TEKELEK Ultrasonic LoRaWAN User manual

1

9-5848-06

Ultrasonic LoRaWAN

Installation Guide

Thank you for purchasing the Ultrasonic LoRaWAN.

This sensor uses ultrasonic technology to measure the liquid level

of your tank and then sends the information over a LoRaWAN

network.

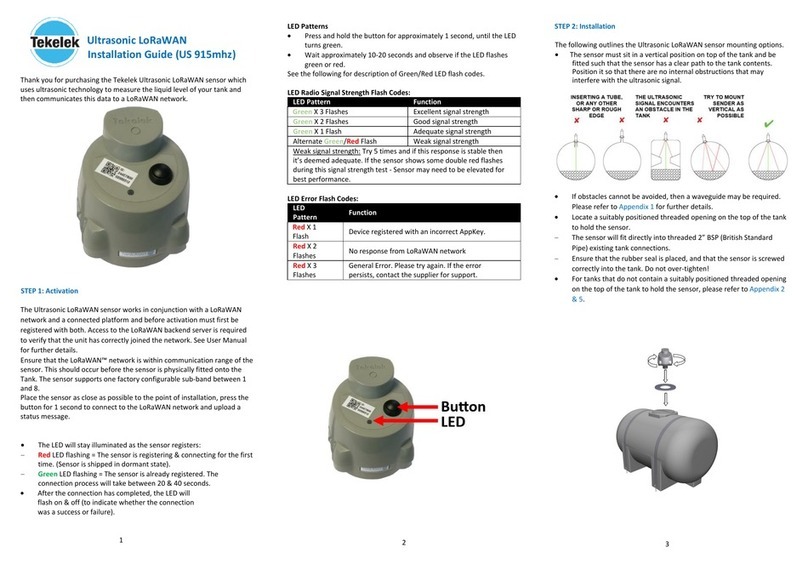

STEP 1: Activation:

Ensure that the LoRaWAN™ network is within communication

range of the sensor. This should occur before the sensor is

physically fitted onto the Tank. The external antenna version

needs the antenna to be connected prior to activation test.

a. Place sensor on or close to installation location.

b. Press the button for 1 second to connect to the

LoRaWAN network and upload a status

message.

c. The LED will stay illuminated as the sensor registers:

- The sensor is registering & connecting for the

first time. (Sensor is shipped in dormant state).

- The sensor is already registered.

The connection process will take

between 20 & 40 seconds.

d. After the connection has completed, the LED will

flash on & off (to indicate whether the connection

was a success or failure).

e. Please review the LED flash codes provided. In the

case of double red LED flashes an external

antenna may be a solution (especially for

underground tanks). Refer to step 4 for further

details.

STEP 2: Attaching the sensor to your tank:

a. Identify a spare threaded opening (typically 2”).

Remove and store the cap.

b. Ensure the opening is located away from the sides of

the tank and is clear of internal obstructions to

ensure a good ultrasonic reading. See Appendix for

further details.

c. Ensure the rubber seal (see diagram) is placed

between the opening and threaded adapter.

d. Screw the sensor clockwise into the threaded

opening.

Note: This sensor is not suitable for submersion in water.

NOTE: For the external antenna option self-amalgamating tape is

required to seal the external antenna (SMA) connections. See

Step 4.

DO NOT OVER-TIGHTEN THE SENSOR (Hand tight only).

Technical Specifications

Supports LoRaWan 1.0.2 compliant125 / 250KHz bands.

Operating frequency: 868MHz

Fits onto tanks with a 2” BSP threaded opening. 1 1/2” or

1 1/4” adapters are available.

Power output maximum 14dBm

Up to 14 years battery life using a 3.6v 2/3AA Li-SOCL2 cell

Operational temperature range –20 to +50° C

Dimensions 118mm x 90mm. Weight 250g

STEP 3: Manually testing the sensor:

Once the sensor has been installed successfully, it is

recommended to force a manual connection 4-5 times to test

the communications strength of the radio signal.

a. Press and hold the button for approximately 1

second, until the LED turns green.

b. Wait approximately 10-20 seconds and observe if the

LED flashes green or red.

c. Green flashes indicate a successful test connection

and data transmission.

d. Red flashes mean an unsuccessful connection.

See the following for description of Green/Red LED

flash codes.

