CGEO INTERNATIONAL LIMITED CGEO-TEM2 User manual

CGEO INTERNATIONAL LIMITED

CGEO-TEM2

Resistance Temperature Sensor

Installation Manual

(REV A)

Contents

1. Brief Introduction.................................................................................................................. 1

2. Main Specifications .............................................................................................................. 1

3. Cable Welding Lengthening................................................................................................. 2

4. Using Surroundings & Installation Notice............................................................................3

5. Operation & Data Process..................................................................................................... 3

6. Temperature Calculation Formula........................................................................................4

7. Trouble Shooting .................................................................................................................. 5

CGEO-TEM2 Resistance Temperature Sensor 1

1. Brief Introduction

CGEO-TEM2 Thermometer is composed of a stainless steel crust, thermo-resistance, and

the CGEO-4-SCT special cable with the outstanding water-proof capability and signal

stability. It is widely used in temperature controlling and monitoring of high technology,

industrial production and science research and other areas. The temperature of the measured

environment can be read out directly by CGEO-PR-VW Readout .

Cable

Stainless steel crust and transducer

Structure of CGEO-TEM2 Temperature Gauge

The features of CGEO-TEM2 Temperature Gauge as follows:

•Good long-time stability

•Stainless steel structure, which is adaptable to all kinds of atrocious environment

•Good water-proof capability

•Long working life

•High sensitivity

•Applicable to the measuring of the temperature of liquid, solid or gas in the non-strong-acid,

non-strong-alkali or non-strong-corrosive environment.

2. Main Specifications

•Temperature Range: -30℃~+70℃

• Accuracy: standard ±0.5℃(Option:±0.2℃,±0.1℃)

• Resistance in normal temperature: 3KΩ(At 25℃)

• Insulated resistance: ≥50MΩ

• withstanding voltage: 1500V

• Outer Size: Φ11×110mm

•Color of the lead of cable: green/white (temperature transducer), shield (grounded)

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

2

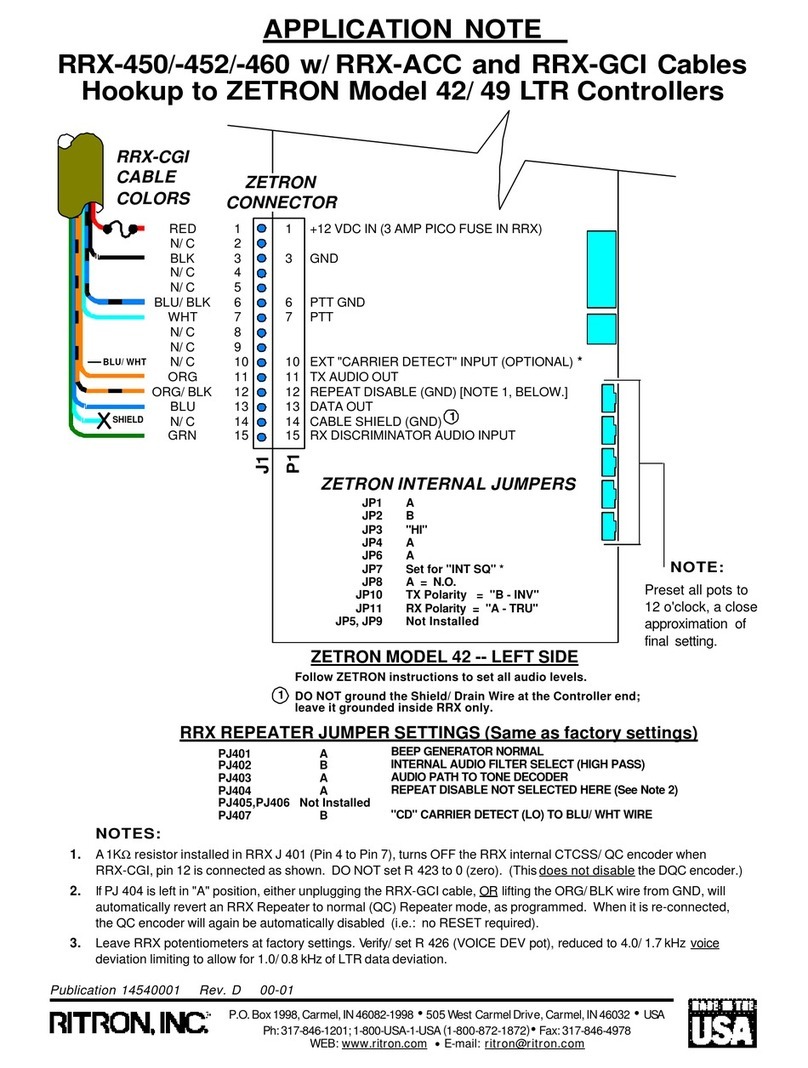

3. Cable Welding Lengthening

A standard CGEO-TEM2 model temperature gauge equips with 1m cable in ex-factory,

cable model is CGEO-4-SCT. For cable lengthening adopted is CGEO-4-SCT dedicated cable,

and BSIL-4-SC cable as well as. Proceed lengthening basing on the field circumstance before

installation. Avoid connection as possible as in the cable buried in soil. If cable connection is

inevitable, should adopt waterproof connection, recommend using ES-3 model dedicated

heat-shrinkable connector, and also epoxy connector, like 3M ScotchcastTM 82-A1 dedicated

cable connector, those connector devices can be ordered from Beijing SOIL.

