5 PAGE 6 PAGE

F60

F

G

8) To keep the clean water tank clean, debris falling into it may block the water drainage system.

9) The adjustment of the squeegee will directly affect the suction effect of the squeegee.

Keep the squeegee at 90° perpendicular to the ground.

When the squeegee is worn out,adjust the squeegee swivel knob or the elevation

knob as shown in the right picture.To keep the squeegee rubber strip in a proper

position with the ground.

Elevation knob

Universal wheel knob

If the squeegee is not in the 90° position with the ground,

it may cause bad wiping at the center of the squeegee,

and cause the rubber strips at both ends to be too close

to the ground, excessive wear of the rubber strips, and

even dislocation of the front rubber strips;

10) This machine adopts the brush plate to assist the adjustment of the vessel.

When you feel that the advancement is laborious during use, you can

adjust this knob to adjust; please refer to the figure

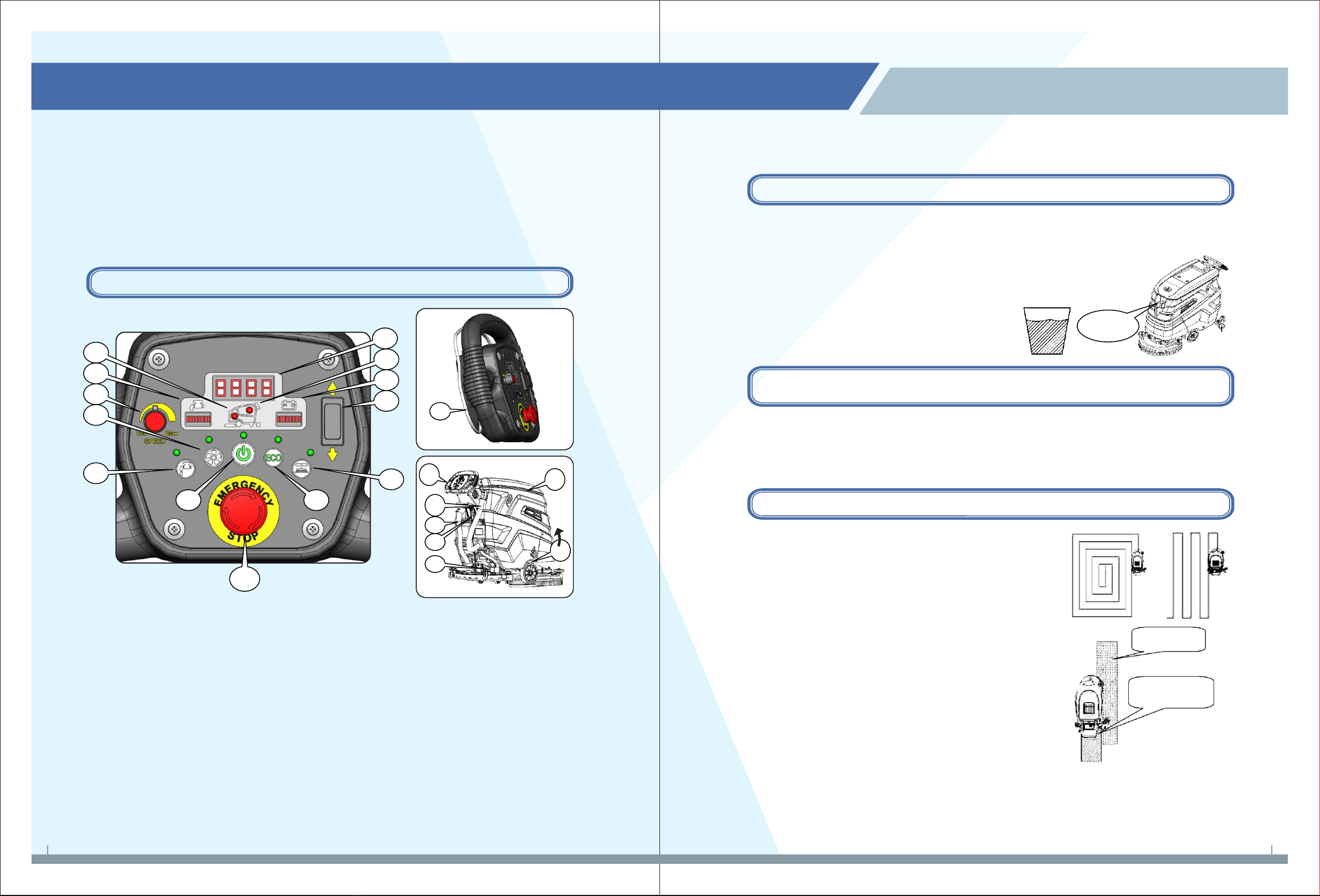

Loosen the screws at positions F and G (including the two opposite ones),

let the motor tilt 5 to 10 degrees to the left in the forward direction, and

then tighten the screws.

11) Keep the adhesive strips clean during work, prepare a towel and a pocket, and

clean up when the adhesive strips get stuck in debris

Note: The new machine may leave processing residues

in the clean water tank, so it is necessary to increase the

frequency of cleaning the filter in the early stage of use.

