Neptune Technology TRICON SmartTrol Product manual

TRICON®SmartTrol™

Installation and Maintenance Guide

TRICON®SmartTrol™

Installation and Maintenance Guide

Copyright

This manual is an unpublished work and contains the trade secrets and confidential

information of Neptune Technology Group Inc., which are not to be divulged to third parties

and may not be reproduced or transmitted in whole or part, in any form or by any means,

electronic or mechanical, for any purpose, without the express written permission of

Neptune Technology Group Inc. All rights to designs or inventions disclosed herein, including

the right to manufacture, are reserved to Neptune Technology Group Inc.

Neptune engages in ongoing research and development to improve and enhance its products.

Therefore, Neptune reserves the right to change product or system specifications without

notice.

Trademarks used in this manual

Neptune and TRICON are registered trademarks of Neptune Technology Group Inc. SmartTrol

is a trademark of Neptune Technology Group Inc. Other brands or product names are the

trademarks or registered trademarks of their respective holders.

TRICON®SmartTrol™

Installation and Maintenance Guide

Literature No. IMSmartTrol 09.2021

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

Tel: (800) 633-8754

Fax: (334) 283-7293

Copyright © 2013 - 2021

Neptune Technology Group Inc.

All Rights Reserved

Contents

Chapter 1: Introduction 1

Chapter 2: Typical Application 3

Chapter 3: Operating the SmartTrol™ 5

Display Total 5

Display Grand Total 5

Display Rate 6

Setup the SmartTrol™ 6

Chapter 4: General Description and Principles of Operation 7

Display 7

Resets 7

Presets 7

Relays 8

K Factor 8

Ratemeter 8

Counter 8

Lockout 8

RS-232C Communications 9

4-20 mA Output 9

Entering Decimal Points 9

Chapter 5: Specifications 11

Chapter 6: Mounting and Installation 13

Panel Mounting 13

Chapter 7: Connections to the SmartTrol™ 15

Power Connection For Alternating Current (AC) 15

Power Connection for Direct Current (DC) 15

Relay Output Connection 15

4-20 mA Option 15

Schematics 15

Chapter 8: Programming Worksheet 23

Chapter 9: Using the Worksheet 25

Counter 25

K Factor A and K Factor B (Counter) 25

TRICON®SmartTrol™Installation and Maintenance Guide iii

Fractional Units of Volume 25

Changing Units of Volume 26

Datalost 26

Reset to Zero or Set to Preset 26

Automatic or Manual Reset 26

Decimal Location 27

Ratemeter 27

K Factor A and K Factor B (Rate) 27

Changing Units of Times 28

Changing Units of Volume 28

Weight 28

Window 28

Significant Figures 29

Lock Out 29

OutPut Card 29

Unit Number 29

Serial or Parallel 29

Baud Rate 30

Parity 30

Analog Output 30

Relay Operation 30

Presets 31

Chapter 10: Setting Up the SmartTrol™ 33

Setting Up the Counter 33

Setting Up the Ratemeter 34

Setting Up the Lock Out Code 34

Setting Up the OUTCARD for RS-232 Communications 35

Setting Up the 4-20 mA OUTPUT 36

Setting Up the Relay Operation 36

Setting Up Preset A 37

Setting Up Preset B 37

Chapter 11: RS-232C Serial Communication Operations 39

PINAssignments 39

Command Code Definitions 40

iv TRICON®SmartTrol™Installation and Maintenance Guide

Contents

TRICON®SmartTrol™Installation and Maintenance Guide v

Example: Unit Number 1 41

Chapter 12: Warranty 43

Chapter 13: Assistance 45

By Phone 45

By Email 45

Appendix A: Specifications 47

47

48

49

50

50

51

51

52

52

TRICON/E® Performance Data

Trident® Turbine Performance Data

HP Turbine Performance Data

DISC Elements in Compound Meters

TRU/FLO® Compound Meter (Turbine Side)

Trident® PROTECTUS® (Turbine Side)

HP TRU/FLO® Compound Meter (Turbine Side)

HP PROTECTUS® III (Turbine Side)

TRU/MAG™ High Frequency Output / K Factor

TRU/MAG™ Pulse Rates 53

55

63

63

Appendix

B:

Communications

Program

Appendix

C:

TRICON®/S

Performance Data

Appendix

D:

Register

Tracking

65

Making the Total Agree with the Register 65

Overview of the Procedures 65

Preparing the SmartTrol™ to Accept the Current Register Reading 65

Enter the Current Register Reading 66

Setting the SmartTrol™ to Increment Total Keeping Pace with the Meter Register 66

Glossary 69

Index 73

Contents

This page intentionally left blank.

vi TRICON®SmartTrol™Installation and Maintenance Guide

Contents

Figures

1

3

13

16

16

17

18

19

20

21

Figure 1 – TRICON® SmartTrol™

Figure 2 – SmartTrol™ to Power Single TRICON/E® Transmitter

Figure 3 – SmartTrol™ Dimensions

Figure 4 – SmartTrol™ and Single TRICON/E® Transmitter (Pulse Output and Remote Reset)

Figure 5 – SmartTrol™ and Two TRICON/E® Transmitters (Pulse Output and Remote Reset)

Figure 6 – SmartTrol™ and 4-20 mA TRICON/E® and SmartChart

Figure 7 – SmartTrol™ with 4-20 mA Output Option and SmartChart and Single TRICON/E®

Transmitter with Pulse Output

Figure 8 – SmartTrol™ Powered by +24 VDC, Relays Controlling +24 VDC, and Single TRICON/E®

Transmitter with Pulse Output

Figure 9 – SmartTrol™ and Single TRICON®/S Transmitter (Pulse Output and Remote Reset)

Figure 10 – SmartTrol™ with 4-20 mA Output Option and Remote Device and Battery-Powered

TRU/MAG™

Figure 11 – SmartTrol™ with 4-20 mA Output Option and Remote Device and DC-Powered

TRU/MAG™ 22

TRICON®SmartTrol™Installation and Maintenance Guide vii

This page intentionally left blank.

viii TRICON®SmartTrol™Installation and Maintenance Guide

Figures

Tables

5

5

6

6

6

11

23

33

34

34

35

36

36

37

37

39

40

41

47

48

48

49

50

50

51

51

52

52

53

Table 1 – Display Total

Table 2 – Display Grand Total

Table 3 – Return to Total

Table 4 – Display Rate

Table 5 – Return to Total

Table 6 – Specifications

Table 7 – Example Programming Worksheet

Table 8 – Setting Up the Counter

Table 9 – Setting Up the Ratemeter

Table 10 – Setting Up the Lock Out Code

Table 11 – Setting Up the OUTCARD for RS-232 Communications

Table 12 – Setting Up the 4-20 mA OUTPUT

Table 13 – Setting Up the Relay Operation

Table 14 – Setting Up Preset A

Table 15 – Setting Up Preset B

Table 16 – Pin Assignments

Table 17 – Command Code Definitions

Table 18 – Example: Unit Number 1

Table 19 – TRICON/E® Performance Data (T-10)

Table 20 – TRICON/E® Performance Data (T-8)

Table 21 – Trident® Turbine Performance Data

Table 22 – HP Turbine Performance Data

Table 23 – DISC Elements in Compound Meters

Table 24 – TRU/FLO® Compound Meter (Turbine Side)

Table 25 – Trident® PROTECTUS (Turbine Side)

Table 26 – HP TRU/FLO® Compound Meter (Turbine Side)

Table 27 – HP PROTECTUS® III (Turbine Side)

Table 28 – TRU/MAG™ High Frequency Output / K Factor

Table 29 – TRU/MAG™ Pulse Rates

Table 30 – TRICON®/S Performance Data 63

TRICON®SmartTrol™Installation and Maintenance Guide ix

TRICON®SmartTrol™Installation and Maintenance Guide 1

Chapter 1: Introduction

The Neptune®SmartTrol™ is a versatile microprocessor-based controller for use with

TRICON/E®electronic registers. The main functions of the unit are to:

lDisplay rate and totalization values.

lControl relays for batching or alarming.

The SmartTrol allows two meter flows to be measured, separately scaled for both rate and

total, then combined into one overall rate and total. This dual input capability permits the

SmartTrol to be used with TRU/FLO®and PROTECTUS®meters having two separate

measuring elements to monitor flow.

Figure 1 – TRICON®SmartTrol™

This page intentionally left blank.

