Nemag Quick Release Links User manual

Nemag

user manual

quick release link

Nemag | User Manual | Quick Release Link EN | Revision 1.3

2

Table of contents

1GENERAL INFORMATION............................................................................................................................................................3

2SAFETY INFORMATION ...............................................................................................................................................................4

3TECHNICAL SPECIFICATIONS ....................................................................................................................................................5

4DESCRIPTION AND FUNCTION ...................................................................................................................................................9

5OPERATION................................................................................................................................................................................11

6MAINTENANCE...........................................................................................................................................................................13

7REJECTION.................................................................................................................................................................................15

8TRANSPORT AND STORAGE ....................................................................................................................................................16

Disclaimer

All rights reserved.

Copyright

No part of this manual may be reproduced, transmitted, stored in any retrieval system or translated into any language, without the prior

written permission of NEMAG B.V. The products and trademarks are protected by copyright ©, various trademarks ® and patents.

Changes

All possible care has been taken in the preparation of this manual. All information, illustrations and specifications are based on the latest

information available at the time of publication. NEMAG B.V. reserves the right to make changes without notice to both this manual

(including dimension tables) and to the products that are described in this manual.

Product warranty

Any warranties, expressed or implied, concerning the use of Rope Pear Sockets and Quick Release Links apply to new, unused

products when tested in a standard testing machine under controlled conditions, in direct tension, and at a uniform rate of speed. The

term “Breaking load” contains no implication of what load a Rope Pear Socket and Quick Release Link will withstand if not properly

used, or if it suffers abuse. All equipment using Rope Pear Sockets and Quick Release Links must be properly maintained. Rope Pear

Sockets and Quick Release Links must be properly stored, handled, used and maintained within the rules of user manual. Most

importantly, Rope Pear Sockets and Quick Release Links must be regularly inspected before and during each use. Inspections must

meet local or applicable national safety regulations. Damage, abuse, overloading or improper maintenance can cause failure and

accidents. If in doubt about the safe and proper use of Rope Pear Sockets and Quick Release Links consult manufacturer.

© Copyright NEMAG B.V., the Netherlands

Nemag | User Manual | Quick Release Link EN | Revision 1.3

3

1 General information

1.1 Purpose of the document

This manual gives the information that is necessary for safe use of the product. Read and understand this manual before you use

the product. The information provided is based on general data known at the time of publication of this manual. Nemag BV has a

policy of continuous improvement and reserves the right to change or modify the product.

1.2 Conventions

1.2.1 Language

The original text of the manual is written in US English. Any translation is a derivative of the original text.

1.2.2 Illustrations

The illustrations in the manual are a typical example of the delivered product. Essential differences in configuration between

product types are indicated in the text.

1.2.3 Units

All data in this manual is given in accordance with metrical European units and standards.

1.3 Admonitions

DANGER

Indicates a hazard with a high level of risk which, if not avoided or if the instruction is executed incorrectly,

will cause death,

serious personal injury, or damage to the product.

WARNING

Indicates a hazard with a medium level of risk which, if not avoided or if the instruction is executed incorrectly, can cause

death, serious personal inju

ry, or damage to the product.

CAUTION

Indicates a hazard with a low level of risk which, if not avoided or if the instruction is executed incorrectly, can cause mi

nor

personal injury, or damage to the product.

NOTE

Indicates important information for correct use of the product.

1.4 Availability and storage

Keep this manual at a safe location for future reference. All manuals can be downloaded from our website. NEMAG B.V. can

supply more copies on request.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

