Net Media RoHS Series User manual

NetMedia RoHS Serial LCD Module v1.1

Table of Contents:

Pinout.................................................................................................................................. 2

Connections......................................................................................................................... 2

Jumper Settings................................................................................................................... 3

Contrast Adjustment ........................................................................................................... 3

Interfacing........................................................................................................................... 4

LCD Control Codes ............................................................................................................ 5

Creating Custom Characters............................................................................................... 7

Complete BasicX-24 Example Program............................................................................. 8

2x16 Specifications............................................................................................................. 9

4x20 Specifications............................................................................................................. 9

2x16 Current Specs............................................................................................................. 9

4x20 Current Specs............................................................................................................. 9

Optional Bezel Dimensions .............................................................................................. 10

Dimensions ....................................................................................................................... 11

Warranty

NetMedia, Inc. warrants this product against defects in materials and workmanship for a period of 90 days

from purchase date. Repaired/replaced products will be returned via standard shipping. Expedited return

shipping is available at customer’s expense. Any product that has been abused, modified or had its polarity

reversed is not covered under warranty. Our technicians check all returns. Items damaged by customer

abuse/misuse will not be warranted and will only be returned at the customer’s request and expense.

Extended warranties are available for large volume OEM customers. Please contact a

NetMedia sales representative for more information.

Pinout

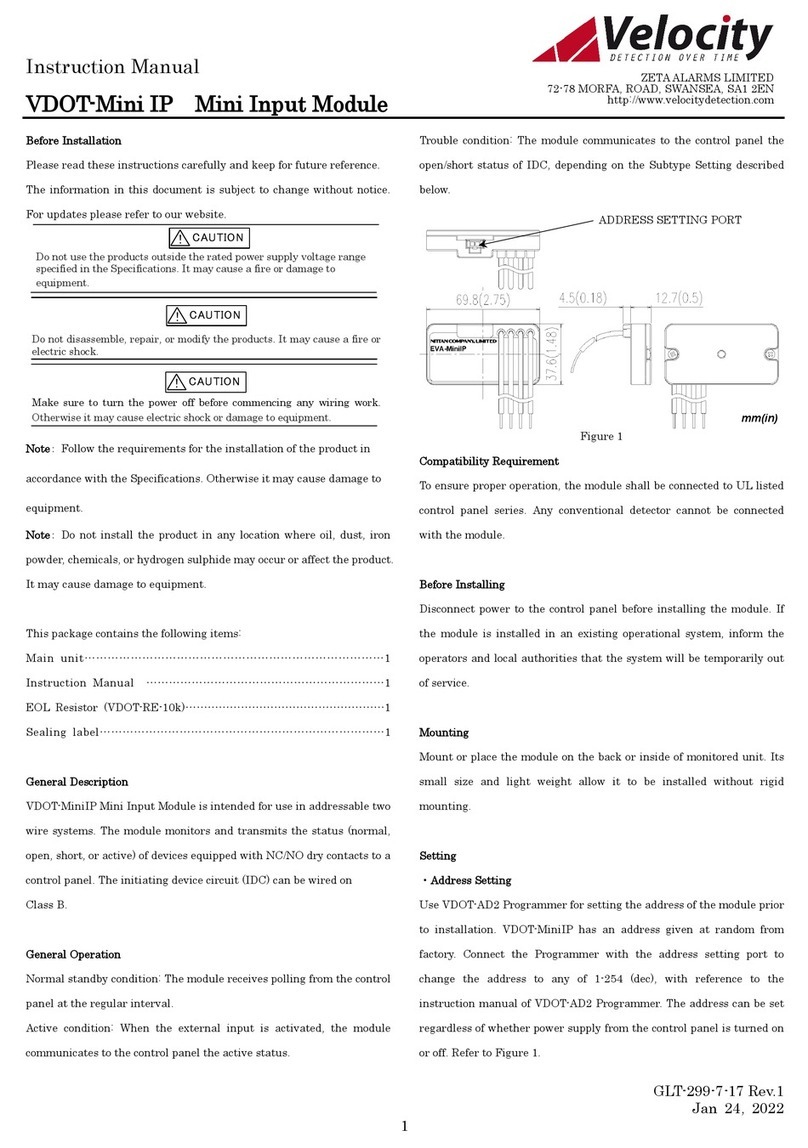

All power and communications connections are made via header JP2. Connection JP1 connects the serial module to the

LCD header. JP3 contains additional power connectors and user TTL outputs 0 & 1.

