Please review this entire manual before beginning assembly.

By doing so it will help you better understand each step as you progress in the

actual building of your kit, and you will do a better job in assembly.

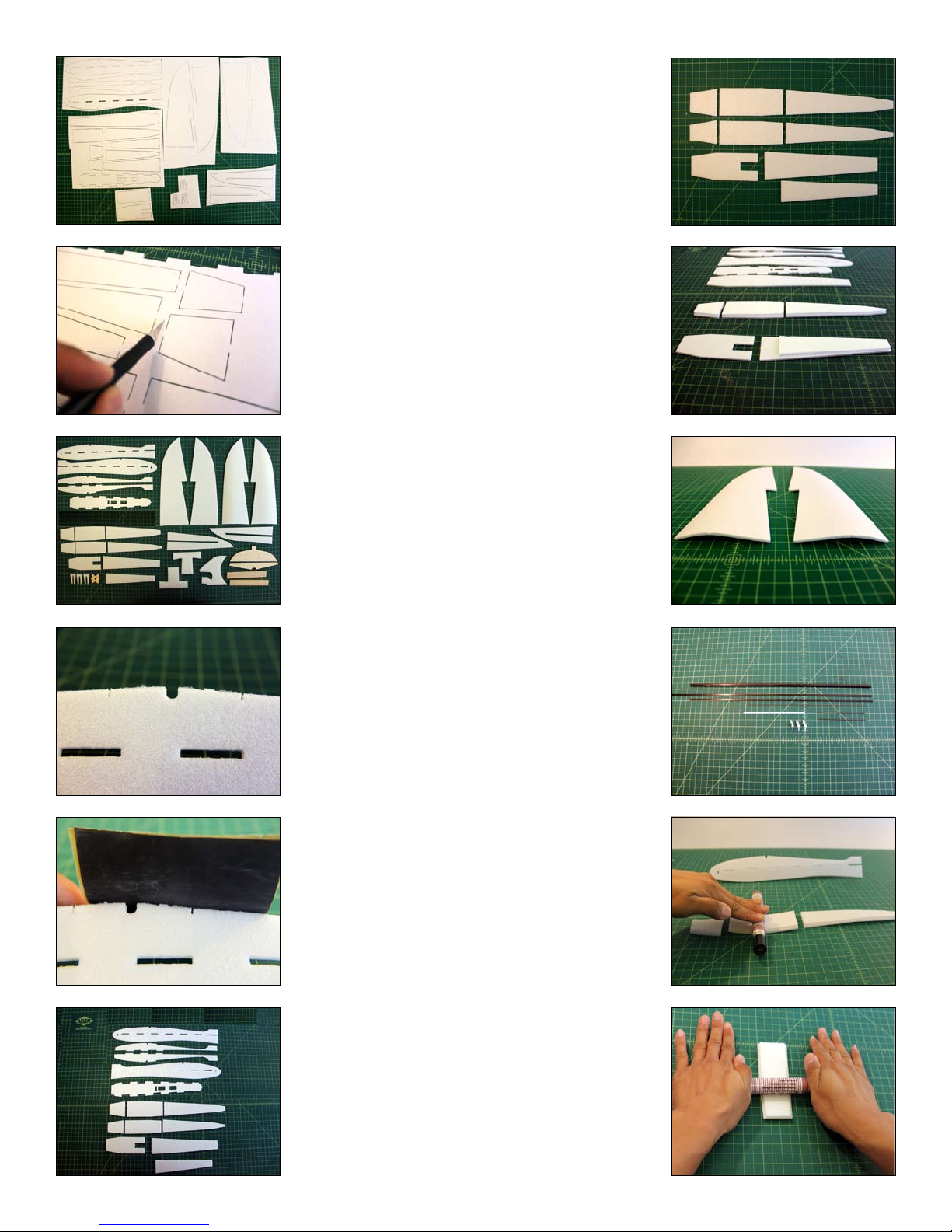

INCLUDED IN THIS KIT:

