10

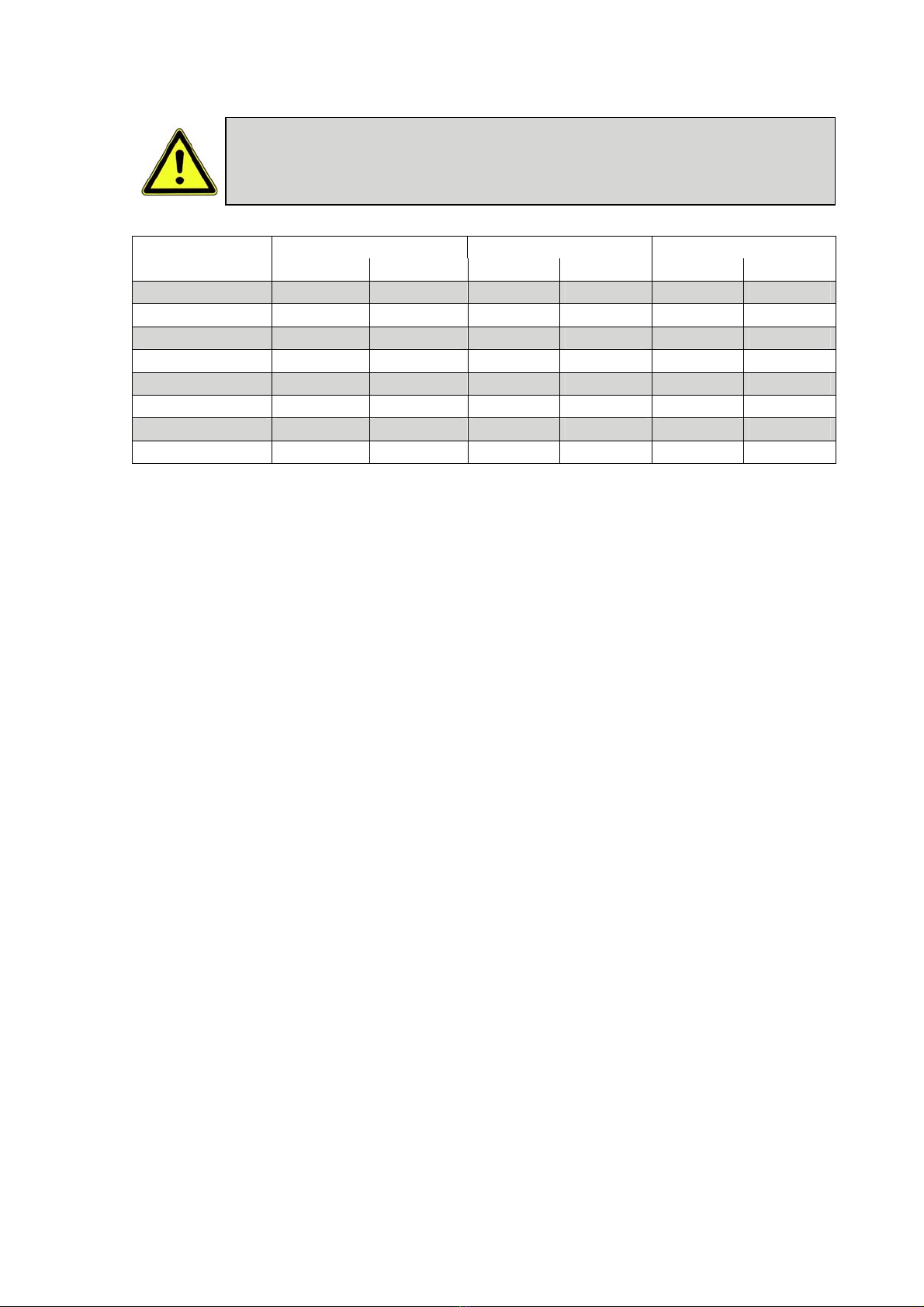

Direction of rotation:

Hydraulic vibrators of type NHG without leak oil port must only be operated

with the specified direction of rotation. With these units a loading of the

return flow with system pressure must be ruled out.

