4

1. Introduction

1.1 Safety

Read all the safety instructions. Failure to install and operate

the libbi in accordance with these instructions may cause

injury or death, damage to the unit or inefficient operation and

invalidate the manufacturer’s warranty.

The libbi utilises warning signs which contain important

information for the system to be operated safely. Ensure these

remain undamaged and clear to read. If damaged, warning

signs must be replaced immediately.

Manual Keeping

This manual contains important information about operating

the system. Before operating, please read it verycarefully. The

system should be operated in strict accordance with the

instructions in this manual. This manual should be kept for

future maintenance and reparation for the duration of the

products lifecycle.

DANGER

Danger to life due to high voltages of the PV array, battery and

electric shock. When exposed to sunlight, the PV array

generates a dangerous DC voltage which will be present in the

DC conductors and the live components of the inverter.

Touching the DC conductors or the live components can lead

to lethal electric shocks. If you disconnect the DC connectors

from the system under load, an electric arc may occur leading

to electric shock and burns. Therefore, for safety reasons,

testing must be carried out with a properly calibrated voltage

tester before an installer works on the equipment.

•The invertercan keep a life-threatening voltage even after

disconnecting it from the DC and/or AC side

•Do not touch uninsulated cable ends

•Do not touch the DC conductors

•Do not open the inverter and battery

•Do not wipe the system with a wet cloth

•Have the system installed and commissioned by qualified

personnel with the appropriate skills only

•Prior to performing any work on the inverter or the battery

pack, disconnect the inverter from all voltage sources, as

described in this document.

Emergency power down procedure can be found in this

document on page 27.

WARNING

Risk of chemical burns from electrolyte or toxic gases. During

normal operation, no electrolyte shall leak from the battery

pack and no toxic gases shall form. Despite careful

construction, if the battery pack is damaged or a fault occurs,

it is possible that electrolyte may be leaked or toxic gases

formed.

Do not install the battery and inverter in any environment of

temperature below -10°C or over 50°C or in which humidity is

over 95%

•Do not install the controller in any environment of

temperature below -10°C or over 40°C

•libbi battery and inverter may be sited indoors or outdoors

and must be orientated vertically and mounted to a

suitable surface or wall

•The controller must be sited indoors and must be

orientated vertically and mounted to a suitable surface or

wall

•Do not touch the system with wet hands

•Do not put any heavy objects on top of the system

•Do not damage the system with sharp objects

•Do not install or operate the system in potentially

explosive atmospheres or areas of high humidity

•Do not mount the inverter and the battery pack in areas

containing highly flammable materials or gases

•If moisture has penetrated the system (e.g. due to a

damaged enclosure), do not install or operate the system

•When transporting, secure the system to prevent tipping

•The libbi is not to be used by persons (including children)

with reduced physical, sensory, or mental capabilities, or

lack of experience and knowledge, unless they are

supervised or have been given instruction concerning use

of the device by a person responsible for their safety

•The transportation of libbi system must be arranged by the

manufacturer or instructed personnel, including the

Installer. These instructions shall be recorded and

repeated

•A certified ABC fire extinguisher with minimum capacityof

2kg must be carried along when transporting

•It is totally prohibited to smoke in or near to the

transporting vehicle, at any time

•For the exchange of a battery module, please request for

new hazardous goods packaging if needed, pack it and let

it be picked up by myenergi or a 3rd party arranged by

myenergi

•In case of contact with electrolyte, rinse the affected areas

immediately with water and consult a doctor without delay

•Avoid any maintenance to this equipment in adverse

weather conditions, when located outdoors

CAUTION

Risk of injury through lifting or dropping the system. The

inverter and battery are heavy. There is a risk of injury if the

inverter or battery is lifted incorrectly or dropped during

transportation or when attaching to or removing from the wall.

Ensure all operations are carried out to the National Manual

Handling Guidelines and in accordance with the Manual

Handling Operations Regulations 1992.

•Lifting and transporting the inverter and battery must be

carried out by a minimum of 2 people

•The system should be operated in strict accordance with

the instructions in this manual. This manual should be kept

for future reference for any maintenance and reparation.