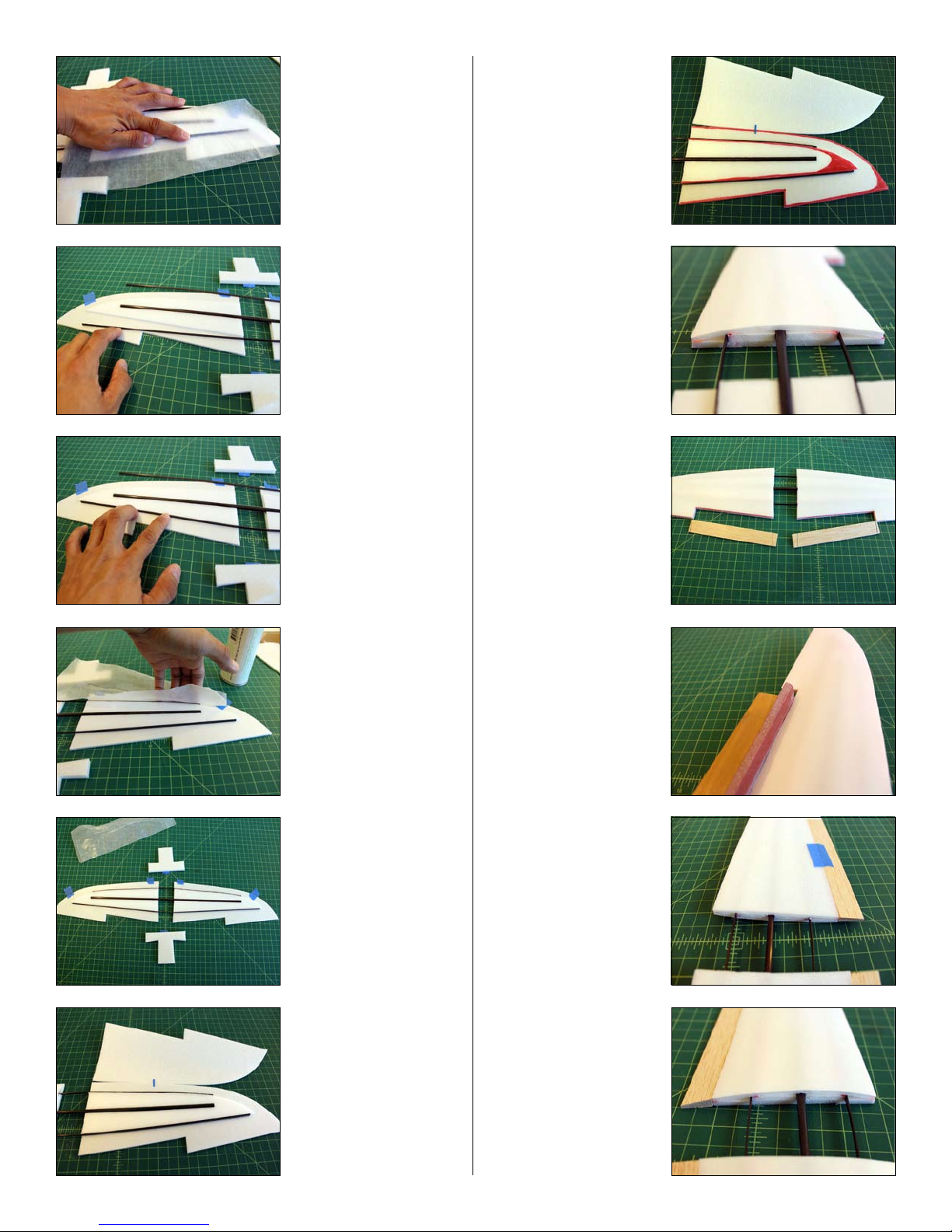

• All laser cut Depron parts

• Balsa ailerons, balsa horizontal stabilizer, and balsa elevator

• Plywood motor mount

