Negele LAR-361 User manual

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

1

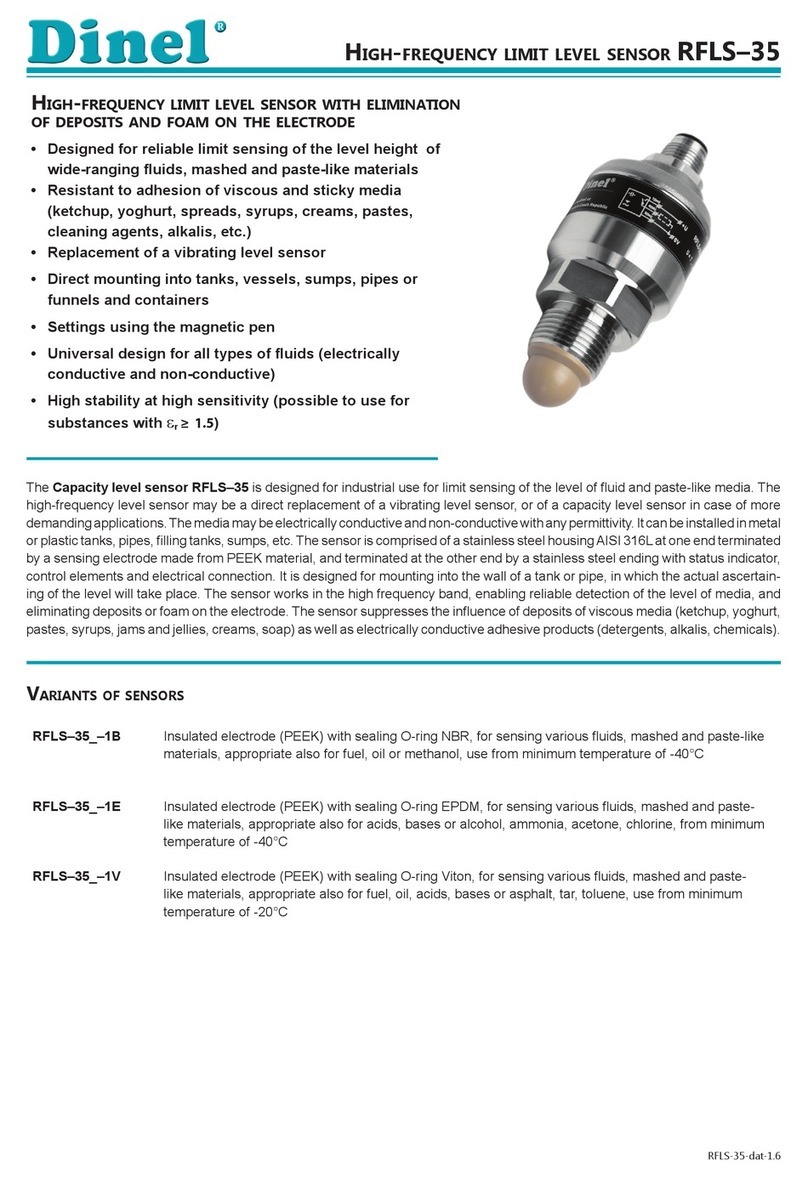

Application / Specifi ed usage

·· Hydrostatic level measurement in humid ambiance

·· Special applicable for exterior storage vessels

Application examples

·· Level measurement with LAR, linearization and evaluation with PEM-DD

(6 standard geometries, 1 geometry programmable; see separate product

information)

·· Difference pressure measurement with 2 x LAR and evaluation device PEM-DD

Hygienic design / Process connection

·· By using the Negele weld-in sleeve EMZ-352 or the build-in system

EHG-.../1" a front-fl ush, hygienic and easy cleanable measurement

point will be achieved.