Figure1

Connections

JP1 Pins 1 - 8 Description JP1 Pins 9 -16 Description

Pin1 Ground Pin9 D2 (Not Used)

Pin2 VCC (+5) Pin10 D3 (Not Used)

Pin3 Contrast Pin11 D4

Pin4 Data/Command (R/S) Pin12 D5

Pin5 Read/Write (W) Pin13 D6

Pin6 Enable (E1) Pin14 D7

Pin7 D0 (Not Used) Pin15 VCC (LEDSV+)

Pin8 D1 (Not Used) Pin16 Ground

JP2 Pins Description Notes

GND Power Ground Reversing Polarity voids warranty!

+5 Power + 5 supply Tie to +5vdc 15mA+ supply

RX Serial Input RS232 or logic level (if used leave RX* disconnected)

RX* Serial Input (Inverted) RS232 or logic level (if used leave RX disconnected)

LED+ Backlight Power Tie to 5-14vdc 100mA+ supply

JP3 Pins Description Notes

1 User Output Pin 0

2 User Output Pin 1

3 Power +5 Supply Ties to +5 pin on JP2

4 Power Ground Ties to GND pin on JP2

5 Factory Program Pin DO NOT USE!

2

Jumper Settings

Jumper connections J1 and J2 are used to set the modules baud rate and display type, J3 sets the backlight current.

Note: Always disconnect power before changing jumper positions!

Jumpers J1, J2 & J3 Description

J1 J1 Not Soldered = 9600 Baud, Soldered = 2400 Baud

J2 J2 Not Soldered = 2x16, Soldered = 4x20

J3 Backlight current, Not soldered = 2x16, Soldered = 4x20

Contrast Adjustment

When purchased with an attached LCD the contrast is preset at the factory and should not need any major adjustment.

The LCD contrast is adjusted using the potentiometer shown in Figure1 (Marked Contrast Pot ). All adjustments must

be made using a plastic potentiometer adjustment tool! Anything else may damage the potentiometer and void your

warranty.

3

Interfacing

The following diagrams show two common methods for interfacing the 2x16 LCD.

Connection LEDSV+ is 5-14vdc.

Note: Never connect LED+ to +5 on the BX-24! The BX-24 +5 regulator cannot

supply enough current to power the LCD backlight and will overheat.

4

LCD Control Codes

Description Keyboard Code ASCII or Decimal value

Display custom character 0-7 Ctrl-@ -Through- Ctrl-G 0 - 7

Back Space Ctrl-H 8

Horizontal Tab Ctrl-I 9

New Line Ctrl-J 10

Vertical Tab Ctrl-K 11

Form Feed (Clear Screen) Ctrl-L 12

Carriage Return Ctrl-M 13

Reset Controller Ctrl-N 14

Set Geometry Ctrl-O 15

Set Tab Size Ctrl-P 16

Set Cursor Position Ctrl-Q 17

Set Custom Character *New Command* Ctrl-R 18

Set Contrast Ctrl-S 19

Set Backlight Ctrl-T 20

Command Escape Ctrl-U 21

Data Escape Ctrl-V 22

Raw Data Escape Ctrl-W 23

Toggle TTL Outputs Ctrl-X 24

Display an ASCII Character None 25 - 255

Back Space Ctrl-H

Causes the cursor to move back once space. The cursor will wrap from the first column of a line to the last column of a

previous line. Sending backspace when at the home position causes the cursor to wrap to the last character position of

the last line.

Horizontal Tab Ctrl-I

Causes the cursor to move forward to the next tab position. If the cursor is near the end of the line and no more tab

positions are on the line, then the cursor will advance to the next line. The LCD Controller is initial set up with tab

positions at every 4’th column. To set the tab position at a different column use the “Set Tab Size” command.

New Line Ctrl-J

Causes the cursor to advance to column 1 of the next line. If the cursor is on the last line, it will wrap to the home

position.

