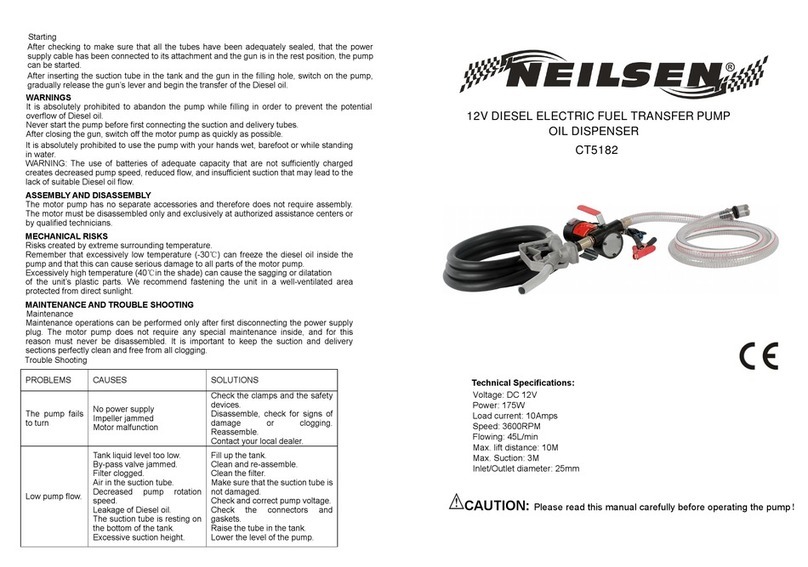

a. Stay alert, watch what you are doing and use common sense when operating a

pump. Do not use a pump while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating pumps may result

in serious personal injury.

b. Avoid accidental starting. Ensure the switch is in the off position before

plugging in. Carrying pumps with your finger on the switch or plugging in pumps

that have the switch on invites accidents.

c. Remove any adjusting key or wrench before turning the pump on. A wrench

or a key left attached to a rotating part of the pump may result in personal injury.

d. Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

a. Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing pumps. Such preventive safety measures

reduce the risk of starting the pump accidentally.

b. Maintain pumps. Check for misalignment or binding of moving parts,breakage

of parts and any other condition that may affect the pumps operation. If damaged,

have the pump repaired before use. Many accidents are caused by poorly

c. Use the pump, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of pump,taking into

account the working conditions and the work to be performed. Use of the pump

for operations different from intended could result in a hazardous situation.

a. Have your pump serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the pump is maintained.