·· EHEDG certifi cate for hygienic process connection CLEANadapt (LAR-361)

·· 3-A-certifi cate for versions with TriClamp DIRECTadapt (LAR-761)

·· CIP- / SIP-cleanable up to 140 °C (284 °F) / max. 30 min

·· Front-fl ush stainless steel sensor cell

·· All wetted materials are FDA-conform

·· Sensor completely made of stainless steel

·· Protection class IP 69 K (with cable connection)

·· Available process connections (adapter):

Tri-Clamp, SMS, DRD, Varivent, BioControl

Features / Advantages

··Measurement cell without any contact to atmosphere, fully closed

measurement system

·· No drift problems caused by condensation

·· Very high accuracy and long term stability

·· Measurement up to 130 °C (265 °F) medium temperature

·· Oil fi lling, FDA approved

·· Factory or fi eld calibration

·· Integrated two-wire measurement trancducer 4...20 mA

··3 years warranty

Options / Accessories

·· Material certifi cate 3.1

·· Special pressure ranges, specifi c pressure calibration ex works

·· Electrical connection with M12 plug-in connector

·· Preassembled cable for M12 plug-in connector

Measuring principle

The pressure sensor utilizes an internal piezoelectric transducer to convert

the mechanical pressure into a corresponding mV signal. The mV signal then

passes through custom linearization and conditioning circuitry. The resulting

signal is an industry standard 4...20 mA, according to the specifi ed range.

In addition, onboard circuitry handles temperature compensation to ensure a

stable reading during all phases of operation.

Authorizations

Product Information LAR-361 | LAR-761

Climatic Independent Level Sensor LAR

LAR-361 with EMZ-352

Measuring principle

atmospherical

pressure

temperature

sensor 1

hydraulic

coupling

piezoelectric

transducer

hydraulic

coupling

temperature

sensor 2

hydrostatic pressure

+ atmospherical

pressure

TYPE EL

March 2006

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

2

Specification

Specification

Pressure ranges, standard relativ 0...0,35 / 1,0 / 2,0 /3,3 / 4,0 bar

Over-range rating factor 2 times base range

Process connection LAR-361: CLEANadapt thread G1" sensor, combined with

Negele CLEANadapt process connection,

torque max. 20 Nm

LAR-761: DIRECTadapt Tri-Clamp 1...1½" or 2"

coupling nut RD 52 x 1/6 for universal adapter 44 mm

thread M38 x 1,5

Materials connector head SS 316 (1.4305), Ø 65 mm

thread connection SS 316L (1.4404)

diaphragm SS 316L (1.4404), Ra < 0,4 µm

oil filling Drakeol 35, Drakeol 10B, FDA approval number

21CFR172.878, 21CFR178.3620, 21CFR573.680

Temperature ranges ambient -10...+50 °C (15...120 °F)

process -20...+130 °C (0...265 °F)

compensated -20...120 °C (0...250 °F)

CIP / SIP 140 °C (284 °F) max. 30 min.

Temperature compensation time

T90 30 s / 10 K

Accuracy hysteresis ≤ 0,075 % of full scale

linearity ≤ 0,05 % of full scale

reproduceability ≤ 0,075 % of full scale

Temperature drift zero < 0,04 % of full scale / K

span < 0,04 % of full scale / K

Electrical connection cable gland M16 x 1,5 (PG)

cable connection M12 plug-in SS 316 (1.4305) (option)

Protection class IP 67 (with cable gland)

IP 69 K (with cable connection)

Supply voltage 12...40 V DC

Output 2-wire current loop analog 4...20 mA short circuit proof

Max. loop resistance power supply max. resistive load

(not incl. LAR) 18 V DC 300 Ω

24 V DC 600 Ω

40 V DC 1200 Ω

Weight approx. 1050 g

Pressure ranges

Type min. operation range max. operation range over-range rating

LAR-x61 / 0 0…0,1 bar 0…0,35 bar 0,6 bar

LAR-x61 / 1 0…0,35 bar 0…1,0 bar 2,0 bar

LAR-x61 / 2 0…1,0 bar 0…2,0 bar 4,0 bar

LAR-x61 / 3 0…2,0 bar 0…3,3 bar 6,6 bar

LAR-x61 / 4 0…3,3 bar 0…4,0 bar 8,0 bar

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

3Dimensioned Drawings | Installation

Mechanical connection / Installation

·· Pay attention to the maximum tightening torque of 20 Nm if using Negele CLEANadapt system!