Chapter 1: Introduction

2TRICON®SmartTrol™Installation and Maintenance Guide

TRICON®SmartTrol™Installation and Maintenance Guide 3

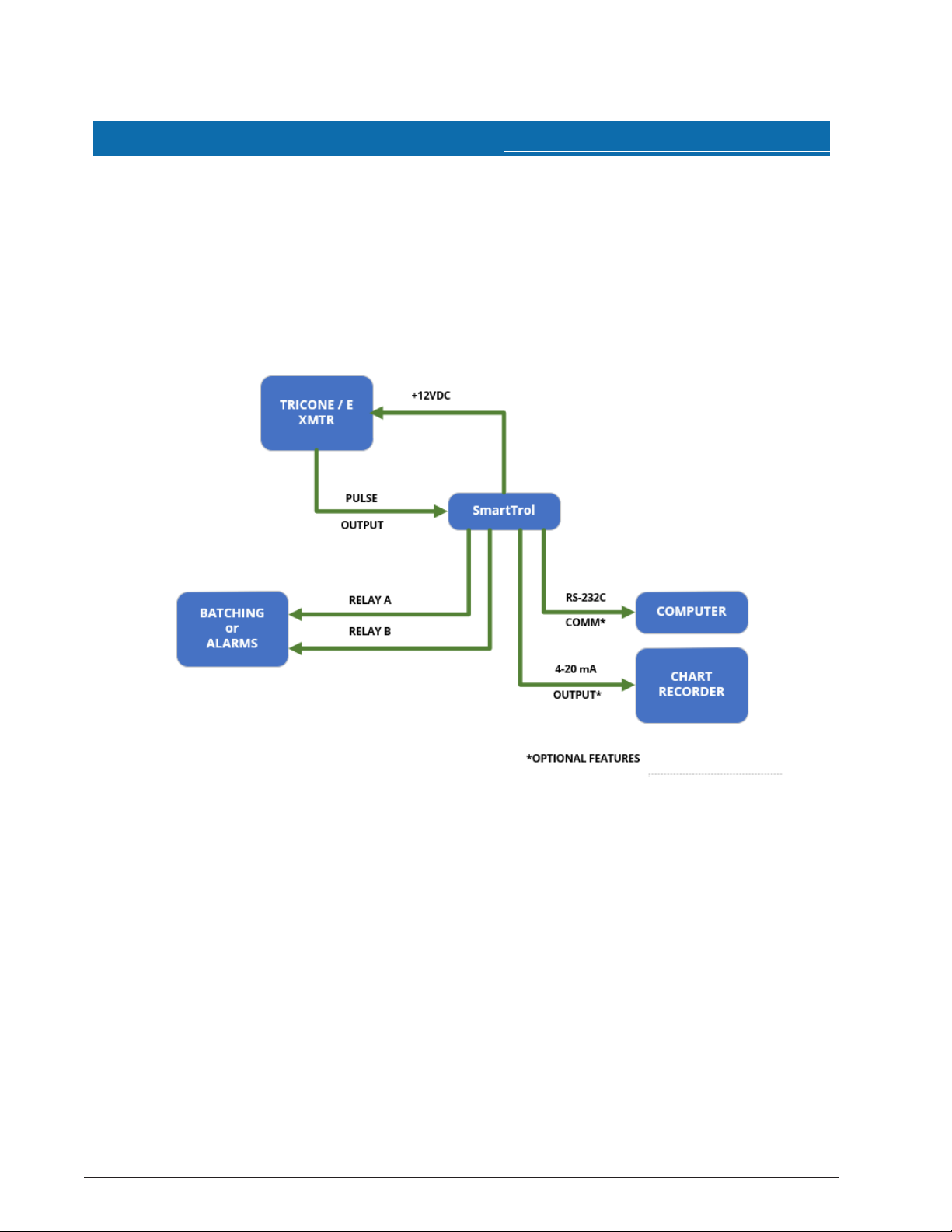

Chapter 2: Typical Application

In the following illustration, the SmartTrol™ powers a single TRICON/E®transmitter that

provides digital pulses to the SmartTrol. The SmartTrol scales the pulse input to determine

rate of flow and total quantity through the meter. The SmartTrol uses the rate of flow or

total values to operate two relays. The relays are used for single or two-stage batching, or

under / over alarming. You can order the SmartTrol with optional RS-232C serial

communications, or 4-20 mA analog output, or both.