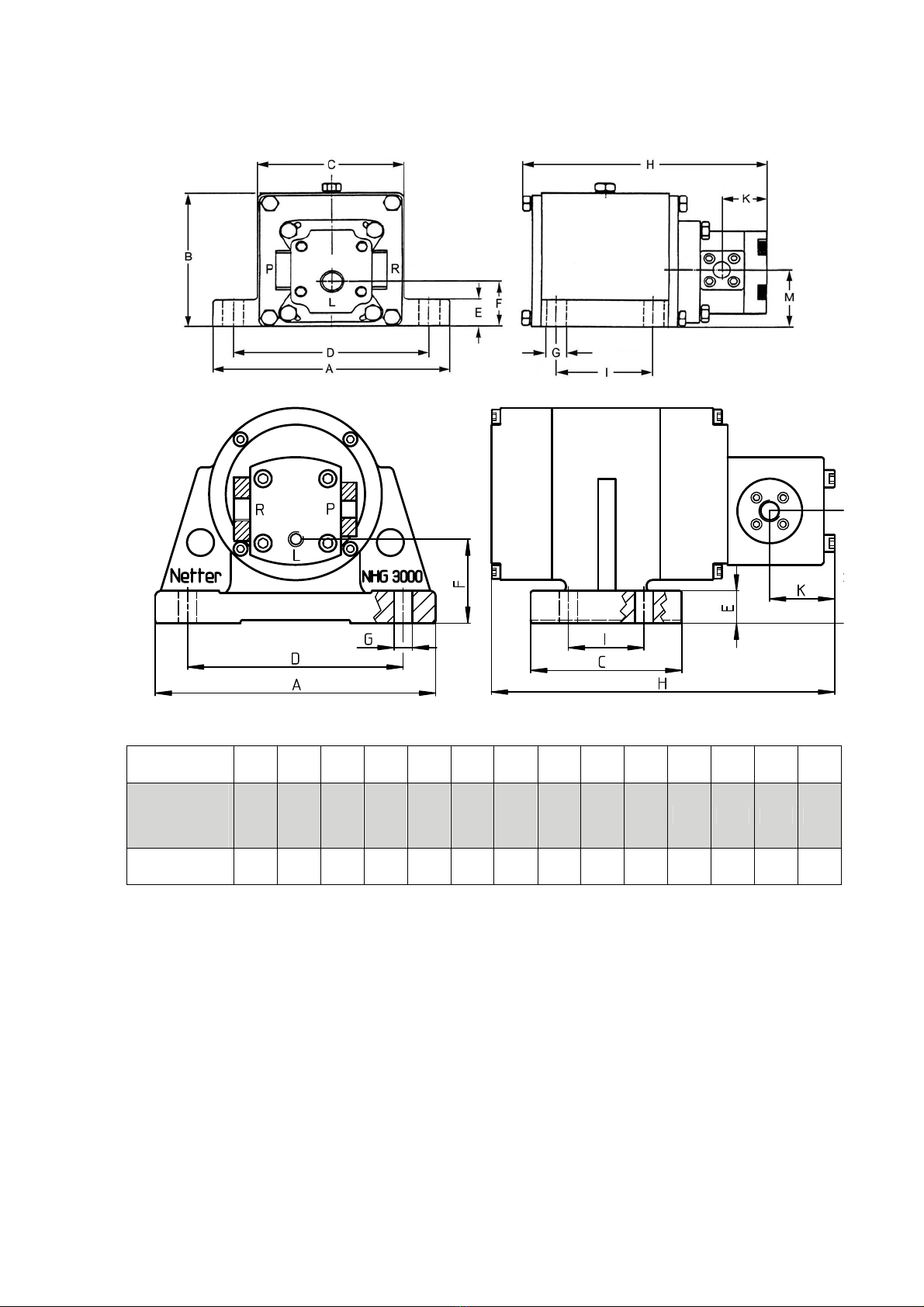

Connecting data

Pressure Return side Leakage line

Type Thread NW [mm] Thread NW[mm] Thread NW[mm]

NHG 500 G 1/4 8-12 G 3/8 12-15 - -

NHG 600 R G 1/4 8-12 G 3/8 12-15 - -

NHG 900 G 1/4 8-12 G 3/8 12-15 - -

NHG 3000 G 3/8 12-15 G 1/2 15-18 - -

NHG 500 L G 1/4 8-12 G 3/8 12-15 G 1/48

NHG 600 R L G 1/4 8-12 G 3/8 12-15 G 1/48

NHG 900 L G 1/4 8-12 G 3/8 12-15 G 1/48

NHG 3000 L G 3/8 12-15 G 1/2 15-18 M12×1,5 8

Checklist for installation:

1)

2)

3)

4)

Consider the expected operating temperature.

Tighten the fastening screws for the NHG.

Assemble way and flow control valve, supply, return and by-pass lines.

Check!

Has the direction of rotation of the hydraulic motor been observed?

Have the hoses been tightened?

Have the specifications on nominal diameters been observed?

Has the unit been secured against falling down?

