Netafim Fertikit 3G User manual

FERTIKIT

™3G

V 001.08 - MAY 2015

USER MANUAL

2 FERTIKIT USER MANUAL

© COPYRIGHT 2013, NETAFIM™

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM™ TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM™ WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM USE OF NETAFIM'S PRODUCTS OR

USE OF THIS MANUAL.

NETAFIM™ RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE.

FOREIGN LANGUAGES

In the event that you are reading this manual in a language other than the English language, you

acknowledge and agree that the English language version shall prevail in case of inconsistency or

contradiction in interpretation or translation.

FERTIKIT USER MANUAL 3

ELECTRICAL HAZARD

The following text contains instructions aimed at preventing bodily injury or direct damage to the

FertiKit™ 3G and/or the infrastructure in the presence of electricity.

WARNING

The following text contains instructions aimed at preventing bodily injury or direct damage to the

crops, the FertiKit™ 3G and/or the infrastructure.

CAUTION

The following text contains instructions aimed at preventing unwanted system operation,

installation or conditions that, if not followed, might void the warranty.

ATTENTION

The following text contains instructions aimed at enhancing the efficiency of usage of the

instructions in the manual.

NOTE

The following text contains instructions aimed at emphasizing certain aspect of the operation of

the system or installation.

SAFETY FOOTWEAR

The following text contains instructions aimed at preventing foot injury.

TIP

The following text provides clarification, tips or useful information.

ACID HAZARD

The following text contains instructions aimed at preventing bodily injury or direct damage to the

crops, the product and/or the infrastructure in the presence of acid.

PROTECTIVE EQUIPMENT

The following text contains instructions aimed at preventing damage to health or bodily

injury in the presence of fertilizers, acid or other chemicals.

EXAMPLE

The following text provides an example to clarify the operation of the settings, method of

operation or installation.

The values used in the examples are hypothetical. Do not apply these values to your own

situation.

Use of symbols

The symbols used in this manual refer to the following:

4 FERTIKIT USER MANUAL

5

6

7

7

7

8

8

8

8

8

9

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25

27

Safety

Safety instructions

When using acid/chemicals

Description

Introduction

Advantages

Basic functions

Operating principle

Modularity

Compatibility

Service

Maintenance

Typical installation overview

The 7 modes

PL modes (PL/PS/PR/RL)

PB mode

SP mode

MS mode (MS/RS)

IL mode

ST mode

PD mode

Operation and maintenance

Operation

Maintenance

Winterization

Troublehooting

Symptoms regarding more than one single dosing channel

Symptoms regarding a single dosing channel

Symptoms while idle

Switchboard warning

Warranty

Appendices

Appendix 1 - Calibration:

1. Calculation of dosing channels opening percentage

2. Simulation with a 10 liter (2 US gal) bucket of water

3. Calibration of the FertiKitTM while irrigating

CONTENTS

FERTIKIT USER MANUAL 5

SAFETY

Safety instructions

•All safety regulations must be applied.

•Ensure that the installation is carried out in a manner that prevents leaks from the FertiKitTM,

the fertilizer/acid tanks and lines, the peripherals and the accessories (contaminating the

environment, soil or ambient area).

•When using acid always observe the acid manufacturer's safety instructions.

•Electrical installation and troubleshooting should be performed by an authorized electrician only.

•The electrical installation must comply with the local safety standards and regulations.

•Installation should be performed by authorized technicians only.

•Protection provided by the equipment can be impaired if the equipment is used in a manner other than

that specified by the manufacturer.

CAUTION

Read the Safety instructions chapter before using, maintaining or troubleshooting the FertiKit™ 3G.

WARNING

In agricultural environment - always wear protective footwear.

CAUTION

When opening or closing any manual valve, always do it gradually, to prevent damage to the

system by water hammer.

WARNING

Always use protective equipment, gloves and goggles when handling fertilizers, acid and

other chemicals!

NOTE

The maximum sound level produced by the equipment does not exceed 70dB.