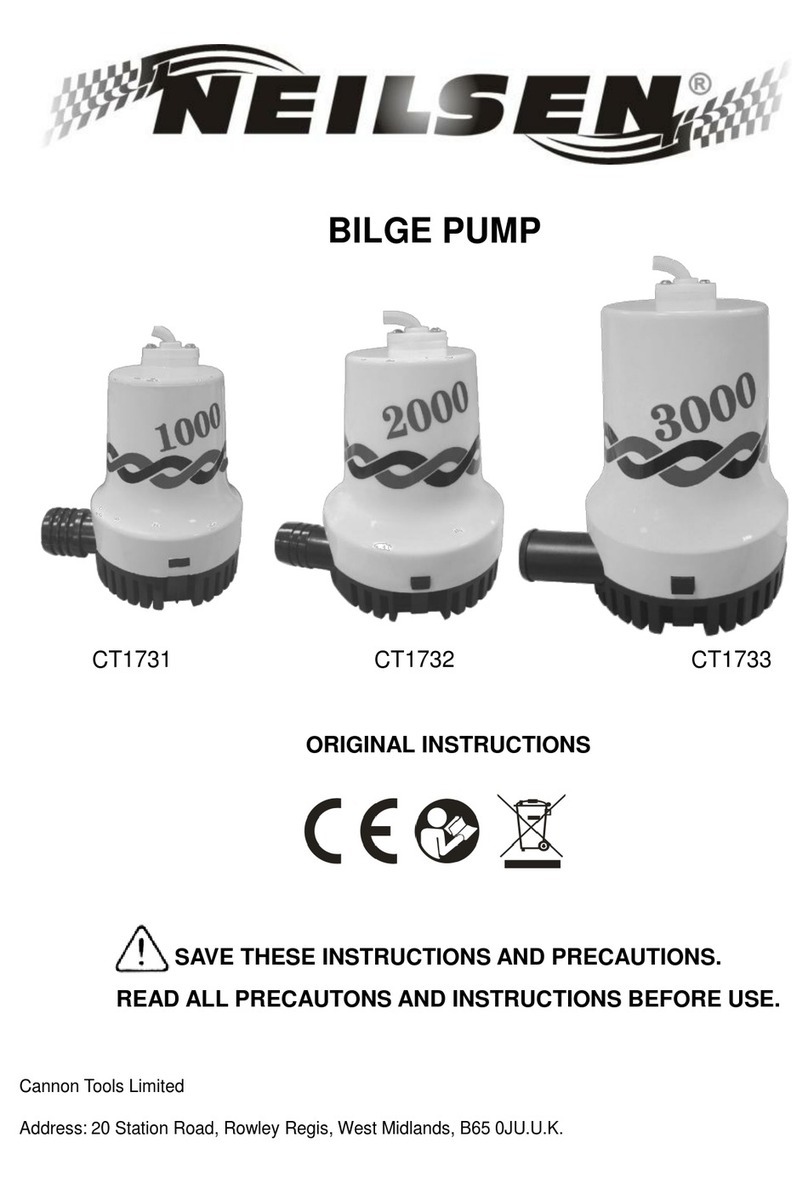

Submersible Pump Safety Warnings

CAUTION: Not intended for cleaning and other maintenance of swimming pools.

Do not use it for corrosive, abrasive, explosive or dangerous liquids. Fluids other

than water will damage the submersible pump and/or create a fire hazard.

WARNING! This product is not suitable for use with drinking (potable) water.

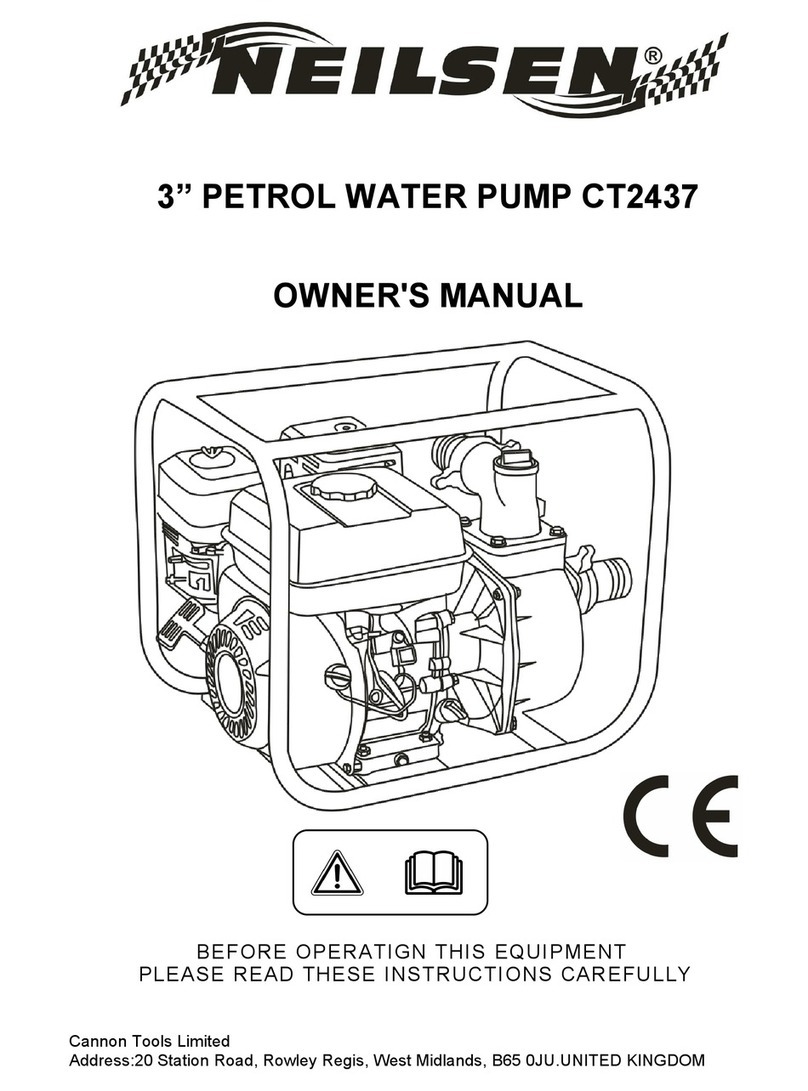

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they don’t play with the appliance.

• Ensure the submersible pump is disconnected from mains power when installing