• 3 Pushrods + 1 Pushrod tube

• 3 Micro control horns

• 1 Carbon ber tube and 2 at spars

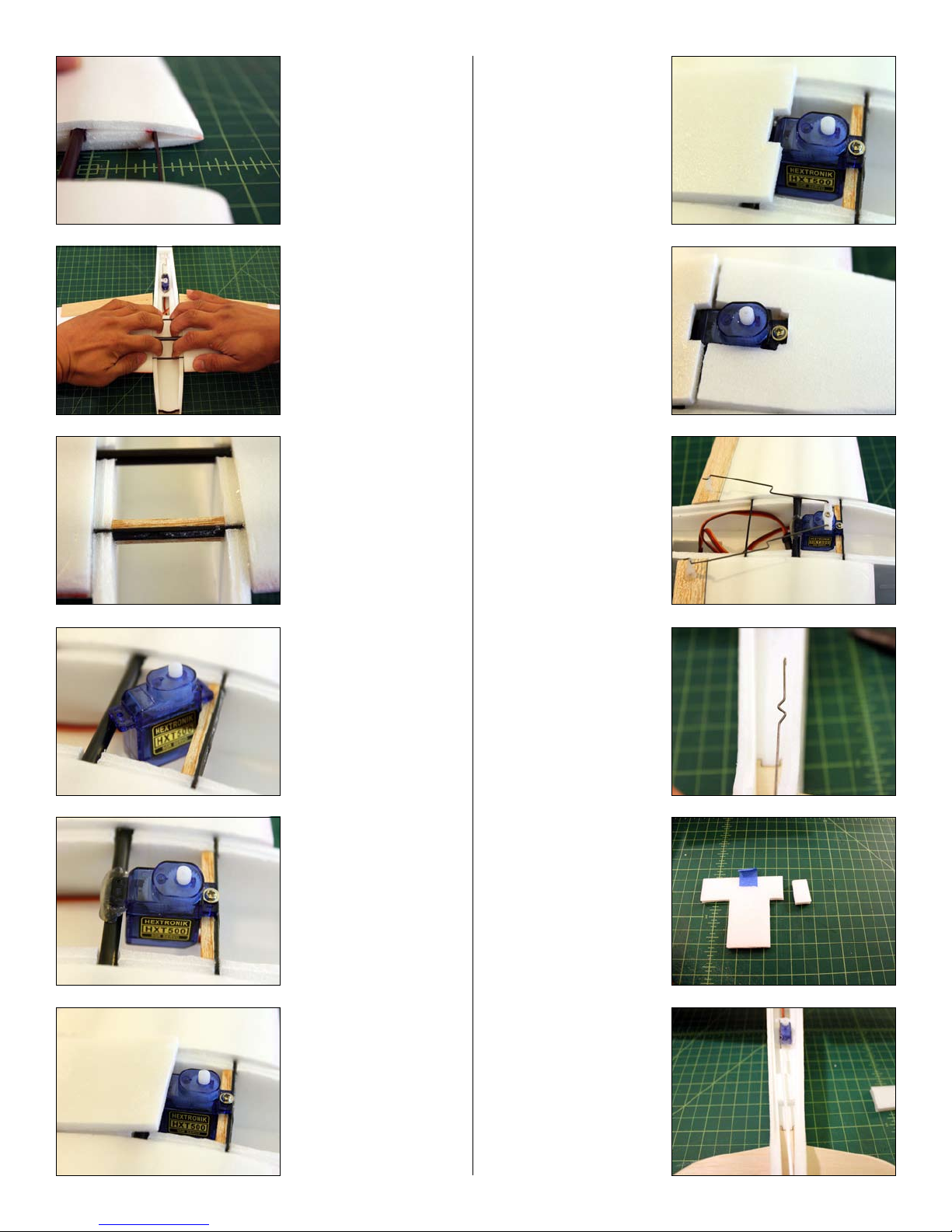

• 1 Balsa short stick for servo mount

SPECIFICATION:

• Wing Span: 24 inch

• Length: 17.5 inch

• Dry weight: 5.5 oz

• Ready to Fly Weight: 7.7 oz with 2S 7.4v 1050mAh

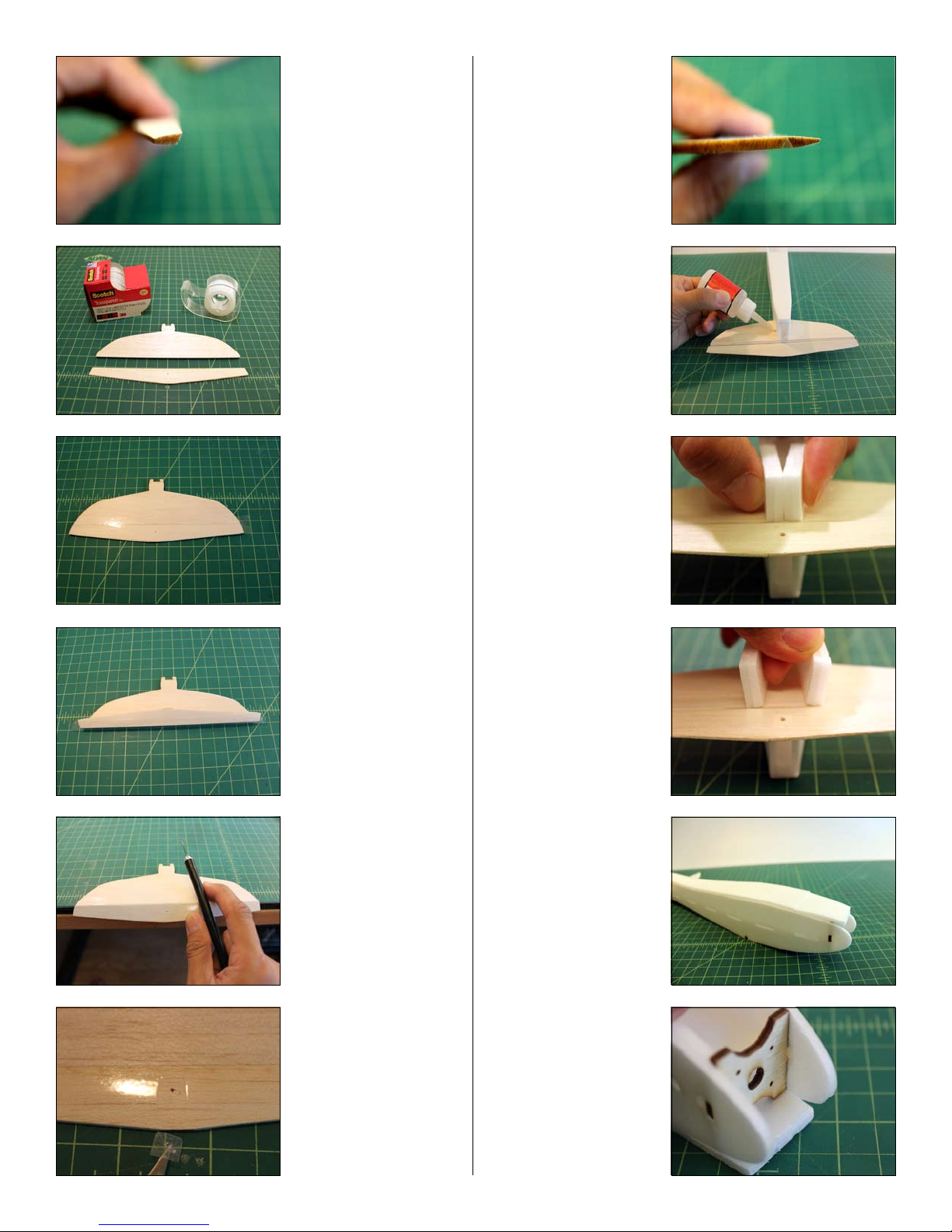

NEEDED BUILDING TOOLS:

• Foam Safe / Odorless CA glue + Foam Safe Accelerator

(User Friendly Odorless “UFO” highly recommended)

• Blenderm Hinge Tape or Transparent Scotch Tape

• Sandpaper + Sanding Bar

• Hobby Knife

• Ruler (preferably metal)

