USE GUIDE

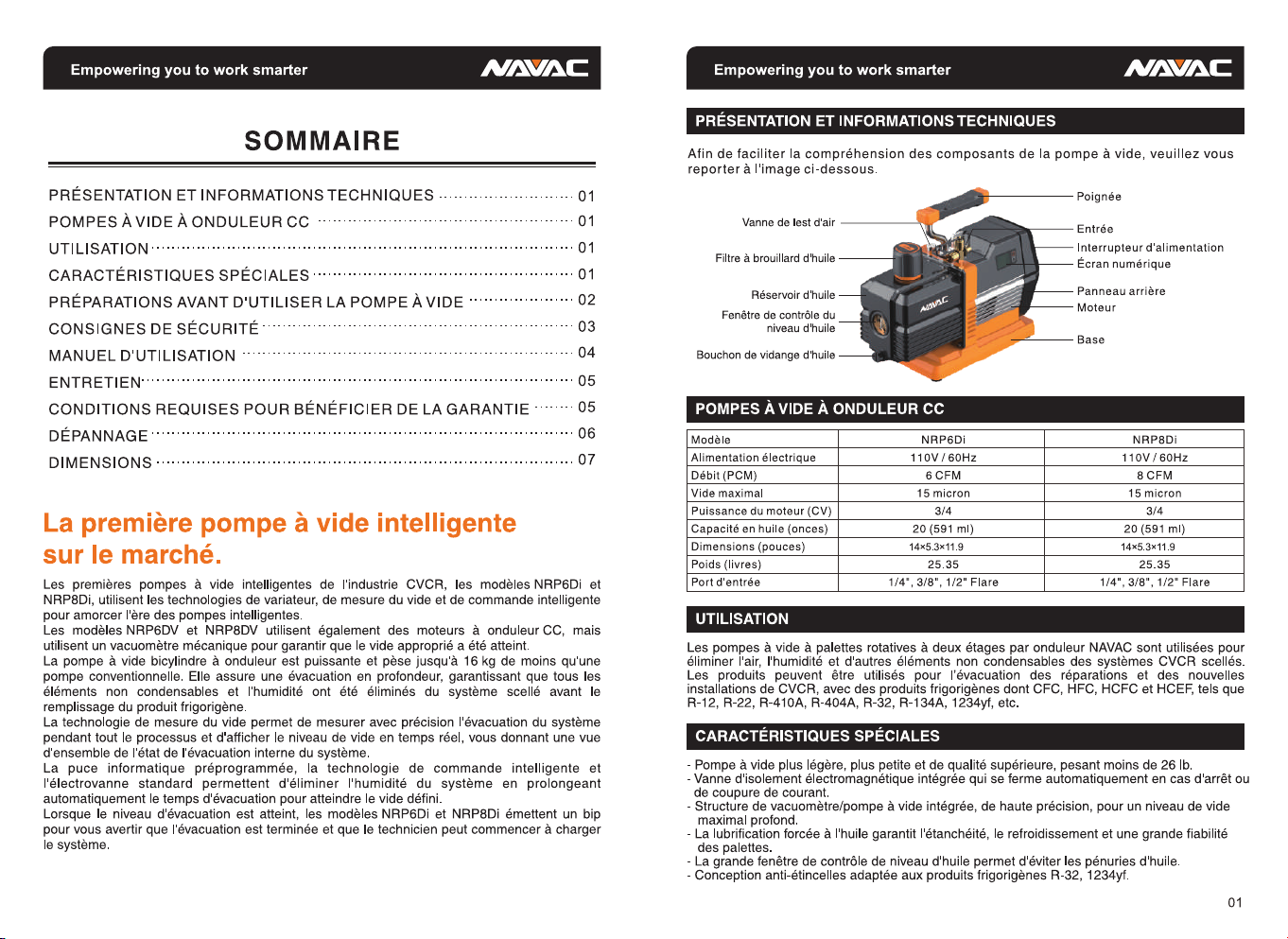

1. When using the vacuum pump, remove the inlet

protection cap from the desired (1/4”, 3/8”, or

1/2”) connecting port, as shown in the diagram

above, and connect the pump to the system or piping

to be evacuated.

Use shortest hoses possible for faster and more

thorough evacuation.

2. Inspect the hose inlet connection, as well as all connecting hoses for proper seal. There must be

no leakage or it will be impossible to draw the required deep vacuum level.