WARNING

Measures must be taken to prevent fertilizer infiltration of the water source, to avoid water pollution.

6 FERTIKIT USER MANUAL

SAFETY

When using acid/chemicals

ACID HAZARD

When using acid - always observe the acid manufacturer's safety instructions.

WARNING

Always use protective equipment, gloves and goggles when handling fertilizers, acid and

other chemicals!

WARNING

Exceeding the recommended acid concentrations will damage the dosing channels.

WARNING

Substances

such as chemicals for pest/disease control might be corrosive and damage the

FertiKit™ 3G. When using any substance

other than

fertilizers or acids not exceeding the

concentrations in the table above, always observe the manufacturer's instructions for corrosivity.

In case of any doubt, contact your Netafim™ local representative.

ATTENTION

When dosing acid, use a dosing channel fitted with the appropriate components according to

the type and concentration of the acid used*:

For pH correction For maintenance of drippers

Type of dosing channel

Diaphragm

and O-rings

Nitric

(HNO3)

Phosphoric

(H3PO4)

Sulfuric

(H2SO4)

Hydrochloric

(HCl)

Hydrogen

peroxide

(H2O2)

Chlorine (as

hypochloride)

For diluted acid EPDM <3% <85% <30% <10% <30% <1%

For concentrated acid Viton <40% <85% <90% <33% <50% <10%

% is by weight at 21oC (70oF)

*The table indicates the resistance of the dosing channel components to acid,

and is not a recommendation to use the acids mentioned.

CAUTION

There are fertilizer combinations that at high concentration might induce crystallization in the FertiKit's

lower manifold and cause clogging of the pipes.

Fertilizer combinations prone to induce crystallization:

•

Calcium Nitrate + Ammonium Sulfate => Calcium Sulfate

•

Calcium Nitrate + Potassium Sulfate => Calcium Sulfate

•

MKP + Calcium Nitrate => Calcium Phosphate

•

MAP + Calcium Nitrate => Calcium Phosphate

•

Phosphoric acid + Calcium Nitrate => Calcium Phosphate

When injecting these fertilizer combinations:

•

Make sure to dilute each fertilizers to the allowed concentration in the fertilizer tank prior to

injection through the FertiKit™.

•

Imediately after each injection of any of the fertilizer combination above, flush the FertiKit™ with

clean water for at least 2 minutes.

In case of doubt regarding the use of any

combination of

fertilizers, contact your Netafim™ local

representative.

FERTIKIT USER MANUAL 7

DESCRIPTION

Introduction

The FertiKitTM 3G is a fully configurable fertilizer/acid dosing unit - a highly cost-effective solution for

precise NutrigationTM .

Based on a standard platform, the FertiKitTM offers 7 different operation modes, selectable according

to the site conditions, in order to maximize usage of available water flow rate and pressure on the main

irrigation line, ensuring the highest efficiency with minimum investment.

The FertiKitTM can accommodate a variety of dosing channels, dosing boosters, controllers, peripherals and

accessories to meet a vast range of applications and infrastructure constraints.

Capacity range

The FertiKitTM ensures a satisfactory mixture in an extremely vast range of flow capacities.

It will accommodate a 0.1 Ha (0.25 Acres) nursery or a 400 Ha (1000 Acres) sugar cane plantation.

Main line pressure range: up to 8.5 bars (123.0 PSI).

Main line flow rate range: from 1.0 to 700.0 m3/h (from 4.4 to 3000.0 GPM).

Advantages

•A modular NutrigationTM system for soil or substrate applications with minimum investment

•Efficient usage of water, fertilizers and energy

•Unrivaled range of irrigation water capacities

•Designed for any application where quantitative or proportional NutrigationTM is required

•Highly profitable price/performance ratio

•Venturi operating principle - no moving parts

•Fits easily into any existing irrigation system

•Precise NutrigationTM based on high-accuracy dosing channels

•Quick action dosing valves

•Available with up to 6 fertilizer/acid dosing channels

•NutrigationTM recipes can be changed quickly and efficiently

•Can be operated manually or fully computerized

•NMC and other controllers can be assembled on the FertiKitTM for advanced NutrigationTM control

•

A wide variety of accessories and peripherals can be integrated into the FertiKitTM to enhance its functions

•High-quality components and PVC pipe work

•Aluminum, corrosion-resistant frame with adjustable legs

•Easy to install and to maintain

•Made by Netafim™

Basic functions

The FertiKitTM supports the following NutrigationTM functions:

•Fully controlled dosing and mixing of fertilizers/acid with source water into a homogenous nutrient

solution.