·· Pay attention to remain open the 4 ports of atmospheric vent location.

LAR-361 | G1" CLEANadapt LAR-761 | Tri-Clamp

atmospheric

vent location

atmospheric

vent location

LAR-761 | EHS LAR-761 | HPV

atmospheric

vent location

atmospheric

vent location

Tri-Clamp size

Type Ø D

TC1 50,5 mm

TC2 64 mm

54

65

100

G1"

72

54

65

ØD

Ø65

54

73

RD 52 x1/6

54

65

105

M38 x 1,5

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

4

20

12

4

0

50 1000

20

12

4

0

50 1000

Electrical Connection | Installation

Electrical connection With M12-plug

Configuration M12-plug

1. supply +24 V DC

2. output 4...20 mA

3. not connected

4. not connected

4...20 mA

2-wire current loop

Start up

·· Connect the sensor with power supply (12…36VDC) -> see “electrical connection LAR”.

·· The sensor is now ready for use.

·· At standard factory-setting 0...100 % of the full range are equivalent to 4...20 mA of the current output.

Example: LAR-xxx/1 = 0...1 bar -> 0 bar = 4 mA; 1 bar = 20 mA

·· In case of specific factory calibration the customized measurement range is equal to 4...20 mA of the current output.

Example: LAR-xxx/1 calibrated to 0...0,8 bar -> 0 bar = 4 mA; 0,8 bar = 20 mA

·· Calibration is on-site customizable for special measurement tasks.

·· Settings of ZERO (4 mA) and SPAN (20 mA) are non-interactive, having no effect on each other.

Empty adjustment Empty adjustment (with empty vessel)

·· After mounting an empty adjustment is strongly

recommended, because mounting position can affect

the ZERO setting.

·· Empty vessel completely (no pressure or product on

diaphragm, vessel is vented to atmosphere)

·· Switch in position “RUN MODE”

·· Actuate key switch “ZERO” for 5 seconds

·· Empty adjustment is done.

·· Output current is 4 mA.

·· For maximum accuracy we advice an empty adjustment

one more time after 3 weeks.

·· After that an annually empty adjustment is

recommended.

Level / Pressure [%]

Current output [mA]

Press “ZERO”-button

for 5 seconds

Full adjustment 1. Full adjustment (with filled vessel utilizing level

in vessel)

·· Fill vessel to desired maximum level

·· Please pay attention that hydrostatic pressure must

be between min. and max. range of sensor

(see table of pressure ranges page 2).

·· Switch in position “RUN MODE”

·· Actuate key switch “SPAN” for 5 seconds

·· Full adjustment is done.

·· Output current is 20 mA

Level / Pressure [%]

Current output [mA]

Press “SPAN”-button

for 5 seconds

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

5Installation

2. Utilizing on-board setup

If “wet calibration” (by vessel filling) is not possible, full adjustment can be done by on-board setup.

First of all, the desired range (full value) must be calculated to a corresponding current value.

Afterwards, the calculated current will be adjusted by multimeter to perform new calibration.

In the following, a current calibration procedure is described as an example.

Calibration hookup

4...20 mA

2-wire current loop

Multimeter

LAR calibration values

Type Base range

in bar

Upper

lineariza-

tion value

in bar

Current

CAL at

base range

in mA

LAR-x61/0 0,35 0,3612 19,50

LAR-x61/1 1,00 1,0462 19,29

LAR-x61/2 2,00 2,0799 19,39

LAR-x61/3 3,30 3,4623 19,25

LAR-x61/4 4,00 4,0228 19,91

2.1 Calculating the current to adjust

For calculating the current to adjust the “upper linearization value” is needed (see table calibration values).