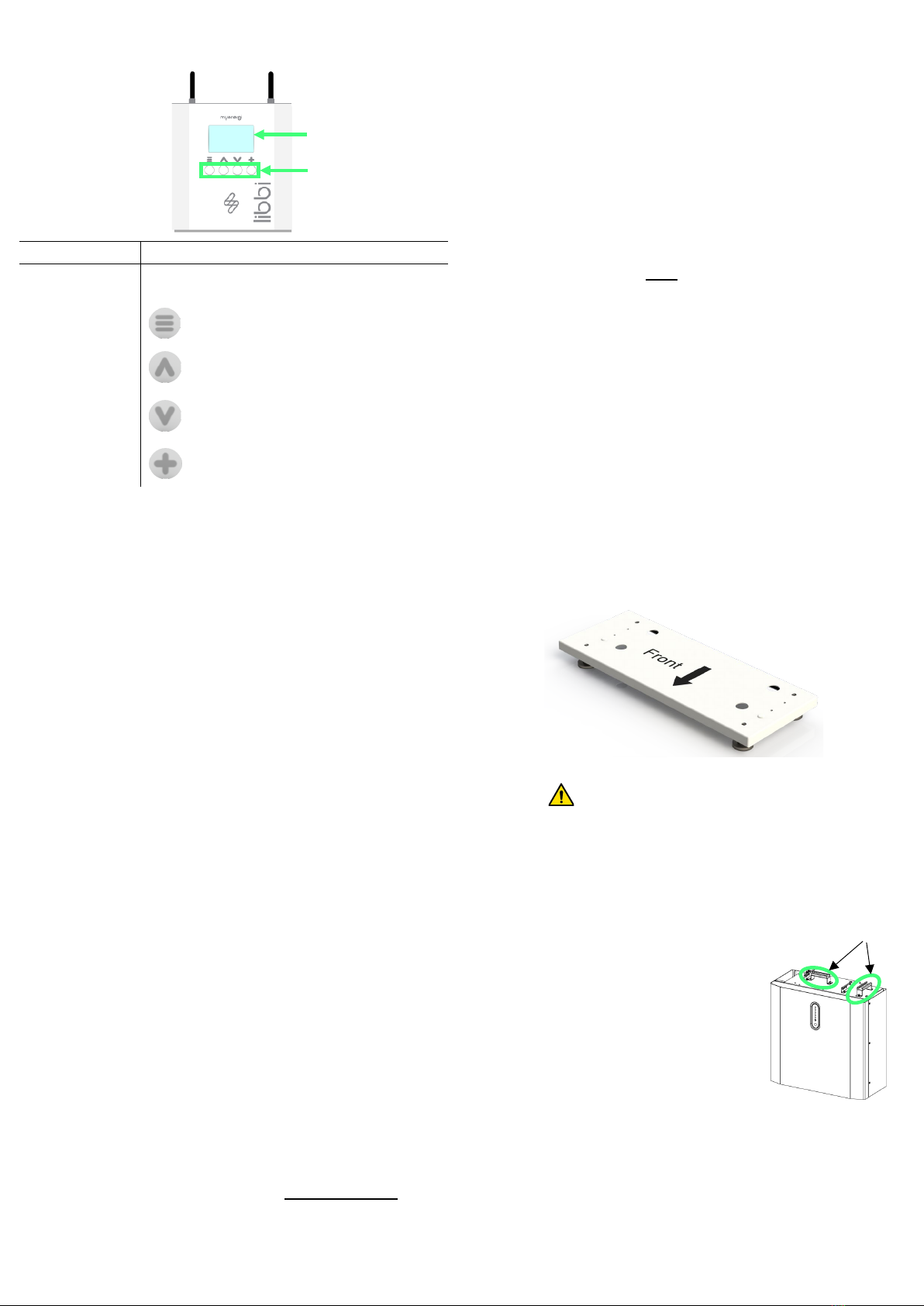

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a notice or ‘tip’ to guide you along your