•EC/pH correction of the nutrient solution.

•Water pre-treatment

8 FERTIKIT USER MANUAL

DESCRIPTION

Operating principle

The FertiKitTM doses the various fertilizers and acid into a homogeneous solution and injects it into the

irrigation water main line. The suction of the fertilizers and acid in the dosing channels is based on the

Venturi principle. This requires a pressure differentiation - available on the main line or supplied by the main

line pump or the FertiKit's dosing booster.

Modularity

The modular FertiKitTM 3G concept is based upon an array of interchangeable components that enables

rapid assembly of a wide range of configurations.

Each FertiKitTM is delivered according to the precise customer’s order, either fully factory assembled or

assembled by the local dealer.

The dealer stocks the assortment of the FertiKitTM interchangeable components.

This concept enables the dealer to assemble any specific FertiKitTM according to the customer’s order,

saving

the need to stock a large quantity of fully assembled FertiKitTM units of various common configurations.

The modular FertiKitTM 3G concept ensures prompt delivery schedules without delays!

Stock selection option

Enables the dosing of multiple fertilizers through a single dosing channel (in cases where simultaneous

dosing is not required). Suits all modes of FertiKitTM.Available in a wide variety of configurations, from a

single dosing channel with 2 fertilizers to as many dosing channels and fertilizers as required. For further

information, contact Netafim™.

Compatibility

The FertiKitTM 3G can be incorporated in an existing or a planned project; in either case it offers a highly

cost-effective solution for NutrigationTM by taking maximum advantage of the infrastructure conditions.

Any available pressure surplus can be used for the FertiKit’s operation. In order to configure the most

cost-effective FertiKitTM, making the maximum use of available pressure.

ATTENTION

Calculations are either in metric or in US units - consistency in the type of units used is essential.

Service

Servicing the FertiKitTM 3G is a prompt and simple process. The dealer keeps a small quantity of

interchangeable components on hand, for replacement on site within a few minutes.

Maintenance

To prevent failures and extend the life cycle of the FertiKitTM, regular maintenance must be carried out

by the user, such as periodic rinsing of filters and calibration of the EC/pH sensors. For full maintenance

instructions, see Maintenance (page 18).

FERTIKIT USER MANUAL 9

DESCRIPTION

The 7 modes

Each one of the FertiKit™ 3G 7 modes depicted on the folowing pages fits a specific infrastructure configuration.

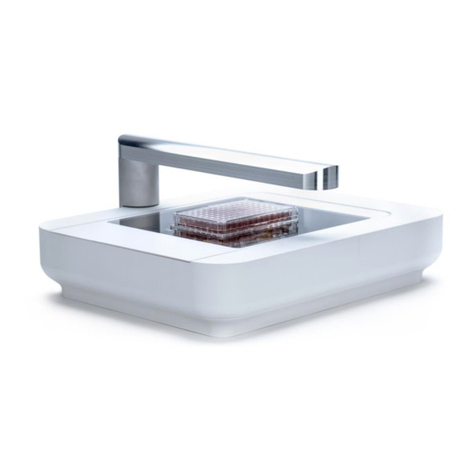

Typical installation overview

The drawing below represents the typical infrastructure suitable for the PL mode.

Each one of the FertiKit™

3G 7 modes fits a

different

infrastructure configuration.

(see the schematic diagrams in Modes, pages 10-16

).

Main parts of the FertiKit™ and its infrastructure

The list below presents the Main parts of the FertiKit™ and the parts of the infrastructure required for the

operation of the FertiKit™ various modes (see pages

10-16

).

