FNM HPE 300 User manual

OWNER’S

MANUAL

HPE 300

Marine Diesel Engines

OWNER’S MANUAL

Index

ENG rel. 1/11

www.fnm-marine.com

i

General Information _____________________________________________________________________________1

Engine manufacturer’s indications _________________________________________________________________7

Safety rules & info ______________________________________________________________________________8

Residual risks __________________________________________________________________________________9

HPE 300 Engines general info and drawings: _______________________________________________________11

HPE 300 ANODES ______________________________________________________________________________12

HPE300 without cover top view___________________________________________________________________12

Main engine components________________________________________________________________________13

Documentation and info plates ___________________________________________________________________13

HPE 300 stern drive version installation drawings ___________________________________________________15

Engine data ___________________________________________________________________________________16

Engine cylinder numbering ______________________________________________________________________16

Sea water circuit crossing order__________________________________________________________________17

Engine delivery ________________________________________________________________________________18

Engine lifting __________________________________________________________________________________19

Engine maintenance indications (when installed on board) ___________________________________________20

Engine maintenance information (out of board before installation) _____________________________________21

First engine start on board. ______________________________________________________________________21

Stop the engine________________________________________________________________________________22

Long engine inactivity (prediction of extended storage) ______________________________________________22

Engine treatment & maintenance products _________________________________________________________26

Fuel characteristics ____________________________________________________________________________26

Paint _________________________________________________________________________________________26

HPE / HPEL engines ECU BOX ___________________________________________________________________27

Fuses & Relays ________________________________________________________________________________28

Tightening torques _____________________________________________________________________________29

Engine-boat interface (connections and optional kit ) ________________________________________________29

Battery cable section chart ______________________________________________________________________29

Instrument panel_______________________________________________________________________________30

Ignition block functioning _______________________________________________________________________32

Accessory indicator lights_______________________________________________________________________33

Instrument panel electrical scheme _______________________________________________________________34

Diagnosis_____________________________________________________________________________________37

Electronic throttle station _______________________________________________________________________38

Mechanical remote control ______________________________________________________________________41

Gearboxes data (oil type and quantity) ____________________________________________________________43

Engine requirements ___________________________________________________________________________43

Installation form _______________________________________________________________________________44

Engine maintenance____________________________________________________________________________51

Every 10 hours or before every engine start ________________________________________________________51

Check the engine oil level _______________________________________________________________________51

Check the coolant level _________________________________________________________________________53

Clean the sea water filter ________________________________________________________________________55

Verify oil level _________________________________________________________________________________55

HPE engine gearbox version, verify the transmission oil level_________________________________________56

Weekly maintenance____________________________________________________________________________58

Verify battery electrolyte level and status __________________________________________________________58

Maintenance after first 50 hours and every 2 months ________________________________________________60

Drain the fuel filter _____________________________________________________________________________60

Zinc anodes___________________________________________________________________________________61

Verify the belts status___________________________________________________________________________62

Air filter ______________________________________________________________________________________63

Sea water pump impeller ________________________________________________________________________63

Every 200 hours or once every year _______________________________________________________________65

Engine oil change ______________________________________________________________________________65

Oil filter replacement ___________________________________________________________________________66

Fuel filter replacement __________________________________________________________________________67

Clean the sea water circuits and exchangers _______________________________________________________67

Marine Diesel Engines

OWNER’S MANUAL

Index

ENG rel. 1/11

www.fnm-marine.com

ii

Lubricate or grease the joints, bearings and gears. __________________________________________________70

Every 200 hours or every 2 years _________________________________________________________________72

Engine winter maintenance ______________________________________________________________________72

Troubleshooting _______________________________________________________________________________73

Ordinary maintenance schedule __________________________________________________________________77

Winter Maintenance : ___________________________________________________________________________79

Engine maintenance operations summary table_____________________________________________________81

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE300

ENG rel. 1/11

www.fnm-marine.com

1

General Information

This manual is integral part of the engine; it

is made by the manufacturer to give all the

useful information to whoever will interact

with the engine during its life: installers,

carriers and end-users.