This linearization value is greater than the base range. LAR needs this value to calculate the characteristic line.

Calculation formula:

(( desired range / upper linearisation value ) * 16 ) + 4 = current to adjust

Example:

LAR-361/1 needs to be calibrated to 0,8 bar: (( 0,8 / 1,0462 ) * 16 ) + 4 = 16,23 mA

2.2 LAR adjustment

·· Connect LAR with power supply -> see figure calibration hookup above.

·· Perform meter hookup with test points (setting mA/DC).

·· Set MODE SWITCH to “FIELD CAL”.

·· Meter output will automatically move to 19,99 mA – LAR is waiting for entry of new calibration range.

·· Using the switches “SPAN” and “ZERO”, raise or lower the current until the calculated value (see above) has

been reached.

·· Once the proper value has been reached, simultaneously depress both the “SPAN” and the “ZERO” switch for one

second – this will lock in new sensor calibration.

·· Place MODE SWITCH in “CURRENT CAL” position and verify meter is reading calculated value. (When switching to

“CURRENT CAL” position, current output is equal to actual calibration).

·· Set MODE SWITCH to “RUN MODE”

·· LAR is now ready for use with new calibration setting.

2.3 Reset to factory setting

If factory reset to base range is needed, perform calibration shown in procedure 2.2 and adjust current acc. to table

“LAR calibration values” (CURRENT CAL at base range).

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

6

H

Warnings | Application Examples

Cleaning

·· Cleaning with fl uids does not effect operation

·· Metal diaphragm (process and reference) mustn´t

be cleaned mechanically

·· In case of using pressure washers, don‘t point

nozzle directly to electrical connection or reference

diaphragm!

·· No pressure washing of mebrane with more than

2 x nominal pressure.

·· In case of inside cleaning with pressure washers,

don‘t point nozzle directly to the diaphragm!

Disposal

·· This instrument is not subject to the WEEE directive

2002/96/EC and the respective national laws.

·· Pass the instrument directly on to a specialised

recycling company and do not use the municipal

collecting points.

Transport / Storage

·· No outdoor storage

·· Dry and dust free

·· Not exposed to corrosive media

·· Protected against solar radiation

·· Avoiding mechanical shock and vibration

·· Storage temperature 0...40 °C

·· Relative humidity max. 80 %

Reshipment

·· Sensors shall be clean and must not be contamina-

ted with dangerous media!

·· Use suitable transport packaging only to avoid

damage of the equipment!

Advice to EMC

·· Applicable directives: Electromagnetic Compatibility

Equipment Directive 2004/108/EC

·· The CE label confi rms compliance of this product

with the applicable EC directives.

·· The operator is responsible for ensuring compliance

with the directives that are applicable to the overall

system.

Difference Pressure Measurement and

Linearization with 2 x LAR and PEM-DD

Hydrostatic Level Measurement and Linaerization

with LAR an d PEM-DD

Advice for differential pressure measurement in pressurized vessels

Po < 4 x Phydrostatic

To guarantee a stable differential pressure measurement in pressurized vessels the overpressure must not be

higher than 4 times of the hydrostatic pressure!

Conventional Usage

·· Not suitable for applications in explosive areas.

Not suitable for applications in security-relevant

equipments (SIL).

Phydrostatic + Po

Pdifference = (Phydrostatic + Po) - Po

Pdifference = Phydrostatic

Ventilation

Phydrostatic

Po

Po

Phydrostatic Phydrostatic + Po

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

7

Process Connections

Overview of possible process connections for LAR-361.

The complete overview of all available adapters you will fi nd at product information CLEANadapt.

