Preface

HR8 Motor User Manual IV

Table of Contents

1. INTRODUCTION ........................................................................................................1-1

1.1 About the Motor.................................................................................................1-1

1.2 Vacuum Motors..................................................................................................1-1

1.3 HR8 System Parts..............................................................................................1-2

1.4 Handling.............................................................................................................1-2

1.5 Installation and Servicing .................................................................................1-2

2. PREPARATION AND INSTALLATION ......................................................................2-1

2.1 Preparation.........................................................................................................2-1

2.1.1 Mounting Base..............................................................................................2-2

2.1.2 Limiting Stage Motion....................................................................................2-3

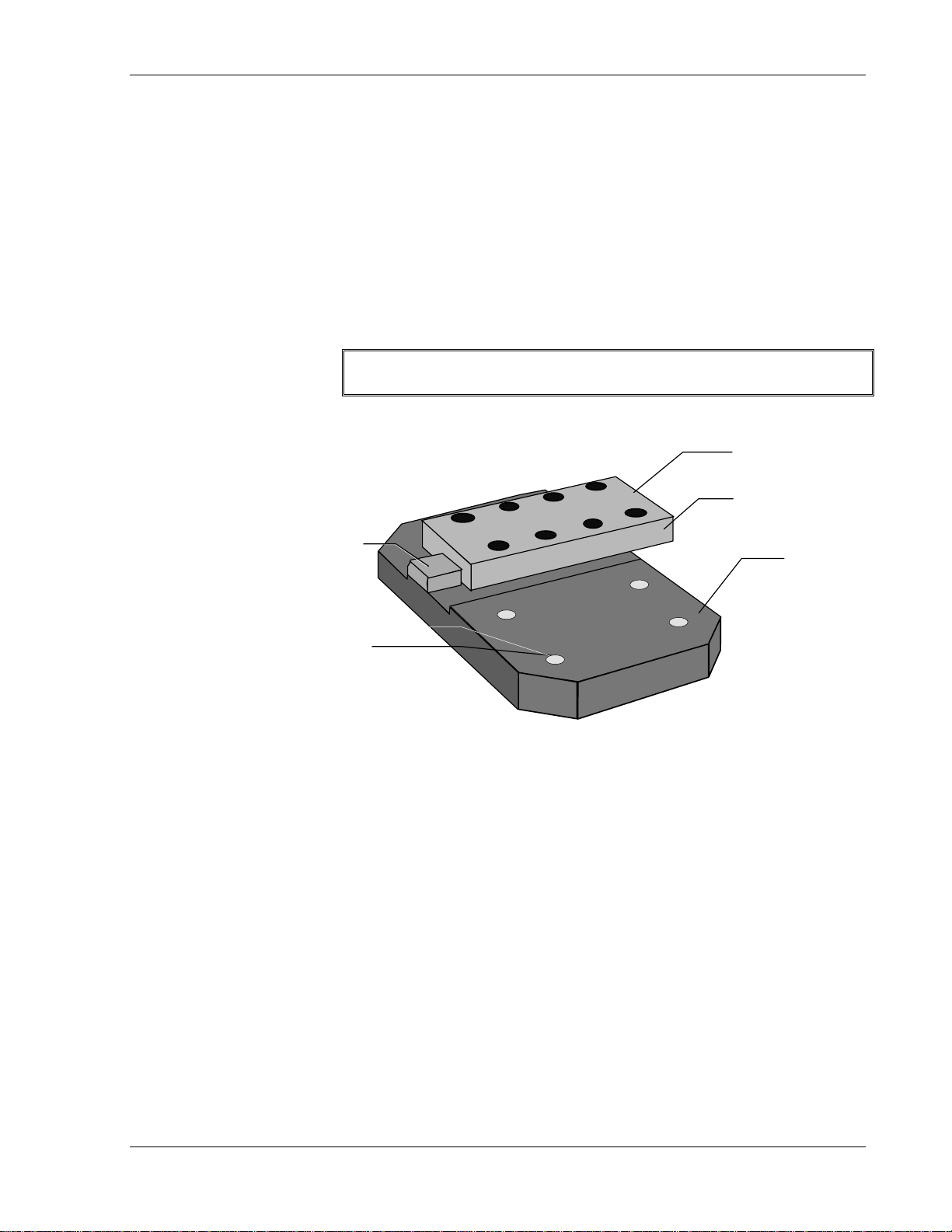

2.2 Motor Installation...............................................................................................2-4

2.2.1 Bonding the Driving Plate to the Stage..........................................................2-4

2.2.2 Mounting the Motor .......................................................................................2-7

2.2.3 Motor Grounding ...........................................................................................2-9

2.2.4 Motor Connections......................................................................................2-10

2.2.4.1 Motor Connector Pinout...............................................................................2-10

2.2.4.2 System Electrical Configuration...................................................................2-11

2.2.5 Motor Run-In...............................................................................................2-12

3. SPECIFICATIONS......................................................................................................3-1

3.1 General...............................................................................................................3-1

3.2 Specification Parameters..................................................................................3-3

3.2.1 Performance..................................................................................................3-3

3.2.2 Electrical .......................................................................................................3-3

3.2.3 Environmental...............................................................................................3-3

3.2.4 Physical Dimensions .....................................................................................3-3

3.2.5 Performance Envelope..................................................................................3-4

3.3 Schematics ........................................................................................................3-5

3.3.1 Dimensions for Standard and High-Vacuum Motors......................................3-6

3.3.2 Dimensions for Ultra-High-Vacuum Motors...................................................3-7

3.3.3 Mounting Base Dimensions...........................................................................3-8