Table of Contents

Overview.....................................................................................................................................................................6

Visual Overview......................................................................................................................................................6

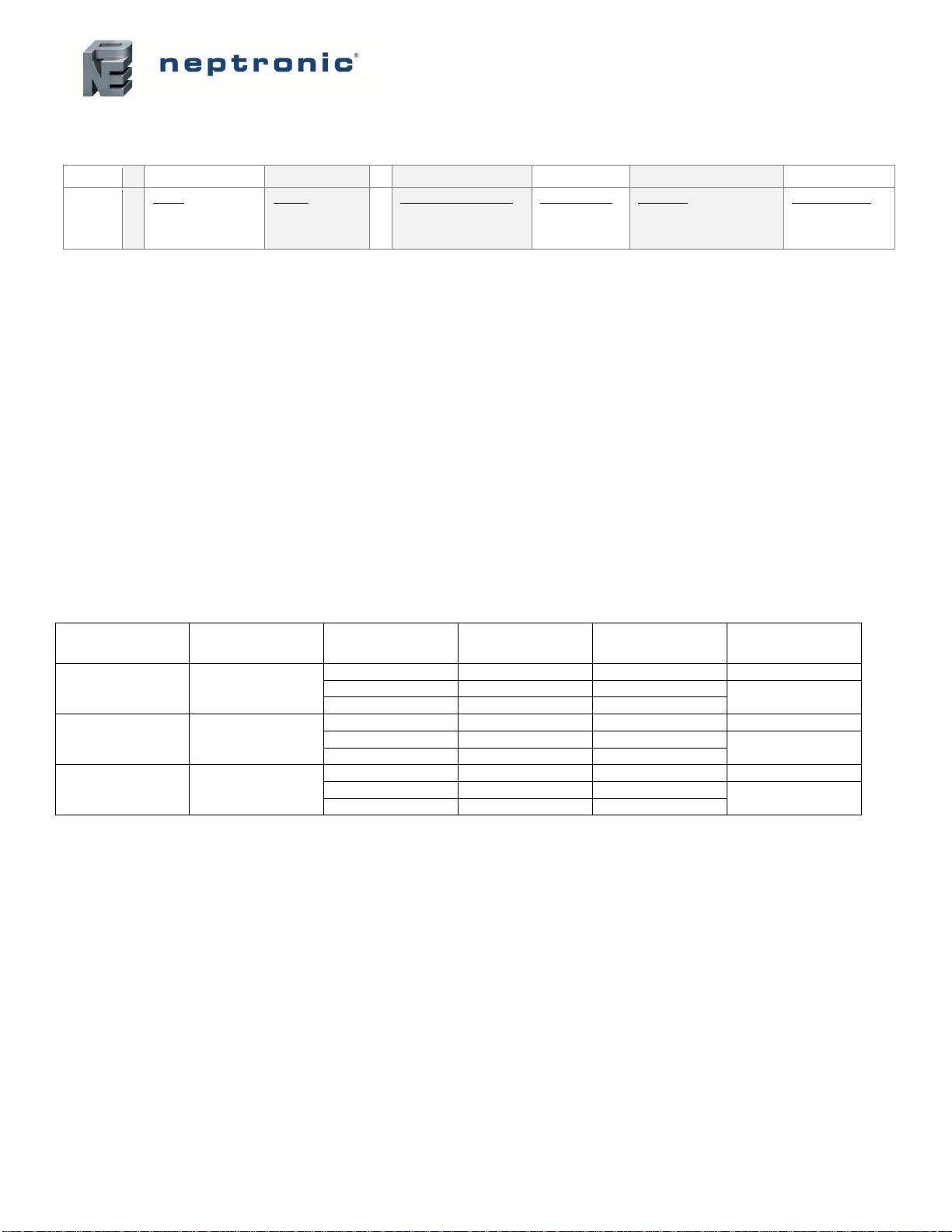

Nomenclature.........................................................................................................................................................7

Available Options....................................................................................................................................................7

Technical Specifications.........................................................................................................................................7

Output Specifications .............................................................................................................................................8