4

2 Safety information

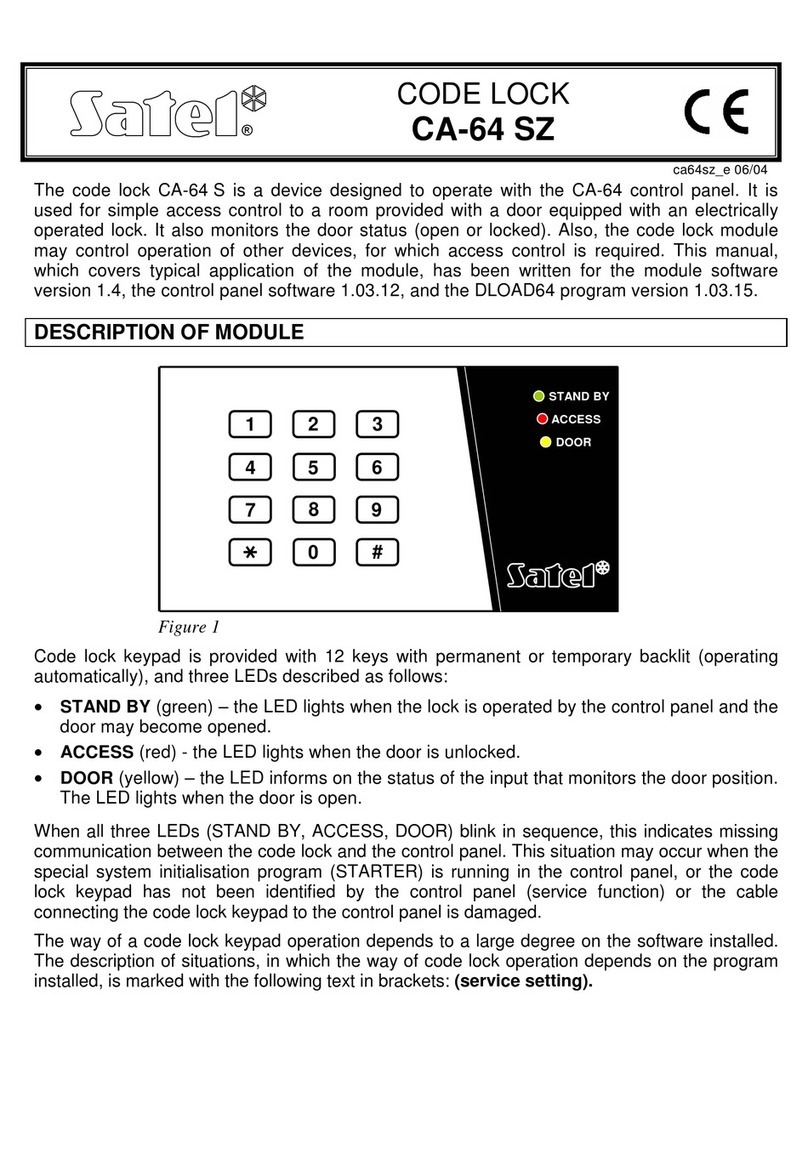

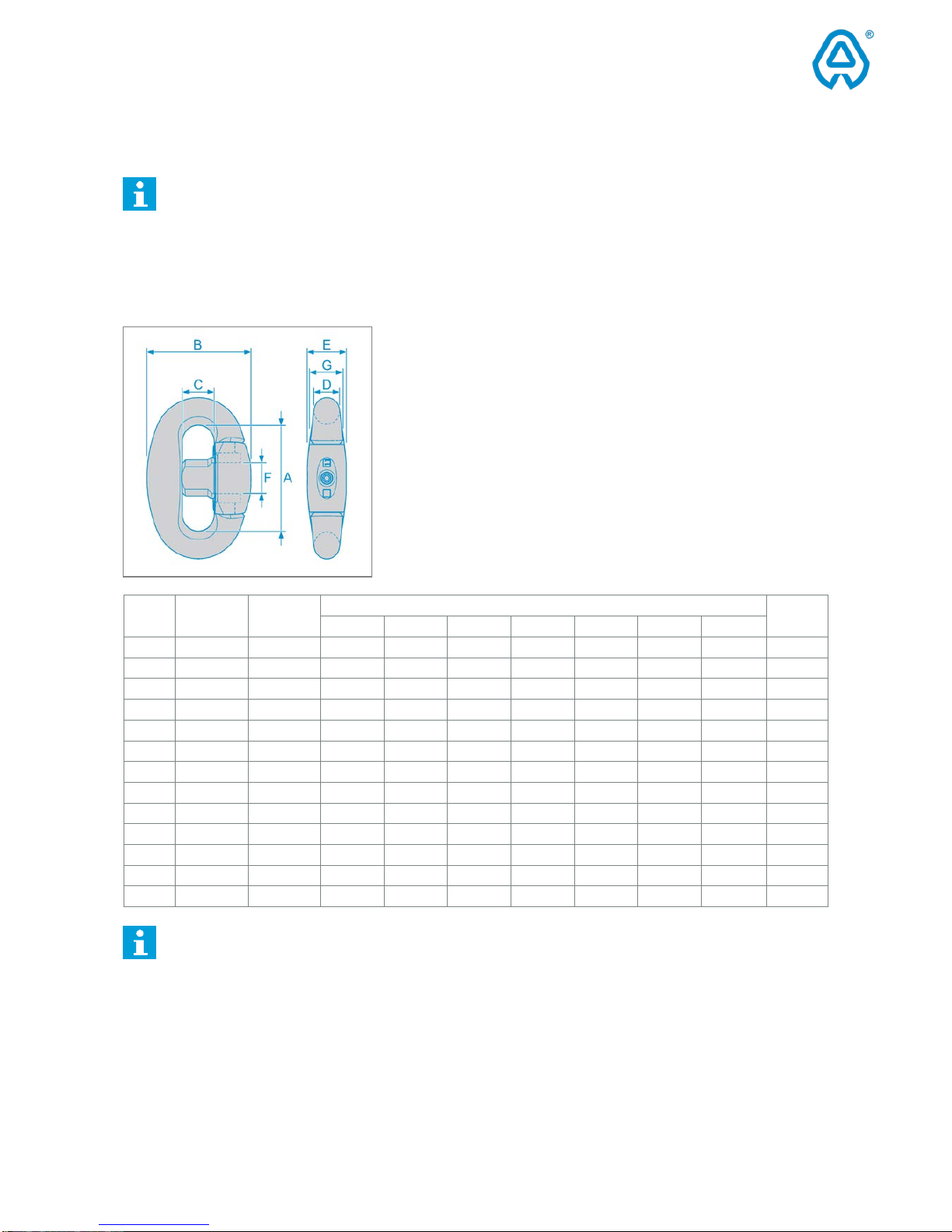

2.1 Marking

The following information is given on the NEMAG Quick Release Link:

A

Safe working load (SWL) in tons

E

CE mark

B

Brand name and country of origin

F

Size

C

Registration number

G

Batch code

D

Date (month + year) of the final test

H

Patent number

The various figures and values in the illustration are an example.

2.2 Safety instructions

Read this manual carefully and keep the manual for future reference.

•Always obey the safety instructions in this manual and in the manual(s) of associated equipment that is used with the NEMAG

Quick Release Link.

•The NEMAG Quick Release Link and any associated equipment must be used, maintained and stored in accordance with this

manual, the manual(s) of the associated equipment, and the applicable local legislation.

•The NEMAG Quick Release Link must be inspected before and during each use, as described in this manual, and in

accordance with the applicable local legislation.

•Do not use the NEMAG Quick Release Link without a valid certificate.

•Only use the NEMAG Quick Release Link when the locking piece is installed and locked.

•Do not use the NEMAG Quick Release Link if you have any doubts about the correct functioning of the bolt in the locking piece.

•Do not subject the NEMAG Quick Release Link to temperatures that are higher than 200° C.

•Do not use the NEMAG Quick Release Link in substances that stimulate oxidation.

•Do not use the NEMAG Quick Release Link if the number of undergone load cycles is more than 250,000 loads at SWL.

•Do not use the NEMAG Quick Release Link if it has been overloaded by more than 200%.

•Do not use the NEMAG Quick Release Link if it is permanently deformed or seriously damaged.

•Do not weld or heat-treat the NEMAG Quick Release Link.

•Do not replace parts with non-NEMAG parts.

•Reject and destroy the NEMAG Quick Release Link if any of the conditions in chapter 7.

When you are in doubt about the safe and correct use of the NEMAG Rope Pear Socket, refer to NEMAG B.V.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

5

3 Technical specifications

NOTE

The working load is the recommended maximum load for grabbing operations when NEMAG Quick Release Links and

NEMAG Rope Pear Sockets pass over a wide ‘U’ cable sheave. For other applications, you must adhere to a safety factor that

is in li

ne with official local and international directives.

3.1 NEMAG Quick Release Links

Link

size Working

load (kg) Breaking

load (kg) Dimensions (mm) Weight

(kg)

A B C D E F G

4 3,000 25,000 76 76 24.5 19 30 21 25.2 1.0

5

4,500 33,000 84 84 27 21 32.5 23 28 1.3

6

5,000 37,500 92 92 29.5 23 35 25 30.3 1.6

7 7,000 49,000 100 100 32 25 38 28 32.8 2.0

8 8,000 54,000 108 108 34.5 27 40.5 31 35.3 2.6

9 9,500 60,000 116 116 37 29 43.5 34 38 3.0

10

12,000 75,000 128 128 40.5 32 48 37 41.6 4.2

11

15,000 95,000 140 140 44 35 53 40 45.8 5.5

12 17,000 110,000 152 152 47.5 38 57 43 49.6 7.1

13 21,000 135,000 164 164 51 41 61.5 46 53.4 9.1

14 26,000 160,000 176 173 54 44 66 50 58 10.8

15

30,000 175,000 188 188 58 47 70.5 52 61 13.7

17

42,500 260,000 222 222 68 56 84 62 71 22.8

NOTE

The force transmitting parts of the NEMAG Quick Release Link are made of material in accordance with the specifications laid

down in standard EN 1677

-1 Components for slings – Forged steel components – Grade 8.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

6

3.2 NEMAG Rope Pear Sockets

Pear

size Wire rope

diam. (mm) Working

load (kg) Breaking

load (kg)

Dimensions (mm)

L

(mm) Weight

(kg)

