IOM-EZVAVINST

Date: 10-2016 Supersedes: 7-2016

Nailor reserves the right to change any information concerning product or specification without notice or obligation.

Page 4 of 48

Installation and Operation Manual ●EZvav Digital Controls

Secon 1: About the Controllers

This secon provides a descripon of the EZvav series of controllers. It also introduces safety informaon. Review this material

before selecng, installing, or operang the controllers.

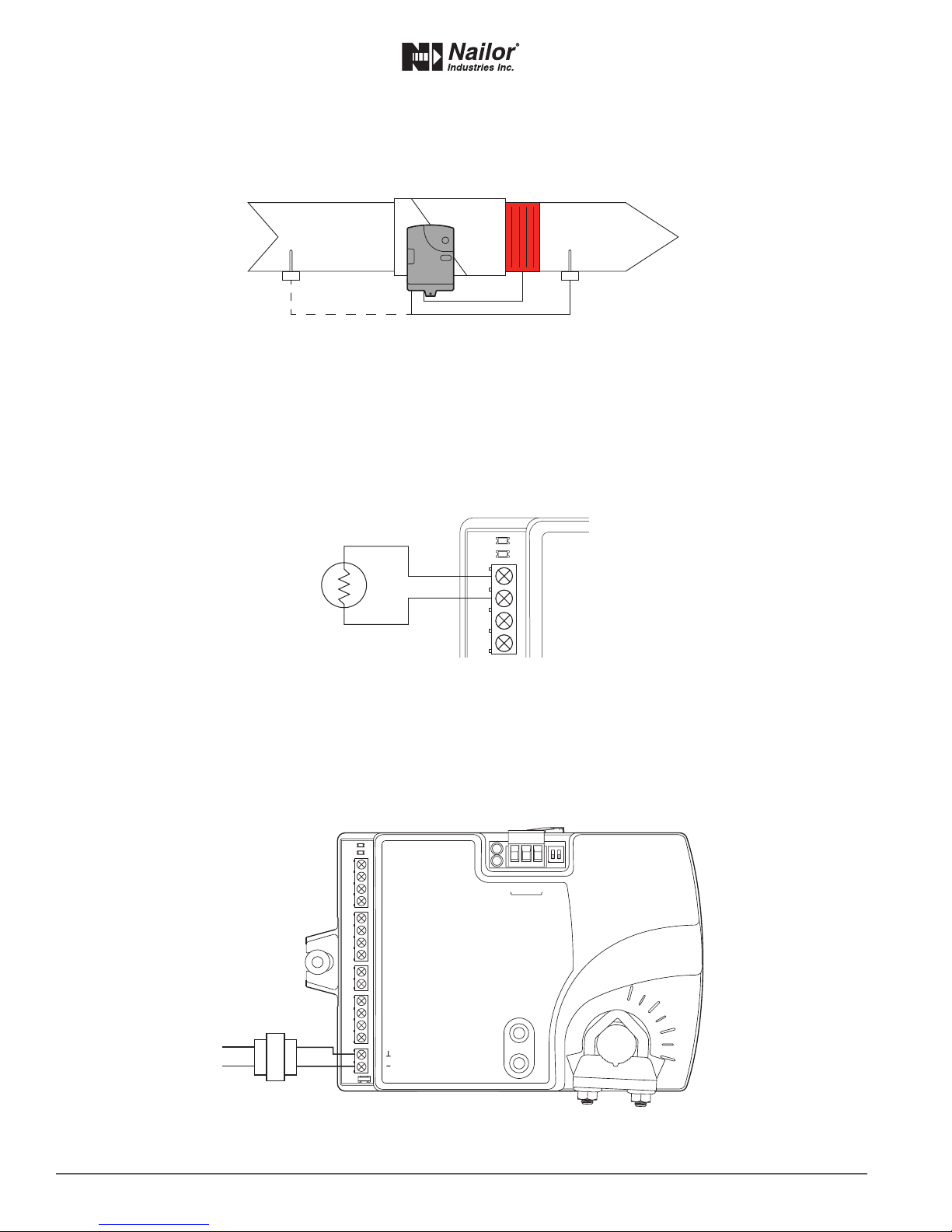

The EZvav series of controllers are an easy and unique approach to operang a wide variety of VAV terminal units. The integrated

actuators, internal airow sensors, and wide variety of applicaon programs make these BACnet Applicaon Specic controllers

ideal for either new or retrot installaons.

The controllers feature simple, menu driven setup choices when used with a EZvav digital sensor. No special programming skills

or soware tools are required to choose applicaons, enter set points, set network addressing, and balance airow. All opons

can be set by using a STE-8001W36 sensor and can be installed as the permanent room sensor or temporarily connected as a

technician’s service tool.

All models are BACnet Applicaon Specic Controllers that are ready to connect to a BACnet MS/TP network. Device instance,

MAC address, and baud rate are set from an STE-8001W36 without special soware.

Model BAC-8001-36 is supplied with inputs, outputs, and sequences of operaon for the following funcons.

• Single duct heang and cooling VAV.

• Automac heang/cooling changeover including morning warm up.

• Occupancy setback—requires STE-8201W36.

• System diagnosc indicators.

• Airow balancing.

Model BAC-8005-36 and BAC-8205-36 are supplied with inputs, outputs, and sequences of operaon for the following funcons.

• Single duct heang and cooling VAV.

• Modulang, oang, and staged reheat.

• Series and parallel fan control.

• Automac heang/cooling changeover including morning warm up.

• Discharge air temperature liming.

• Occupancy setback—requires STE-8201W36.

• Actuator posion feedback for true damper posioning (BAC-8205-36 only).

• System diagnosc indicators.

• Airow balancing.

Model BAC-8007-36 is supplied with inputs, outputs, and sequences of operaon for the following funcons.

• Dual duct VAV heang and cooling.

• Occupancy setback—requires STE-8201W36.

• System diagnosc indicators.

• Airow balancing.

Addional topics in this secon

Specicaons ......................................................................................................................................5

Safety consideraons ..........................................................................................................................7