ENGLISH

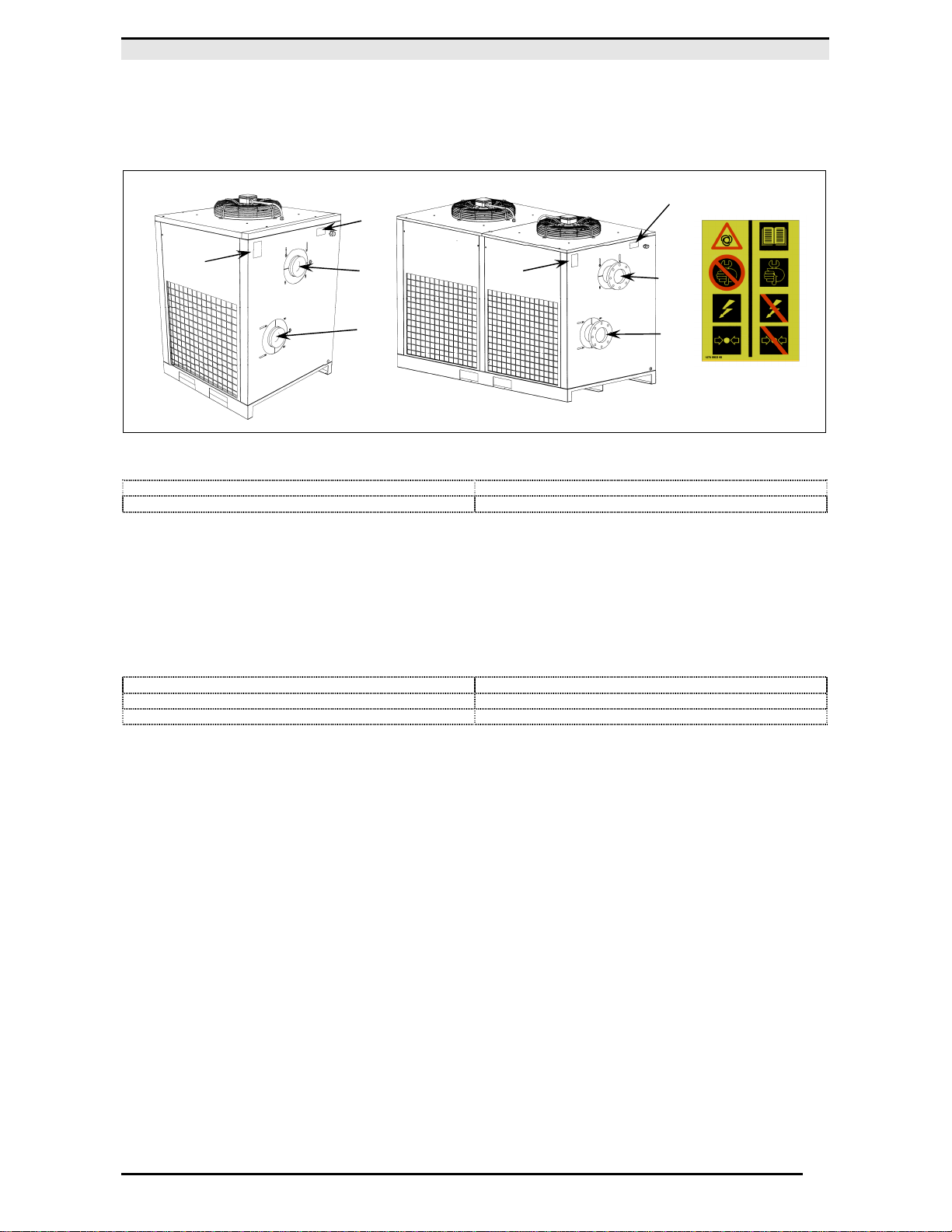

1.0 GENERAL CHARACTERISTICS

The dryer is a chilling machine with direct expansion heat exchanger and dry evaporator.

The air to be dried is sent to the heat exchanger in which the water vapor present is condensed: the condensate gathers

in the separator and is discharged outside through an electronic level sensing drain..