LED Radio Signal Strength Flash Code

After a manual transmission is successfully completed, the

sensor LED will flash GREEN to indicate RF quality:

X 3 Flashes: Excellent signal strength quality (> -110dBm).

X 2 Flashes: Good signal strength quality (< -110 dBm & > -

115dBm).

X 1 Flash: Adequate signal strength quality (<-115dBm & > -

119dBm).

Alternate Flash: Weak RF signal: try 5 times and if this

response is stable then it’s deemed adequate. If the sensor

shows some double red flashes during this signal strength test -

then an external antenna should be tried. It may need to be

elevated for best performance.

LED Error Flash Code

If a manual activation fails to connect successfully, the red LED

will flash the following code:

X 1 Flash: LoRaWAN network Join Fail. The unit may not be

registered on the network. Contact supplier.

X 2 Flashes: No Response from LoRaWAN network. This

occurs if unit is not registered, no radio reception or response

timeout

X 3 Flashes: General error, please try again. If the error

persists then contact the supplier for support.

X 5 Flashes: Maximum number of allowed button presses

exceeded (up to 6 button presses per hour allowed).

= Red LED Flash

= Green LED Flash

2

9-5848-06

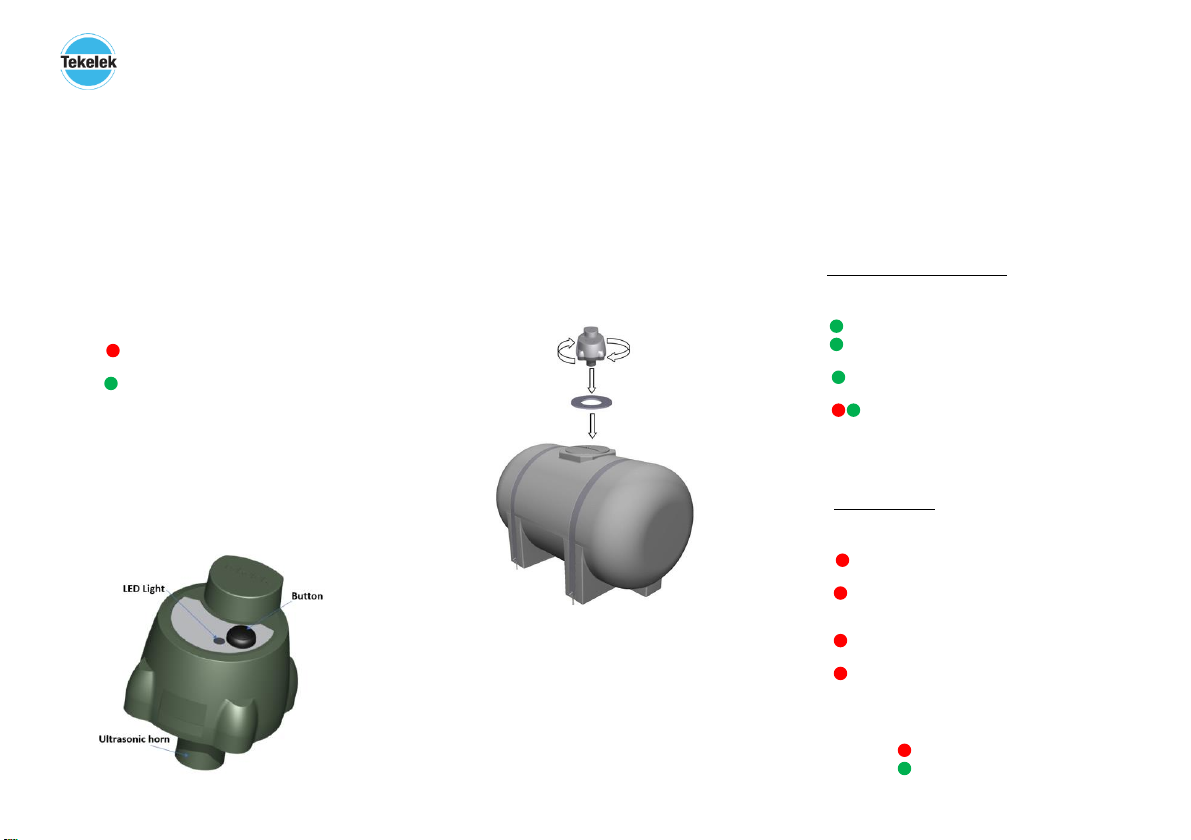

STEP 4: External antenna installation:

The external antenna should be elevated and clear of near

obstacles for best performance. The antenna should be mounted

on a magnetic surface (at least 15cm2 area) for best

performance. The antenna requires self-amalgamating tape to

seal the antenna cable joint - Note: This cable joint, while water

resistant, should not be submerged in water. The YouTube link

(page 4) shows the recommended application of the sealing tape.