Please keep this manual for the entire life of

the product to obtain rapid information about

the engine during use.

The manufacturer reserves the right to

modify this document without prior

notice.

Danger and warning symbols

Indicates dangerous situations that can

compromise personal safety and functionality of

the engine.

Indicates the need to follow the instructions.

Indicates important technical information.

ATTENTION!

If the engine is serviced by unauthorized

technicians or if non-original spare parts are

used, you will lose immediately any rights in

terms of warranty of the purchased product.

ATTENTION

The observance of the installation procedures

and routine maintenance contained in this manual

and in the installation manual*, ensures

compliance for 10 years at the declared

performance and at the gas exhaust emission and

noise parameters for which your engine is

approved in accordance with Directive

2003/44/EC.

Dear Client, we wish to thank you for

purchasing an engine of HPE range.

FNM ® engines are designed and developed

according to demand and the needs of

customers and builders of pleasure and

work boats.

CMD S.p.A., the company that produces and

markets worldwide the marine diesel

engines under the trade name FNM®offers

a wide range of products and models

according to each customer's request.

The FNM®marine diesel engines are known

worldwide for their performances.

- for their compact structure and

outstanding power-to-weight ratio;

- for their long life and low fuel

consumption.

This means that, when buying an FNM®

engine, you have chosen not only a

technologically advanced engine, but also

an engine designed to satisfy the anti-

pollution standards and regulations. For the

engine service and maintenance always

refer to an authorized service points and to

FNM®service network. Only by using

original spare parts and relying on our

specialized staff you can get the best

performances from your engine and ensure

a long life.

THE FNM SERVICE NETWORK

The FNM® service points offer low costs and a high

degree of specialization. They make sure that your

FNM® engine works and operates in accordance

with your expectations. Visit our website to know

the nearest service point.

This manual provides important

information on maintenance, operations

to be carried out periodically and

handling of your engine.

Before starting your engine, we advise

you to read this manual in order to get the

information necessary to operate your

engine.

The proper use of the FNM ® marine

engine as well as proper maintenance

plan during the lifetime of the engine

ensures durability and performance.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE300

ENG rel. 1/11

www.fnm-marine.com

2

ATTENTION!

The reliability of the total propulsion unit is

dependent on the quality of the installation. Nearly

all the problems are caused by faults or

inaccuracies which occur during the installation.

FNM®is not responsible for damages (engine

and/or persons) caused by wrong installation.

Spare Parts

The exclusive use of FNM® original spare

parts is an essential condition for a good

maintenance of the engine. The use of non-

original spare parts may cause the warranty to

expire and it also exempts the company CMD

S.p.A (owner of the FNM® brand name and

logo) from any responsibility.

Responsibility

The responsibility of the Manufacturer is

subject to the correct execution of the

“Maintenance Procedures” operations that are

described in this manual. For this purpose, it

will be necessary to demonstrate that all the

maintenance procedures and operations have

been carried out according to the manual and

that, in case of extraordinary maintenance, the

procedures and operations have been carried

out by FNM® Service Points.

ATTENTION!

The information featured in this manual only refer

to the engine itself; more specifically, the

illustrations serve as a pure indication and the

instructions are described in a purely functional

way with the purpose of providing help and

guidance in carrying out the ordinary maintenance.

The execution of such operations may vary based

on the configuration of the controls and/or

accessories of the boat where the engine has been

installed. The information featured in this manual is

correct at the time of printing. The Engine

Manufacturer reserves the right to make

modifications without notice at any time for

technical or commercial reasons as well as for the

need to abide by new regulations or norms. The

Engine Manufacturer declines any responsibility

that may arise from possible mistakes and/or

omissions during the installation.