Color code:

Supplied (part of the FertiKit™), Not supplied (part of infrastructure), Optional.

1Dosing channel + Venturi

2

Upper manifold pressure gauge

3Lower manifold presure gauge

4Sampling outlet

5Controller

6EC sensor

7pH sensor

8EC/pH transducer

9Dosing booster

10 Dosing booster switchbox

11 Check valve

12 Pressure switch

13 Fertilizer/acid stock tank

14 Manual valve (fertilizer)

15 Fertilizer/acid filter

16 Manual valve (isolation)

17

Main line

pressure sustaining valve (PSV)

18 Irrigation valve

19 Water meter

20 Main line filter

21 Main line pump

22

Main line

pressure reducing valve (PRV)

23 Sampling outlet

24 Saddle fitting

25 Command tube

26

Pressure sustaining valve (PSV)

27 Pressure reducing valve (PRV)

28 Water meter

29 Air release valve

FertiKitTM 3G

13

14

15

16

17

18

19

20

21

22

16

10 FERTIKIT USER MANUAL

14 13

16

17

18

19

20

21

16

5

8

10

1

2

3

4

6

7

9

11

12

26

27

22

PL modes (PL/PS/PR/RL)

Operating principle: The pressure differential required to

generate fertilizer suction via the Venturis is produced by a

booster pump integrated in the FertiKitTM.

These modes of operation, where the lower manifold is under

low pressure (around 0 bars/PSI), permits the use of high-efficiency

Venturis with high suction capacity and low motive flow consumption.

Flow rate: 20 - 700 m³/h (85 - 3000 GPM)

Suitable for main line pressure:

PL

: 2.5 - 6.5 bars (36 - 94 PSI).

PR

with PRV 27: 6.5 - 8.5 bars (94 - 123 PSI)

PS

with PSV 26 : Based on cavitation risk.

RL

with PRV 27 and PSV 26 : 2.5 - 8.5 bars (36 - 123 PSI)

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer

and concentrated/diluted acid:

•Up to 6 x 50 - 1000 l/h (13 - 265 GPH)

•Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 6000 l/h (1585 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior, (Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

DESCRIPTION

See legend on page 9

Dosing channel

Scope of delivery

Direction of flow

15

FERTIKIT USER MANUAL 11

PB mode

Operating principle: The pressure differential required

to generate fertilizer suction via the Venturis is produced

by a booster pump integrated in the FertiKitTM.

This mode of operation, where the smaller system pump

is installed upstream from the Venturis, permits the use of a small

booster pump, reducing the investment required and saving energy.

This mode is suitable for relatively low flow rates and pressures.

Flow rate: 5 - 70 m³/h (22 - 300 GPM)

Suitable for main line pressure: 1.5 - 2.5 bars (22 - 36 PSI)

Additional conditions:

The pressure supplied by the dosing booster is added to the main line

pressure. Their sum (in the upper manifold) should not exceed

6.5 bars (94 PSI)

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer

and concentrated/diluted acid:

•Up to 4 x 50 - 370 l/h (13 - 100 GPH) •Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 1480 l/h (390 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior, (Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

22

14

15 13

16 17

18

19

20

21

16

5

8

10

1

2

3

4

6

7

9

11

12

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

12 FERTIKIT USER MANUAL

14

15 13

16

17

18

16

5

8

10

1

2

4

9

11

6

7

12

19

20

21 22

SP mode

Operating principle: The pressure differential required

to generate fertilizer suction via the Venturis is produced

by a booster pump integrated in the FertiKitTM.

This mode of operation, where the system pump

is installed upstream from the Venturis, permits the use of a smaller

booster pump, reducing the investment required and saving energy.

This mode is suitable for relatively low flow rates and pressures.

For applications that use very high concentration fertilizers and acid.

The solution has to be mixed in the main line.

SP mode is not equipped with a lower manifold.

(Can be supplied to the USA market with all parts inch-based to

facilitate replacement using locally available spare parts).