Instructions and Link for sealing the SMA connector.

Video Link: https://www.youtube.com/watch?v=RG6XjjlGnEk

Sealing SMA Connection Instructions

1. Cut 300mm of ‘Tesa’ (provided) self-amalgamating tape.

2. After fitting in the required site location, connect the SMA

connector from the Antenna to that of the sensor.

3. Start wrapping the tape 70cm away from the SMA connection.

The tape needs to be kept in tension by stretching and the clear

plastic backing of the tape should be unwrapped as the

installation proceeds.

4. Keep the tape stretched while wrapping, over-lapping half the

width of the previous turn.

5. Continue to wrap the tape to a distance of 70cm on the other

side of the SMA connector. Then reverse the direction and

continue to wrap back along to the starting point. Note: the tape

must be stretched for best performance.

6. See the sensor with sealed SMA connections (see the following

picture).

Excess cable can be looped and tie-wrapped as shown.

7. The antenna should be placed on a magnetic surface (larger

than 15cm2 area for best performance).

8. A P-clip (highlighted in the picture below) is supplied to secure

the antenna cable and keep the sealed joint away from any

standing water.

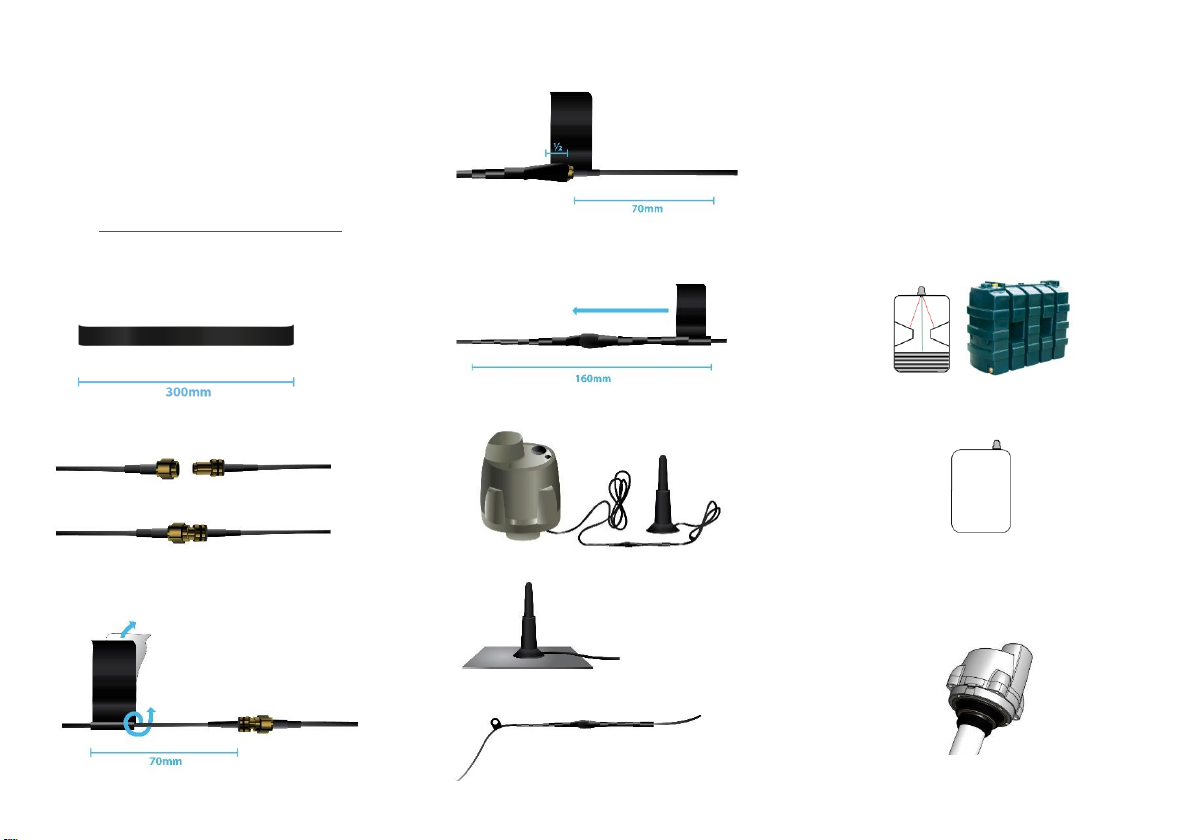

STEP 5: Waveguide installation:

The Ultrasonic LoRaWAN uses ultrasonic technology to

measure the liquid level of your tank. The ultrasonic

transducer requires a clear path with no obstacles in

order to function correctly.

In normal operation, the Tank sensor is directly attached to the

tank as outlined in STEP 2. The appendix at the end of this

document outlines the recommended ultrasonic clearance

path for optimum performance.

However, there are many tanks that have internal obstructions

such as pipes, baffles or structural bracing that can cause

reflections at different liquid levels (as shown in the following

graphics).

Additionally, some Tank installations have mounting points for

the Tank sensor that are close to the edge of the tank (as

shown in the following graphic). This will also present

difficulties for the ultrasonic signal detection.

The recommended solution for these use cases is the

installation of a waveguide around the horn of the tank sensor.

The waveguide is a tubular pipe that is connected to an

adapter on the Ultrasonic sensor and extends close to the floor

of the tank (it is cut to match the tank height). This pipe

constrains the ultrasonic signal to within the pipe and avoids

issues with signal reflections as outlined previously.

3

9-5848-06

