30308677 Issue 1.03

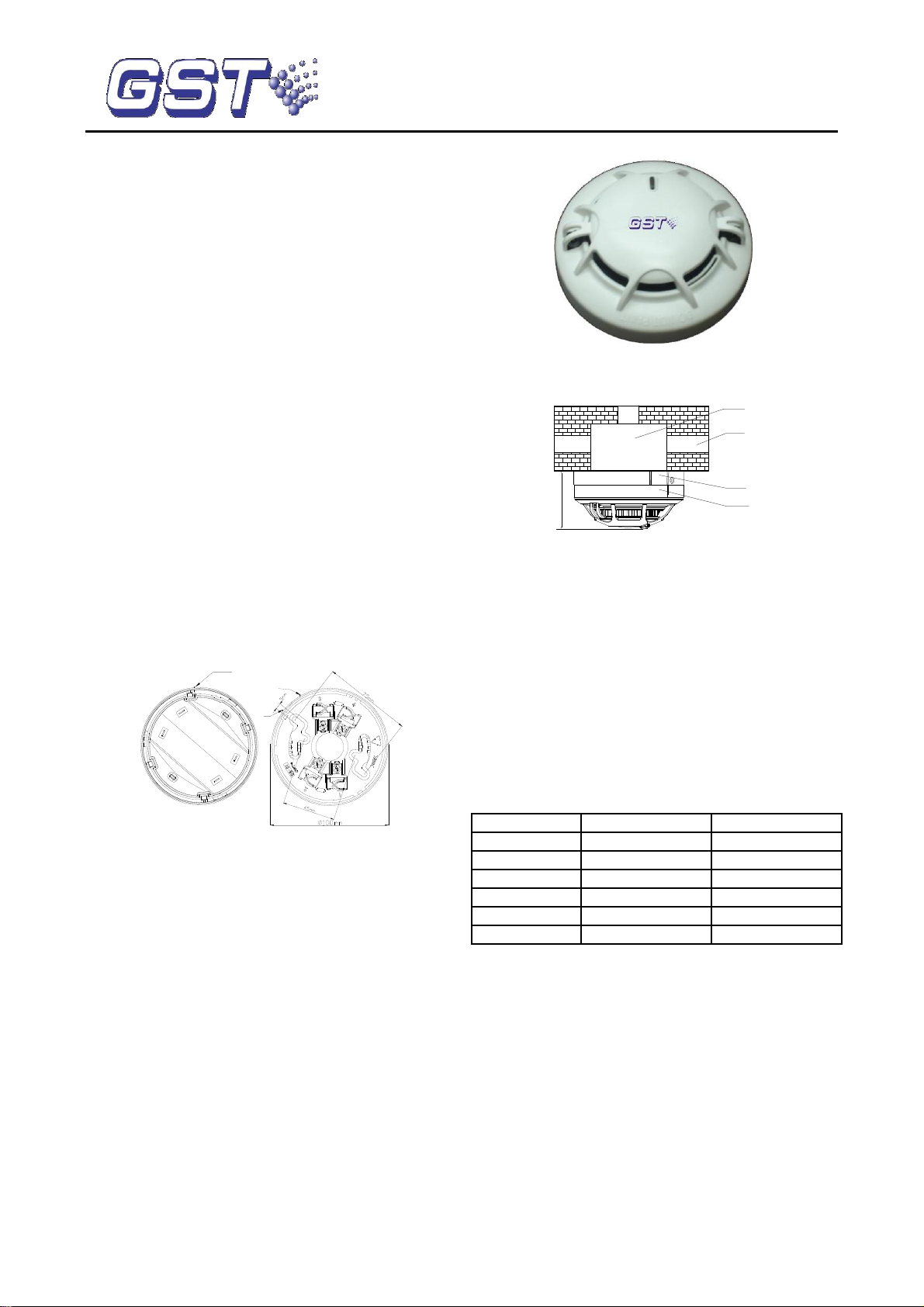

Fig. 4

b) Smoke test

Taking a smoldering cotton rope close to the

detector, blow the smoke into the detector until the

detector generates alarm.

c) Temperature test

Approach a heater (such as a hair drier) to the

thermistor of the detector until it alarms.

3) After testing, disconnect the power to the detector for

over 5 seconds to reset it. Notify the proper authorities

that the system is back to normal operation.

If a detector fails in testing, clean it by the steps in

Maintenance, and retest it. If it still fails, return it for

repair.

Maintenance

The detector should be installed just before

commissioning and kept well before installation,

taken corresponding measures for dust-proof,

damp-proof and corrosion-proof.

The dust-proof cover should not be removed until

the project is plunged into usage. Otherwise it may

not report alarm properly.

Clean the detectors regularly, at least once a year

to ensure normal operation of the system.

If unwanted alarms are often found of the detector

on site, the sensing chamber should be cleaned.

Power must be removed from the detector before

cleaning.

Steps for chamber cleaning:

a) Open the top cover of detector, and draw out

the sensing chamber by slightly lifting its two

sides using a straight screwdriver, as shown in

Fig. 5.

Fig. 5

b) Clean the internal of the chamber by alcohol

cotton swab with tweezers or using clean water

and brush. Make sure not to leave any fiber in

the chamber.

c) Put back the chamber and the top cover.

Before cleaning, notify the proper authorities that

the system is under maintenance and will

temporarily be out of service. Disable the automatic

controls relating to the zone or system under

maintenance to avoid unwanted actions.

The detector should be tested after re-installed to

ensure normal operation.

Fire simulation test should be done to the detector

at least every 6 months.

Specification

≤1.8mA(without remote indicator)

≤3.8mA(with remote indicator)

Red. Flashes in polling, and

illuminates in alarm

Directly connecting with indicator

Quiet in normal condition; flashes in

alarm.

Electronically programming

Non-polarized 2-core for loop.

Polarized 2-core for remote indicator.

Response Temperature:135℉

(57.2℃)

Response Velocity:15℉/min (8.3℃

/min)

Ingress Protection

Rating

Diameter: 100mm

Height: 54.5mm (with base)

Accessories and Tools

Limited Warranty

GST warrants that the product will be free of charge for

repairing or replacing from defects in design, materials

and workmanship during the warranty period. This

warranty does not cover any product that is found to have

been improperly installed or used in any way not in

accordance with the instructions supplied with the product.

Anybody, including the agents, distributors or employees,

is not in the position to amend the contents of this

warranty. Please contact your local distributor for products

not covered by this warranty.

This Data Sheet is subject to change without notice. Please contact GST for more information or questions.

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei, P. R. China 066004

Tel: +86 (0) 335 8502434 Fax: +86 (0) 335 8502532

service.gst@fs.utc.com www.gst.com.cn