Flow rate: 5 - 250 m³/h (22 - 1100 GPM)

Suitable for main line pressure: 1.5 - 3.5 bars (22 – 51 PSI)

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer and concentrated/diluted acid:

•Up to 4 x 50 - 370 l/h (13 - 100 GPH) •Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 1480 l/h (400 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior, (Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

FERTIKIT USER MANUAL 13

MS mode (MS/RS)

Operating principle: For systems operating under negative suction -

from a reservoir or a tank [max. height: 6 meters (20 feet)]

Utilizes the main line pump pressure.

Saves the need for a dosing booster.

Flow rate: 20 - 700 m³/h (85 - 3000 GPM)

Suitable for main line pressure:

Upstream from the pump: -0.3

-

+0.6 bar (-4

-

+9 PSI)

At the outlet of the pump: 2.5

-

6.5 bars (36

-

94 PSI)

RS

with PRV 27:

6.5

-

8.5 bars (94

-

123 PSI) at the FertiKitTM inlet.

Additional conditions:

Requires the connection of the FertiKit's outlet to the main line

upstream from the pump.

The main line pump should be able to deliver the flow rate required for the

operation of the FertiKit

TM

+ the field consumption.

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer and concentrated/diluted acid:

•Up to 6 x 50 - 1000 l/h (13 - 265 GPH) •Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 6000 l/h (1585 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior, (Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

14

15 13

16

17

18

19

20

21

16

5

8

1

2

3

4

6

7

27

P-0.3

-

+0.6 bar

(-4

-

+9 PSI)

P2.5

-

6.5 bar

(36

-

94 PSI)

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

14 FERTIKIT USER MANUAL

IL mode

Operating principle: The pressure differential required to

generate fertilizer suction via the Venturis is produced by a

booster pump integrated in the FertiKitTM.

In this mode of operation, the lower manifold is at low

pressure (around 0 bar/psi) this allows the use of high-efficiency

Venturis with high suction capacity and low motive flow consumption.

Since all the main line water flows through the system, slight

pressure losses at the FettiKit™ outlet should be considered

(see the table below).

Flow rate: 3 - 18 m³/h (13 - 85 GPM)

Suitable for main line pressure: 2.5 - 5.5 bars (36 - 79 PSI)

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer and

concentrated/diluted acid:

•Up to 6 x 50 - 600 l/h (13 - 156 GPH)

•Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 3600 l/h (950 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior,

(Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

Flow rate

m³/h (GPM)

Pressure losse

bar (PSI)

5 (22) 0.1 (1.45)

10 (44) 0.3 (4.35)

15 (66) 0.6 (9.55)

Pressure losses

14

15 13

18

21

5

8

10

1

2

3

4

6

7

9

11

12

2728 20

29

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

FERTIKIT USER MANUAL 15

14

15 13

17

18

5

8

10

1

2

3

4

6

7

9

11

12

20

19

29

P-0.3

-

+0.6 bar

(-4

-

+9 PSI)

16

ST mode

Operating principle: For systems operating at low pressure -

from an on-ground reservoir or a tank

[max. height: 6 meters (20 feet)]

The dosing booster pump also serves as main line pump.

Supplied with a manual or a semi-automatic filter.

Flow rate: 1 - 16 m³/h (4.4 - 70 GPM)

Suitable for main line pressure:

Upstream from the pump: -0.3

-

+0.6 bar (-4

-

+9 PSI)

At the outlet of the pump: 2.0

-

5.5 bars (29

-

80 PSI)

Additional conditions:

The selection of the dosing booster considers the required

field flow + the TC.

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer

and concentrated/diluted acid:

•Up to 6 x 50 - 600 l/h (13 - 156 GPH) •Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 3600 l/h (950 GPH).

Controller: NMC-Pro, NMC-XL, NMC-Junior, (Other controllers or manual system without controller - optional).

EC/pH: Single, monitoring and control.

Schematic diagram

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

16 FERTIKIT USER MANUAL

PD mode

Operating principle: Utilizes the main line pressure

or gravity feed.