A

B

C

D

E

F

G

H

I

2 12-13 2,000 14,000 95 56 25 195 15.5 13.5 22 25 16 41 0.4

3 14-15 2,500 17,500 109 64 28 220 17.5 15.5 24 29 19 48 0.7

4

16-17 3,000 22,500 123 70 31 220 19.5 17.5 26 31 21 58 0.9

5

18-19 4,500 27,500 135 84 33 245 21 19 30 42 23 64 1.4

6

20-21

5,000

35,000

152

84

36

310

23

21

33

38

26

74

1.6

7 22-24 7,000 42,500 166 100 40 310 26 23 37 48 30 78 2.2

8 25-27 8,000 52,500 186 100 43 350 28 25 39 44 32 90 2.5

9

28-30 11,000 70,000 202 120 45 350 32 28 40 58 35 98 3.7

10

31-33 13,000 85,000 222 120 52 445 32 28.5 45 56 39 110 4.0

11

34-36

15,000

95,000

239

142

55

445

36

31.5

50

70

42

110

6.1

12 37-39 17,000 110,000 264 142 60 495 39 34.5 51 64 45 130 6.3

13 40-42 21,000 125,000 285 166 63 555 43 36.5 59 80 48 132 8.8

14

43-45 26,000 155,000 312 166 68 595 47 40 62 72 51 155 10.7

15

46-48 30,000 180,000 337 170 75 595 51 44 66 68 55 170 11.6

17

52-56

42,500

240,000

400

220

84

880

60

54

75

90

63

200

22.1

NEMAG Rope Pear Sockets type S

Pear

size Wire rope

diam. (mm) Working

load (kg) Breaking

load (kg)

Dimensions (mm)

L

(mm) Weight

(kg)

A

B

C

D

E

F

G

H

I

924 22-24 11,000 70,000 192 133 40 325 31 27 40 58 29 96 4.1

1026 25-27 13,000 85,000 212 143 43 375 35 30.5 43 60 32 108 5.0

1130

28-30 15,000 95,000 239 156 45 400 36 31.5 50 70 35 122 6.0

1232

31-33 17,000 110,000 249 165 52 425 39 34.5 57 72 38 118 8.2

1336

34-36

21,000

125,000

257

184

62

450

43

36.5

60

80

42

118

9.1

1440 37-40 26,000 155,000 297 192 60 475 47 40 62 80 46 142 11.8

3221 42-44 32,500 189,000 314 204 66 425 53 46 70 80 49 144 13.8

1548

46-48 30,000 180,000 329 192 67 575 51 44 66 80 57 157 12.4

1648

46-48 36,000 215,000 343 218 70 500 56 50 75 90 54 157 16.3

Nemag | User Manual | Quick Release Link EN | Revision 1.3

7

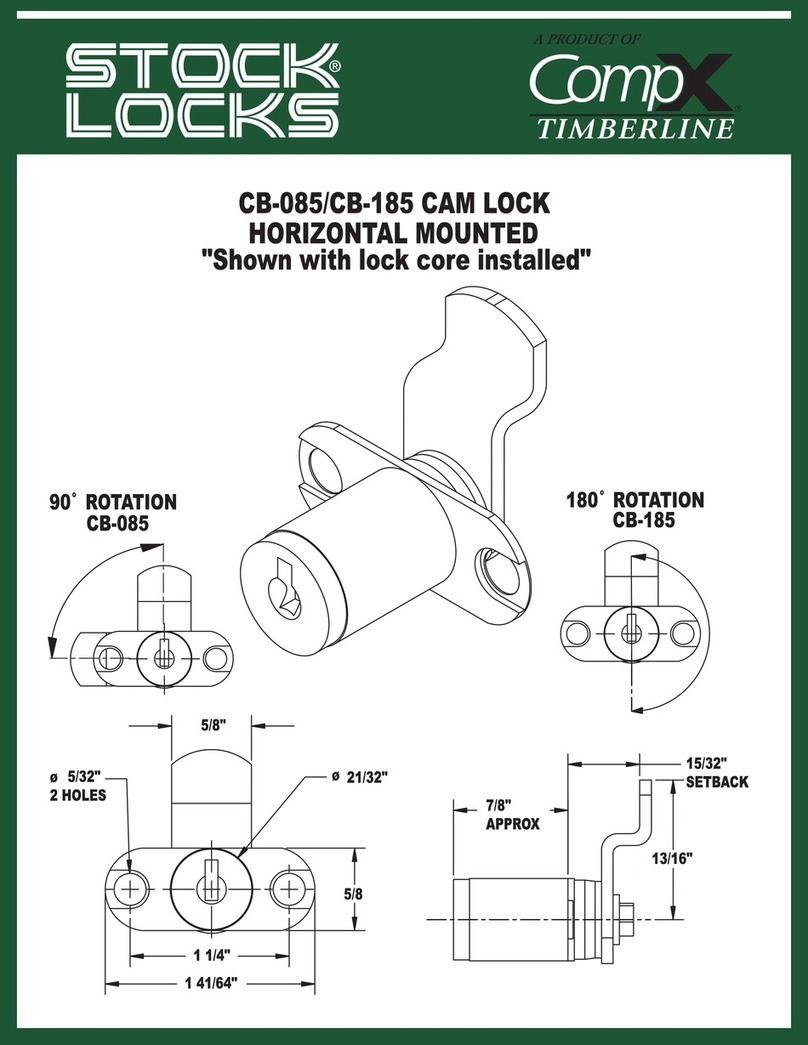

3.3 Connection between NEMAG Rope Pear Sockets and

NEMAG Quick Release Links

A NEMAG Rope Pear Socket can be connected with a NEMAG Quick Release Link of the same size, or to a NEMAG Quick

Release Link of a different size as shown in the table below. The example below shows how you can find the correct size Quick

Release Link and Rope Pear Socket. An additional safety factor can be included.

Given:

•Steel wire rope with a diameter of 26 mm

•Safe working load of the steel wire rope: 10,000 kg

1. According to section 3.1 select NEMAG Rope Pear Socket no. 1026

2. Then, according section 3.1 and the table below, NEMAG Quick Release Link no.10 is possible

NEMAG Quick Release Link

size 4 5 6 7 8 9 10 11 12 13 14 15 17

NEMAG Rope Pear Socket

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

type s

924

1026

1130

1232

1336

1440

3221

1548

1648

Connection possible

Connection not possible

Nemag | User Manual | Quick Release Link EN | Revision 1.3

8

3.4 Wide ‘U’ cable sheaves

Pear

size Wire rope

diam. (mm) Link

sizes

Dimensions (mm)

A

B

C

D

E

R

4 16-17 4 560 694 750 60 9 7

5 18-19 4-5-6 630 788 850 70 10 9

6 20-21 5-6-7 710 880 960 75 11 12

7 22-24 6-7-8 710 890 970 80 12 10

924 22-24 8-9-10 710 890 970 80 12 10

8 25-27 7-8-9 800 984 1060 80 14 13

1026 25-27 9-10 800 984 1060 80 14 13

9 28-30 8-9-10 900 1116 1210 95 15 13

1130 28-30 10-11-12 900 1116 1210 95 15 13

10 31-33 9-10-11 1000 1240 1360 105 17 16

1232 31-33 11-12-13 1000 1240 1360 105 17 16

11 34-36 10-11-12 1000 1240 1360 105 19 14

1336 34-36 12-13-14 1000 1240 1360 105 19 14

12 37-39 11-12-13 1200 1450 1560 110 20 12

1440 37-40 13-14-15 1200 1450 1560 110 20 12

13 40-42 12-13-14 1200 1450 1560 110 21 12

3221 42-44 15 1200 1455 1560 110 23 16

14 43-45 13-14-15 1400 1655 1760 110

23

16

15 46-48 14-15 1600 1870 1960 110 25 25

1548 46-48 14-15 1400 1655 1760 110 25 16

1648 46-48 15-17 1400 1680 1760 122 25 16

17 52-56 17 1800 2085 2200 122 29 18

NOTE

Wide ‘U’ cable sheaves

generally have the dimensions as shown in the table above. In case of different dimensions, refer to

NEMAG B.V.