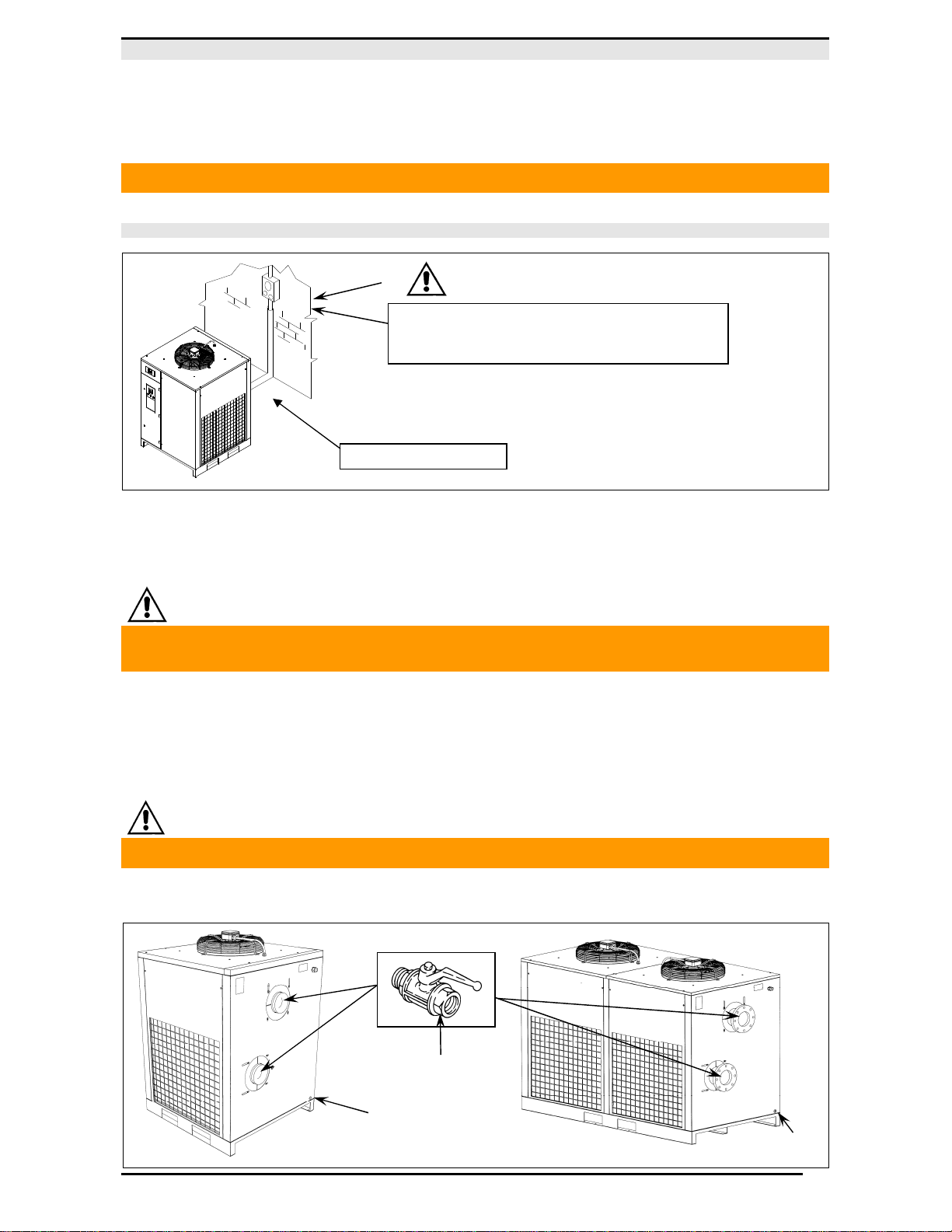

2.0 INTENDED USE

The dryer has been designed and built to dry compressed air for industrial use. The dryer cannot be used in premises

where there is a risk of fire or explosion or where work is carried out which releases substances into the environment

which are dangerous with regard to safety (for example: solvents, inflammable vapours, alcohol, etc.).

In particular the appliance cannot be used to produce air to be breathed by humans or used on direct contact with

foodstuffs. These uses are only allowed if the compressed air is additionally treated by means of a suitable purification

system

(Consult the manufacturer for these special uses.)

This appliance must be used only for the purpose for which it was specifically designed. All other uses are to be

considered incorrect and therefore unreasonable. The Manufacturer cannot be held responsible for any damage resulting

from improper, incorrect, or unreasonable use.

