E8 Swing Automatic Gate. Revision 1.1.8 –1112

2 of 19

Important Safety Information

All safety instructions and installation methods should be read and completely

understood by installer and the owner prior to the installation of the Autogate system.

This product is designed and manufactured for the use indicated in this document.

Remember that all automatic gates are intended for vehicular gates only. A separate

gate or entrance must be installed for pedestrian use.

Any other use, not expressly indicated may damage the product or be a source of

danger.

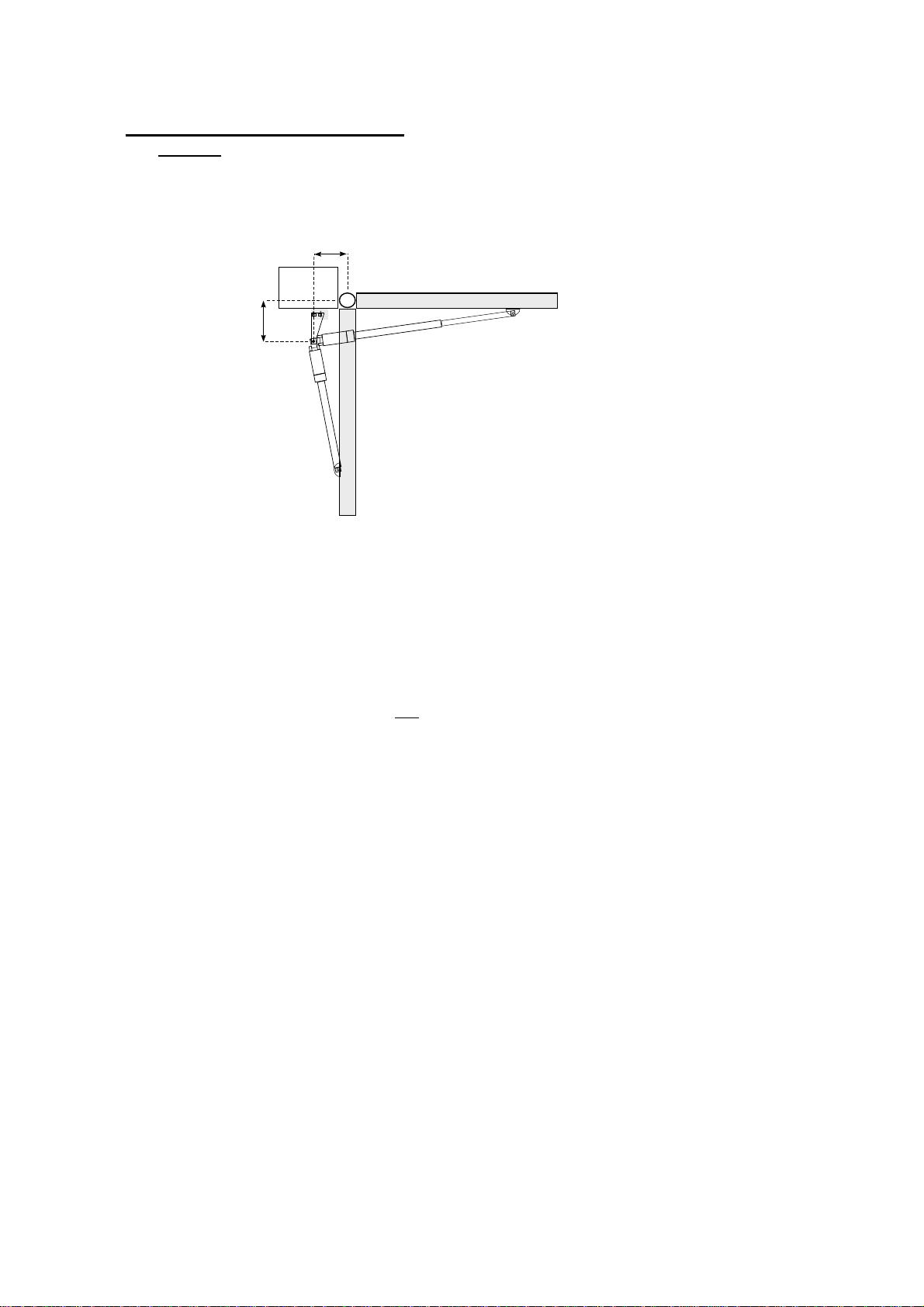

Swing Gate Motor – Model E8 Arm

E8 Swing Gate Motor is suitable for Light – Medium weight gates. Do not use it on

large sized gate which exceed the maximum recommended gate weight. Wrong

selection of motor will result in unreliable operation.