Figure 2 – SmartTrol™ to Power Single TRICON/E®Transmitter

This page intentionally left blank.

Chapter 2: Typical Application

4TRICON®SmartTrol™Installation and Maintenance Guide

TRICON®SmartTrol™Installation and Maintenance Guide 5

Chapter 3: Operating the SmartTrol™

When you power on the SmartTrol™, it is in the normal operating mode. You can view

Total, Grand Total, and Rate.

To view Total, Grand Total, or Rate, apply power to one of the following displays.

Display Total

When you power on the SmartTrol, the current value of Total is displayed as indicated.

Until you select another variable, Total remains on the display. Total represents the volume

of liquid through the meter since Total was last reset. The value of Total is preserved when

you remove power from the SmartTrol and is restored when you reapply power.

Total is updated only while power is applied.

Display Description

Apply Power VER #. # Displayed 1 second.

N/A ######## Current value of Total.

Table 1 – Display Total

Display Grand Total

Grand Total represents the volume of liquid passing through the meter since Grand Total

was last reset. Like the value of Total, Grand Total is preserved when you remove power

from the SmartTrol, and is restored when you reapply power. Grand Total is updated only

while power is applied.

Press the key indicated in the table to display the Grand Total.

Press Display Description

ENT GRTOTAL Displayed 1 second.

N/A ######## Current value of Grand Total

blinks.

Table 2 – Display Grand Total

Press the key indicated in the table to return to the Total.

Press Display Description

ENT ######## Current value of Total.

Table 3 – Return to Total

Display Rate

When Rate is displayed, the first character position on the display is “R”. Rate represents

the volume of liquid passing through the meter in a unit of time (for example: gallons per

minute).

Press the key indicated in the table to display the Rate.

Press Display Description

C(Rate / Total) R ###### Current value of Rate.

Table 4 – Display Rate

Press the key indicated in the table to return to the Total.

Press Display Description

C(Rate / Total) ######## Current value of Total.

Table 5 – Return to Total

Setup the SmartTrol™

Before using the SmartTrol, you must program several setup values from the Setup Menu.

Fill out the Worksheet on Page 23 using the instructions beginning on Page 25.

Instructions for setting up the SmartTrol begin on Page 33. To enter the Menu from the

normal operating mode, press the “D” (MENU) key.

6 TRICON®SmartTrol™ Installation and Maintenance Guide

Chapter 3: Operating the SmartTrol™

TRICON®SmartTrol™Installation and Maintenance Guide 7

Chapter 4: General Description and Principles of Operation

This chapter provides a general description and the operating principles of the

TRICON®SmartTrol™.

Display

The SmartTrol shows one of three different variables on its eight-digit, alphanumeric

displays:

lTotal - the volume through the meter in gallons, cubic feet, or cubic meter units.

lGrand Total - similar to Total but continues to count when Total is reset.

lRate - the volume flowing through the meter per unit of time.

Since Rate and Total values are scaled independently, different units can be used for each.

For example: Rate displayed in gallons / minutes and Total in cubic feet.

Resets

A Reset returns the value of a Total or Grand Total to a predetermined point to begin

counting up to or counting down from. To Reset the Total or Grand Total, complete one of

the following:

lManually enter the value through the keypad and press the “CLR” key.

lRemotely enter the value by applying 3 to 30 VDC pulses for a minimum of 5 seconds to

Pin 5.

lUse a host computer via RS-232C communications.

The SmartTrol can be programmed to reset automatically when it reaches the endpoint.

Presets

Presets are the values of Total or Grand Total the totalizer must reach, or the Rate of flow

the ratemeter must register, to trigger relay operation. Total is configured to count up

from zero after a reset, or to count down from the preset value to zero after reset. Grand

Total only counts up from zero to the preset value after a reset.

Relays

The SmartTrol is used for monitoring or for control purposes, such as batching. There are

two control relays in the SmartTrol whose operations are based on preset values of Rate,

Total, or Grand Total. Each relay may be programmed to its own preset value. The presets

can be programmed to allow two-stage stepping of a process providing precise control of

a dispensing or blending application. For batching applications, an Auto Reset mode can

be selected for continuous blending processes. When Total or Grand Total values are

used, relay duration may be set from 1 to 99 seconds or minutes.

Relay operation is disabled when you enter the MENU function.