7 Operation

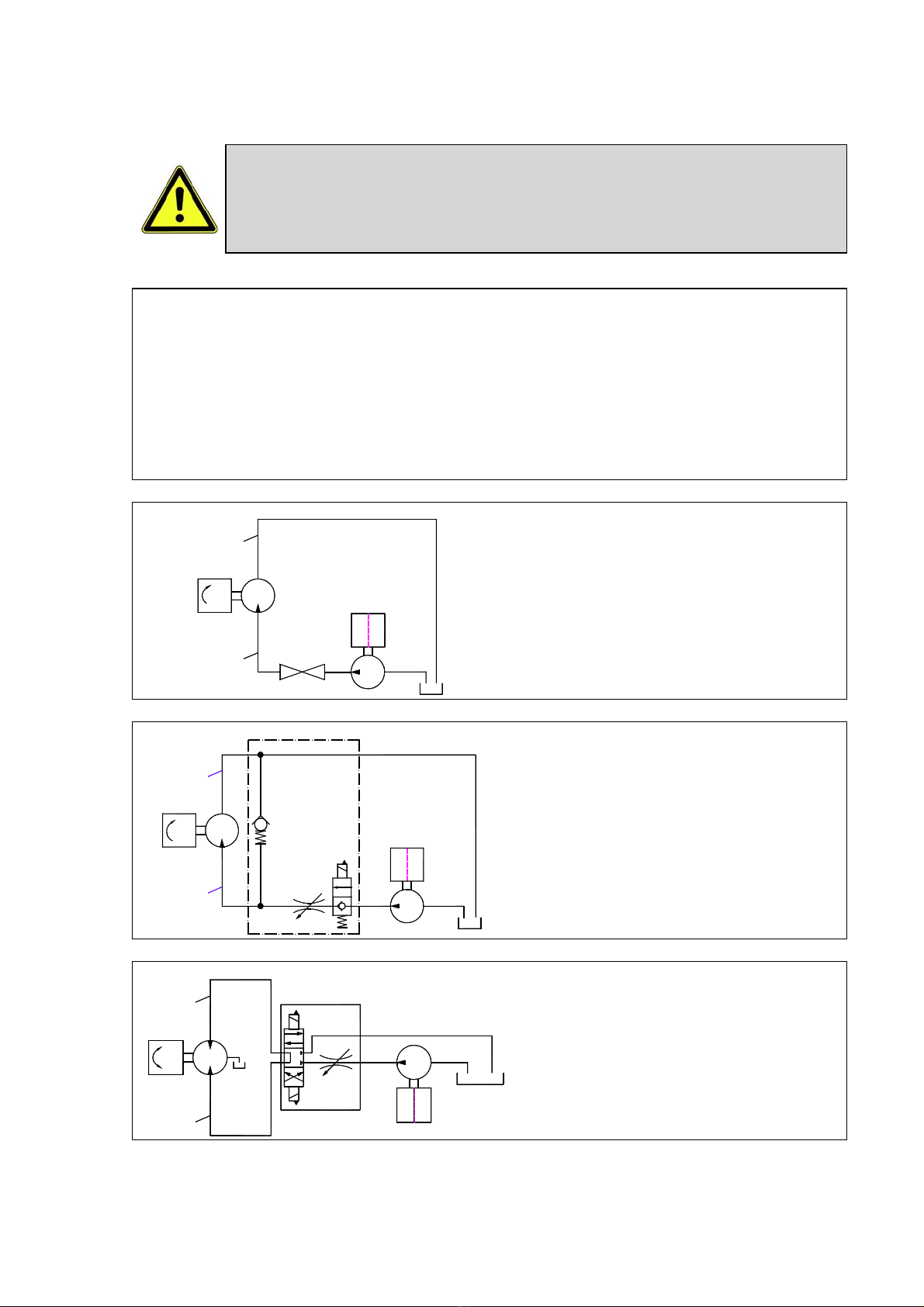

Flushing:

Before starting hydraulic external

vibrators all corrosion protection

residues or impurities that have

entered during transport and storage

must be flushed out with the hydraulic

fluid to be used.

Filter:

During the running-in phase use a

filter R5μm for 2-3 hours, then

change to R10μm (19/16 ISO 4406).

Leak oil port:

If NHG have to be operated with

higher pressures in the return flow, the

version with leak oil port must be used

(for permissible operating pressures

refer to chapter 4 safety page 7).

The leakage line must be routed in a

size and should end in the tank below

the fluid level, so that the unit stays

filled, but no siphon effect is created

inside the tank.

Direction of rotation:

Hydraulic external vibrators without

leak oil port (L) have only one

permissible direction of rotation. A

change in the direction of rotation can

only be made by Netter GmbH.

Hydraulic external vibrators with

leakage port can be used for both

directions of rotation.

Regulating the speed:

Regulation of the speed can only be

accomplished by an external control

with adjustable flow control valve.

Possible controls see chapter 6

"Assembly” on page 9.