the terminal (blue

connector). Using your wire strippers,

tighten the terminal at two places: at the

front, to hold the wire in place, and at

the back to tighten the insulator around

the wire (figure 5). If the insulator does

not completely cover the stripped wire,

use electrical tape to insulate the wire

adquately, and prevent all contact between

the 2 wires. Insert the terminal into the

low voltage inlet (figure 6).

To disconnect

Do not pull on wire. Simply remove the

terminal from the low voltage inlet.