It is forbidden to alter the characteristics of the

engine and in particular the configuration of the

ECU box because such modifications and/or

alterations will invalid the warranty and safety

terms.

ATTENTION!

Never use the engine at the maximum

power for a period longer than 5 minutes.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

6

Page in blank

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

7

Engine manufacturer’s indications

The ID label is applied on the engine and on the ECU box as show in pictures below:

ID label data are indicated in the picture below:

Made in

Italy

Eng. type:

Eng. family:

Serial Num:

RPM kW HP

Serial number code definition

Type of engine code

Year of construction

Progressive numbering

6

1

1

1

0

0

1

Engine serial number is also printed on the engine block. It position is shown in the picture below:

Engine manufacturer data:

C. M. D. S. p. A.

Direzione Generale (Head Office)

S. S. 87 Km 23, 300 –81020 S. Nicola La Strada (CE) -ITALY

Tel.: (+39) 0823/424055 –Fax: (+39) 0823/452103

E-mail: sales@cmdengine.com

Production plant

Nucleo Industriale –Valle di Vitalba –85020 Atella (PZ)-ITALY

Tel.: (+39) 0972/715757 –Fax: (+39) 0972/715696

E-mail: plant@cmdengine.com

SERIAL NUMBER

ID LABEL

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

8

Safety rules & info

- Read carefully the information contained in the manual and those applied to the engine in order to

avoid unpleasant incidents.

- The manufacturer cannot be held responsible for any damage resulting from misuse of the

engine ,from the failure to follow the indications contained in this manual and for every

tampering with or change made without the manufacturer’ s authorization.

- Use the engine only for the tasks authorized by the manufacturer, do not tamper any

device to obtain different performances.

- Consult their own technical staff, with specific experience and technical skills. The lack of these

requirements could result in damage to people’s safety as well as damage to the engine.

- Pay attention to the meaning of the symbols and to the applied plates. Keep them visible and

follow the stated information

- Carry out the engine handling in accordance with the information provided directly on the

engine and on the packaging and follow the instructions of this manual.

- During the engine lifting and transportation, use means with appropriate load capacity.

- During the installation the installer shall follow the manufacturer’s instructions. Do not make

changes to the engine components for any reason!

- Before using the engine for the first time simulate a few trial maneuvers to identify the controls

and their main functions, especially those related to start -stop operations.

- Do not keep using the engine if anomalies are detected.

- In case of anomaly, stop immediately the engine or reduce the speed as far as possible. Start

again only when the normal operating conditions are restored.

- Keep the engine and related components in conditions of maximum efficiency and carry out the

maintenance operations established by the manufacturer.

- -Replace only original spare parts. Use oil. lubricants and grease recommended by the

manufacturer in accordance with the specifications of this manual.

- Pay attention to the disposal of polluting residues (used oil, diesel fuel, etc.)... Follow

the local legislation and disposal procedures.

- Do not open the expansion tank cap of the cooling circuit when the engine is hot! Slowly turn

until any steam under pressure comes out, and then remove the cap.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

9

- Do not start the engine without the air filter, the detachment of rotor parts of the compressor

during operation could cause damage to persons, furthermore any aspirated particles could

damage the blades. Avoid contact of hands with the rotor.

- Do not touch the turbogroup and the turbine cover with hands immediately after

using the engine, risk of burns. Let engine cool before interacting with the hot parts.

- Do not smoke near the battery compartment! The battery can release flammable gases.

Wrong battery connection could provoke sparks and explosion.

- Don’t provoke short circuits, electrical risk.

- If you use pressure water jet to clean the engine never point this to rubber pipes or electrical

connections.

- Use proper protection (clothing, gloves, etc.) during maintenance and/or work on the engine.

- During maintenance operations provide correct ventilation. Avoid stagnation of toxic and/or

flammable vapors.

- The replacement of fuel filter is to be made with cold engine to avoid the risk of fire and burn.

