Nets NS-DWDM-OP01-DCI-AC User manual

NS-DWDM-OP01-DCI-AC Stackable over

100G wave division transmission platform

Quick Installation Guide

Document version:01

Date:2022-09-01

- 2 -

The installation process

Start

Prepareto

install Page5-6

Page6

Page7-8

Page9

Page7

Page8

Page9

Page10

Page10

Page11

Page11

Page10-15

Page12

Page13-14

Page15

Page22

Page16-21

Page16

Page16-20

Page21

Page23

Page22-24

Page24

Attention

Install Tool

Install Device

Install business

board

Install /Remove

board

Set Up Cables

Checkbefore

power-on

Checkafter

power-on

Connect device

Checkafter

Installation

Appendix

Installation

Complete

Rack

Requirements

Install the

machine box

Install power

cables

Connect protection

ground wire

Install management

communication fiber

Introduction of

board slot

Plug and unplug

optical module

PlaceCables

Checkfiber loss

Changethe

fan unit

Changepower

unit

Changecontrol

board

- 3 -

With the rapid development of industry communication, the demand for long distance and large

capacity bandwidth increases rapidly. In order to adapt to the new load bearing requirements, for

data center interconnection (DCI) optoelectronic integrated wave division transmission equipment --

NS-DWDM-OP01-DCI-AC. The device is mainly located in the MAN, including the metropolitan core

layer, the convergence layer, and the metropolitan access layer. It can meet the rapidly growing

bandwidth demand between DCS, realize the flexible deployment of devices,create an open optical

network architecture, and lead the DCI market into a new era of high-speed all-optical

interconnection.

Product Appearance

Product Features

lPhotoelectric integrated, pluggable modular design; Components are hot-swappable, deployed on

demand, and expanded on demand.

lThe heat dissipation design adopts the forward air and rear air exhaust, and provides 1+1 FRU fan

units,support automatic speed regulation.

lThe 19-inch standard rack fits into the data center equipment room and can be deployed in the same

cabinet with IT devices.

lEach pair of optical fiber transmission capacity can reach 25.6 Tbit/s @ 400 g * 64 + C band lambda,

each sub-rack the highest 1.6 Tbit/s.

lSingle-wave capacity is 400 g, 600 g & 800 g & 1.2 T continued evolution.

lThe optical laminates are highly integrated with functions such as OA, WSS, VOA, OSC, OTDR,

OCM, and OLP to simplify the internal optical fiber connection.

lSupports 10GE, 100GE, 100GE FlexE(Unware mode), STM-64, 10GE WAN, OTU2, and OTU4

services.

lSupports 9-D ROADM networking and Flexible Grid.

lSupport business layer, OTN layer, optical layer comprehensive performance monitoring, quality

visible.

lProvides multiple network - and device-level protection solutions. The protection switchover delay is

less than 50ms, ensuring superior protection performance

lSupport NETCONF/YANG standard open interface and GUI management platform based on B/S

architecture.

NS-DWDM-OP01-DCI-AC Device Introduction

- 4 -

Product specification

Parameter Instructions

Rack

Size 2U:44mm(H)x444mm(W)x490mm(D)

Maximum Capacity 1.6Tbit/s

Number of business

slots 4

Apply cabinet 19’ cabinet, 800mm depth or above

Ports of line

side

Speed

✪200G (PDM_QPSK)

✪200G (PDM_8QAM)

✪200G (PDM_16QAM)

✪400G (PDM_16QAM)

Optical module Pluggable CFP2、adjustable wave length

Ports of

client side

Business type

10GE、100GE

OTU2、OTU4

STM-64、10GE WAN

Optical module

✪pluggable SFP+

✪pluggable QSFP28

Maximum number of wavelengths Fixed grid: 96 waves@50 GHz

Channel spacing Flexible grid: 50 GHz/75 GHz/100 GHz/150 GHz

Center frequency range 191.35 GHz ~ 196.1 GHz

Central wavelength range 1528.77 nm ~ 1566.73 nm

Protection function

✪Optical line protection(OLP)

✪Optical wdm section protection(OMSP)

✪Optical channel protection(OCHP)

Network management

✪Supports hot swap of the main control board

✪Supports CLI, NETCONF, and GUI management

platforms based on B/S architecture

✪Supports OSC-based DCN communication

Power

supply

Back up Standard CRPS power supply 1+1 backup

AC

✪Rated voltage range:

– 100 V AC~130 V AC (50/60Hz)

– 200 V AC~240 V AC (50/60Hz)

✪Maximum voltage range:90 V AC~264 V AC

(45Hz~65Hz)