NOTE

Diameter C has been designed for a NEMAG Quick Release Link that is one size larger than the NEMAG Rope Pear

Socket

that is indicated in the table.

Radius E depends on the diameter of the applied steel wire rope.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

9

4 Description and function

4.1 Overview

‘C’ section

The 'C' section is forged of a steel alloy that is not subject to ageing. It is quenched

and tempered up

to a tensile strength of 1000-1100 N/mm2. The inside of the bow

is induction hardened for extra wear resistance.

The 'C' section has been accurately machined, so that exchange of parts is possible

.

Locking piece

The locking piece closes the 'C'

section. A spring-loaded bolt that can be operated

swiftly with the key secures the locking piece. The locking piece has these parts:

•

The force transmitting body, which is forged of steel that is not subject to

ageing. It is quenched and tempered up to a tensile strength of 800-1000

N/mm2.

•

The locking mechanism, which is made of high-tensile CrMo steel. It is sealed

to prevent the ingress of dirt and lifetime lubricated with a compound lubricant.

•

The spring-loaded 10 mm inside hexagon bolt, which is fully countersunk in the

body.

Key

The key has a 10 mm outer hexagon tip that fits in the inside hexagon bolt of the

locking piece. The handle is big enough to exert a rotating as well as a pressing

force.

One side of the handle has a chisel point to clean

the inside hexagon bolt if

necessary. The other side of the handle has a hammer face.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

10

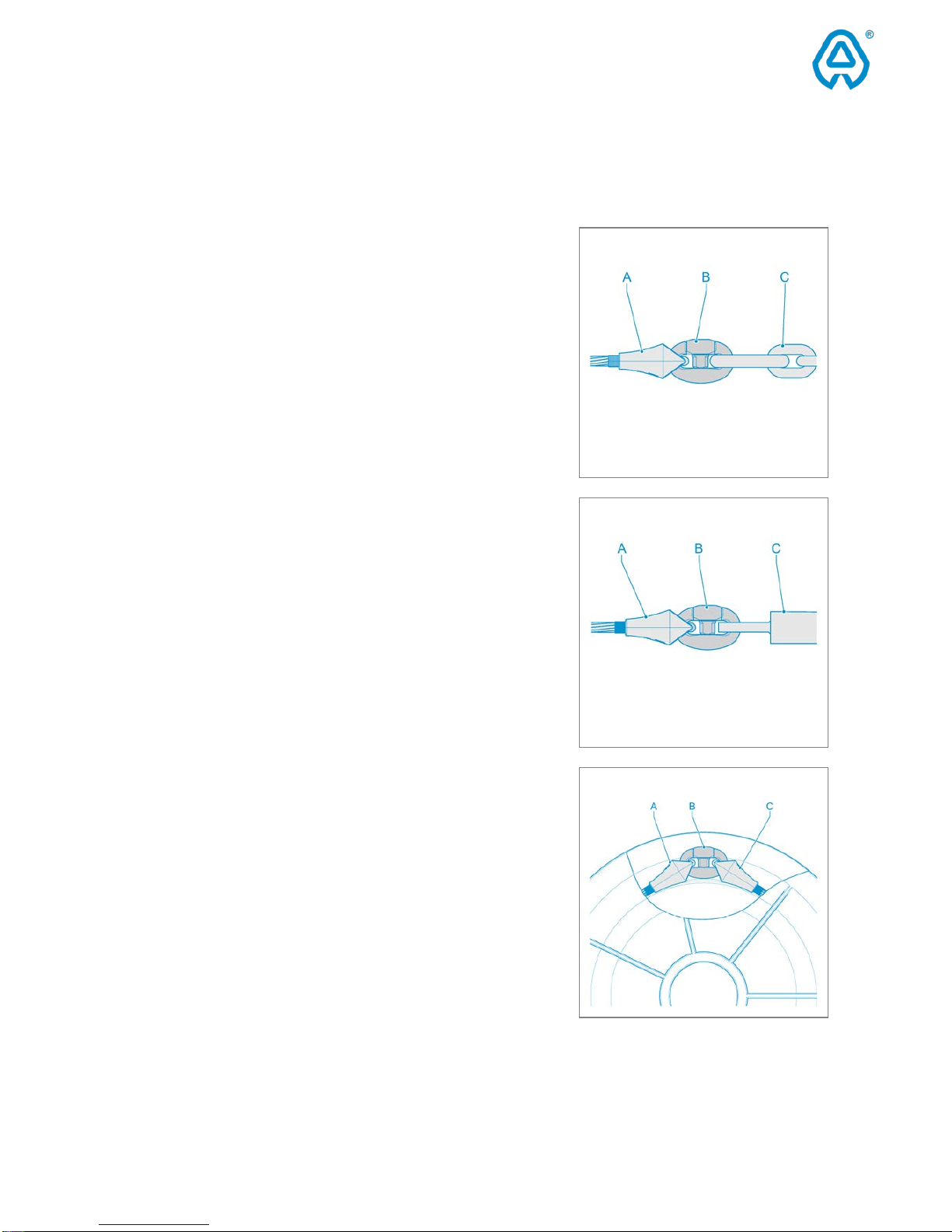

4.2 Intended use

The NEMAG Quick Release Link has been developed for quick, straightforward, safe and wear-resistant coupling and uncoupling

of steel wire ropes, chains or other equipment such as grabs on cranes.

Typical connections that can be made with the NEMAG Quick Release Link (B) are:

•

2 chain outer ends

•

1 outer end of a steel wire rope fitted with a NEMAG Rope Pear Socket (A)

and 1 chain outer end (C)

•

1 outer end of the steel wire rope fitted with a NEMAG Rope Pear Socket (A) and

1 piece of equipment that is fitted with a fixed eye (C).

•

2 outer ends of steel wire ropes fitted with NEMAG Rope Pear Sockets (A, C).

This combination is suitable to pass over a special rope sheave, called a wide 'U'

sheave.

See also section 3.

F

or other applications, refer to NEMAG B.V.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