As following details introduction of connection method of using ES-3 model dedicated

heat-shrinkable connector.

Measure the resistance between cores of transducer with millimeter and note it before

welding. Thereinto, the resistance between green and white core should be 3kat room

temperature 25℃. As to CGEO-TEM2 model temperature gauge, the resistance between red

and black core leads is the same as green and white.

Before welding divest the outer leather of cable end part, length about 8cm, and expose

the core leads, roughen rest cable outer leather part with emery cloth or sandpaper, length

about 3 cm. Sleeve φ12mm heat-shrinkable tube onto outside cable (length about 14cm).

Strip outer skin of cores 0.5~0.8 cm with stripping pliers, jacket φ2mm heat-shrinkable tube

onto core leads. After twisting core leads together corresponding to colors, solder tin with

electric soldering iron. Should avoid poor soldering and remove burrs during soldering

process. 5 pieces of cores all are needed to solder, please note: 1). Stagger each core

connector; 2). Ensure every core lead length same and ensure each core uniformly forced

when cable is pulled. After soldering, naked core line length about 7 cm, push φ2mm outer

heat-shrinkable tube onto core leads connector part, and make it shrunk in connector part with

heat wind gun. At last push φ12mm heat-shrinkable tube unto cable connector and heat-

shrunk in connector part with heat wind gun. φ12mm heat-shrinkable tube should be

pressed 3 cm over each end of cable outer skin. Should control the temperature when using

heat-wind gun so that heat-shrinkable tube internal in transparent, fluid status, and fully filled

with connector internal. But too high temperature will melt core lead outer skin and cause

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

3

core lead short, cause heat-shrinkable tube carbonization and brittle.

Note: after core leads welding work finishing, you must check the reading

measurement with readout, and examine the resistance between cores of cable with

millimeter in case welding work causes connector part short and cut

Figure 5 Cable welding splice diagram

4. Using Surroundings & Installation Notice

Though the CGEO-TEM2 Temperature Transducer can be used in all atrocious

environments, it is still necessary to avoid using in the area which is over the standard range

(with the exception of the customized), and avoid long-time using in strong acid and alkaline

areas.

The CGEO-TEM2 Temperature Transducer can be installed directly inside concrete, soil

or borehole. But what is needed to do is to protect the cable and meet all the standard

requirements.

5. Operation & Data Process

The signal cable of CGEO-TEM2 Temperature Gauge adopts 4-core shielded cable,

the colors of cable core wires are Black, Red, Green, and White respectively and another

naked wire is shield wire to ground. Among them, red and white are in parallel connected, so

do green and Black, when measuring, you can connect at discretion black, red core wires or

green, white core wires. You also can twist together red, white core wires or green, black core

wires of temperature gauge and then connect with green, white wires of readout box to

measure.

φ12mm heat-shrinkable tube

热缩套管

Cable outer skin

φ2mm heat-shrinkable tube

Core connector

Transducer core leads

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

4

Red

Red

红

Whit

e白

Gree

n绿

Blac

Readout

Box

读数仪

Gree

n绿

Whit

e白

CGEO-TEM2 thermometer wiring schematic diagram

When measuring, connect the green and white nips of CGEO-PR-VW to the black, red wires

of the transducers to read out directly, or connect green, white nips to black, red wire of

thermometer, and then the thermistor readings can be displayed directly in C.

Note,please do not connect 4 colors nips of readout box to 4 core wires of thermometer

simultaneously, that is, it is just allowed to connect two wires every time to measure

temperature, otherwise it will result in readings error.

There are no polarity difference in signal lines of CGEO-TEM2 thermometer, green,

white wire are changeable.

6. Temperature Calculation Formula

TA B LnR C LnR

1273 2

3

( ) ( ) .

where:

T

Temperature in

C.

R

Resistance of the temperature transducers inΩ.

LnR

Natural Log of Thermistor Resistance

A

1.4051

10-3 (coefficient is effective in range -50℃~+150℃)

B

2.369

10-4

C

1.019

10-7

If there is no special readout, the thermistor can be read by using a digital ohmmeter in

conjunction with the above equation, or get the temperature by Appendix A.