- Always close the sea water inlet tap when you dismount the coolant system!

- Danger of fire due to fuel splashing on hot parts, do not remove the guards.

Residual risks

- Potential/additional risks to persons:

- Risk of injury: do not put hands in any moving parts (pulleys, flywheel, belts, etc.).

- Risk of burns: attention to hot surfaces (exhaust manifold, turbocharger, raiser, etc.)

- Danger from splashes of hot oil-fuel, battery acids of accumulators or fuel: use gloves and

safety glasses.

- Risk of shock: use safety shoes when lifting the engine and/or working in the engine

compartment.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

10

ATTENTION!

FNM ® is not responsible for damage caused by misuse of the engine and for non-compliance with the

procedures issued and for damages caused by unauthorized personnel.

Do not drive the boat if you consume alcohol or other substances that may alter your

state of attention and reflexes.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

11

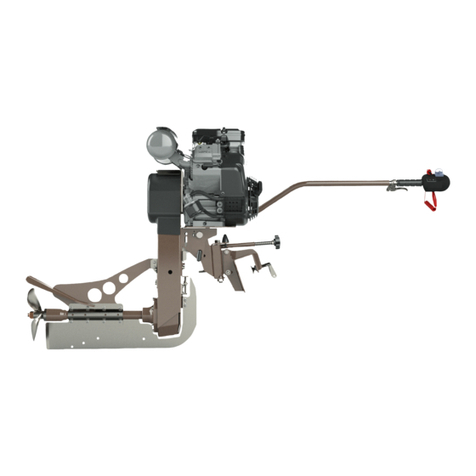

HPE 300 Engines general info and drawings:

\

OIL VAPOUR

CONDENSER

HIGH PRESSURE FUEL

SUPPLY PUMP

INTERCOOLER HOUSING

WATER/WATER

EXCHANGER

ACELERATOR

POTENTIOMETER

LOW PRESSURE FUEL

SUPPLY PUMP

SEA WATER PUMP

ANODE 3

ANODE 1

FUEL OR STEERING

OIL/FUEL EXCAHNGER

ENGINE OIL FILTER

EXPANSION TANK

OIL FILLING CAP

ANODE 2

ALTERNATOR

SECONDARY

THERMOSTAT HOUSING

STARTER

TURBOCHARGER

AUXILIARY SERVCES

PULLEY

MAIN THERMOSTAT

HOUSING

OIL SUMP

EXHAUST RAISER

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

12

HPE 300 Anodes

On the engine there are n. 3 anodes positioned as follows:

1) Water to water exchanger front cover.

2) Exhaust manifold front cover (under the expansion tank)

3) Intercooler rear cover

The graphical identification of the elements on the engine can be found on the previous page.

HPE300 without cover top view

RAIL

INJECTORS

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

13

Main engine components

Intercooler :

Reduces the temperature of compressed air from the

compressor of the turbogroup that flows to the engine intake

duct using a bundle of finned tubes crossed by sea water.

Expansion tank:

Contains the engine coolant.

Oil sump:

Contains engine lubrication oil

Zinc anode (3):

Prevents the galvanic oxidation of metal parts.

Oil exchanger:

Reduces the temperature of the engine lubrication oil.

Fuel exchanger (single):

Reduces the diesel fuel temperature in the return line to the

heat exchanger.

Air filter:

Retains the impurities in the air intake.

Double exchanger (power steering oil-diesel fuel):

Reduces the temperature of steering oil and diesel fuel.

Turbocharger:

Compresses the intake air exploiting the energy of exhaust

gases through the use of a turbine-compressor group.

Fuel filter (mounted in the engine compartment)

Filters diesel fuel in inlet to the supply line of the engine

Raiser:

Reduces the temperature of the exhaust gases coming out of

the turbine, conveys fumes towards the exhaust and prevents

the return of sea water into the turbine.