11

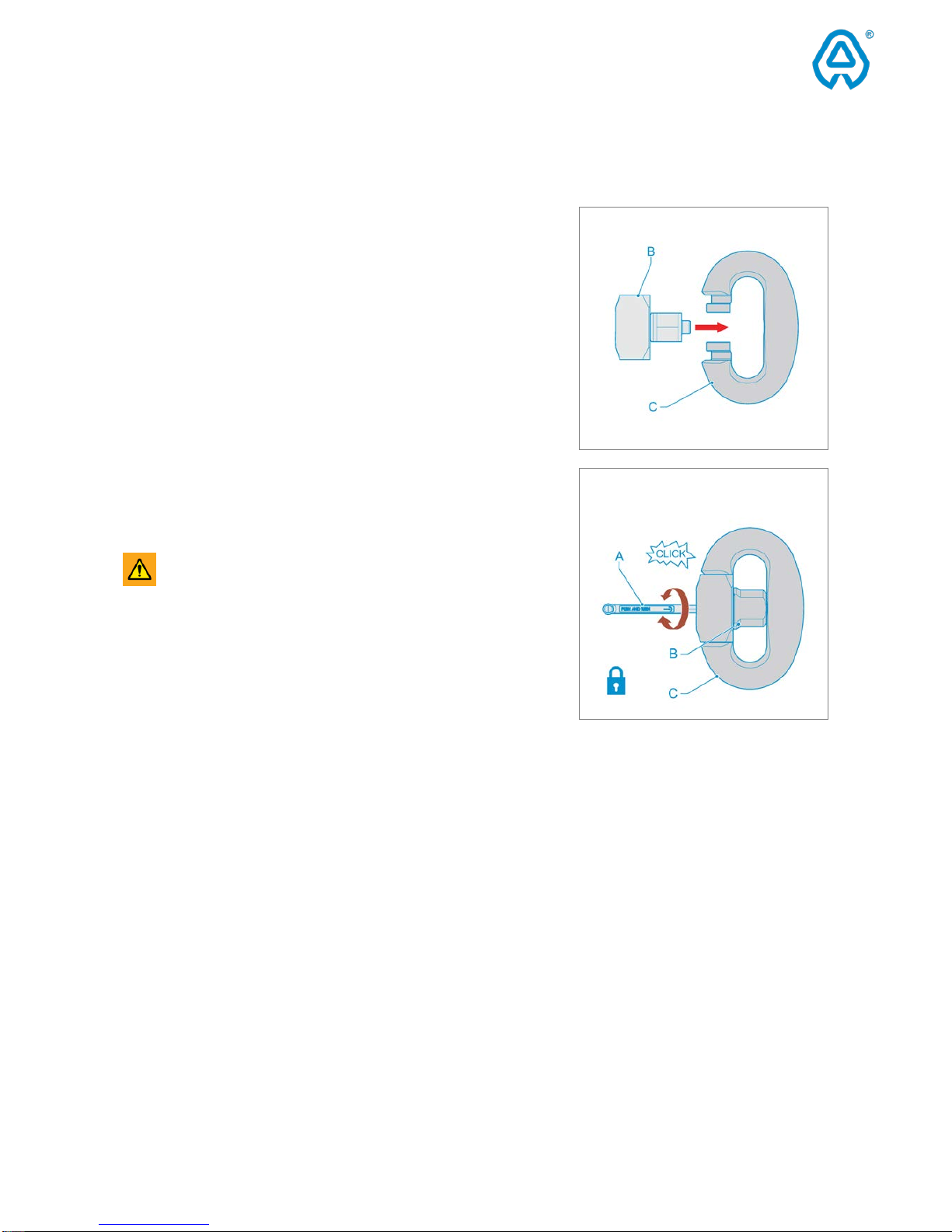

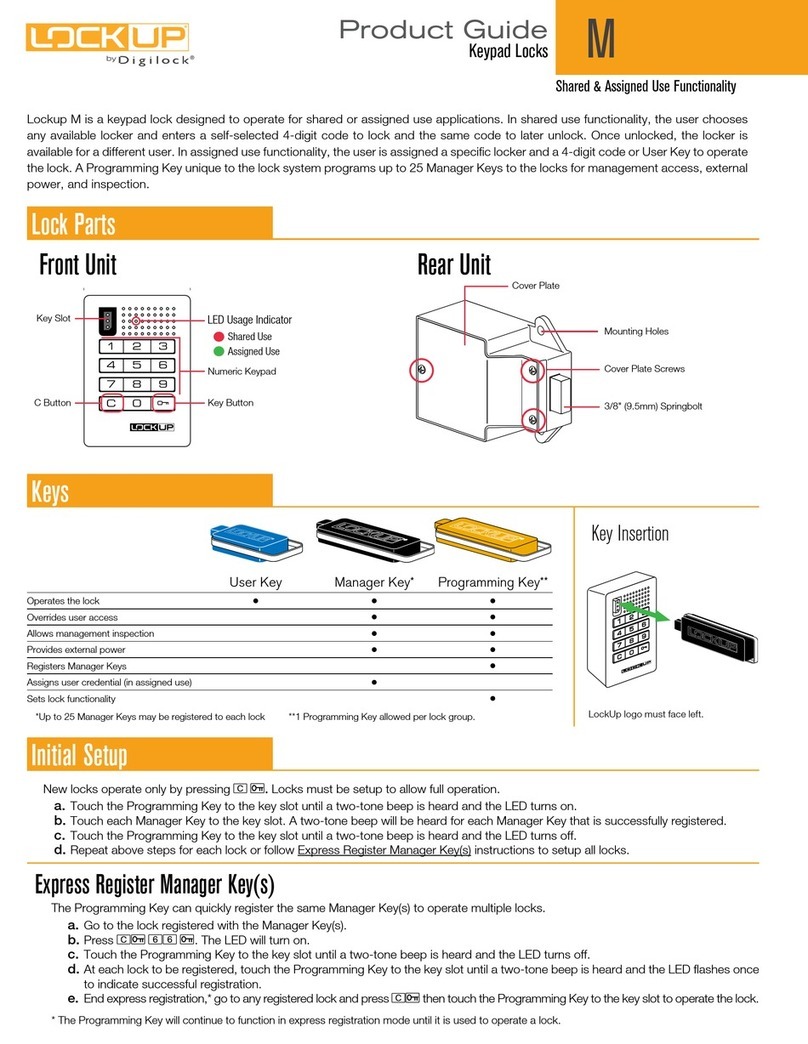

5 Operation

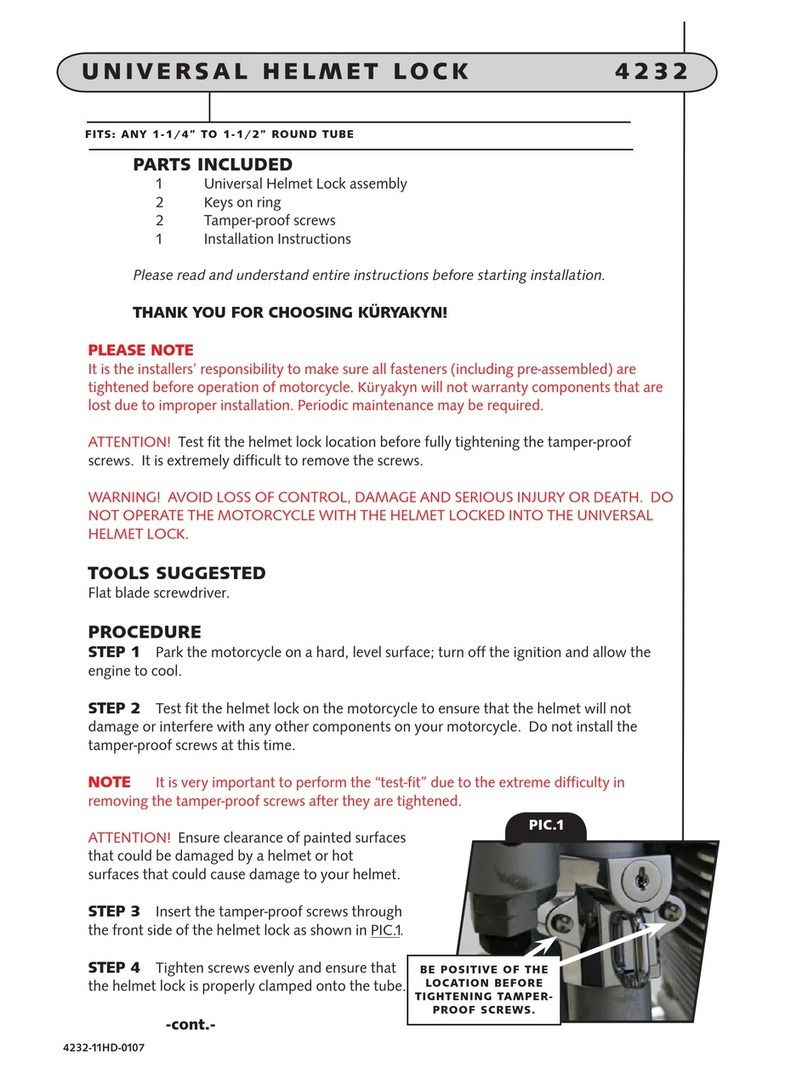

5.1 Install the locking piece

1.