Vertical Tab Ctrl-K

Causes the cursor to advance to the next line, but stay on the same column. If the cursor is on the last line of the screen,

it will wrap to the first line of the screen.

Form Feed Ctrl-L

Causes the screen to be cleared and the cursor positioned to the home position. The form feed command takes some

time to complete. It may take up to 2ms to complete. Since the LCD Controller has a finite amount of internal buffer

space (16 bytes) for storing commands and data before sending to the LCD, you may overrun the internal buffer when

sending multiple form feed commands in succession followed by other data.

5

Carriage Return Ctrl-M

Causes the cursor to go to column 1 of the current line

Reset Controller Ctrl-N

Resets the LCD controller as if it had been just power on. This command will also cause the hardware jumpers to be

reread, so you can use it if you want to change baud rate or display size. This command takes about 1 second to

complete.

Set Geometry Ctrl-O

Defines the layout (or geometry of the LCD). Only use this command for displays other than standard 2x16 or 4x20,

these displays are selected via jumper pad J2. You need to send 5 additional bytes after sending a “Set Geometry”

command.

15+ Number of columns+Line1 starting address+Line2 starting address+Line3 starting address+Lline4 starting

address

Example:

15,20,128,192,148,212 Standard 20 column by 4 line display

15,16,128,192,148,212 Standard 16 column by 4 line display

15,16,128,192,128,128 Standard 16 column by 2 line display

If the display is less than 4 lines then you still need to send the line 1 starting address for the unused starting addresses.

Set Tab Size Ctrl-P

Sets the size of a tab. You need to send a byte that is the negative of the tab size. The default tab size is 4. The tab size

should be a power of 2 (i.e. 0, 1, 2, 4, 8, 16)

Set Cursor Position Ctrl-Q

Sets the cursor position. The following 2 bytes specify the zero based row and column of the cursor position. The bytes

need to be within the display range. Sending bytes outside the display range will position the cursor to unpredictable

locations.

Set Custom Character Ctrl-S **** New Command ****

Sets custom character within the LCD module. To define a custom character you send a Dec 18 followed by the new

characters address and the eight byte that make up that character. Explained later in this text.

Set Contrast Ctrl-S **** No longer Used ****

Sets the display contrast. The byte following the “Set Contrast” command will set the display contrast. A contrast of 0

is no contrast and a contrast of 255 is full contrast. The contrast is automatically set to 50% at power up.

Set Backlight Ctrl-T

Sets the display backlight brightness. The byte following the “Set Brightness” command will set the display brightness.

A brightness level of 0 will turn off the backlight completely. A brightness level of 255 is full brightness. At power-up

the brightness is set to 0 or off.

Command Escape Ctrl-U

The following byte is sent to the LCD controller as a raw LCD controller command. See the appendix for a list of

commands that the LCD controller supports. You will mostly use this command to define custom characters and to set

the cursor shape and visibility.

6

Data Escape Ctrl-V

The following byte is treated as data. This command is used to send bytes that would normally be interpreted as

commands. Some LCD displays (in particular the European font LCDs) have characters in the same range as the

commands of the LCD controller. This command allows these characters to be sent. After data is output to the LCD

controller, the cursor is updated properly.

Raw Data Escape Ctrl-W

The following byte is treated as raw data. This command is used to send bytes that are used for the creation of custom

characters. No attempt is made to advance the cursor since this would interfere with custom character creation.

Toggle TTL Outputs Ctrl-X **** New Command ****

This command sets the state of on-board TTL user outputs. Outputs can sink/source 25mA and can be used for

operating piezo buzzers, relays, LEDs or whatever other device you can come up with. After sending the Ctrl_X byte

the next byte selects the TTL output number (0 or 1) and the last byte selects the state (0 for low and 1 for high). The

Serial LCD module sets both user outputs to low at power up.

Creating Custom Characters

Creating custom character is an easy way to add missing letters, symbols or characters to your display. Up to 8

characters can be created. A character is added by sending Chr(18) + Chr( RAM Storage Address ) + Character (row

byte) x 8. The RAM Storage address is the location where the character will be stored.

