1

INTRODUCTION

The Clipper Compass is supplied complete with display unit, sensor unit, and

Mounting kit. It is designed to operate from the vessel’s 12V battery supply.

PRE-TEST OF INSTRUMENT

Before mounting the units, check that the instrument is complete and undamaged.

Connect the sensor unit to the display unit and apply 12 volts. Confirm that a reading

is shown on the display.

INSTALLATION OF SENSOR

The sensor measures the direction of the Earth’s weak magnetic field, and so is

sensitive to other magnetic fields which can affect the unit’s accuracy. It should

therefore be positioned carefully. Select a sensor position as far as possible away from large

ferrous objects such as engines, and items such as DC motors or loudspeakers which

have powerful permanent magnets in them. Check also for small ferrous objects close

to the mounting location such as screws, nails, hinges etc. These can become

magnetised and cause errors. When a likely location has been found, a check for

reasonable accuracy can be made with a hand bearing compass to confirm its

suitability.

The magnetic sensor itself is gimballed within the housing. To accommodate pitch

and roll motions most effectively, mount the sensor as near to horizontal as possible.

For best performance in rough weather conditions, it is also advisable to mount the

sensor in a position (usually amidships) that minimises lateral accelerations due to

pitch and roll. Avoid mounting the sensor high above the water line because doing so

also increases pitch and roll accelerations. The sensor is waterproof to CFR-46

standard. Ensure the sensor does not become submerged.

Position the sensor unit and mark and drill pilot holes for mounting screws to allow the

sensor to be rotated to align it exactly with the vessel’s axis. Now mount the sensor

carefully in position using non-magnetic screws. The rotational position of the sensor

should be chosen to ensure that the arrow points as close as possible fore-and-aft.

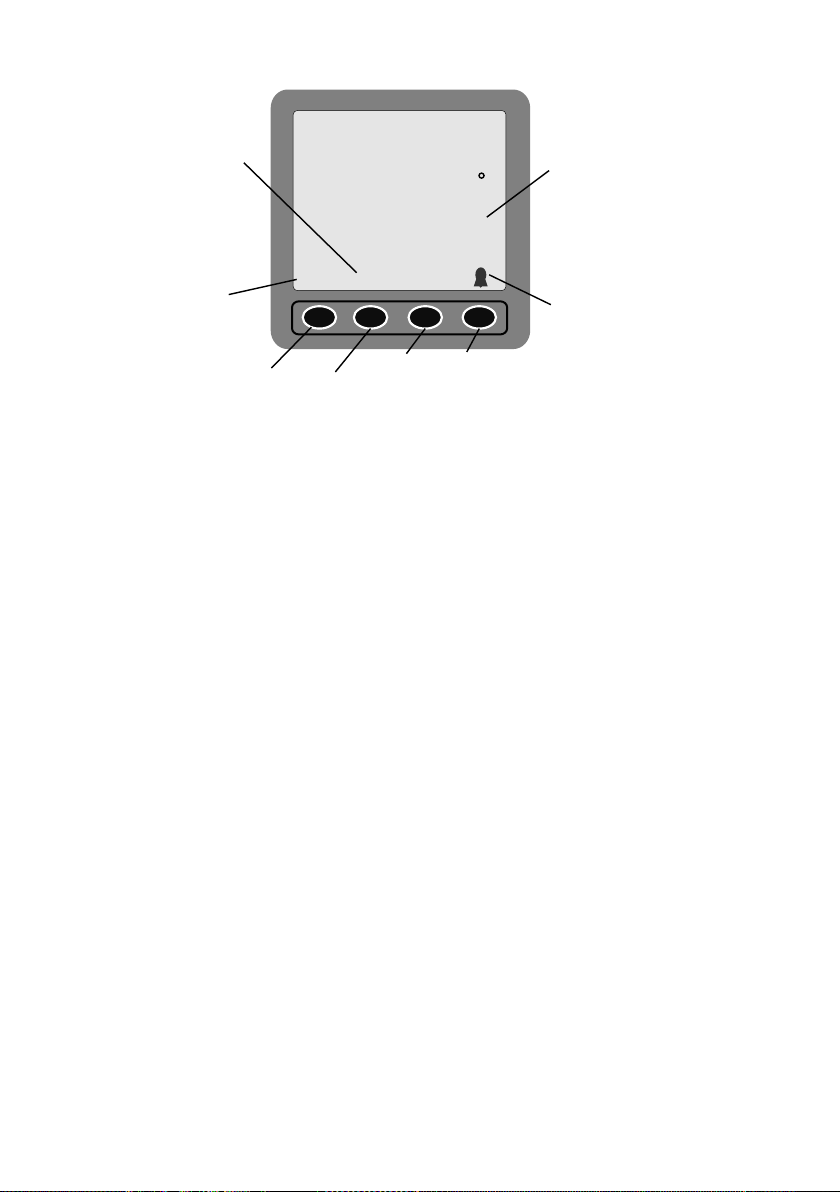

INSTALLING THE DISPLAY

Select a convenient position for the display on a panel or bulk-head. The site must be

flat and the cavity behind the panel must remain dry at all times. (The cable entry is

deliberately not sealed to ensure adequate ventilation. This prevents misting of the

display).

Cut a hole in the panel 67mm high and 87mm wide. Bring the wiring through the hole

in the panel and connect as shown on Figure 1. It is wise to use a fused supply to

provide protection should a fault occur. The current consumption is very small, so any

supply with a ¼-Amp fuse is more than adequate.

Unscrew and remove the wing nut from the rear of the instrument and remove

the stainless steel clamping bracket. Fit the “O” ring seal into the groove in the panel

mounting face of the instrument. Ensure that it is correctly lying in its groove before

fitting the instrument to the panel, which provides the watertight seal for the display.