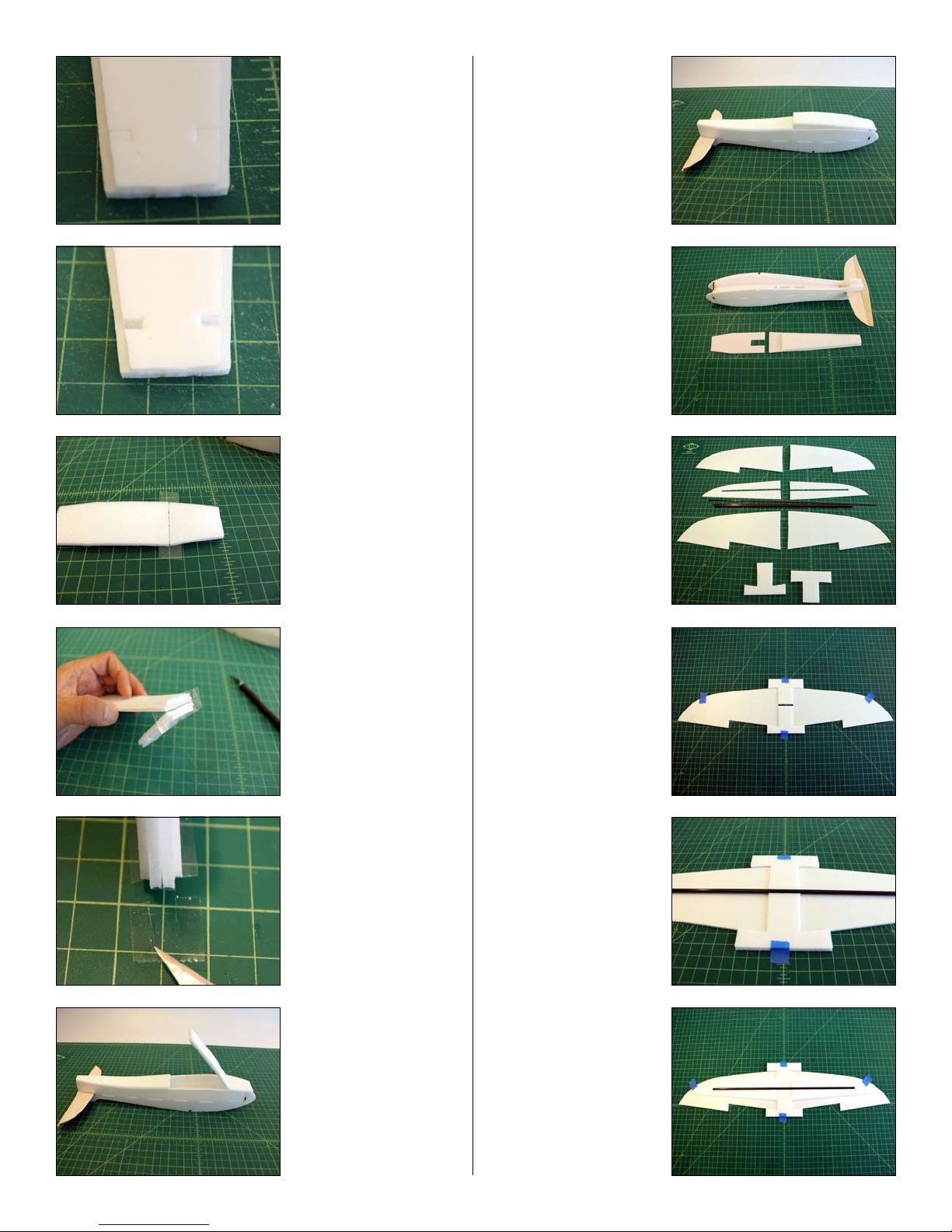

REQUIRED EQUIPMENT:

• 4 Channel Transmitter + Micro Receiver (AR6100E, AR6110E or similar)

• 2 Micro Servos (5~8 gram)

(HXT500, SG-50 or Hitec HS-55 or similar)

• Small & Light High KV Outrunner

(HXT 24gram 3000kv, Turnigy 2730 3000kv or similar)

• ESC: 30Amp

• APC Prop: (4.75x4.75 on 3S ONLY), or (5x5~6x5 on 2S only)

• Prop Adapter: 3mm (will t both recommended motors)

• Lipo Battery: Nano-Power 1100mAh 11.1v 35C

• Maximum Battery size: 73x34x18 mm

(Size is very crucial here. This size is the largest t for width and thickness possible in

the small fuselage)