Character RAM StorageAddresses Table

Character Number Character RAM storage address

0 64 (Dec)

1 72 (Dec)

2 80 (Dec)

3 88 (Dec)

4 96 (Dec)

5 104 (Dec)

6 112 (Dec)

7 120 (Dec)

Calculating Character Row Byte Value

7

Custom Character BasicX Code Snippet:

' Load Down Arrow as char 0

Call PutQueueStr(Com3Out,Chr(18) & Chr(64) & Chr(4) & Chr(4) & Chr(4) & Chr(4) & Chr(4) & Chr(31) & Chr(14) & Chr(4))

‘ Print char 0 (new down arrow)

Call PutQueueStr(Com3Out,Chr(0))

Complete BasicX-24 Example Program

' This program turns on the LCD 2X16 backlight and displays a “Hello World” message.

' Connections:

' LCD Gnd to BasicX-24 Pin23

' LCD +5 to BasicX-24

' LCD LEDSV+ to BasicX-24 Pin24 or 5-12Vdc 150mA + supply

' LCD RX to BasicX-24 Pin 5

' Define Com3 buffer sizes

Dim Com3In(1 to 15) As Byte

Dim Com3Out(1 to 40) As Byte

' Define the LCD control constants we will use

Const BackLite As Byte = 20

Const Clear_LCD As Byte = 12

Const Set_Cursor As Byte = 17

'************************************************************

Sub Main()

' Wait 1/2 second after power up for LCD to stabilize

Call Sleep(256)

' Open Com3 Buffers

Call OpenQueue(Com3In, 15)

Call OpenQueue(Com3Out, 40)

' Set Com3 to Inverted Logic, 8 Data Bits, No Parity, Pin12 TX, 0 = NO RX pin

Call DefineCom3(0, 5, bx1000_1000)

' Open Com3

Call OpenCom(3, 9600, Com3In, Com3Out)

' Run greeting subroutine

Call Greeting

Do 'We are done. Sit here and do nothing

Loop

End Sub

'************************************************************

Sub Greeting()

' Set backlight to full brightness

Call PutQueueStr(Com3Out,Chr(BackLite) & Chr(255))

' Send Clear LCD command and first 1/2 of message "Hello World!"

Call PutQueueStr(Com3Out,Chr(Clear_LCD) & " Hello World!")

' Move cursor to Row 2 column 4

Call PutQueueStr(Com3Out,Chr(Set_cursor) & Chr(1) & Chr(3))

' Display the rest of the message "I'm Alive!"

Call PutQueueStr(Com3Out,"I'm Alive!")

End Sub ' Return

8

2x16 Specifications

Power ………….4.9-5.2 Vdc @5mA (No Backlight), 135mA (Full Backlight)

Serial Input………………8N1, 9600 or 2400 Baud, RS232 or TTL/CMOS level

Maximum Operating Temperature…………………………………….0° - 50° C

4x20 Specifications

Power ………….4.9-5.2 Vdc @5mA (No Backlight), 225mA (Full Backlight)

Serial Input………………8N1, 9600 or 2400 Baud, RS232 or TTL/CMOS level

Maximum Operating Temperature…………………………………….0° - 50° C

2x16 Current Specs

Current Usage Notes

Backlight Off 4.75mA All Colors

Backlight Full On 130mA LCD with Blue Backlight

Backlight Full On 66mA LCD with Red Backlight

Backlight Full On 66mA LCD with Green Backlight

4x20 Current Specs

Current Usage Notes

Backlight Off 4.75mA All Colors

Backlight Full On 88mA LCD with Blue Backlight

Backlight Full On 86mA LCD with Red Backlight

Backlight Full On 225mA LCD with Green Backlight

9

Optional Bezel Dimensions

10

Dimensions

Serial 2x16

Serial 4x20

Copyright 2006 by NetMedia, Inc.

10940 N. Stallard Place

Tucson, AZ 85737

(520) 544-4567

11

Table of contents

Popular Control Unit manuals by other brands

Anritsu

Anritsu Network Master MT9090A Series Operation manual

Leadshine Technology

Leadshine Technology MA860C user manual

KYLAND

KYLAND TimeServer Module Hardware installation manual

Mankenberg

Mankenberg EB 1.12 Original operating manual

Bender

Bender MEDICS UMC107E-25 operating manual

FlexRadio Systems

FlexRadio Systems Maestro A manual