‐NWG410 ‐

2

CONTENTS

1PRECAUTIONSFORSAFETYANDUSE.............................................................................4

2TECHNICALDATA...........................................................................................................5

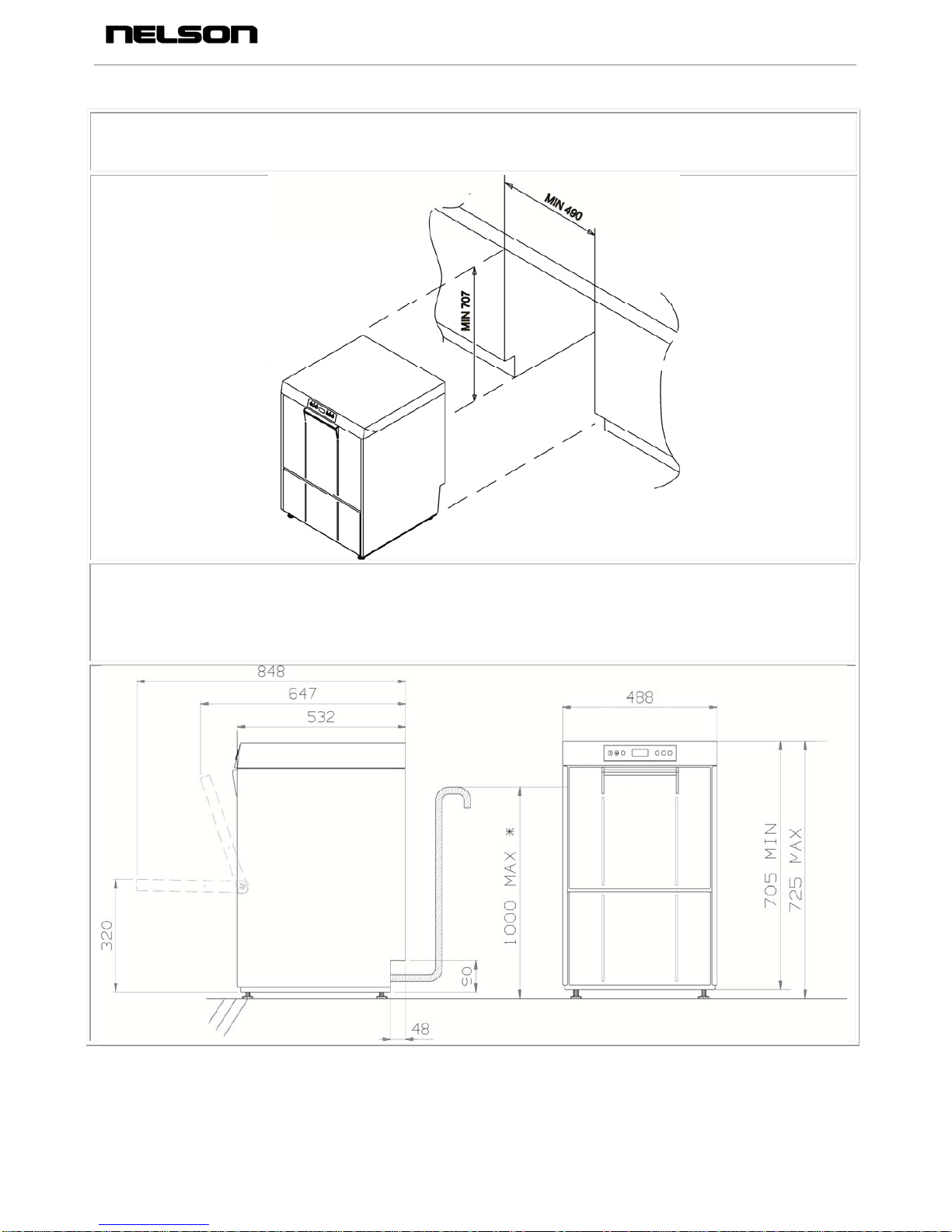

3INSTALLATIONANDPOSITIONING.................................................................................7

4INSTRUCTIONSFORTECHNICALSTAFF..........................................................................8

4.1PlumbingConnection..............................................................................................8

4.2Electricalconnection...............................................................................................9

5FIRSTSTART‐UP...........................................................................................................11

5.1Usingthewatersoftener(onmodelswiththisfeatureonly)..............................12

6SET‐UP.........................................................................................................................13

6.1DisplayContents..................................................................................................13

6.2Noteondisplayoftemperatures.........................................................................13

6.3Parameterprogrammingprocedure....................................................................13

6.4Modifiableparameters........................................................................................14

6.5Alarmtriggertimethresholds..............................................................................14

6.6Adjustingdetergentandrinseaiddispensing......................................................15

6.7Adjustingtheregenerationfrequency(modelswithsofteneronly)...................16

6.8Memorisationprocedure.....................................................................................16

6.9Tableofparameters............................................................................................16

7MALFUNCTIONSSHOWNONTHEDISPLAY(FORTHETECHNICIAN)...........................17

8INSTRUCTIONSFORTHEUSER....................................................................................18

8.1Controlpanel.......................................................................................................18

8.2Beforewashing....................................................................................................19

8.3Firstuseeachday(tankandboilerempty)..........................................................20

8.4Choosingtheprogram.........................................................................................21

8.5Changingtheprogram(notpossibleoncetheprogramhasstarted)..................21

9MAINTENANCEANDCLEANING..................................................................................23

9.1Dailycleaningoffilters........................................................................................23