8

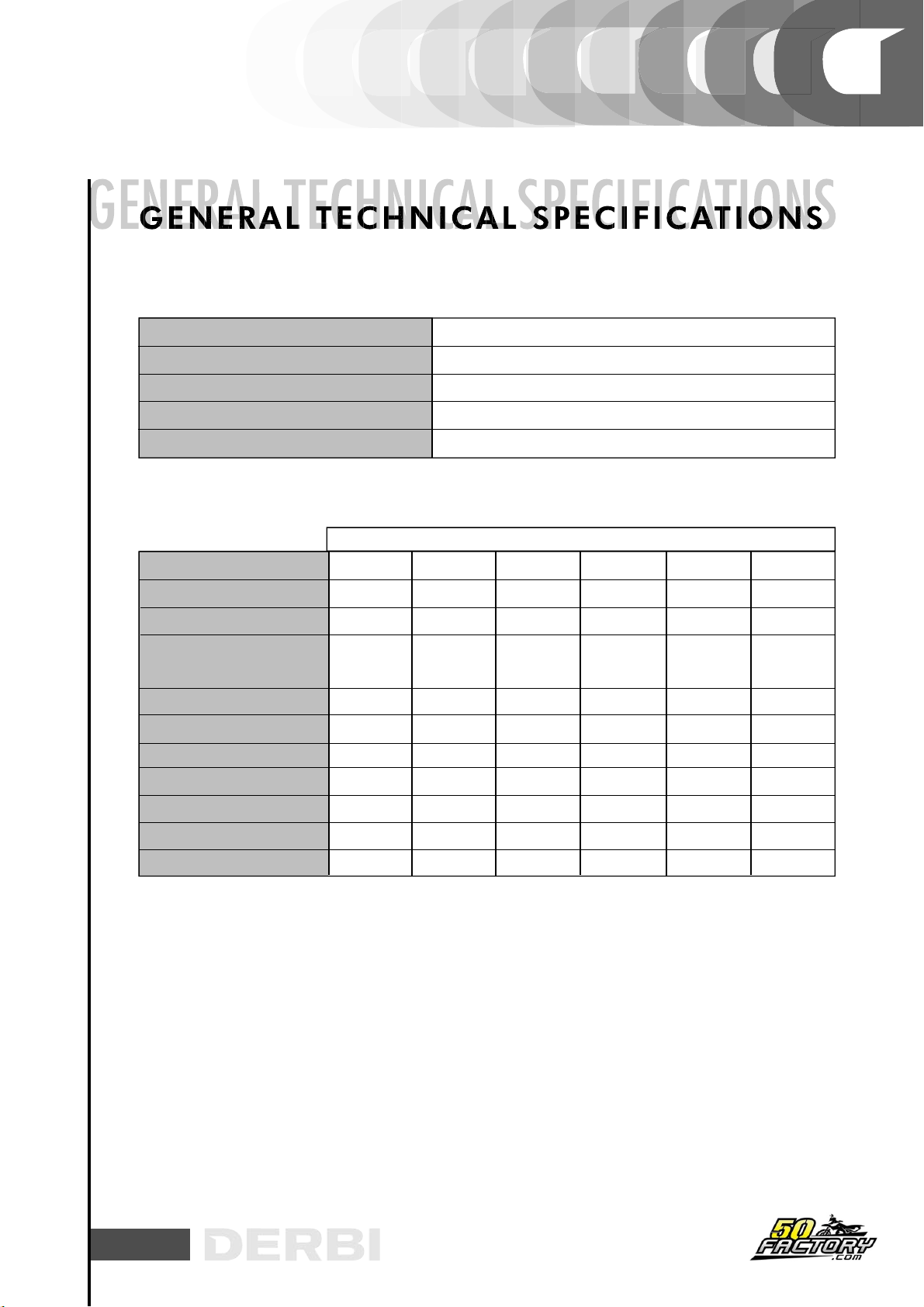

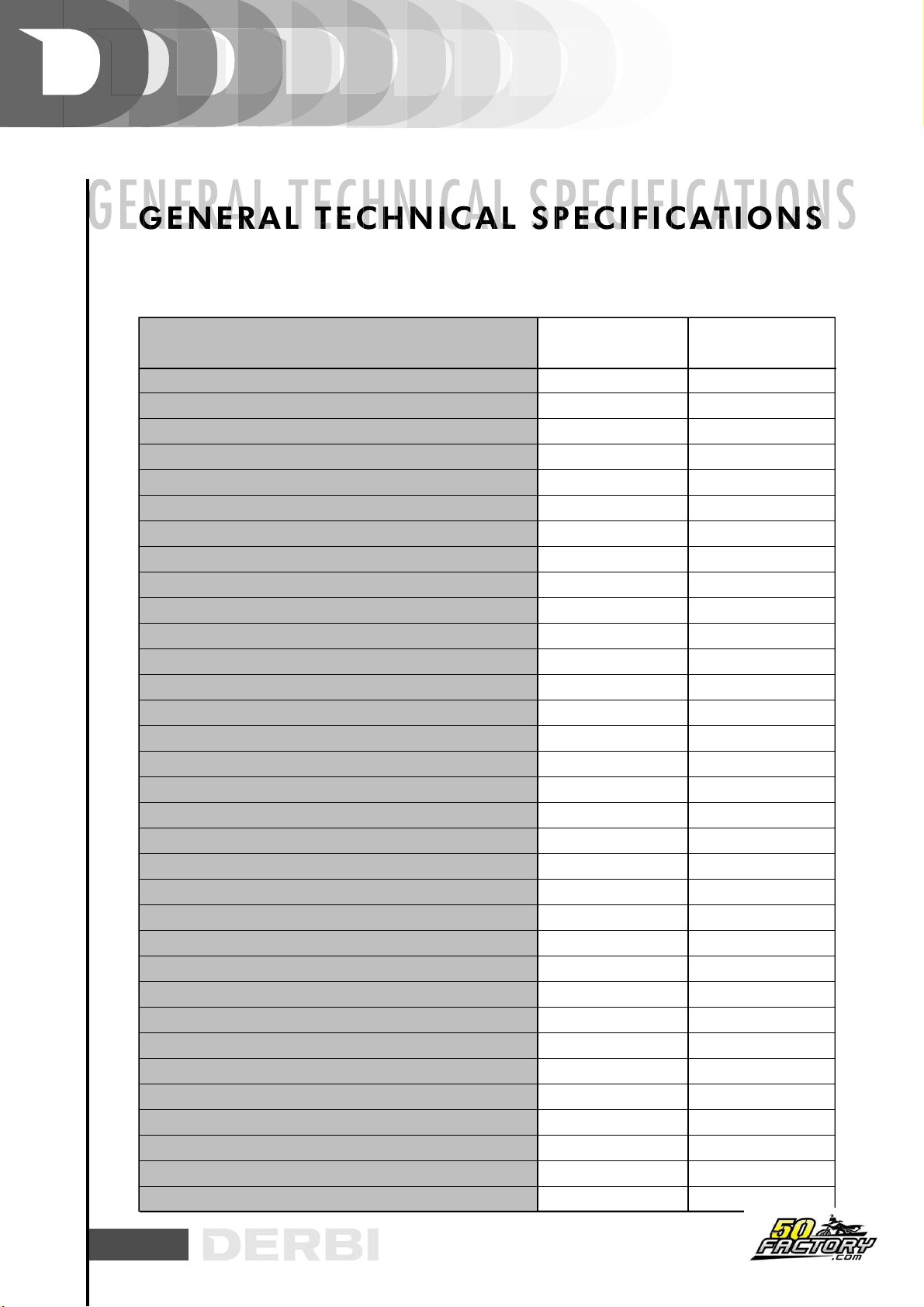

TORQUE TIGHTENING TABLE

M1 4x125 spark plug-cylinder head securing device

M6x100 cylinder head cover-cylinder sec.dev.