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

5

7. Trouble Shooting

When troubles occur, a millimeter is usually used to check core wire resistance and examine

the breakdown phenomena.

When checking, connect the digital millimeter to the cores of the transducer, the normal

condition is that the resistance matches the environment temperature (check Appendix A). In

25

C, the resistance should be 3000Ω. If the resistance deviates from the norms, it is caused

normally by cable open or short, should focus on inspecting the cable for damage.

If the cable is damaged or affected with damp, the reading will be fuzzy, a bit bigger than the

correct reading. What should be noticed is that, if the cable is too long and under the

high-temperature environment, the resistance of cable core should be taken into consideration

during calculating, to gain a higher precision. This resistance will not be taken into

consideration under low-temperature environment. The resistance of matched cable core is

about 50Ω/1000m, and doubled when in two-direction.

Appendix A: Resistance versus Temperature Table

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

6

Ohms

Temp

Ohms

Temp

Ohms

Temp

Ohms

Temp

Ohms

Temp

201.1K

-50

16.60K

-10

2417

30

525.4

70

153.2

110

187.3K

-49

15.72K

-9

2317

31

507.8

71

149.0

111

174.5K

-48

14.90K

-8

2221

32

490.9

72

145.0

112

162.7K

-47

14.12K

-7

2130

33

474.7

73

141.1

113

151.7K

-46

13.39K

-6

2042

34

459.0

74

137.2

114

141.6K

-45

12.70K

-5

1959

35

444.0

75

133.6

115

132.2K

-44

12.05K

-4

1880

36

429.5

76

130.0

116

123.5K

-43

11.44K

-3

1805

37

415.6

77

126.5

117

115.4K

-42

10.86K

-2

1733

38

402.2

78

123.2

118

107.9K

-41

10.31K

-1

1664

39

389.3

79

119.9

119

101.0K

-40

9796

0

1598

40

376.9

80

116.8

120

94.48K

-39

9310

1

1535

41

364.9

81

113.8

121

88.46K

-38

8851

2

1475

42

353.4

82

110.8

122

82.87K

-37

8417

3

1418

43

342.2

83

107.9

123

77.66K

-36

8006

4

1363

44

331.5

84

105.2

124

72.81K

-35

7618

5

1310

45

321.2

85

102.5

125

68.30K

-34

7252

6

1260

46

311.3

86

99.9

126

64.09K

-33

6905

7

1212

47

301.7

87

97.3

127

60.17K

-32

6576

8

1167

48

292.4

88

94.9

128

56.51K

-31

6265

9

1123

49

283.5

89

92.5

129

53.10K

-30

5971

10

1081

50

274.9

90

90.2

130

49.91K

-29

5692

11

1040

51

266.6

91

87.9

131

46.94K

-28

5427

12

1002

52

258.6

92

85.7

132

44.16K

-27

5177

13

965.0

53

250.9

93

83.6

133

41.56K

-26

4939

14

929.6

54

243.4

94

81.6

134

39.13K

-25

4714

15

895.8

55

236.2

95

79.6

135

36.86K

-24

4500

16

863.3

56

229.3

96

77.6

136

34.73K

-23

4297

17

832.2

57

222.6

97

75.8

137

32.74K

-22

4105

18

802.3

58

216.1

98

73.9

138

30.87K

-21

3922

19

773.7

59

209.8

99

72.2

139

29.13K

-20

3748

20

746.3

60

203.8

100

70.4

140

27.49K

-19

3583

21

719.9

61

197.9

101

68.8

141

25.95K

-18

3426

22

694.7

62

192.2

102

67.1

142

24.51K

-17

3277

23

670.4

63

186.8

103

65.5

143

23.16K

-16

3135

24

647.1

64

181.5

104

64.0

144

21.89K

-15

3000

25

624.7

65

176.4

105

62.5

145

20.70K

-14

2872

26

603.3

66

171.4

106

61.1

146

19.58K

-13

2750

27

582.6

67

166.7

107

59.6

147

18.52K

-12

2633

28

562.8

68

162.0

108

58.3

148

17.53K

-11

2523

29

543.7

69

157.6

109

56.8

149

55.6

150

BSIL-T2-1.1 Instruction Manual

CGEO INTERNATIONAL LIMITED Installation Manual

7

CGEO-TEM2 Semiconductor Thermometer Control Table of Resistance - Temperature

Table of contents

Popular Accessories manuals by other brands

Ritron

Ritron RRX-450 Application note

Crivit

Crivit 322422 1901 Instructions for use

IFM Electronic

IFM Electronic O5E5 A Series operating instructions

Banner

Banner L-GAGE LE250 IO-Link instruction manual

TVILIGHT

TVILIGHT CitySense Plus installation manual

PCB Piezotronics

PCB Piezotronics 353B01 Installation and operating manual