- 5 -

High voltage direct

current

✪Rated voltage range:240 V HVDC

✪Maximum voltage range:192 V HVDC~288 V HVDC

DC

✪Rated voltage range:-48 V DC/-60 V DC

✪Maximum voltage range:-40 V DC~-72 V DC

Heat dissipation

✪After the forward wind comes the wind

✪1+1 Fan Board Backup

Typical power consumption <550W(fully equip)

Environment

Working temperature

✪short term:-5℃~+45℃

✪long term:0℃~40℃

Storage temperature -40℃~+70℃

Humidity 5%~95% (No condensation)

1.1 Safety Precautions

■ To ensure the safety of the human body and the device, follow the labels on the device and the safety

precautions in this document when installing, operating, and maintaining the device. The items such as

" Danger" and " Caution" in this manual do not represent all the safety precautions to be

followed. They are only supplements to the safety precautions.

■ During the operation of our company's equipment, we must strictly follow the relevant equipment

precautions and special safety instructions provided by NewNets. The "safety warnings" listed in the

manual only reflect the requirements of Newnets, not the general safety requirements. NewNets, LLC

does not assume any responsibility for any loss caused by the violation of the general safe operation

requirements or the violation of the design, production and use of equipment safety standards.

Instructions

Intended Audience This document provides a quick and concise guide for hardware installation.

This document does not describe the installation operations performed before delivery. It only

describes the operations involved in onsite installation.

Attention

- 6 -

Attention

Electrostatic

To prevent the static electricity of the human body from damaging the sensitive components, wear ESD

gloves or an ESD wrist strap and ground the other end of the ESD wrist strap well before touching the

device or holding the board, board, or IC chip.

Binding wire

lThe interval between cable ties and optical fiber bundling tapes inside cabinets should not exceed

250mm. (The interval between binding cable ties inside the cabinet should not exceed 200mm.)

lOutside the cabinet, bind all cables and corrugated pipes based on the distance between two beams.

For cable troughs without beams, bind cables with a distance of not more than 250mm.

Check before installation

lBefore installing a device, check the equipment room, cabinet, power supply, ground cable, optical

cable, and supporting facilities. After the construction conditions are determined, the construction

shall be carried out according to the engineering design documents.

l When installing and maintaining the NS-DWDM-OP01-DCI-AC, take ESD measures, such as

wearing an ESD wrist strap or ESD gloves.

l When transporting, moving, or installing the NS-DWDM-OP01-DCI-AC, avoid collision with doors, walls,

or shelves. Do not touch parts or unpainted metal surfaces with sweaty or dirty gloves.

l Do not pile up sundry on the equipment.

Attention

NS-DWDM-OP01-DCI-AC device has it’s own fan. The air inlet is in the front, and the air outlet is in

the back. Ensure that the air inlet and air outlet are not blocked by optical fibers or paper etc.

Front - inlet Rear side - Air outlet

- 7 -

1.2 Installation Environment Requirements

lDo not place the device in an environment with flammable or explosive gas or smoke, and do not

perform any operations in such an environment.

lThe device must be installed in a clean, dry, well-ventilated, and temperature-controlled place. Water

seepage, dripping and condensation are strictly prohibited in the installation site.

lDust proof measures should be taken in the installation site. Indoor dust on devices causes

electrostatic adsorption and poor contact between metal connectors or metal contacts. This not only

affects the service life of devices but also easily causes device faults.

lEnsure the installation of ambient air circulation,do not plug the heat dissipation holes of the

NS-DWDM-OP01-DCI-AC device. Leave more than 50mm space around the device for heat dissipation.

lThe temperature and humidity at the installation site must be within the normal operating temperature

range (-5 ° C to 45 ° C (typical) (0m to 1800m), altitude range (1800m to 5000m), and humidity

range (5%-95% RH without condensation).

Installation Tools

2.1 Device Installation Tool

matters need attention

Phillipsscrewdriver Flat-head screwdriver multimeter wire crimper bolt clipper

wire stripper cable clamp Installthe gloves antistatic Esdwrist strap

ladder Optical fiber Velcro Electricalinsulation tape network tester optical power meter

- 8 -

3.1 Rack requirements

l NS-DWDM-OP01-DCI-AC width of the device complies with industry standards and can be installed

in the IEC 19-inch standard cabinet.

l NS-DWDM-OP01-DCI-AC cabinet depth must be at least 800mm.

l cabinet at the front of the linear space for not less than 120 mm, can appear otherwise cable his

problem.

lA tray is installed in the cabinet.

lFor a 19-inch cabinet, ensure that there is at least 75mm of space on both sides to prevent the air

inlet and outlet from being blocked

lThe porosity of the cabinet door is greater than 50%, which meets the heat dissipation requirements

of the device.

lThe cabinet has reserved ground terminals that connect to devices.

lIf the upper cabling mode is used, reserve an outlet on the top of the cabinet. If underfloor cabling is

used, reserve an outlet at the bottom of the cabinet.