Starter:

Starts the engine.

Water to water exchanger:

Reduces the temperature of engine coolant through heat

exchange with sea water.

Low-pressure electric fuel pump

Sucks fuel from the low pressure line and sends it to the high

pressure line.

Main thermostat housing:

Contains the thermostatic valve of the cooling circuit.

Secondary thermostat housing:

Contains the thermostatic valve of the auxiliary cooling

circuit.

Sea water pump:

Sucks water from the sea water intake and pushes it in the

cooling circuit.

Alternator:

Generates electric power, the output voltage is 12 Volt.

Oil filler cap:

Useful in filling the engine oil.

Lifting eyes

Documentation and info plates

The engine is shipped with this technical documentation:

Owner’s Manual

Installation Manual

Transmission producer installation manual

Installation form

Certificates

HPE 300 engines are certified for CE directive 94/25/EC as amended by directive 2003/44/EC for exhaust

emissions (SYSTEMS WITH AND WITHOUT INTEGRATED EXHAUST):

- Standard reference EN ISO 8178-1 Reciprocating internal combustion engines, EXHAUST EMISSION MEASUREMENT.

HPE 300 engines are certified for noise emissions:

- Standard reference ISO 14509 Small Craft Measurement of airborne SOUND EMITTED by powered recreational craft.

IMPORTANT!

At moment of delivery you can find on the engine some yellow plates indicating important information, take

care to read the info.

In addition the engine has warning labels whose the meaning is indicated below. Note: labels bearing the

exclamation mark highlight a potential danger.

Lifting point (of the motor only)

Risk of burns, ejection of hot water

under pressure.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

14

Fuel introduction cap (on the tank, if

present)

Risk of burns, presence of parts at high

temperature

Lubricating oil introduction cap.

Risk of fire, presence of fuel

Lubricating oil dipstick

Risk of impact and hooking to moving

parts, presence of fans, pulleys, belts or

other.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

15

HPE 300 stern drive version installation drawings

Raiser outer diameter 90 mm

Sea water inlet pipe to the engine outer diameter 32 mm

Fuel line: (inlet outlet) rubber hoses inner diameter 8 mm

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

16

Engine data

Displacement

2988 cc

Bore

95.8 mm

Stroke

104 mm

Type

Four stroke diesel engine -

4 cylinder inline

Compression ratio

18 : 1

Injection

Electronically controlled Common Rail

Boosting

Water-cooled turbocharger

Timing system

16-Valve DOHC

Firing order

1-3-4-2

No-load revolution speed

750-850 RPM

Max revolution speed (with load)

4000-4200 RPM

Max power

300 HP at 4000-RPM

Max torque

560 N m at 2600 RPM

Alternator

110 A 12V

Engine oil capacity including filter

7.5 l

Engine oil type

Advice. Synthetic Multigrade SAE5W40–ACEA A3-B3-B4, API SL SM

CF, MB 229.3, VW 505.00-502. 00, BMW Longlife 98

**see the oil spec. in function of utilization temperature

ATTENTION! FNM advises use of FNM special BARDAHL OIL

Only with this oil the engine service intervals are guarantee.

-Avoid mixing different types of oil.

If you don’t find FNM lubricant oil, use oil with the same

specifications

Thermostatic valves

1) Starts opening at 80°C ± 1.5°C, fully open at 85°C

2) Starts opening at 65°C ± 1.5°C, fully open at 70°C

Coolant

approx. 14 l

**mixing ratio according to the specifications of the

supplier of the fluid and operating temperatures.

Sea water flow (at max RPM )

approx. 100 l/min

Starter

12V -2.6 kW

Weight

(without transmission and ECU)

350 kg

Engine cylinder numbering

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

17

Sea water circuit crossing order

1) Pump suction side.