Important Observations

Owner should observe the following:

1. Do not cross the gate while it is operating.

2. Keep children away from the gate and the remote control.

3. Do not adjust the setting of the control panel and the motor. Contact installer

to adjust to the required settings as per this manual.

4. Test the system frequently and monitor the high and low speed of the system.

5. Practice the use of the Emergency Override key. This is crucial in the event

that the system does not work.

6. Place the WARNING signs prominently on the gate to warn pedestrian of the

Automatic Gate operation in your premise. It is your responsibility to post the

warning signs on both sides of the gate.

Installer should observe the following:

1. Make sure gate weight does not exceed the maximum weight specified.

2. The gate design must be suitable for the installation of Autogate system.

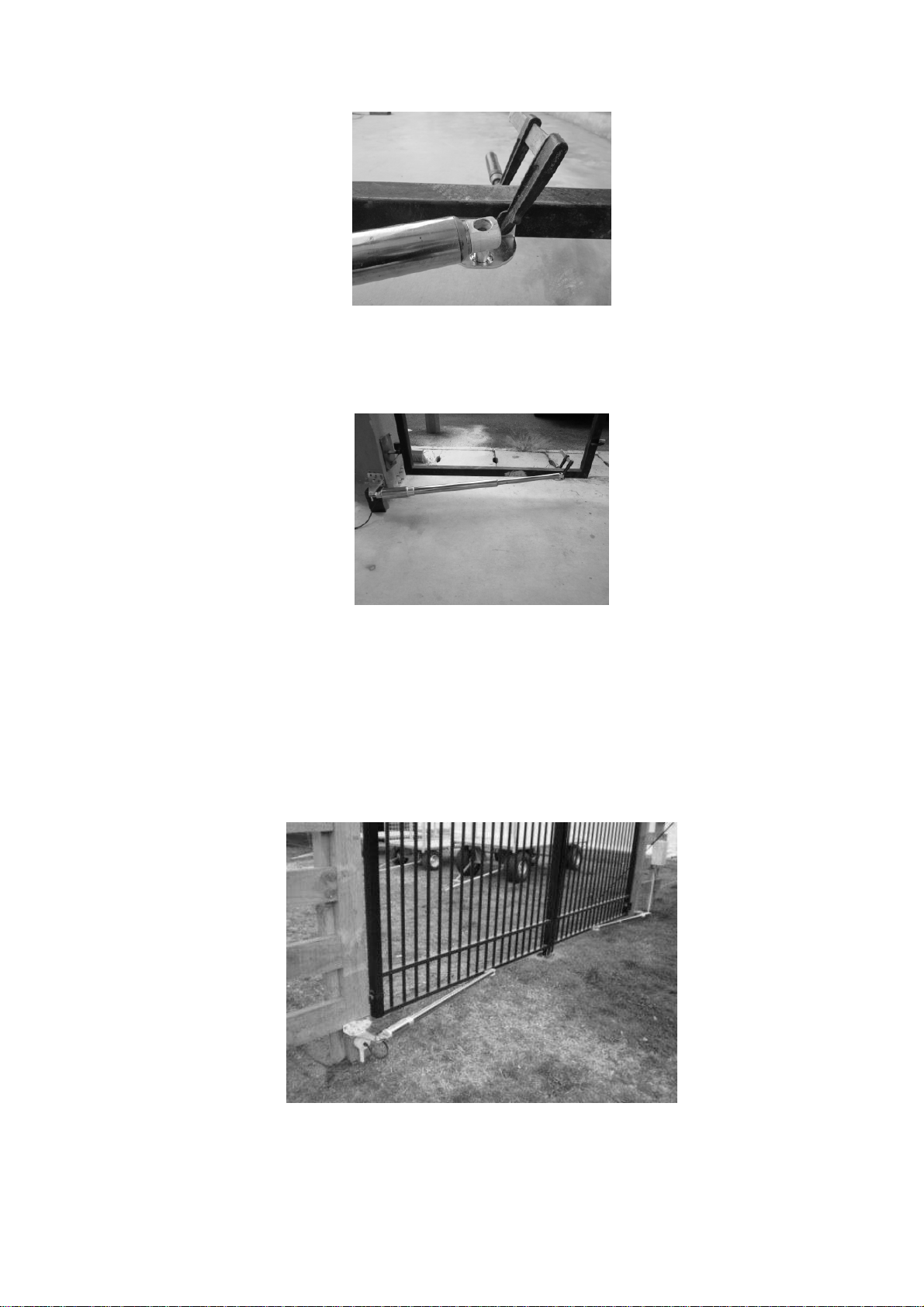

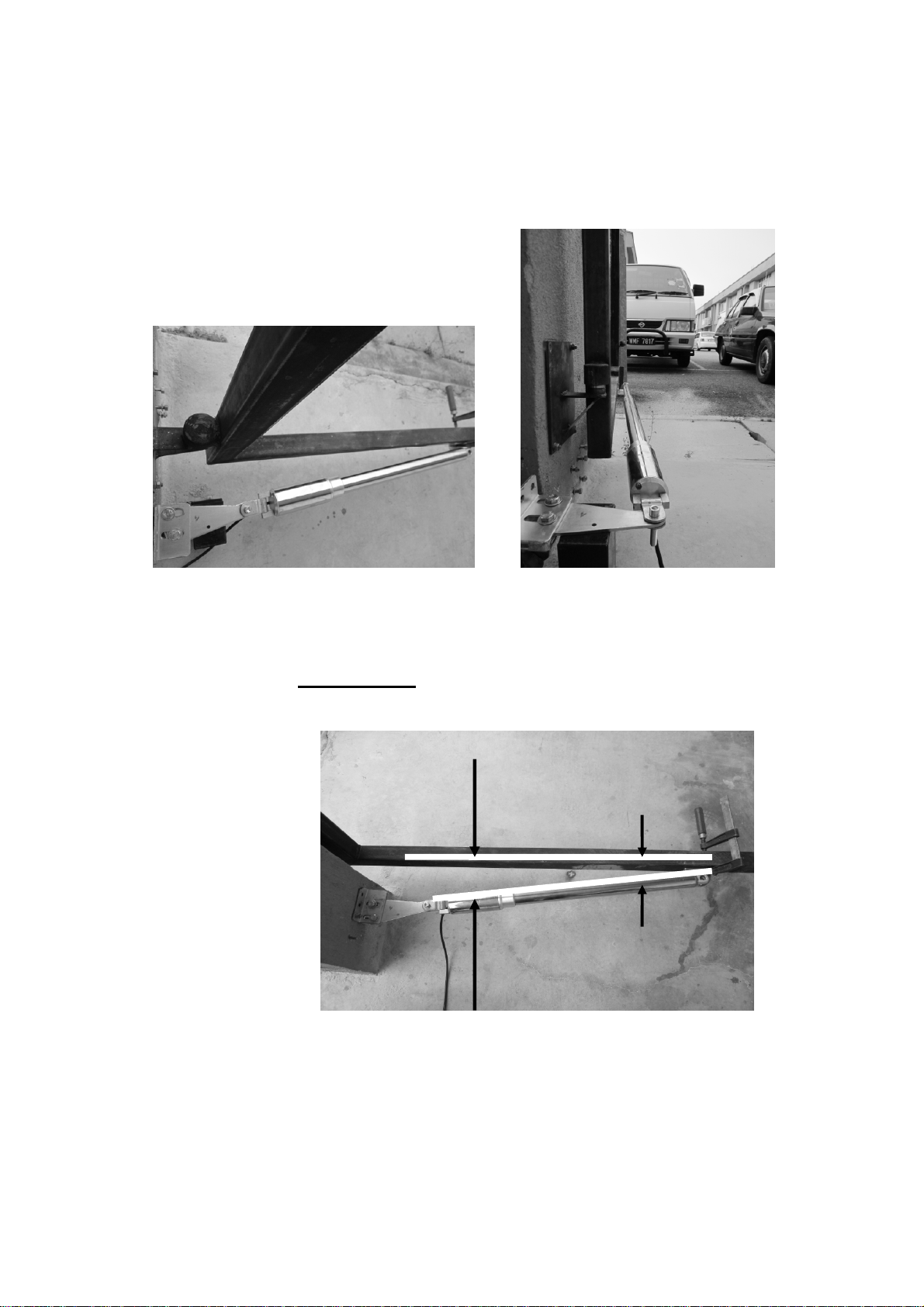

3. Ensure that the gate is installed on flat, level ground and can move freely in

both directions along the entire swing of the gate. A properly balanced

swinging type gate should NOT swing-open or swing-close when no pushing

or pulling force is exerted onto it.