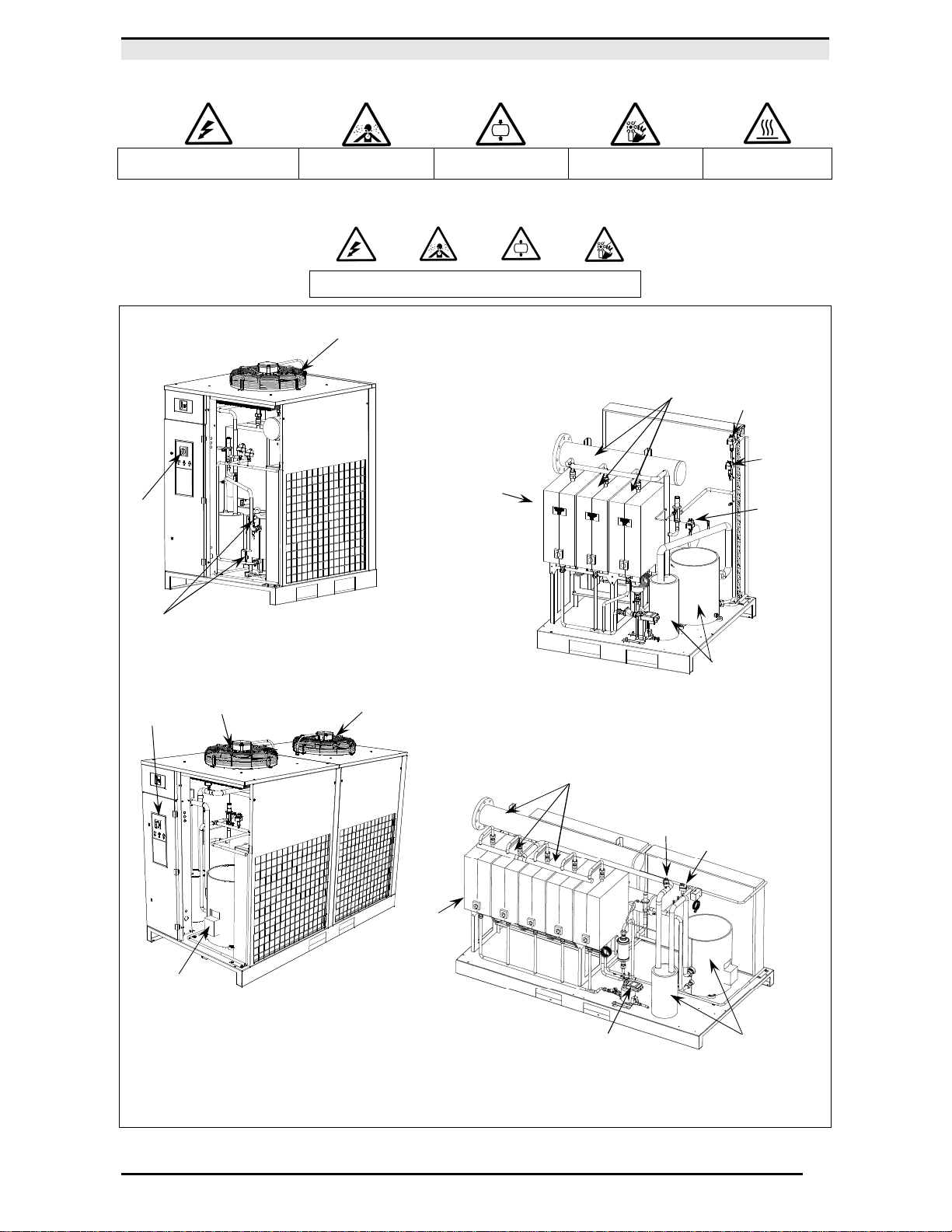

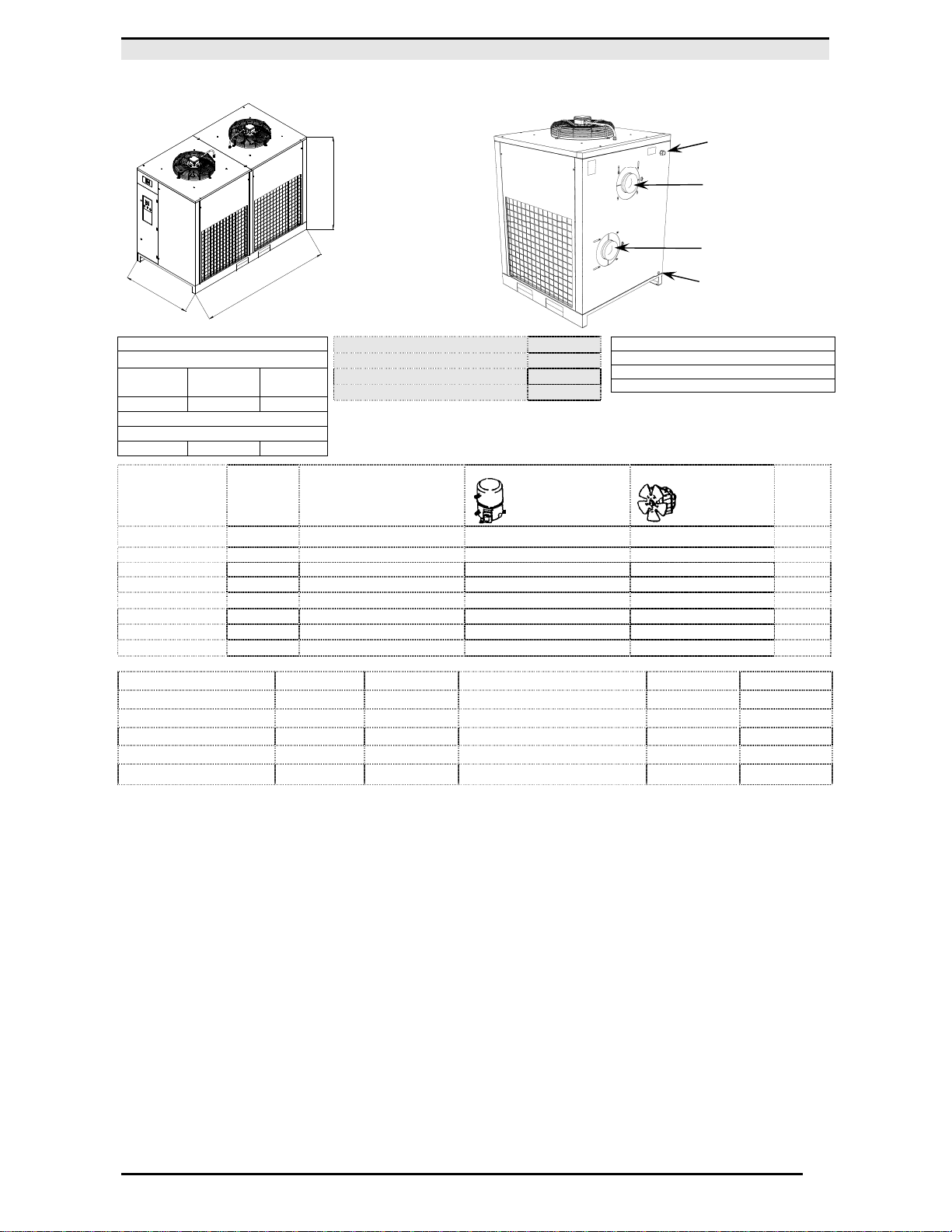

3.0 OPERATION

The hot gaseous refrigerant leaves the evaporator (4) and enters the refrigeration compressor (1) where it is compressed

and pumped into the condenser (2). With the aid of a cooling fan (3) the refrigerant is condensed into a liquid. The

condensed liquid refrigerant then passes through a filter/dryer (8) to remove any residual moisture. A capillary tube (7) is

used as an expansion device before the refrigerant re-enters the evaporator (4). The expansion and evaporation of the

refrigerant produces a cooling effect. Due to the heat exchange with the compressed air passing through the heat

exchanger, the air temperature is reduced causing water vapour to condense out of the air stream. The water is

removed in a water separator (5) so that it can be evacuated though the automatic level drain (13). The now gaseous

refrigerant is returned to the compressor (1) where the cycle repeats.