Slide the locking piece (B) on the ‘C’ section (C).

2.

Place the hexagon tip of the key (A) in the inside hexagon bolt of the locking

piece.

3.

Rotate the key (A) 90° to the left or to the right. This locks the locking piece (B)

on the ‘C’ section (C).

WARNING

The locking piece is only safely locked if:

•

A ‘click’ is heard.

•

The inside hexagon bolt cannot be rotated any further with the key.

•

The inside hexagon bolt comes up at least 3.5 mm in the chamber of

the locking piece.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

12

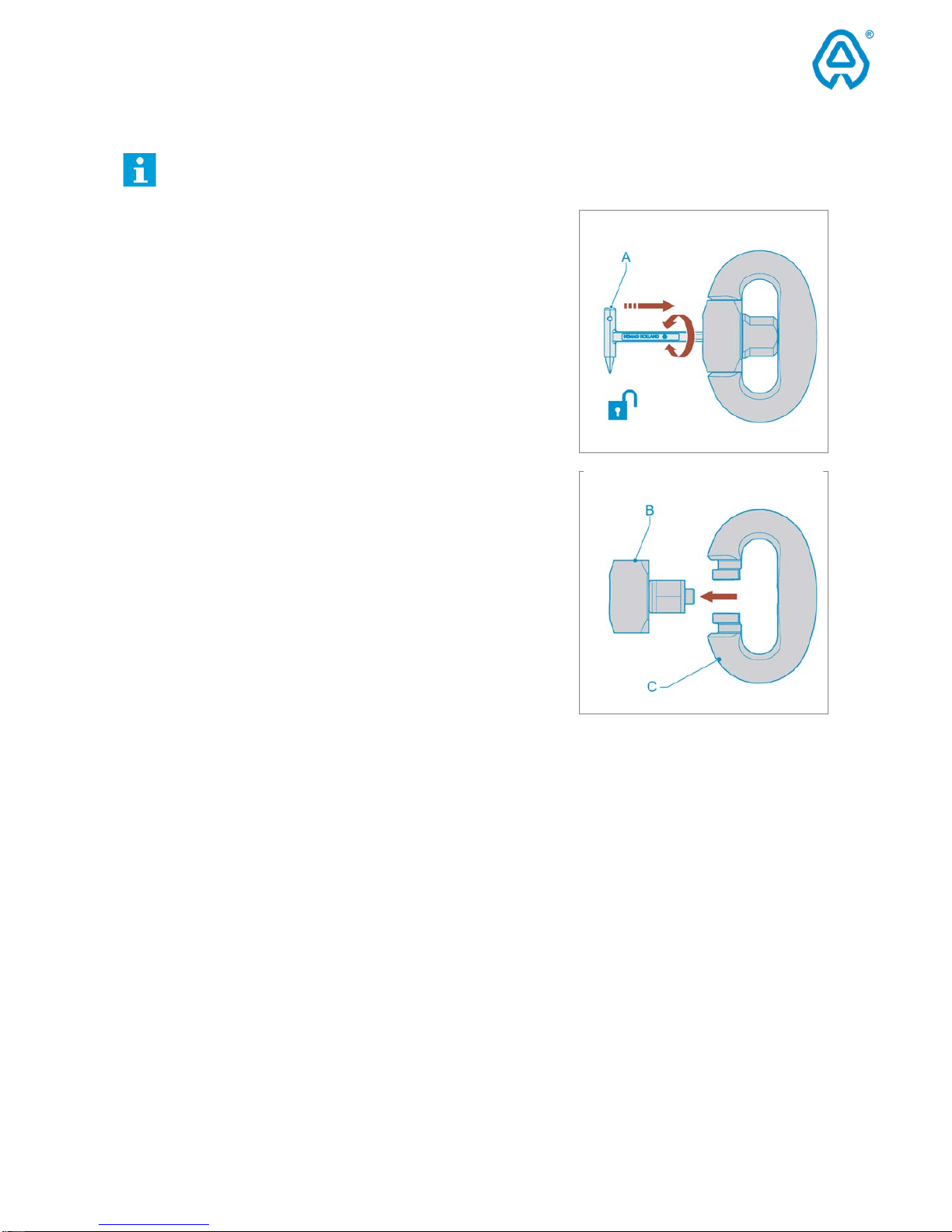

5.2 Remove the locking piece

NOTE

If necessary, use the chisel point of the key

to remove dirt from the inside hexagon bolt of the locking piece.

1.

lace the hexagon tip of the key (A) in the inside hexagon bolt of the locking

piece.

2.

Use the key to push the mechanism inside to the stop.

3.

Keep the mechanism pressed in and rotate the key (A) 90° to the left or to the

right. The locking piece (B) is released.

4.

Take the locking piece (B) out of the ‘C’ section (C).

Nemag | User Manual | Quick Release Link EN | Revision 1.3

13

6 Maintenance

Carry out maintenance (lubrication, cleaning, inspection and tests, removing burrs) as described in this chapter and according to

the applicable local legislation.

