802-009 Switch Panel

SM802 Installation and Operation Manual

Section 2 Rev: 1.01 Issue 4 Page 2-3

ENG-FORM: 805-0121.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIRBORNE TECHNOLOGY LTD.

2.4.4 Mechanical Mounting

Installation dimensions are shown on the Outline drawing 802-009 listed in Section 2.6. No shock or

vibration isolators are required for mounting.

The 802-009 Switch Panel may be mounted to a metal, plastic or composite surface however, it is

absolutely necessary to ground the enclosure to the metal aircraft ground structure. When mounting to a

plastic or composite surface, use a grounding strap. An 8-32" x 1/2" grounding stud is provided on the

rear of the enclosure for chassis grounding. The switch panel enclosure and mounting surface is finished

with an electrically conductive film. It is not necessary to remove the film for electrical bonding to any

metal aircraft ground structure.

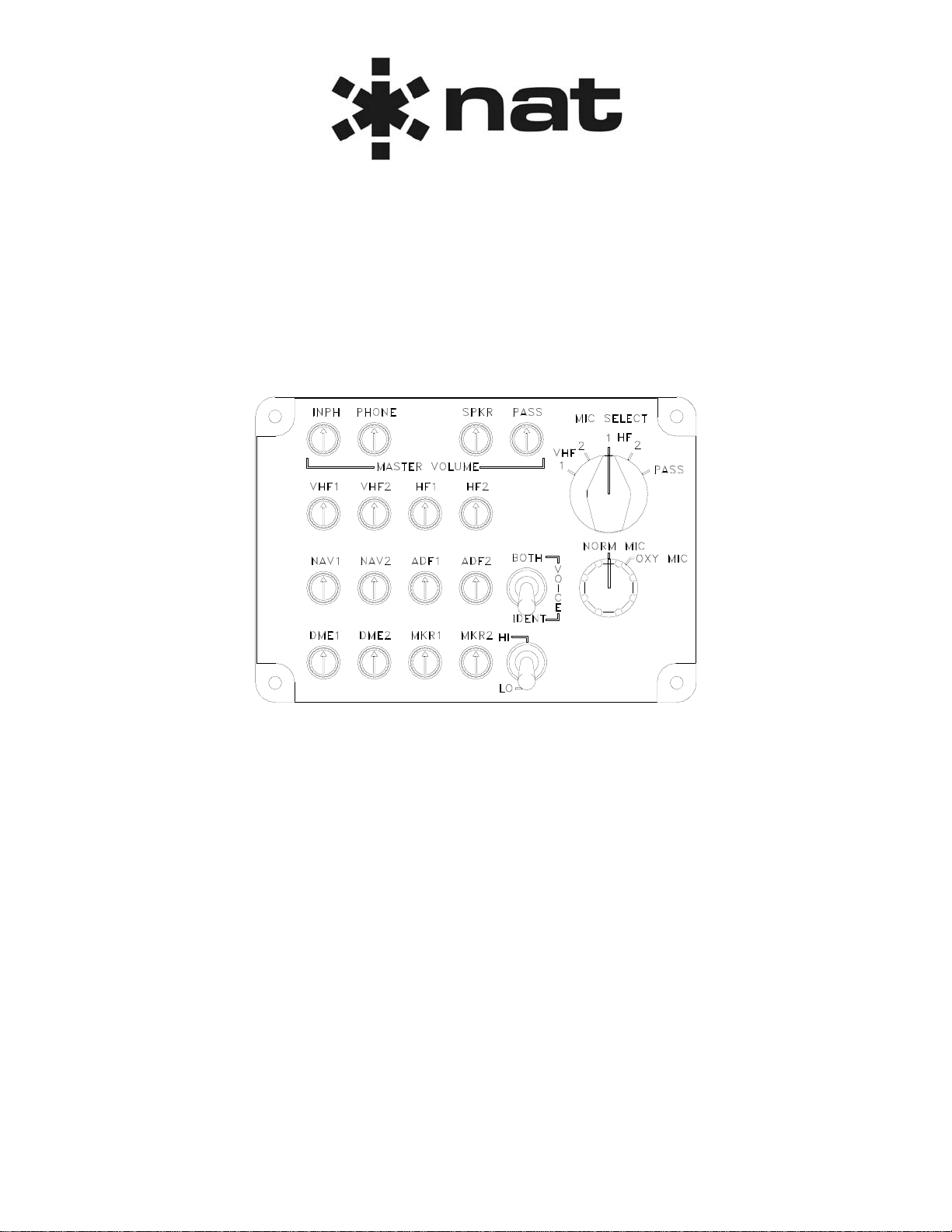

If replacement of the front panel overlay is necessary, it may be removed by first loosening the set screws

on the MIC SELECT and NORM MIC/OXY MIC knobs and removing the knobs. Then the four 4-40 flush

socket head screws on the backside of the mounting flanges may be removed and the overlay may be

pulled off straight forward. Installing a new overlay requires the same steps in reverse order however,

care should be taken to align the overlay before tightening the four 4-40 socket head screws so that the

lighting power connector mates properly and the lighted knobs do not rub on their through holes in the

overlay.

2.4.5 Installation Notes

Connecting P1-8 of the pilot's 802-009 to P1-7 of the copilot's 802-009 provides relay switching of the

802-009 PASS volume control to the paging amplifier. When the PA volume relay internal to the 802-009

is in the relaxed position, the BRIEFER preset volume potentiometer in the rear of the copilot 802-009 is

connected to the paging amplifier. When the TRANSMIT SELECTOR switch is placed in the PASS

position and PTT is keyed, the PA VOLUME relay is energized, connecting the PASS volume control on

the 802-009 front panel to the paging amplifier. The PA volume interconnect line allows this logic to

function for both pilot and copilot positions.

If the INPH LISTEN input on the 802-009 is grounded, then interphone audio may be heard on the

headphones at all times however, the INPH switch must still be turned ON in order to talk on the

interphone with the normal boom or oxygen mask mics. In addition to the HOT MIC microphone output,

there are six other microphone outputs provided, one each for the selected transmitter or PA amplifier.

2.4.5.1 MIC INPUTS

NORM MIC The NORM MIC input, intended for the normal boom or headset microphone, is

compatible with carbon and amplified dynamic microphones. This input may be used for

both interphone communications and transmitting. A transmitter is keyed for this mic input

using the yoke mounted PTT switch.

OXY MIC The OXY MIC input, intended for the oxygen mask microphone, is compatible with

carbon and amplified dynamic microphones. This input may be used for both interphone

communications and transmitting. A transmitter is keyed for this mic input using the yoke

mounted PTT switch.