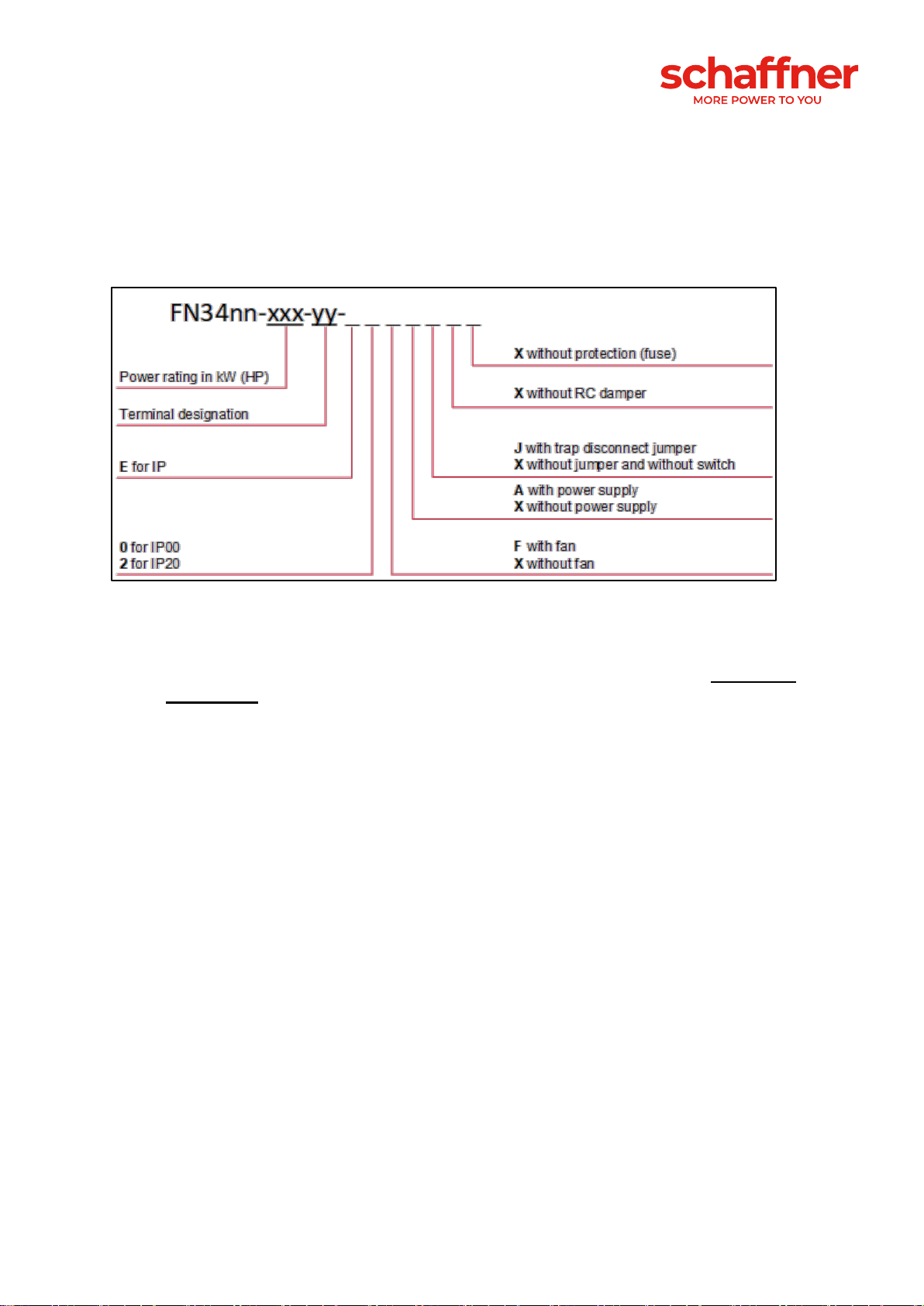

User and installation manual Ecosine Flex Passive Harmonic Filters 2/46

i. Ecosine Flex Passive Harmonic Filters product

highlights

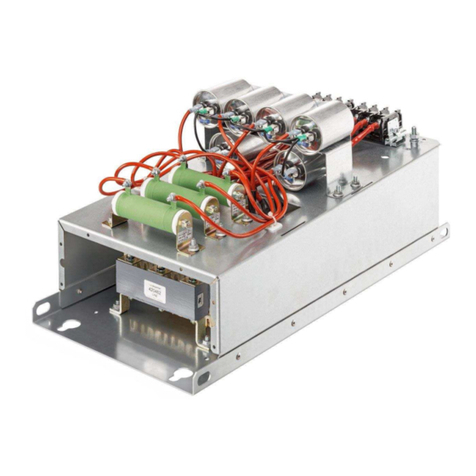

Schaffner Ecosine Flex Passive Harmonic Filters are configurable products which provide an

economical solution for current harmonics mitigation of 3-phase 6 pulse non-linear loads.

The two product lines, FN3446 and FN3458 are applicable for low voltage 50 Hz and 60 Hz systems

respectively and they are particularly suitable for AC and DC motor drives, battery chargers and other

power electronics applications with 6-pulse front-end rectifiers.

Ecosine Flex Passive Harmonic Filters are the most economical harmonic mitigation solution to reach

10% THDi and introduce the following aspects of novelty:

▪Ecosine Flex provides a ready to use solution for the most competitive projects. Ecosine

Flex Passive Harmonic Filters are designed for three-phase diode and thyristor rectifier. It allows

to reach performances below 10% THDi with drives equipped with ≥4% DC-Link choke (Ldc). It

can also be used with drives equipped with a DC-Link choke <4% or without DC-Link choke for

a performance below 15% THDi. The new generation Ecosine Flex Passive Harmonic Filters

targets the requirement of EN 61000-3-12 and IEEE-519 for Isc/IL <50 and other stringent in-

ternational power quality standards.

▪Most compact design, robust, reliable and ready to use.

▪The upgraded version of the Schaffner power quality simulator SchaffnerPQS3

(pqs.schaffner.com) provides the possibility to simulate Ecosine Flex Passive Harmonic Filters

within an electrical system. It furthermore offers quick and accurate performance checks.