LAR-361

Process

connection

Build-in system

EHG

(DIN 11850 Reihe 2)

Negele

weld-in sleeve

Dairy fl ange

(DIN 11851) Varivent APV-Inline

DN40 EHG-40/1" EMZ-352

suitable for

installation in

vessels

AMK-352/40 AMV-352 AMA-352

DN50 EHG-50/1" AMK-352/50 AMV-352 AMA-352

DN65 EHG-65/1" AMK-352/65 AMV-352 AMA-352

DN80 EHG-80/1" AMK-352/80 AMV-352 AMA-352

DN100 EHG-100/1" AMK-352/100 - AMA-352

Troubleshooting

Symptom Action

1. No output current (0 mA) in any Mode. Loop may be broken - Measure voltage across LOOP+

and LOOP- terminals.

If not between 12...40 V DC, check connector and exter-

nal loop wiring.

Check if mA fuse in DMM is blown. This frequently

occurs during testing.

2. Current output less than 4 mA and does not increase

with level, or if mode switch set to „FIELD CAL“.

Connect milliammeter across LOOP+ terminal and TEST-

testpoint. If loop now works, sensor circuitry has been

damaged. Contact factory.

3. Output stuck between 4 and 20 mA Verify that MODE switch is in RUN mode. Empty vessel

and perform Sensor Rezero Procedure as described on

page 4.

4. Performing sensor rezero procedure does not return

output to 3,96...4,04 mA

Verify that CUR CAL output is between 7,2 and 20 mA.

If current is less than 4 mA, follow instructions for Symp-

tom No. 2. If current is greater than 4 mA, sensor

is damaged. Contact factory.

5. Sensor output is not stable.

6. Output drifts over time.

Verify that CUR CAL value is between 7,2 and 20 mA

Check for signs of moisture or water in housing. Contact

factory.

7. Senosr mA output not as expected for specifi ed level.

8. Output signals are not accurate.

Perform Sensor Rezero procedure when vessel is empty.

Verify proper CUR CAL output according to page 4.

9. Sensor output signal is greater than 20 mA. Sensor may have been zeroed with product in the vessel.

Perform Sensor Rezero Procedure as described on page

4. Sensor maybe over-ranged. Verify CUR CAL value,

and that it is appropriate for the application. Contact

factory for assistance.

10. Sensor output does not increase with the level, but

does increase to 20 mA if mode switch set to „FIELD

CAL“.

Sensor may have been dropped or over-ranged and

permanently damaged. Contact factory for assistance.

Negele Messtechnik GmbH ∙ D-87743 Egg a. d. Günz ∙ Telefon +49 (0) 83 33 / 92 04-0 ∙ Fax +49 (0) 83 33 / 92 04-49 ∙ www.negele.net

8

02.08.11 / 1.2 / MU / at-ac.de

Product Information LAR-361 | LAR-761

Order Code

LAR-361 (Climatic independent level sensor, process connection CLEANadapt G1")

LAR-761 (Climatic independent level sensor, process connection DIRECTadapt)

Measuring range (relative)

0 (0...0,35 bar)

1 (0...1,0 bar)

2 (0...2,0 bar)

3 (0...3,3 bar)

4 (0...4,0 bar)

Process connection (only for LAR-761)

TC1 (Tri-Clamp 1" / 1½")

TC2 (Tri-Clamp 2")

EHS (Coupling nut RD 52 x 1/6, for universal adapter 44 mm)

HPV (Thread M38 x 1,5)

Range adjustment ex works

X (no adjustment)

[end value] (please specify required range in “bar”)

Electrical connection

X (cable gland M16x1,5)

M12 (M12 plug 1.4305)