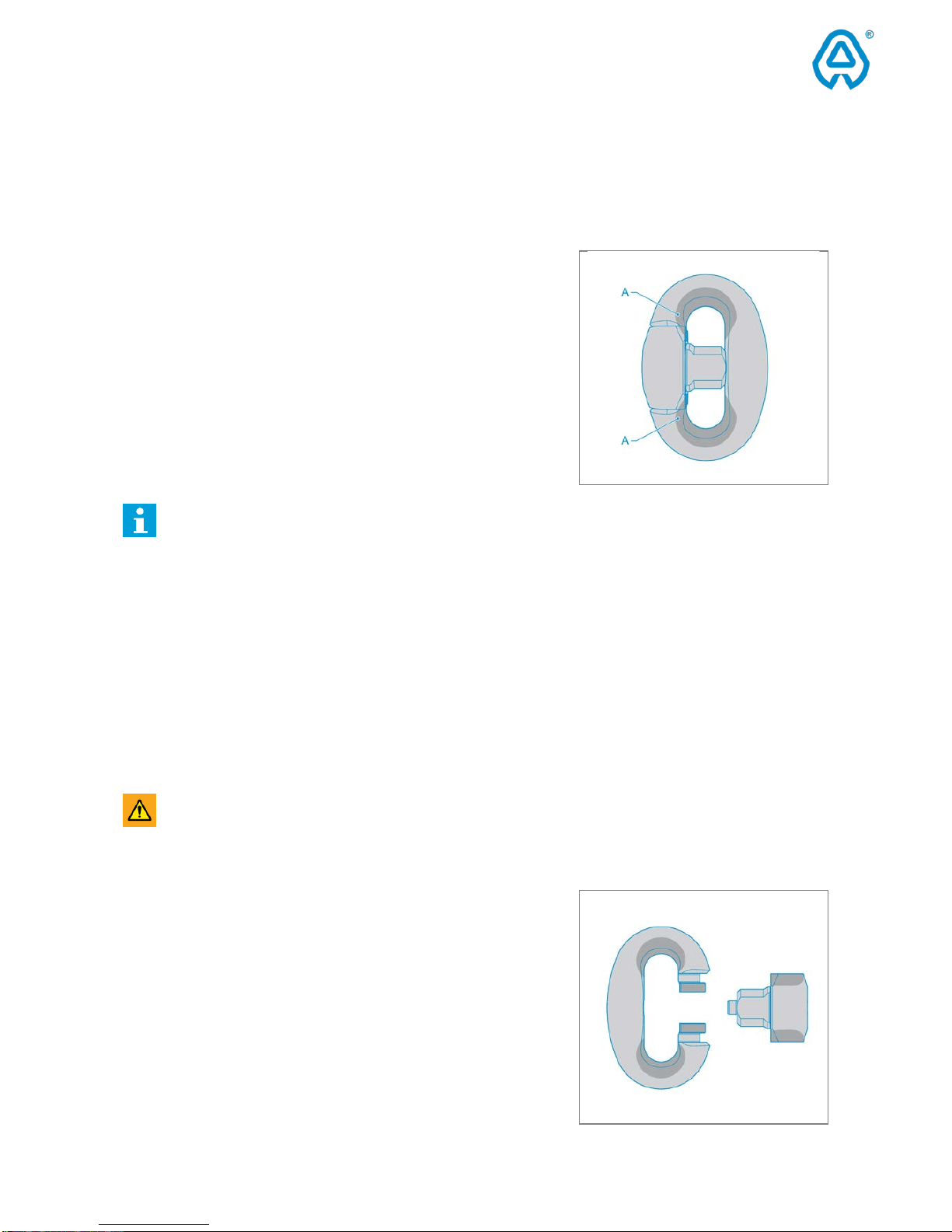

6.1 Lubrication

•

Grease the contact areas (A). This extends the lifetime of both the NEMAG

Quick Release Link and the NEMAG Rope Pear Socket.

•

Use EP3 or EP4 grease (lubricant for high-pressure contact surfaces).

•

Apply grease after every 24 hours of use.

NOTE

Do not grease the NEMAG Rope Pear Socket when it is used in an environment with large quantities of abrasive particles. For

example during transshipment of alumina or other abrasive / dusty ores.

6.2 Cleaning

During use, particles that stimulate wear can become embedded in the lubricant. Therefore, regularly clean the bow of the NEMAG

Quick Release Link.

6.3 Visual inspection

Visually examine the NEMAG Quick Release Link for defects after every 200 hours of use.

6.4 Removing sharp hard points and burrs

Through contact with other equipment, burrs or small bumps can occur on the edges of the contact surfaces of the locking piece.

This can make it difficult to slide the locking piece on the ‘C’ section. Use a file to remove these burrs or small bumps, until the

locking piece functions correctly again, as described in chapter 5.

WARNING

When you remove any defects, make sure that the play between the ‘C’ section and the locking piece, and the overall wear of

the ‘C’ section, do not exceed the values that are given in chapter.7.

6.5 Magnetic Particle Inspection (MPI)

•

To avoid failures that are the result of fatigue cracks, the NEMAG Quick Release

Link must undergo a Magnetic Particle Inspection (MPI) after at least every

125,000 cycles at safe working load (SWL).

•

Do the MPI at the areas that are shown in the illustration.

•

Do the MPI at the intervals that are given in section 6.6.

•

If required by the applicable local legislation, test the NEMAG Quick Release

Link after inspection

Nemag | User Manual | Quick Release Link EN | Revision 1.3

14

6.6 Inspection interval and lifetime indication

CAUTION

The data in the tables below are indicative lifetimes, based on our experience and general applications. High

dynamic

forces in the application decreases the lifetime significantly. You must assess the application to determine the required

inspection interval and lifetime. At new applications, additional inspection intervals must be applied in order to determine

t

he lifetime for that application. The number of load cycles per grab cycle is affected by the average amount of trimming

works and the crane system.

Refer to section 6.3 for the methods of inspection.

Refer to chapter 7 for the criteria of rejection.

Criterion: Number of cycles at Safe

Work Load (SWL)

Grab operation

General purpose and container operation

60 cycles / hour

1,6 load cycle during one grab cycle.

60 cycles / hour

1 load cycle during one operation cycle.