M7x100 cylinder head nut sec.dev.

M1x100 magneto-crankshaft sec.dev.

M5x80 base plate-crankcase sec.dev.

M6x100 right cover-crankcase sec.dev.

M1 0x100 engine pinion-crankshaft sec.dev.

Kick-start lever bush – starter shaft sec.dev. M6x100

M6x100 crankcases sec.dev.

M3x0.5 reeds –support sec.dev.

M6x100 carburettor nozzle-crankcase sec.dev.

M5x80 oil pump-crankcase sec.dev.

M6x100 starter motor-crankcase sec.dev.

M6x100 Bendix cap -crankcase sec.dev.

M5x80 pump runner-pump shaft sec.dev.

M6x100 pump cover-crankcase sec.dev.

M1 4x150 thermistor –cylinder head sec.dev.

M4x70 thermostat—cylinder head cover sec.dev.

M1 2x150 clutch bell housing – primary shaft sec.dev.

M5x80 clutch spring – bell housing sec.dev

M6x100 left cover-crankcase sec.dev.

M5x80 primary shaft bearing seal – crankcase sec.dev.

M5x80 (10.9) drum control head – drum sec.dev.

M1 0x150 oil drain screw – crankcase sec.dev.

M6x100 starter stop – crankcase sec.dev.

M1 0x100 counterweight pinion – counterweight shaft sec.dev.

Release lever-release shaft sec.dev. M6x100

M5x80 seal – change output pinion sec.dev.

M6x100 gear sec. lever -crankcase sec.dev.

M8x125 selector stop – crankcase sec.dev.

M5x80 oil pump cover - right cover sec.dev.

M6x100 gear lever – selector shaft sec.dev.

M1 0x100 (PA6) neutral indicator – crankcase sec.dev.

2 ÷ 4

0,8 ÷ 1

1,9 ÷ 2,2

3,5 ÷ 4,5

0,25 ÷ 0,35 Sealed

0,8 ÷ 1

3,5 ÷ 4,5

0,8 ÷ 1

0,8 ÷ 1

0,1 ÷ 0,2

0,8 ÷ 1

0,35 ÷ 0,45

0,8 ÷ 1

0,8 ÷ 1

0,35 ÷ 0,45

0,8 ÷ 1

3,2 ÷ 3,8

0,1 ÷ 0,15

3,5 ÷ 4,5

0,35 ÷ 0,45

0,2 ÷ 0,35

0,35 ÷ 0,45

0,5 ÷ 0,7

1,5 ÷ 1,8

0,8 ÷ 1

3,5 ÷ 4,5

0,8 ÷ 1

0,35 ÷ 0,45 Sealed

0,8 ÷ 1 Sealed

1,5 ÷ 1,9

0,35 ÷ 0,45

0,8 ÷ 1

0,25 ÷ 0,35

20 ÷ 40

8 ÷ 10

19 ÷ 22

35 ÷ 45

2,5 ÷ 3,5 Sealed

8 ÷ 10

35 ÷ 45

8 ÷ 10

8 ÷ 10

1 ÷ 2

8 ÷ 10

3,5 ÷ 4,5

8 ÷ 10

8 ÷ 10

3,5 ÷ 4,5

8 ÷ 10

32 ÷ 38

1 ÷ 1,5

35 ÷ 45

3,5 ÷ 4,5

2 ÷ 3,5

3,5 ÷ 4,5

5 ÷ 7

15 ÷ 18

8 ÷ 10

35 ÷ 45

8 ÷ 10

3,5 ÷ 4,5 Sealed

8 ÷ 10 Sealed

15 ÷ 19

3,5 ÷ 4,5

8 ÷ 10

2,5 ÷ 3,5

TIGHTENING TORQUE

(N.m.) TIGHTENING TORQUE

(m•kg)

SECURING DEVICE DESCRIPTION