7) When cleaning the sewage tank, check that there is no entanglement on the

floating rod of the liquid level sensor. If there is entanglement, remove it in time.

The level of the liquid level sensor is shown on the right.

6) There is a filter screen in the water valve, and the filter screen should

always be removed for cleaning. To ensure that the water discharge

system is unblocked; (as shown on the right)

1) At the end of each work, check the capacity status of the battery and decide

whether to charge, so as not to affect the next day's work.

2) After the work is finished, empty the sewage and clean the sewage tank.

Do not leave the sewage in the sewage tank, otherwise the service life of

the suction motor will be affected.

3) At the end of the work day, it is best to use up the cleaning agent in the

clean water tank, and do not leave the liquid in the tank for a long time;

4) After working every day, it is best to rinse the parts of the machine in contact

with the cleaning agent with clean water, and use a dry cloth Wipe clean

5) After the work is completed, the squeegee must be lifted and

removed for cleaning to maintain the elasticity and life of the rubber strip:

5.Daily maintenance

Schematic diagram

of sewage discharge

Sewage pipe

Charging must be completed continuously at one time to reduce the number

of charging and discharging and improve battery life

Choosing high-efficiency power-type maintenance-free batteries can bring you greater convenience.

When using high-efficiency maintenance-free batteries, you must maintain an effective charging

time and do not interrupt normal charging at will. Use the maintenance-free charging charger

that is randomly configured. The battery charger is used for maintenance-free battery

charging, which will cause the battery to "burst"!

8) When the power is lower than the specified value during use, the machine

will automatically stop working, and there will be a buzzer alarm. At this time,

the machine needs to be charged. Only turn off the key to stop the buzzer

alarm. If there is still a small amount of work that has not been completed,

you can turn on the key again and use the single-motor working mode to

operate. When the motor operation also alarms, the machine must be charged.

6.Abnormal problems and troubleshooting methods

H

K

L

1) If the machine easily deviates to the left or right during the

working process,the troubleshooting method: adjust the knob

according to the method shown in the figure;

Loosen the screw H1 (including the opposite side) and lift the

brush tray assembly 0.5 to 1cm upwards and tighten the screw.

Note: If you run off to the left, adjust the brush plate assembly side down

2) Bad wiping in the middle or bad at both ends of the squeegee

When using, adjust the knob L to make the water-absorbent tape contact the ground in the best state;

Ground

Right

The rear rubber strip is at 90° to the ground. Keep one

side of the rubber strip in contact with the ground.When

this side is worn, we can replace the other side of the

rubber strip, so that the rubber strip can be reused four

times, saving costs.

Wrong

This state of the back rubber strip not only makes the

wiper effect of the rubber strip bad, but also makes

the rubber strip easily damaged. Once the end surface

of the rubber strip is damaged, the other side of the

rubber strip cannot be used again, greatly shortening

the service life of the rubber strip

The squeegee strip of this machine is designed for double-sided and four-way use, which can effectively reduce your use cost and

maximize your value.

To purchase rubber strips or to purchase oil-resistant rubber strips, please contact your local distributor or equipment manufacturer

When the two ends of the rubber strip are

tilted up, the two ends are not scratched well,

turn clockwise to adjust K

When the rubber strip is tilted up in the middle,

the two ends are not scratched well, turn K

counterclockwise

Adjust the knob as shown in the figure;

"Bad effect in the middle", "Bad effect at both ends" -------Adjust the verticality of the squeegee "The squeegee can be scraped, but the

water overflows from both ends of the squeegee."-----Check whether the suction port of the squeegee has suction power, whether it is

blocked, whether the recovery tank is full, whether the recovery tank sealing strip is not installed, and whether it is dirty Whether the cap

is not covered;

3) Classification and exclusion of water absorption effect

4) There is no response after the water suction motor or the brush motor is turned on;

Remedy: Check whether the fuse is damaged; whether the battery connector is loose or oxidized;

5) The power display is good, and the motor is running weakly.

Check whether the battery output terminal is loose: check whether the connecting connection to the motor is damaged; whether

the machine has maintenance prompts, if so, ask a professional to check whether the carbon brush of the motor is worn;

Check whether the battery is short of liquid? Is each charge completed continuously and uninterrupted as required? Is the green

light on each charge? Elimination method: please add distilled water for lack of liquid: be sure to complete the uninterrupted

charging according to the regulations; each charge must be completed automatically (green light is on): Repeat several times to

see if the battery can recover, if not, replace the battery.

6) The battery voltage is displayed normally,and the use time is getting shorter and shorter.Inspection method:

7) The suction motor is running, but the squeegee has no suction check:

A Check whether the intake pipe in the sewage tank is blocked or the sewage pipe cover is not installed

B Check whether the water inlet of the squeegee is blocked by foreign objects

C Remove the hose connected to the squeegee and check if the hose port is blocked?

8) Check that the machine does not flow out of water or does not flow out smoothly:

(1) Whether the drain switch is turned on

(2) If it is a "one-key start" switch model. Water will only be discharged after starting

(3) Whether the water volume valve adjustment is in place

(4) Unscrew the filter of the water valve to check whether it is blocked

(5) Check whether the water pipe at the bottom of the chassis is compressed