Device Installation

NS-DWDM-OP01-DCI-AC

H=44m

m

- 9 -

3.2 Install the machine box

Device Installation

②Place the NS-DWDM-OP01-DCI-AC device on

the cabinet tray.

④Fix the panel mounting ears to the floating nuts

on the mounting bar of the cabinet using a

screwdriver knob screw.

③Slowly push the mounting ears into the

device so that the mounting ears on the panel

align with the floating nuts on the mounting

bar of the cabinet.

①Determine the installation position of the

device.

- 10 -

4.1 Install/Remove board

Install business board

※Removinga running board mayaffect the normal running of the device and interrupt services.

※If the boards are not installed, place them in ESDbags and mark them.

※When inserting a board, ensure that the board connector is aligned with the backplane socket.

※If the board fails to be inserted, do not forcibly insert the board. Checkthe position

of the board before reinserting the board. 。

Removing the Filler Panel

Loosen the captive screws on the filler

panel counterclockwise. Hold the upper

and lower ends of the filler panel with

both hands and pull the filler panel out

along the guide rails in the slot.

Install the board

Hold the buckle parallel to the board panel,

align the board with the guide slot, and

push the board into the slot with

appropriate force until it is fully

inserted.

Remove the board

Pull the buckle perpendicular to the board

panel and pull the board out along the

guide rails with moderate force.

Attention

Filler panels must be inserted into the empty slots of the chassis to

prevent foreign objects from entering the chassis and causing faults.

- 11 -

5.1 Install Power Cable

5.2 Connect protection ground wire

Set Up Cables

Instructions

The actual delivered power cables comply with the

local standards. The following uses the Chinese

standard C13 straight female to PI straight male AC

power cables as an example

High voltage DC and AC

1.High voltage (240V) DC power supply and AC power

supply use the same power cable.

2.Power cables must be installed for both power ports.

1Wear an ESD wrist strap or ESD gloves. If you wear an ESD wrist strap, ensure that one end of the wrist

strap is grounded and the other end is in good contact with the wearer's skin.

2 Remove the ground screw from the ground point of the device using a Phillips screwdriver.

3 Install the ground screw and ground cable to the ground point of the NS-DWDM-OP01-DCI-AC using

a Phillips screwdriver.

Note: One end of the PGND cable connects

to the device ground point and the other end

connects to the cabinet ground point.

Danger

※Turn off the power when connecting or pulling out the power cable.

Low voltage DC

1.The low-voltage DC power cable connects to the

positive DC terminal (0V) in brown and the negative DC

terminal (-48V) in blue.

Ac power port 2

Ac power port 1

Ac Power cable Appearance

Appearanceof DCPowerCables

- 12 -

5.3 Install management communication fiber

5.4 Introduction of board slot

instruction:

1、ETH:Ports reserved for the master and slave subroutines are cascaded.

2、NM1/NM2:Device management communication port.

3、CONSOLE:Field debugging configuration port.

Place cables

Main control board

OTNS8600-DCI4 Back slot diagram:

SLOT #5 SLOT #6 SLOT #9 SLOT #7 SLOT #8

NS-DWDM-OP01-DCI-AC have 10 slots in total,NS-DWDM-OP01-DCI-AC business slots are 1~4.

NS-DWDM-OP01-DCI-AC Front slot diagram:

SLOT #1 SLOT #2 SLOT #3 SLOT #4

OTNS8600-DCI4 adopts the horizontal board structure and provides 10 board slots.

※Slots 1 to 4 are pluggable discharge layer boards and optical layer boards:P616、P514、P524、

P512、OTA、OLA、WSS、OLP、TFF、OCM8、OTD8

※Slot 9 Installs the main control (SCU) board;

※Slots 6 and 7 Install the FAN board;

※Slots 5 and 8 Insert the PSU board.

- 13 -

5.5 Plug and unplug optical module

Instruction

1、After the optical moduleis installed, do not removethe

dust-proof plug if the optical fiber is not connected

temporarily. 。

2、After the dust plug is removed, keep it properly for

future use.

3、Theoptical moduleneedsto be configured separately and

installed on the host onsite.