2) Intercooler crossing (1 passage)

3) Water to water exchanger crossing (2 passages)

4) Fuel exchanger or fuel/steering oil exchanger crossing (1 passage)

5) Heat exchanger integrated into exhaust manifold crossing (2 passages)

6) Overboard discharge through the riser.

Take care of the sea water pump impeller and pay attention to the maintenance schedule. It is

important to keep the sea water circuit free from dirt and salt deposits to avoid engine

overheating!

Take care of the anodic protections to prevent oxidation of engine metal parts, follow the

maintenance schedule.

Take care of the hoses clamps; they must be correctly screwed to avoid any leaks!

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

18

Engine delivery

At moment of receiving an HPE/HPEL engine (if you’re the receiver) please verify:

The integrity of the packaging (the wood box must be integral; the engine must be fixed on the wood

support and secured to it).

The ECU box must be integral and with no obvious signs of breakage.

The engine wiring and any extensions must be integral with no cuts, the Amphenol® connector

must be integral and all the pins of the connector must be correctly positioned.

The instrument panel and connection cable must be integral.

Check for any fluids leaks.

ATTENTION!

At the time of shipment engines are bench tested and packaged according to internal specifications. FNM®

is not responsible for damages caused by the carrier/transport company.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

19

Engine lifting

The engine lifting hooks are engineered only to lift the engine without any additional weights!

When you install the engine on your boat and open the engine package, lift it using all 3 lifting points as

shown in the figure. Be sure to use a chain in good condition and able to carry the weight of the engine

and of the gearbox, if present.

Engine lifting hooks are positioned as shown in the following figures.

Gearbox weight shifts the engine centre of gravity, take care when lifting the engine.

Marine Diesel Engines

OWNER’S MANUAL

General Information

HPE 300

ENG rel. 1/11

www.fnm-marine.com

20

Engine maintenance indications (when installed on board)

Below you find some indications to guarantee engine long life and to prevent hazards:

-Take care to maintain the engine room dry and well aerated. Residual water in bilge could

vaporize and condensate on the engine, vapor created in this process damages the protection

varnish. Humidity and corrosive vapor damage the electrical connections. Bilge water may wet

engine parts during the boat navigation.

-Maintain the engine room fresh and well aerated. During engine use, the engine room shall be

well aerated and the aeration holes must guarantee a good air flush. To guarantee a good air

supply during the engine use, follow the guideline instructions. Fresh, well aerated and dry engine

room guarantees long life to the engine protection varnish, to the plastic and rubber parts,

increases the engine performances and prevents excessive overheating of hot parts (exhaust,

turbine, etc.).

Maintain the engine room dry and well aerated.

--The ventilation holes must ensure a good flow of air, but should prevent the entrance of salt,

water and dirt in the engine room. The seals of doors and hatches must prevent the entrance of

water in the engine room. Engine room ventilation, in respect of what discussed above, could be

forced or natural.

--Take care of the distance between the turbocharger and the plastic part. The turbocharger

heats up during use and may damage the plastic and fiberglass parts (follow the installation

manual instructions). Insulate with a coating that ensures good thermal protection to

structures and bulkheads of the boat next to the hot parts of the engine to reduce the risk

of fire.

-Take care to oil or fuel leaks. The oil or fuel may come into contact with the turbocharger

during operation resulting in fire.

-Take care to the turbocharger protection varnish. The housing of the turbocharger is painted with

heat resistant varnish. Excessive use and high temperatures could remove this protection.

Periodically check the housing of the turbocharger and, if necessary, spray with new paint

resistant to high temperatures.

The turbocharger becomes hot during use. Take care, risk of fire.

-Electrical and electronic parts are affected by moisture and the attack of corrosive agents.

Never rapidly increase the speed of the engine if the engine does not reach the correct

temperature.

-Pay attention to the state of battery charge, recharge during the engine inactivity, if required

periodically. Maintain the battery compartment aerated and dry to avoid risk of fire.

Table of contents

Other FNM Engine manuals