Saves the need for a dosing booster.

Also suitable for applications where there is no

electricity on the site (contact Netafim™).

Flow rate: 10 - 200 m³/h (44 - 880 GPM)

Suitable for main line pressure: 4.5 - 8.0 Bars (65 - 116 PSI)

Additional conditions:

For the dosing channels to provide proper suction, t

he pressure

downstream from the PRV should be at least 50% of the the pressure upstream

from the PRV (The eficiency of the Venturis

decreases if this condition is not met).

In addition the system must supply

suficient pressure for the field demand

.

Dosing channels:

Accommodates a wide variety of dosing channels for fertilizer and concentrated/diluted acid:

•Up to 4* x 50 - 370 l/h (13 - 100 GPH) •Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 1480 l/h (390 GPH).

*If EC/pH is installed it occupies the location of one dosing channel (power required).

Controller: NMC-Pro, NMC-XL, NMC-Junior, NMC DC

(Other controllers or manual system without controller - optional).

EC/pH: None (Single monitoring only - optional)

Schematic diagram

22

14

15 13

16

19

20

16

5

8

1

2

3

67

23 24

25

18

DESCRIPTION

Dosing channel

Scope of delivery

Direction of flow See legend on page 9

FERTIKIT USER MANUAL 17

OPERATION AND MAINTENANCE

Operation

The routine operation of the FertiKitTM is almost totally automatic, controlled by the controller

(for the operation of the controller, see the Controller Manual).

All you need is to make sure that:

•Electricity is supplied to the FertiKitTM.

•Adequate quality water at the appropriate flow rate and pressure is supplied at the inlet of the FertiKitTM

(see FertiKitTM Hydraulic Conditions Checklist).

•Properly dissolved fertilizers, according to the agronomist's instructions, are constantly present in the

stock tanks.

•If acid is used - it is constantly present in the acid stock tank and does not exceed the recommended

concentration (see AT TENTION, page 6).

Dual dosing channel

If more than 4 dosing channels are required (up to 6), the dual dosing channel option is used.

•Up to 2 dual dosing channels are installed on the FertiKitTM 3G, at the 1and 4manifold positions.

•

The dual dosing channel option is applicable with 50-600 l/h (13-158 GPH) and 1000 l/h (265 GPH) Venturis only.

Dual dosing channel schematic diagram

Scope of the

dual dosing channel

Direction of flow

LEGEND

4321

CAUTION

Only compatible products can be injected through the dual dosing channel.

There are fertilizer combinations that should

never

be used in the dual dosing

channel as they will induce crystallization and cause clogging of the pipes.

Fertilizer combinations prone to induce crystallization:

•

Calcium Nitrate + Ammonium Sulfate => Calcium Sulfate

•

Calcium Nitrate + Potassium Sulfate => Calcium Sulfate

•

MKP + Calcium Nitrate => Calcium Phosphate

•

MAP + Calcium Nitrate => Calcium Phosphate

•

Phosphoric acid + Calcium Nitrate => Calcium Phosphate

In case of doubt regarding the use of any

combination of

fertilizers in the

dual dosing channel

, contact your Netafim™ local representative.

18 FERTIKIT USER MANUAL

OPERATION AND MAINTENANCE

Maintenance

CAUTION

When opening or closing any manual valve, always do it gradually, to prevent damage to the

system by water hammer.

To prevent failures and extend the life cycle of the FertiKitTM, the user must carry out regular maintenance.

•Keep the FertiKitTM dosing unit and its immediate environment clean and dry.

CAUTION

Before calibrating the EC and pH sensors, gradually close the isolation valves and open the

sampling valve until the pressure in the system is released.

•The FertiKitTM dosing unit and the supply water and irrigation system must be inspected regularly.

Regular inspection

Description How often Instructions

Rinsing of fertilizer filters* Once a day

Rinsing of supply water filters* Once a day

Water and fertilizer leak inspection Once a week Visual inspection

Calibration of the pH sensor Every 2-4 weeks See the EC/pH Transducer Manual

Calibration of the EC sensor Every 4 weeks

* Manual filters only.