This user manual is intended to support designers, installers, and application engineers with filter

selection, installation, application, and maintenance. It provides helpful solutions to overcome harmonics

mitigation challenges and answers frequently asked questions.

If you require additional support, please feel free to contact your local Schaffner representative.

ii. Performance Guarantee

By selecting and installing the appropriate ecosine evo passive harmonic filter in a variable frequency

AC drive application, variable speed drive application within our published technical specifications, we

guarantee that the input current distortion will be less than or equal to 15% THDi for standard Ecosine

Flex series filters at rated power when used with drive not equipped with EMI filter, and 10% THDi for

drives with ≥4% Ldc and no EMI filter. Ecosine Flex filters can also provide similar performance in other

drive applications such as, drive with EMI filter, constant torque, DC drives or other phase-controlled

rectifiers, e.g. SCR drives, but actual THDi levels can vary by load and/or speed and/or firing angle of

thyristors and therefore cannot be guaranteed. Consult your local Schaffner representative for

assistance when applying ecosine filters on these types of equipment.

iii. Minimum system requirements

The guaranteed performance levels of this filter will be achieved when the following system conditions

are met:

▪Type of load: Any 3-phase equipment with front-end six-pulse diode rectifier.

▪Type of source: 3-phase power line without neutral

▪Line impedance: <3% (calculated for the rated filter power)

▪Line frequency: 50 Hz ±1 Hz (FN3446), 60 Hz ±1 Hz (FN3458)

▪Line voltage: Nominal line voltage ±10%

▪Line voltage unbalance: <1%

▪Line voltage distortion: THVD <2%