Place cables

①Hold the optical module and insert it into the

board.

②Hold the pull ring and pull out the optical

module.

Attention

When pulling out an optical module, pull out the optical moduleby holding the

ring. Do not pull out the optical module by holding the label.

At the sametime, whenthe moduleinsertion is blocked, do not push the module

in hard, and observe whether the module insertion direction is correct.

- 14 -

5.6 Place fibers

Warning

lWhen installing and maintaining the optical fiber, do not get close to or look into the optical fiber outlet

with naked eyes.

Attention

lBefore installing and routing internal optical fibers, install a fixed optical attenuator on the

corresponding optical port of the board according to the fixed optical failure installation table. It is

recommended to add only one optical attenuator. Multiple optical attenuators may lead to the risk of

top door and service interruption.

lThe bending radius of single-mode G.652 optical fibers must be at least 50mm.

lThe bending radius of multi-mode optical fibers cannot be less than 50mm.

lThe bending radius of MPO optical fibers must be at least 60mm.

5.6.1 Install business board fibers

Place cables

④To remove the optical fiber, gently push the

optical fiber connector inward and pull it out

by holding the buckle. Do not pull out the

optical fiber directly by pulling the optical fiber

connector.

③Bind the optical fibers properly and use

Velcro to bind the optical fibers every 150mm

to 300mm.

①Remove the dust plug from the optical

module and the dust cap from the optical fiber

connector.

②Connect an optical fiber to an optical

module on the corresponding wave channels.

- 15 -

5.6.2 Label between boxes

(1)To:Sub-rack number - Slot number - Board name - Optical port name

Meaning: Insert one end of the optical fiber into the 2-OLP board -SIG (IN) port in slot 1 of the subframe.

(2)From:Sub-rack number - Slot number - Board name - Optical port name

Meaning: Insert the other end of the optical fiber into the -L1 (TX) port of the 1-P616 board in slot 1 of the

chassis.

5.6.3 Manage fibers

After the optical fibers are laid out, they must be in bundles and do not intertwine with each other.

Bind them neatly with fiber binding tapes to avoid optical fibers being squeezed. Insert an optical

connector into an optical port, and put an optical cap on the pigtail that does not connect an optical fiber.

manage correctly

manage incorrectly

Place cables

- 16 -

5.7 check fiber loss

Warning

lDuring the process of checking laser decay, avoid laser exposure to human eyes.

Place cables

Instruction:

1、If the difference between P1 and P2 is less than 1dB, the optical fiber is properly connected.

Otherwise, clean the optical fiber. If the difference between P1 and P2 is still greater than 1dB

after cleaning, replace the optical fiber.

2、It is recommended that the wavelength of light source should be near 1550nm and the

wavelength range of optical power meter should be set to 1550nm. If the device is powered on

and configured with an luminous board, use the luminous board as the light source.

①Test the output optical power of the

light source.

②Test the optical output of the light

source after the optical fiber is checked

Optical power P1Optical power P1

Optical power P2

- 17 -

6.1 Check before power-on

Attention

lCheck whether a fixed optical attenuator is added before power-on according to the configuration

rules for fixed optical attenuators.

lCheck whether the voltage of the external power supply meets requirements.

lCheck whether the capacity of the external power fuse meets requirements.

lWhen the power supply voltage does not meet the requirements, do not power on the device.

Danger

Before the device is powered on, all switches of the device and external power supply devices must be

set to OFF.

(1)Check the fuse capacity of the external power supply.

Rack power supply Type MAX power consumption Recommended fuse

capacity

High voltage DC power supply 550W(240V HVDC)16A

Ac power supply 550W(200V AC~240V AC)16A

550W(100V AC~120V AC)

Dc power supply 550W(-36V~-72V DC)16A

(2)Check the voltage of the external power supply

Rack power supply Type Rated voltage range Maximum voltage range

High voltage DC power supply 240V HVDC 192V HVDC ~ 288V HVDC

Ac power supply 100V AC ~ 130V AC(50 / 60 Hz)

200V AC ~ 240V AC(50 / 60 Hz)90V AC ~ 264V AC(45 / 65 Hz)

Dc power supply -48V DC ~ -60V AC -40V AC ~ -72V AC

(3)Use a multimeter to check whether there is short circuit between the phase line (commonly known as

live line), ground line, and neutral line of each power socket.

(4)Use a multimeter to check whether the input voltage of the external power supply is within the normal

voltage range of the device.

6.2 Check after power-on

After the device is powered on, check the power indicator status of each functional unit and fan running

status to determine whether the device is powered on properly.