Inspection after

125,000 cycles at SWL

125,000 cycles at SWL

Do not use after

250,000 cycles at SWL

250,000 cycles at SWL

Criterion: Hours of operation

Grab operation

General purpose and container operation

Inspection after

1300 hours of operation

2000 hours of operation

Do not use after

2600 hours of operation

4000 hours of operation

Criterion: Shifts of operation

Grab operation

General purpose and container operation

24 hours per day operation Inspection after 8 weeks

Do not use after 16 weeks

Inspection after 12 weeks

Do not use after 24 weeks

16 hours per day operation Inspection after 12 weeks

Do not use after 24 weeks

Inspection after 18 weeks

Do not use after 36 weeks

8 hours per day operation Inspection after 24 weeks

Do not use after 48 weeks

Inspection after 36 weeks

Do not use after 72 weeks

Nemag | User Manual | Quick Release Link EN | Revision 1.3

15

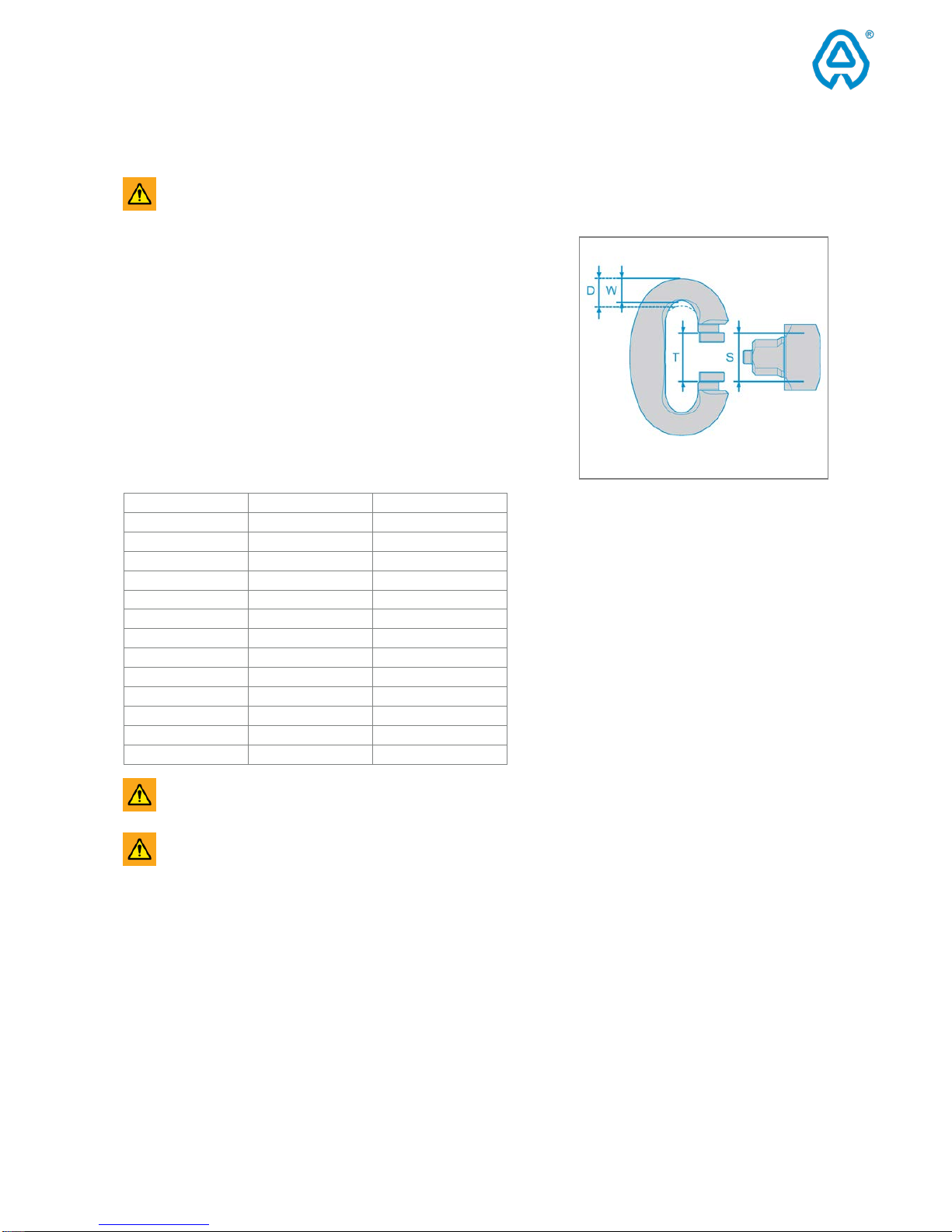

7 Rejection

WARNING

If any of the rejection criteria below are exceeded, the NEMAG

Quick Release Link must be rejected and destroyed.

•

Play between the ‘C’ section and the locking piece (difference between the

dimensions ‘S’ minus ‘T’) is more than the value given in the table.

•

Wear of the ‘C’ section is more than 15% of the nominal dimension at any place.

•

Heating in excess of 200° C has taken place.

•

Any form of welding work or heat treatment has taken place.

•

Any permanent deformation.

•

Any cracks, or indication of cracks, in the material.

•

The number of undergone load cycles is more than 250,000 loads at SWL.

•

The bolt in the locking piece does not function correctly, as described in chapter 5.

•

Any overloading has taken place.

size

S-T [mm]

W [%]

4

> 0.6

> 85% D

5

> 0.6

> 85% D

6

> 0.8

> 85% D

7

> 0.8

> 85% D

8

> 0.8

> 85% D

9

> 0.8

> 85% D

10

> 1.0

> 85% D

11

> 1.0

> 85% D

12

> 1.0

> 85% D

13

> 1.0

> 85% D

14

> 1.0

> 85% D

15

> 1.25

> 85% D

17

> 1.25

> 85% D

WARNING

If

the NEMAG Quick Release Link is seriously damaged, it must be sent to NEMAG B.V. for assessment or destroyed..

WARNING

If the NEMAG Quick

Release Link does not have a certificate, it must be returned to NEMAG B.V. for assessment. If found

OK, a certificate can be issued

.

Nemag | User Manual | Quick Release Link EN | Revision 1.3

16

8 Transport and storage

8.1 Conservation for shipment

The NEMAG Quick Release Link has been conserved for shipment with a rust-proofing agent. Make sure that the NEMAG Quick

Release Link does not make contact with substances that stimulate oxidation.

8.2 Storage

The minimum requirement for storage is protection against humidity. Check the conservation every 3 months if storage takes place

in very humid conditions. If necessary, correct the conservation.

Table of contents

Popular Lock manuals by other brands

Burg

Burg Intro.Code operating manual

Schlage

Schlage ND Series Service manual

Dormakaba

Dormakaba Cobalt Single Installation and operating instructions

Digilock

Digilock Lockup M Product guide

Sargent

Sargent ASSA ABLOY FM7100 Series installation instructions

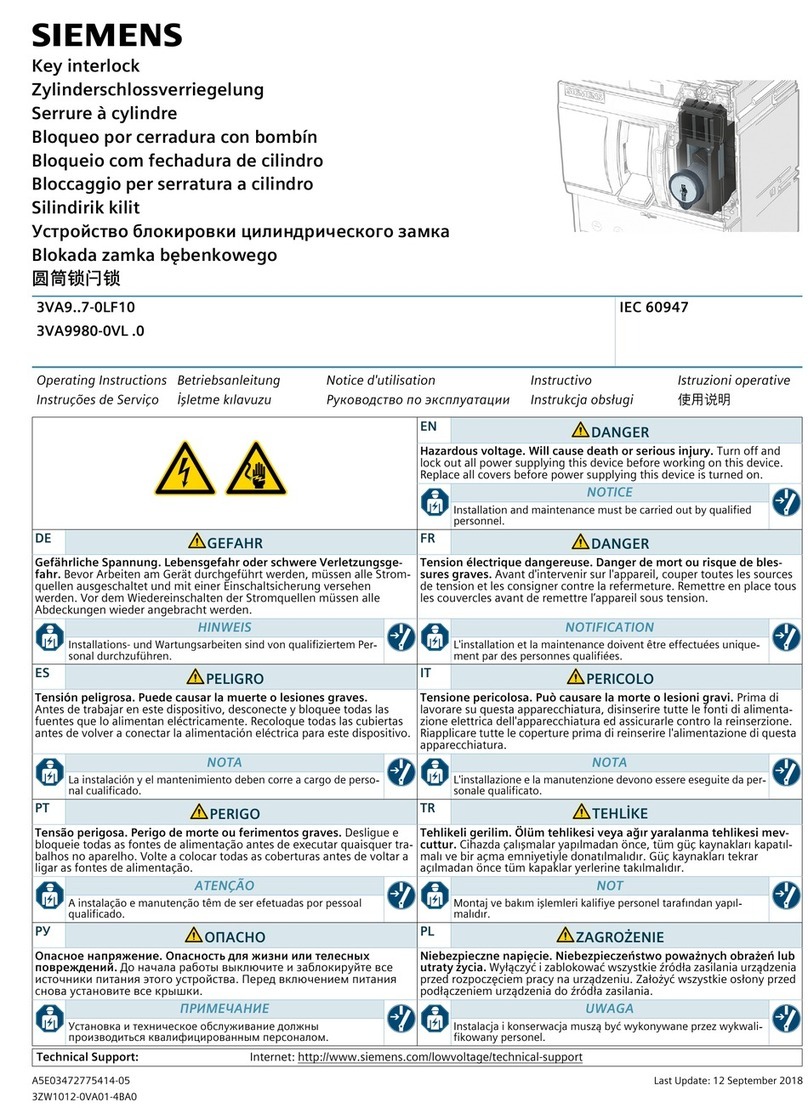

Siemens

Siemens 3VA9980-0VL 0 Series operating instructions