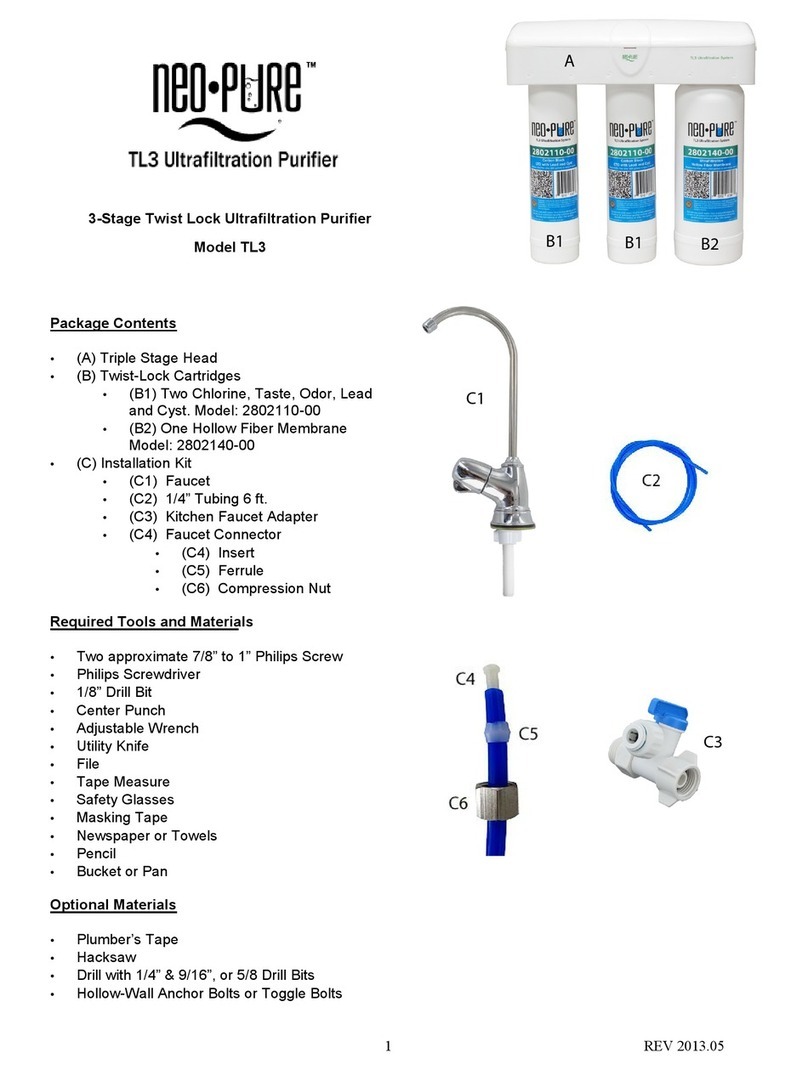

Mount Auxiliary Faucet

Note: This faucet is designed to fit a 5/8" clearance hole

and should clear a 9/16" hole. Most standard sinks come

with 1-3/8" or 1-1/2" diameter water sprayer holes that

can be used to mount this faucet. If the pre-drilled holes

cannot be used or are not in the desired position, a new

hole must be drilled using either a 9/16" or 5/8" drill bit.

The faucet should be positioned securely on a flat

surface with adequate space for proper function.

If you need to drill a hole, go to (1). If you will be using

a pre-drilled hole, go to (5).

1. Line sink with newspaper or towel to prevent parts and

materials from falling down the drain.

2. To help prevent scratching the sink surface or countertop

should the drill bit slip, apply masking tape to the area

to be drilled.

STEP 1:

Install The Angle Stop Valve Adapter

Note: This adaptor is designed to fit ½" NPTF supply threads.

1. Locate the cold water shut-off valve under the sink.

Turn off the cold water supply.

2. Turn on the kitchen faucet. This will release pressure

and allow water to completely drain from the line.

STEP 2:

1. Select easily accessible area under

the sink to mount the filter system.

2. Mount system to a solid cabinet wall or wall.

If this is not an option, use toggle bolts or

hollow-wall anchor bolts (not included) to

secure the system to the surface.

3. Allow a minimum clearance of 4-6" below

the filter cartridges to allow ample space for

cartridge changes. The filter system must be

mounted in a vertical position.

STEP 3:

Install Plastic Tubing For Water Supply Line From

Angle Stop Valve Adapter To System Head Inlet

1. Determine the length of tubing necessary to

connect the system head inlet to the Angle Stop

Valve Adapter making sure to allow enough tubing

to prevent kinking in the line.

2. Check the tubing to be square on both ends

ensuring no jagged edges. If necessary, cut ends

of tubing to be square with no jagged edges, as

this can cause inappropriate seal of tubing in

collet inlet/outlet ports.

STEP 4:

2

3. Mark the drill hole using a center punch.

4. Make a pilot hole using the 1/4" drill bit. Use the 9/16"

or 5/8" drill bit to drill the final hole. Drill through

the sink or countertop completely and smooth rough

edges with a file.

5. Unscrew the faucet stem nut from the faucet stem, and

remove the metal lock washer. Slip the threaded

faucet stem into the sink or countertop hole ensuring

faucet sits flat on top of the sink or countertop.

6. Under the sink, slide the metal lock washer up the faucet

stem and secure with the faucet stem nut.

Tighten until slightly snug and check to ensure the faucet

spout is in the correct position. Using fingers,

tighten the nut to secure the faucet to the sink.

3. Disconnect the cold water faucet line from the ½"

threaded stem on the bottom of the kitchen faucet.

4. Holding the Angle Stop Valve Adapter in an

upright position, thread the female side of the

faucet adapter on to the cold water supply valve.

5. Attach the cold water supply line for the faucet

to the male - top side of the adapter.

4. After removing the cap from the manifold,

use the back panel as your mounting template

marking the holes for the mounting screws

on the wall surface.

5. Drill two pilot holes for the mounting screws using

a 1/8" drill bit. Insert mounting screws into the wall

with a Phillips screwdriver leaving approximately

3/8" of each mounting screw exposed.

6. Position the system head on the eyes of the

bracket and replace the system head cap.

3. Without bending or crimping the tubing, wet one

end of the tubing with water and push it into the Angle

Stop Valve Adapter approximately 5/8" until it stops.

4. Wet the other end of the tubing with water and push

it into the system head inlet on the left side of the

manifold approximately 5/8" until it stops.

5. The tubing does not have to be disconnected for

cartridge replacement or routine maintenance,

however, it may be easily disconnected if desired.

To disconnect, turn off the water supply to the filter

system and press the grey collar around the fitting

while pulling the tubing out with the other hand.