The Ultrasonic LoRaWAN waveguide kit is supplied by Tekelek and

comprises of the accessories needed to connect a waveguide to

the ultrasonic sensor.

The below ‘exploded’ view shows the accessories and the

assembly method. The waveguide should be assembled as

follows:

Waveguide Assembly Instructions

1. Source a suitable pipe to act as the waveguide.

This pipe should conform the dimensions in the figure

below in order to fit the adapter.

The recommended pipe material is PVC (domestic

waste pipe is often used).

Other materials are possible but should checked for

chemical resistance to fuel oil.

2. The pipe should be cleanly cut to length. The length

required should be measured from the top of the tank

(where the sensor is to be mounted) to that of the fuel

outlet point (as shown).

Note: The bottom of the pipe should be a minimum of

5cm from the base (floor) of the tank to prevent it

from touching in the case of tank dimensional changes

due to temperature etc.

3. The waveguide pipe adapter comes attached to the

base adapter as shown in the graphic.

The pre-existing 2’’ adapter should be removed from

the sensor and replaced with the pipe adapter.

4. The adapter should be attached to the ultrasonic

sensor base with M3.5x10 Pozi screws x 4.

5. The waveguide pipe should be securely attached via

the two grub screws and hand tightened with an

M1.5 Allen key (Note: over-tightening the grub screws

can damage the plastic).

Care should be taken to keep the sensor and pipe

vertically aligned and supported, while fitting during

the installation.

Note: Depending on the weight, length and surface

finish of the pipe, it may be necessary to glue it into

position. In this case a hole should be drilled near the

top of the waveguide pipe, just below the adapter, to

ensure that any trapped air can exit.

6. Insert the correctly sized rubber seal ring, as

required for the tank opening (supplied), and

position it on the face of the adapter that is

screwed onto the top of the tank.

7. Insert the whole assembly carefully into the tank,

taking care not to loosen the pipe, and fit into

position. Hand tighten the assembly until the

rubber seal locks into position.

8. The use of a waveguide requires that the Ultrasonic

LoRaWAN sensor be configured with a waveguide

ultrasonic profile from the LoRaWAN server.

Note: the default sensor configuration is non-

waveguide mode and the measurements will be

inaccurate unless a waveguide configuration mode is

used.

Note: The use of this Waveguide option is limited to a

range of 3m and not 4m as per standard operation.

