9kW Immersion Heater, Installation and Operating Instructions, Version 210512 2

When in operation, the heater and probe thermowell must be completely surrounded by the

medium to be heated. Thermally-conditioned flow must not be obstructed. What is known as

“dry operation” of the heating system is to be ruled out.

The installation position is solely horizontal. A collar of a suitable thread size (G1 ½") must be

provided or fitting is done with a counter nut that is not supplied. Before the installation collar,

a space of “installation length +150 mm” is to be kept free for installation and servicing.

The unheated length of the immersion heater is 130mm from the sealing surface. Make sure

that this is longer than the length of the installation collar.

Before any work on the equipment, the heater is to be disconnected from the power.

The ambient temperature on the housing must not exceed 35°C.

The minimum capacity of the water tank is 200l. The heating power must be adjusted to the

volume of the medium to be heated. The user is responsible for correct selection. The specified

surface load must be observed. As appropriate, you must consult the manufacturer before the

equipment is put into operation.

Immersion heaters are designed for max. 10 bar overpressure.

When using the immersion heater in a water heater with heat exchanger installed, the

temperature introduced by the heat exchanger must be limited to 90°C, as otherwise the

thermal cut-out of the immersion heater is triggered.

Exclusion of Liability and Guarantee

A liability and warranty exclusion applies to:

Any damage or injury caused by improper handling or failure to observe the safety-,

assembly and operating instructions

consequential damages

Unauthorized remodelling, disassembly or other interventions in the device,

modification of the product

Damage caused by calcium deposits on heating element.

Damage caused by corrosion at heating element

Installation

The applicable VDE standards and regulations, and the directives applicable in the use case are

to be complied with.

1. Install immersion heater with supplied flat seal in flat collar and/or seal with hemp,

PTFE or similar. If no collar is present, it can also be installed with a counter nut.

Open-ended wrenches of a suitable size are to be used. Installation using pliers or

similar is not permitted.

2. Opening the housing by undoing the four screws. The connection cable must be

introduced by the supplied cable gland into the connection space of the immersion

heater. Ensure there is sufficient space around the connection cable.

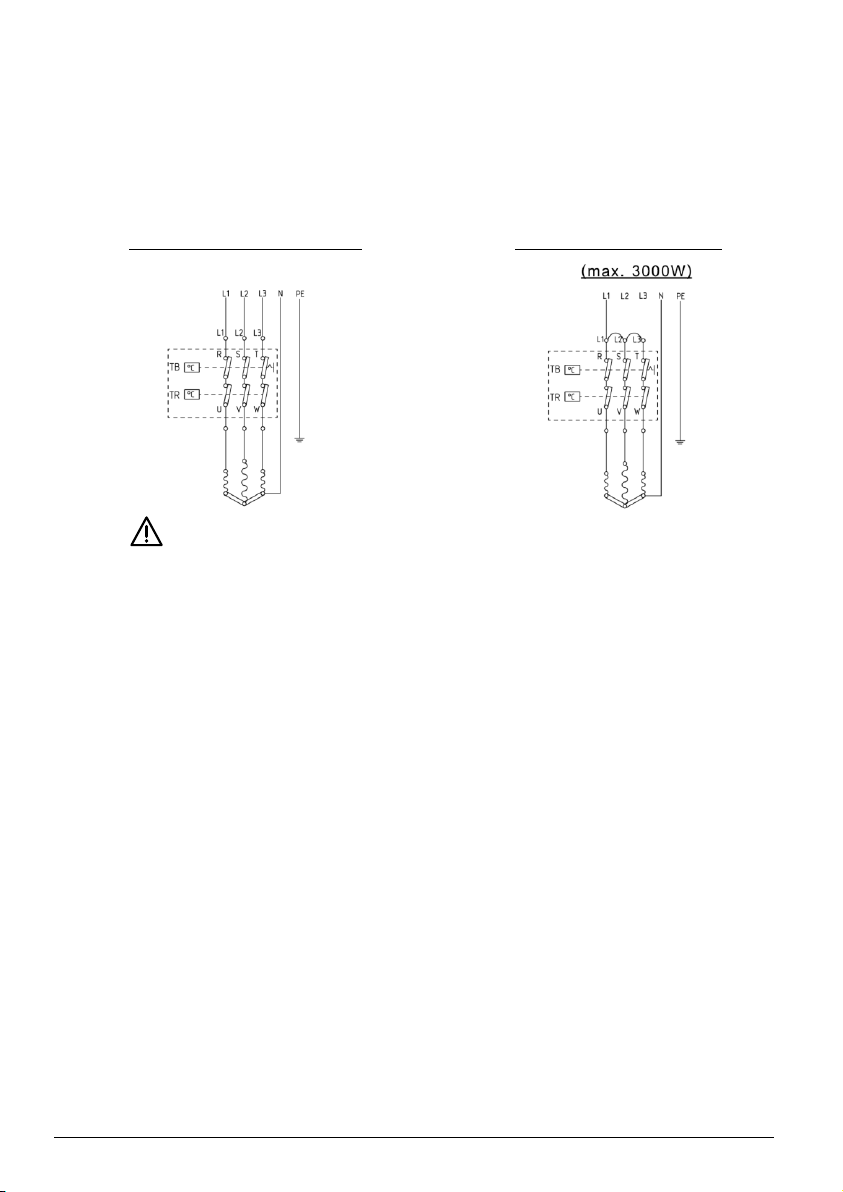

3. Restore electrical connection (see circuit diagram), ensure correct connection voltage.

Before commissioning, the complete circuitry is to be checked according to the circuit

diagram.

4. After the electrical connection has been made, the housing must be closed again. The

housing seals must neither be misaligned nor damaged. Original screws with washers

must be used. A leak caused by improper installation is not covered by the guarantee.