K Factor

The K Factor is divided into the input pulse to convert them into convenient units of

measurement. Separate K Factors are entered into the rate and counter sections of the

SmartTrol for each input, and K Factors may be mixed. Thus, you may batch (totalize) in

gallons and display Rate in cubic feet per hour.

Ratemeter

The ratemeter selection of the SmartTrol calculates Rate based on time between pulses

from a maximum of two inputs. The resulting value of input pulses per second is then

divided by the K Factor to display the Rate in units of volume per time.

Counter

The counter section of the SmartTrol divides pulses from a maximum of two inputs by the

Count K Factors to determine Total and Grand Total volumes through the meter in

convenient units of volume.

Lockout

After the SmartTrol is configured and operating, unauthorized changes can be prevented

by using a lock-out code to allow configuration modification. You can modify the code

periodically to maintain secure operations.

8 TRICON®SmartTrol™ Installation and Maintenance Guide

Chapter 4: General Description and Principles of Operation

Other manuals for TRICON SmartTrol

1

Table of contents

Other Neptune Technology Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

MFJ Enterprises

MFJ Enterprises MFJ-249D instruction manual

ABB

ABB FieldIT AquaMaster Quick reference guide

Abaxis

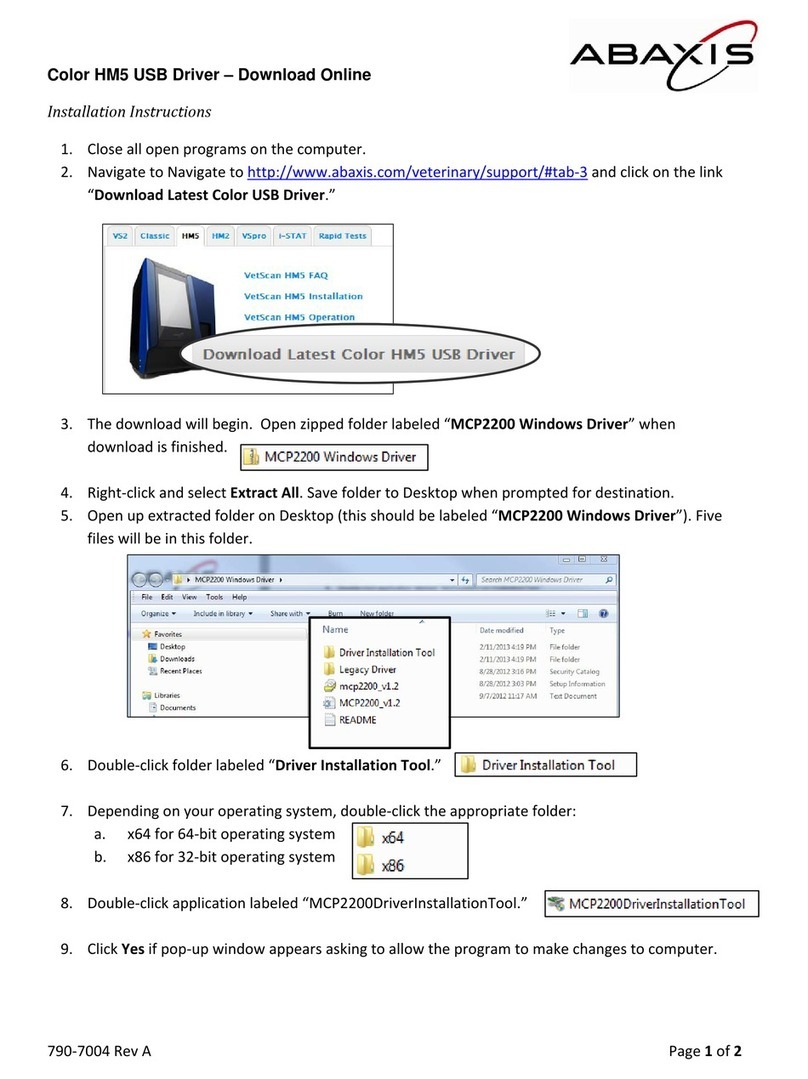

Abaxis VetScan HM5 installation instructions

Honeywell

Honeywell VERSAFLOW SONIC 1000/TWS 9000 Handbook

PCE Instruments

PCE Instruments PCE-360-ICA instruction manual

Bosch

Bosch GAM220MF Professional Original instructions