4

9-5848-06

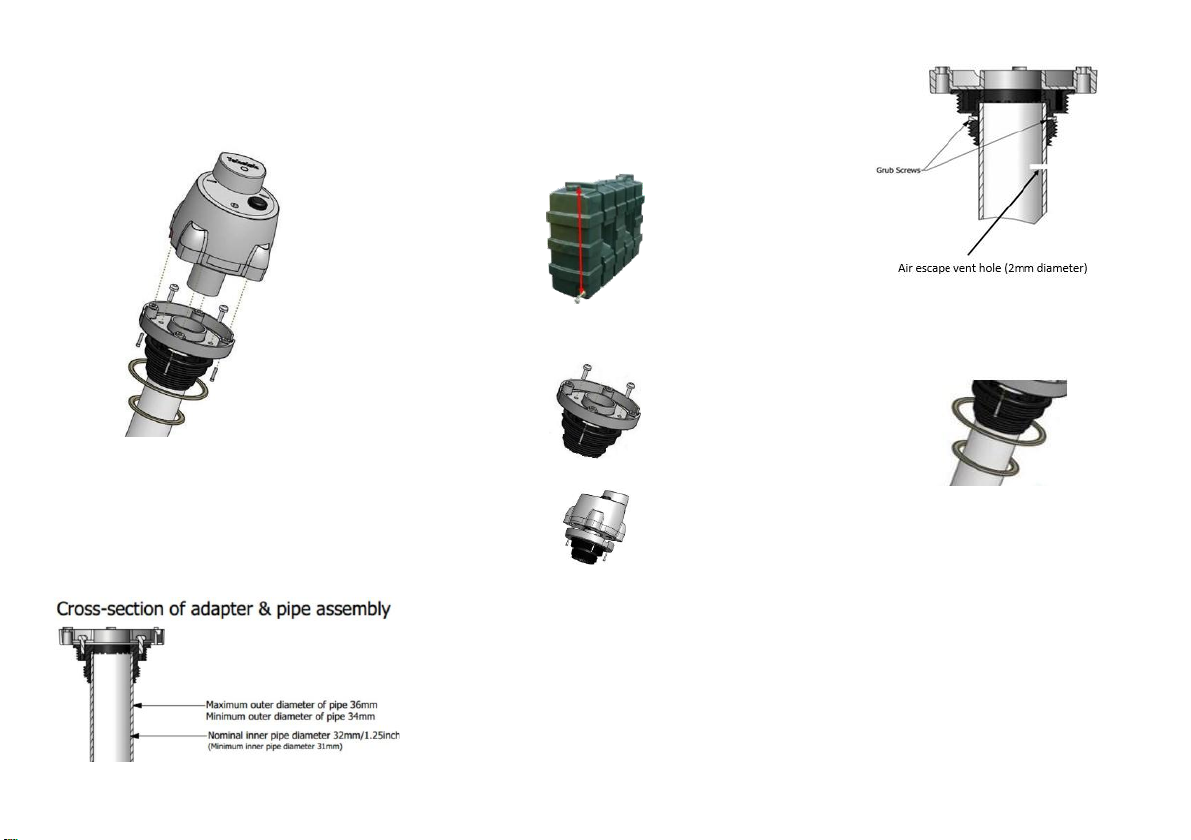

APPENDIX:

Ultrasonic device path clearance requirements

Avoid obstacles in the area outlined by the conical shape.

The table details the required clearance range as the ultrasonic signal

diverges.

Height

(CMs)

Width (CMs)

Ultrasonic signal from transducer clearance

area

10

5.36

20

10.72

30

16.08

w=0.53 x h

40

21.44

50

26.79

60

32.15

70

37.51

80

42.87

90

48.23

100

53.59

110

58.95

120

64.31

130

69.67

Examples where caution regarding the

installation should be observed

140

75.03

150

80.38

160

85.74

170

91.10

180

96.46

190

101.82

200

107.18

210

112.54

220

117.90

230

123.26

240

128.62

250

133.97

260

139.33

Find a position which

respects the ultrasonic

signal –avoid internal

structures such as pipes,

baffles, bracing structures

etc.

Do not install

too close to the

edge.

270

144.69

280

150.05

290

155.41

300

160.77

Note: In the above, a sensor should be installed at least 0.5w from the inner

wall of a tank

For example, a 2m height tank would require 0.53m clearance from the

sidewalls of the tank for best performance.

w

h

Other TEKELEK Accessories manuals