LAR-361 / 1 / / 0,5 / M12

PVC-cable with M12-connection

M12 plug-in screw cap

Accessories

PVC-cable with M12-connection, 1.4305 (303), IP 69 K, unshielded

M12-PVC / 4-5 m PVC-cable 4-pin, length 5 m

M12-PVC / 4-10 m PVC-cable 4-pin, length 10 m

M12-PVC / 4-25 m PVC-cable 4-pin, length 25 m

PVC-cable with M12-connection, brass nickel-plated, IP 67, shielded

M12-PVC / 4G-5 m PVC-cable 4-pin, length 5 m

M12-PVC / 4G-10 m PVC-cable 4-pin, length 10 m

M12-PVC / 4G-25 m PVC-cable 4-pin, length 25 m

M12-EVK M12 plug-in screw cap, 1.4305 (303), with o-ring,

as a protection against humidity and dirt

CERT / 2.2 factory certifi cate 2.2 acc. to EN10204

(only product contacting surface)

CERT / 3.1 inspection certifi cate 3.1 acc. to EN10204

(only product contacting surface)

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

CGEO INTERNATIONAL LIMITED

CGEO INTERNATIONAL LIMITED CGEO-TEM2 installation manual

Krown

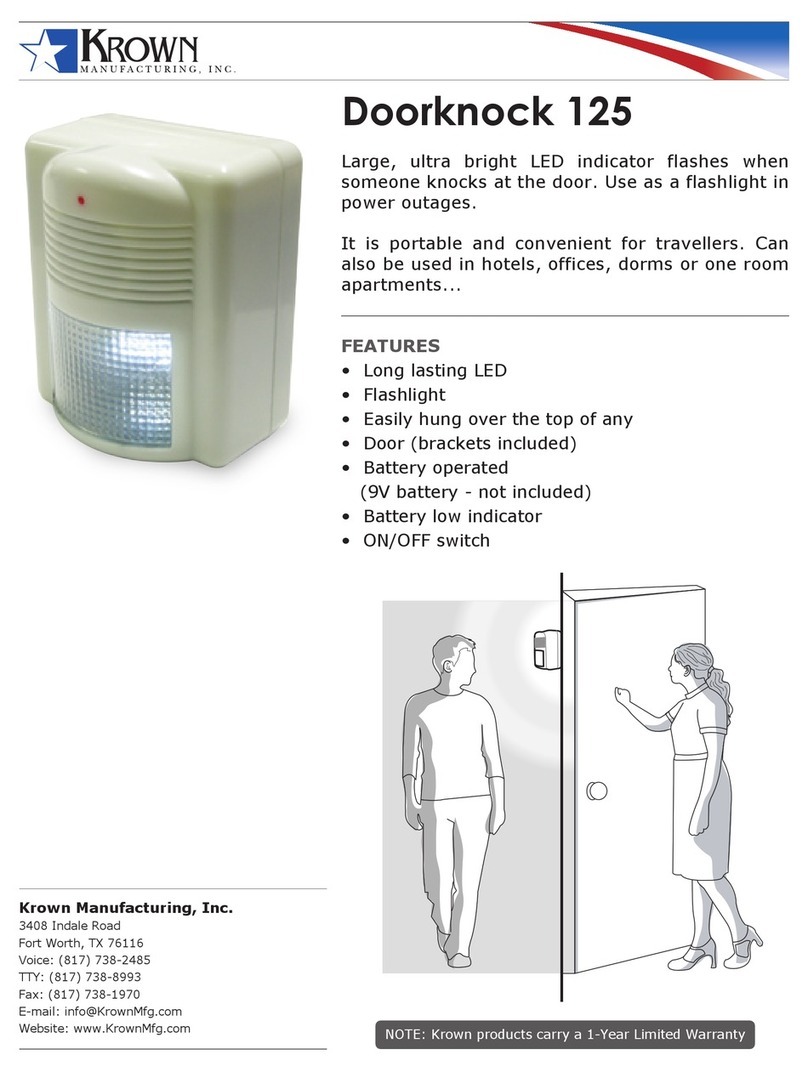

Krown Doorknock 125 datasheet

Brandani

Brandani techno 53232 instruction manual

Burkert

Burkert 8223 instruction manual

Bticino

Bticino 393014D quick start guide

Allstar Innovations

Allstar Innovations Sharper Image UV-ZONE operating instructions