Check after installation

Power indicator description:

Indicator

light

Green

light

Orange

light

Light off Handle exceptions onsite

PWR The power

supply is

normal

The power

supply is

abnormal

The device is

powered off or

cannot work

properly

Disconnect the power supply

immediately, rectify the fault, and then

power on again.

Fan board: Check whether the fan is started at the rear of the device or feel the air volume at the air outlet

of the device.

Meaning of fan indicator::

Indicator

light

Green

light

Red light Light off Handle exceptions onsite

STAT The power

supply is

normal

The power

supply is

abnormal

The device is

powered off or

cannot work

properly

Query software alarms. If alarms

exist, replace the fan box

SCU main control board power indicator description:

Name of printing Functional description

STAT(Board running status

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

ACT(Active and standby status

indicators)

When both the active and standby boards are installed, the one

with the active/standby indicator on is the active board, and the

one with the inactive indicator is the standby board

In the case of a single main control system, the active and standby

indicators are steady on

SFP1(SFP port 1 running status

indicator)

Steady green: SFP port 1 is properly connected

If the indicator is off, the connection to SFP port 1 is abnormal

SFP2(SFP port 2 running status

indicator)

Steady green: SFP port 1 is properly connected

If the indicator is off, the connection to SFP port 1 is abnormal

- 18 -

- 19 -

Description of the indicators on the front panel:

Name of printing Functional description

STAT(Board running status

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

Electrical board panel indicator:

Name of printing Functional description

STAT(Electrical board panel

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

L1 (OTUCn、ODUK、CFP2-DCO

module、OCH layer running status

indicator)

Steady green: The module running status and the cable status are

normal

Steady red: A critical alarm is generated for the port

Blinking red at 1Hz: a major alarm is generated for the port

Steady yellow: A minor alarm is generated for the port

If the indicator is off, no service is running on the port

C1~Cn (OPUk、QSFP28

module、service running status

indicator on the customer side)

Steady green: The module running status and the cable status are

normal

Steady red: A critical alarm is generated for the port

Blinking red at 1Hz: a major alarm is generated for the port

Steady yellow: A minor alarm is generated for the port

If the indicator is off, no service is running on the port

OTA Optical board panel indicator description:

Name of printing Functional description

STAT(Board running status

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

- 20 -

Name of printing Functional description

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

LINE/SIG (Optical port status

indicator)

Steady green, no alarm is generated, and the input light is

generated and within the normal range

Steady yellow, major or minor alarms, with input light but within

the lower threshold

Red Steady on: A critical alarm is generated, indicating that the

input light is absent

OLA Optical board panel indicator description:

Name of printing Functional description

STAT(Board running status

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

LINE1/2 (Optical port status

indicator)

Steady green, no alarm is generated, and the input light is

generated and within the normal range

Steady yellow, major or minor alarms, with input light but within the

lower threshold

Red Steady on: A critical alarm is generated, indicating that the

input light is absent

WSS Optical board panel indicator description:

Name of printing Functional description

STAT(Board running status

indicator)

Steady green: The device is powered on and operating normally

Steady red: A critical alarm is generated

Blinking red at 1Hz: a major alarm is generated

Steady yellow: A minor alarm is generated

Blinking yellow at the frequency of 1Hz, the device software is not

running properly

If the indicator is off, the device is powered off or cannot work

properly

Table of contents

Popular Computer Hardware manuals by other brands

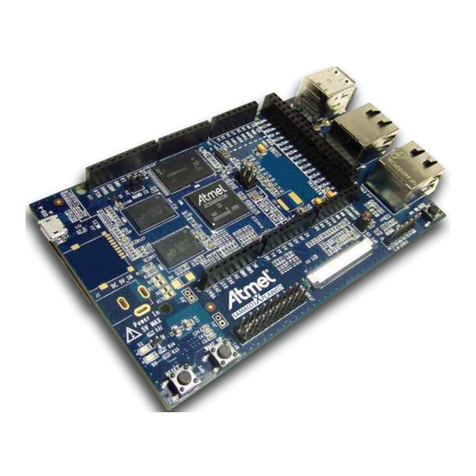

Atmel

Atmel SMART SAMA5D3 Series user guide

Integration

Integration IA OEM-DAUB1 2400 quick start guide

Krell Industries

Krell Industries S-1000 Instructions for use

Digi

Digi NS9210 Hardware reference

PLX Technology

PLX Technology CompactPCI 9030RDK-LITE Hardware reference manual

Microchip Technology

Microchip Technology PD-90 G Series user guide