The circuit is equipped with a hot gas bypass (HGBP) system for the refrigerant which adjusts the available refrigerating

capacity to the actual cooling load. This is achieved by injecting hot gas under the control of the HGBP valve (9) to

maintain a constant refrigerant pressure in the evaporator. With this control the of the refrigeration pressure the

temperature never decreases below (32°F / 0°C).

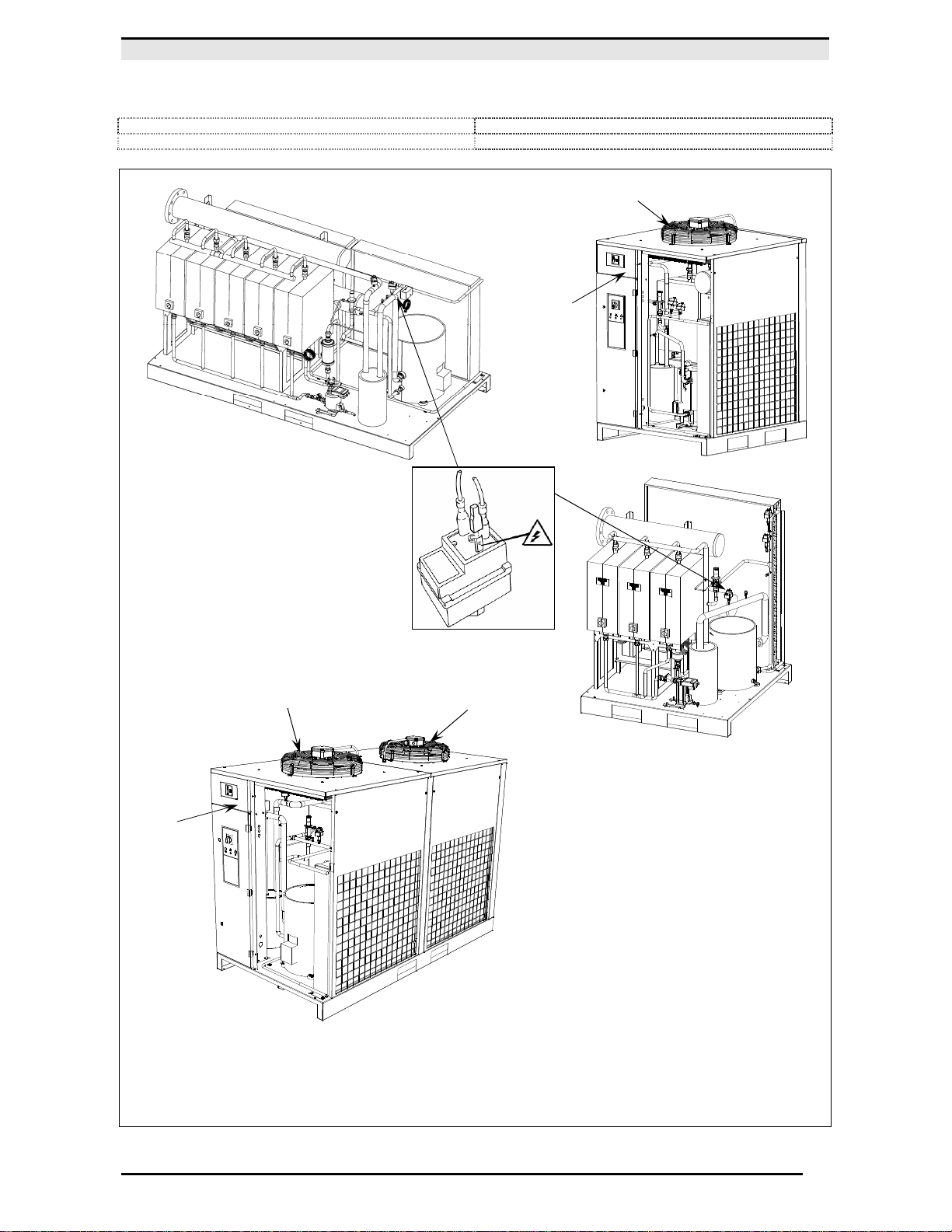

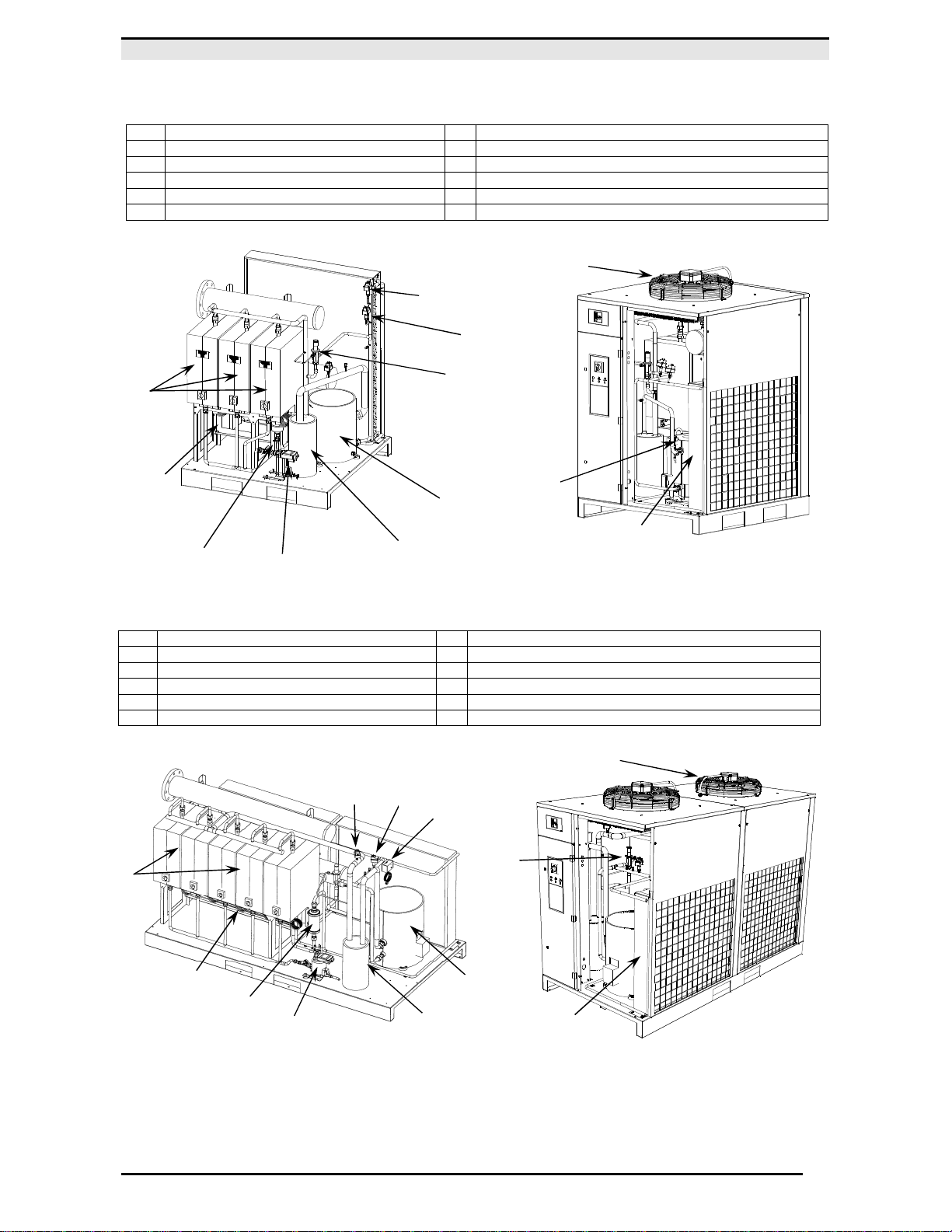

DRYER FLOW DIAGRAM

1) REFRIGERANT COMPRESSOR

) FAN CONTROL PRESSURE SWITCH

5) DEMISTER CONDENSATE SEPARATOR 13) MAX PRESSURE SWITCH

4.0 GENERAL SAFETY STANDARD

The appliance may be used only by specially trained and authorized personnel.

Any tampering with the machine or alterations not approved beforehand by the Manufacturer relieve the latter of

responsibility for any damage resulting from the above actions.

The removal of or tampering with the safety devices constitutes a violation of the European Standards on safety.

ALL WORK ON THE ELECTRONICS AND REFRIGERANT CIRCUIT, HOWEVER SLIGHT, MUST BE CARRIED OUT BY PROFESSIONALLY

SKILLED PERSONNEL.

AIR OUTLET

CONDENSA

D