Check the FertiKit™hydraulic conditions every 4 weeks

Consult the main line flow meter and pressure gauge, the upper manifold and lower

manifold pressure gauges and the Rotameters of the dosing channels, fill in the data on

the FertiKitTM Hydraulic Conditions Checklist provided by the installer and make sure that

all the hydraulic conditions match the reference data.

When verifying the flow rate for each dosing channel,

make sure the cursors on all the Rotameters are adjusted.

NOTE

The Rotameter's sacle is calibrated by the manufacturer for measurement of the

flow rate of water (H2O). Certain inacuracies may be observed when the flow rate

of liquids with different densities, such as fertilizers and acids, is measured.

ATTENTION

Once a month, read the measured flow rates of the dosing channels

and compare them with the flow rates defined in the controller,

to check whether any changes have occurred.

FERTIKIT USER MANUAL 19

OPERATION AND MAINTENANCE

Winterization

CAUTION

When opening or closing any manual valve, always do it gradually, to prevent damage to the

system by water hammer.

In areas susceptible to freezing temperatures, if the system is not required for irrigation during the winter

(mainly in open field applications) perform the following procedure

to avoid damage caused by freezing

when the

FertiKitTM

is idle for the winter period:

At the beginning of winter:

•Gradually close the isolation valves and open the sampling valve until the pressure in the system is

released.

•

Remove EC and pH sensors and store the pH sensor immersed in KCL solution (supplied with the sensor)

or in calibration buffer 4 at temperature 18-25˚C (64-77˚F). The pH sensor must never be dry

(see EC/pH Transducer Manual).

•Empty the FertiKitTM of water.

At the end of winter:

•Reinstall the EC and pH sensors and calibrate them (see EC/pH Transducer Manual).

•Gradually open the isolation valves until the pressure in the system is restored.

20 FERTIKIT USER MANUAL

TROUBLESHOOTING

This chapter is a systematic guide to the actions to be taken in the case of a malfunction of the FertiKitTM.

ATTENTION

Before proceeding to troubleshoot any malfunction, make sure that:

•The controller settings regarding the dosing channels are correct and match the dosing channels

of the FertiKitTM (see the Controller Manual).

•The controller settings regarding the field valves are correct (see the Controller Manual).

Perform the actions in their order of appearance until the malfunction is fixed.

If you identify faulty parts - consult your Netafim™ representative.

CAUTION

Only qualified electricians are permitted to perform electrical installations and repairs!

CAUTION

If isolation valves have been installed on the system, ensure that they are in closed position before

troubleshooting any hydraulic malfunction.

ATTENTION

If fertilizers from a different manufacturer have been recently in use and changes in EC and pH are

recorded, perform calibration of the system before assuming a malfunction of the FertiKitTM

(see Appendix 1 - Calibration, page 25).

Symptoms regarding more than one single dosing channel

If one or more of the following symptoms occur regarding more than one single dosing channel,

perform the actions listed bellow:

Controller warnings

•Low EC

•High pH

•Low fertilizer/acid flow rate

Rotameter reading

•Low fertilizer/acid flow rate

Action

1) For controller warnings only - check and calibrate the EC and pH sensors

(see the EC/pH Transducer Manual).

2) Have a qualified electrician check that electricity is being supplied to the FertiKitTM and that all the

electrical components are properly connected (see the Switchboard Manual).

3) Check that the hydraulic conditions comply with the reference data in the

FertiKitTM Hydraulic Conditions Checklist.

If NO, restore the original hydraulic conditions according to the reference data in the

FertiKitTM Hydraulic Conditions Checklist.

If YES or if the malfunction is still not fixed after restoring the original hydraulic conditions,

in PL or PB mode - have a qualified electrician check the dosing booster:

Does it function? Does it rotate in the correct direction?

If not - the electrician should swap between phases L1 and L3 (see the Dosing Booster Manual).

Other manuals for Fertikit 3G

2

Table of contents

Other Netafim Laboratory Equipment manuals