3. At the beginning of the evacuation process, open the GAS BALLAST screw one full turn

counter-clockwise, and once the vacuum gauge reaches 2000 microns, retighten to achieve

desired vacuum level.

4. After evacuation is completed, the smart vacuum pump will beep to indicate the vacuum is

complete. If a DV-series pump is being used, shut down the pump and close the system access

valve(s).

5. Turn off the power switch on the pump and disconnect power.

6. Remove the evacuation hoses.

7. Close the air entry cap and the air exhaust cap tightly (with the exception of models without air

exhaust cap), to prevent dirt or particulates from entering the pump.

Note:

1. For the Di-series pumps equipped with a digital vacuum gauge, after turning on the power, press

the start button on the display panel to start the pump. When the vacuum reaches 500 microns,

the pump will continue running at a reduced speed. Then 30 minutes after this, buzz alarm

indicates the evacuation is complete.

2. Always evacuate systems in conjunction with a micron vacuum gauge, such as the NAVAC

NMV1, if using the standard inverter drive pump. Micron vacuum gauges precisely measure and

display system evacuation during the entire process, giving you a comprehensive view of the

sealed system internal evacuation condition.

3. Please pay attention to any changes in the oil level during pump operation. If the oil level falls

below the center line, immediately add more vacuum pump oil to avoid damage to the pump.

4. If any residual refrigerant comes in contact with the vacuum gauge sensor, the digital display may

go wrong.Once the refrigerant has been evacuated, the sensor and display will automatically

start working again.

5. Vacuum pump and oil must be above 30℉.

1/4” 1/2”

3/8”

CAUTION-To reduce the risk of electric shock, do not expose to rain. Store indoors.

The product should be placed steadily without any incline when it is working. If it has finished its job ,

please get the plug off and keep the pump housing dustproof by covering a clean film plastic bag on it.

EXTENSION CORDS

If an extension cord must be used, be sure it is:

1. A 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that will accept

the plug on the product

2. In good condition

3. No longer than 50' (15.2m)

4. 16 gauge (AWG) or larger. (Wire size increases as gauge number decreases. 14 AWG and

12AWG may also be used. DO NOT USE 18 AWG )

NOTICE: Risk of Property Damage. The use of an undersized extension cord will cause voltage to

drop resulting in power loss to the motor and overheating.

0504

MAINTENANCE

1. Vacuum pump oil has three major functions: pump lubricant, pump cooling, and pump sealant.

During the evacuation process, the pump oil will absorb moisture being pulled from the system,

causing it to be less effective as a lubricant and pump vane seal, extending evacuation time and

possibly allowing the pump to overheat. We recommend that the oil be changed just before

evacuating each A/C-R system to insure the pump oil is in a clean condition as this is the key factor

in determining if the pump can achieve the required vacuum levels. In order to maintain the

optimum operation of the pump, we recommend that you use NAVAC vacuum pump oil. This oil is

made using a unique process and can maintain proper viscosity during normal operation and

temperatures, and it’s also helpful for cold starts. Should the NAVAC oil not be available, reputable

brands of special-purpose vacuum pump oil may be used.

Note: Should the pump oil become opaque, dirty, or full of moisture, promptly change oil. This will

greatly speed up evacuation, especially when there is a lot of moisture in system piping from

having been left open to the atmosphere for an extended period of time.

Oil change procedure:

1. To ensure that the pump and oil are warm, run pump for approximately one minute prior to

changing oil. Do not run longer than this, as it may be possible to damage the pump.

2. While the pump is running, open one inlet port and allow oil to drain out of the pump. After turning

off pump, open the oil drain plug, and drain used oil into an appropriate vessel and dispose of

properly.

3. As oil stops draining, tip the pump to drain any remaining oil in the bottom of the pump.

4. Replace and tighten oil drain plug.

5. Remove oil fill cap, pour in new oil until the oil is at the proper level in the sight glass (the same

procedure prior to using the pump above).

REQUIREMENTS FOR WARRANTY COVERAGE

Product warranty is provided for product quality problems for two years from date of sale. For

warranty to be valid, the following conditions must be met:

1. Products issues due to manufacturing defects confirmed by qualified agents.

2. Products which have not been maintained or dismantled by unauthorized parties.

3. Products that have been used in accordance with the User Manual. All maintenance services shall

be performed during the warranty period.

Statement: Other than repairing the product defective, the manufacturer of this product will not be

liable for any other costs, such as time spent in fixing the issue, refrigerant consumption,

refrigerant disposal costs, as well as unauthorized transportation and labor costs.