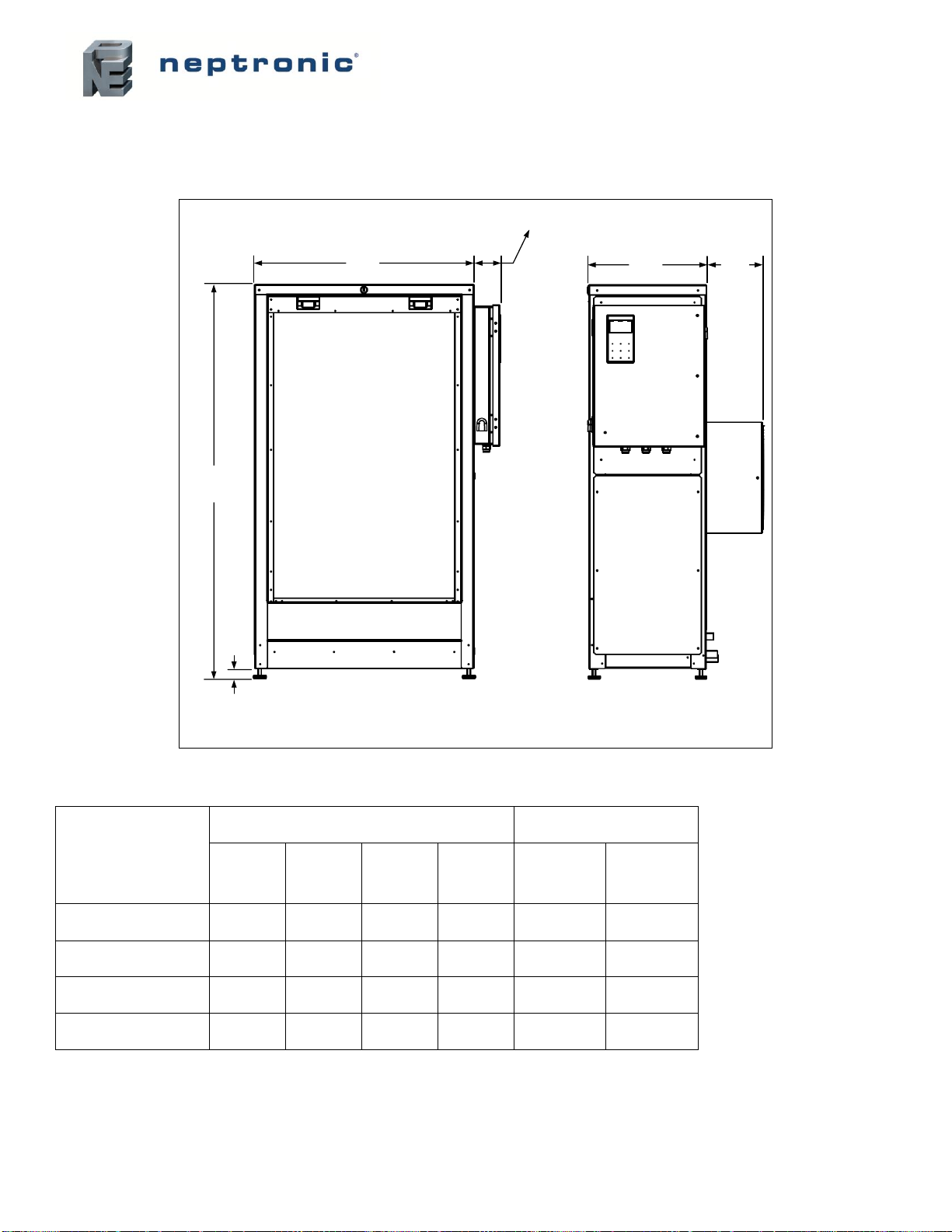

Dimensions and Weight .........................................................................................................................................9

Mechanical Installation.............................................................................................................................................11

General Recommendations..................................................................................................................................11

Floor Installation...................................................................................................................................................12

Ceiling Installation ................................................................................................................................................12

Air Filter Installation (Option)................................................................................................................................13

Plumbing Connections .............................................................................................................................................14

Water Quality Guide.............................................................................................................................................14

Reverse Osmosis Water ..................................................................................................................................14

Controlled Substances .....................................................................................................................................14

Water Monitoring..............................................................................................................................................14

Water Supply Installation......................................................................................................................................15

Water Drain Connections .....................................................................................................................................16

Electrical Connections..............................................................................................................................................17

Electrical Power Supply........................................................................................................................................17

Printed Circuit Board ............................................................................................................................................18

Safety Contacts................................................................................................................................................19

Dry Contacts.....................................................................................................................................................19

ON/OFF Control ...............................................................................................................................................20

Modulating Control ...........................................................................................................................................21

Network Communication ..................................................................................................................................23

HRL24 Control..................................................................................................................................................24

Controller Configuration ...........................................................................................................................................25

Controller Features...............................................................................................................................................25

Menu - General.................................................................................................................................................28

Menu - User Settings........................................................................................................................................31

Menu - Service .................................................................................................................................................33

Menu - Installation............................................................................................................................................34

Menu - Integration ............................................................................................................................................39

List of Alarms........................................................................................................................................................42

Start-up Procedure...................................................................................................................................................43

Servicing and Maintenance......................................................................................................................................45

Preventative Maintenance....................................................................................................................................45

Water Sampling and Testing (Hygiene) ...............................................................................................................46

Removing the Evaporative Media ........................................................................................................................47

Disinfection...........................................................................................................................................................48

De-scaling.............................................................................................................................................................49

Air Filter Maintenance ..........................................................................................................................................50

PCB Fuse Replacement.......................................................................................................................................51

Troubleshooting........................................................................................................................................................52