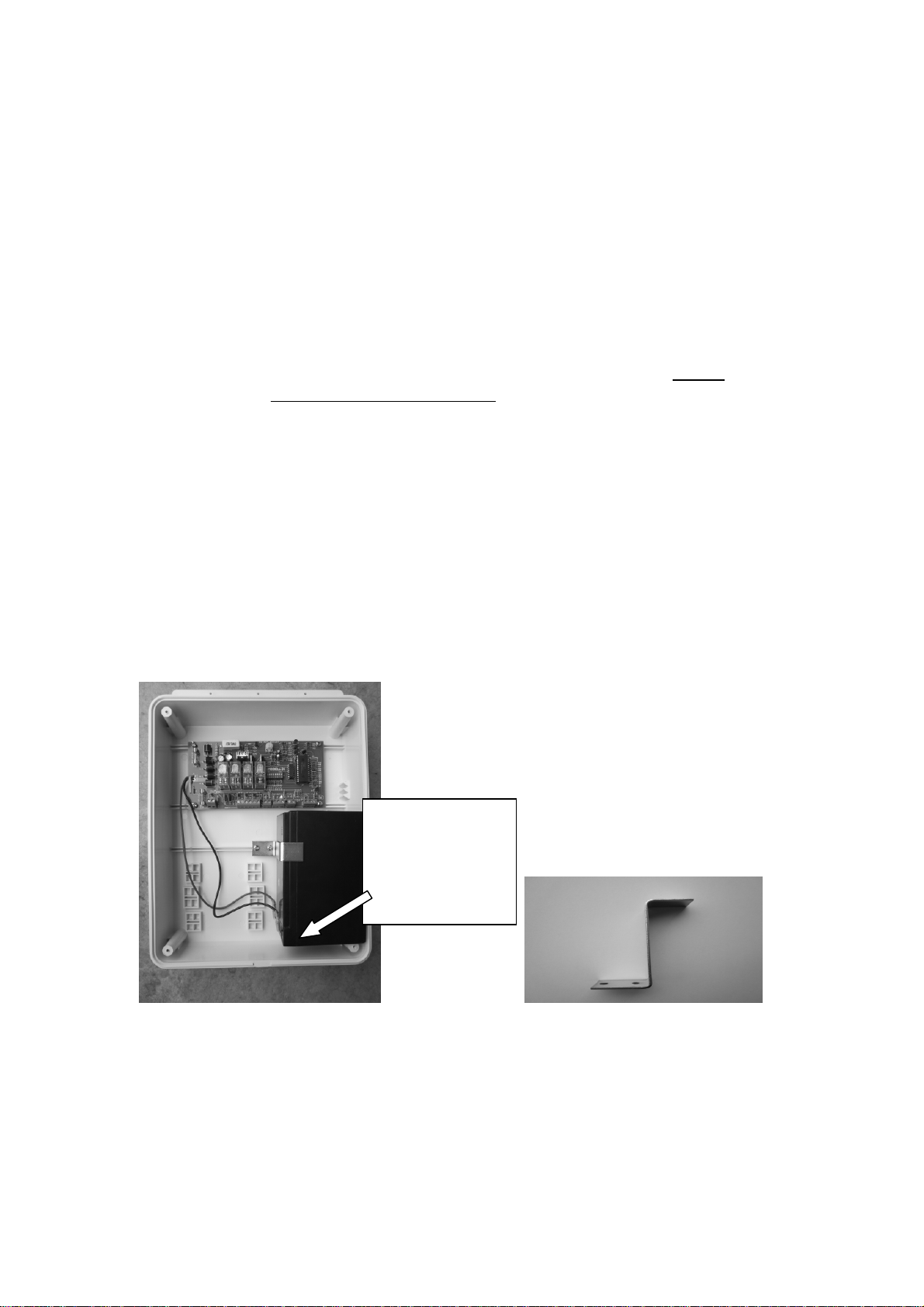

4. Control Panel Box must be installed in the area where it is not easily damaged.

5. Do not change with parts or components not supplied by manufacturer.

6. Make sure all wiring works are correct in accordance with electrical bylaws

and in good condition before supplying the mains power to the control panel.

7. Turn OFF the power when doing any maintenance.

8. Ensure the control panel box free from water leakage and insects to avoid

short circuiting of the control panel.

9. Never supply mains power directly to the DC motor.

10. Transformer MUST be connected to mains power via a RCD (residual current

device).

11. Do not install the operating system if in doubt. Contact the manufacturer or

your local agent.