NETZSCH LFA 447 Nanoflash User manual

Operating Instructions

LFA 447

TM

01/09 J:\LFA447\Contents.doc

Operating Instructions LFA 447TM Nanoflash

Contents

Chapter I General Information

Chapter II Installation

Chapter III System Components

Chapter IV Operating the Instrument

Chapter V Appendix

01/09 J:\LFA447\CHAPTER1.DOC

Chapter I

General Information

LFA 447

TM

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 1

Information

In the design of your instrument, we endeavor to take individual

solutions into account and to include these in the documentation.

However, in order to keep the scope of the technical documentation at

a reasonable level, we must limit the description to a standard model.

We ask for your understanding, if additional information particular to

your instrument is not included within the scope of the standard

instructions.

This additional information can always be found on the corresponding

information sheets.

Prior written permission from NETZSCH-Gerätebau GmbH is required

for electronic or mechanical duplication and distribution of these

instructions.

All technical data, instrument features and other information described

in these operating instructions are presented to the best of our

knowledge and in accordance with the technical standards of the

instrument at the time of printing.

We welcome any comments, suggestions or new ideas concerning the

instrument and these operating instructions. Please address them to:

NETZSCH-Gerätebau GmbH

Wittelsbacherstraße 42

D - 95100 SELB

Telephone: 09287/881- 0

Telefax: 09287/881- 144

Internet: http://www.netzsch-thermal-analysis.com

Maintenance and service must be carried out by NETZSCH Customer

Service personnel.

A service contract is available for our customers.

This instruction manual is provided to give the customer information

on proper operation of the instrument. NETZSCH-Gerätebau GmbH will

accept no liability for damage resulting from improper use.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 2

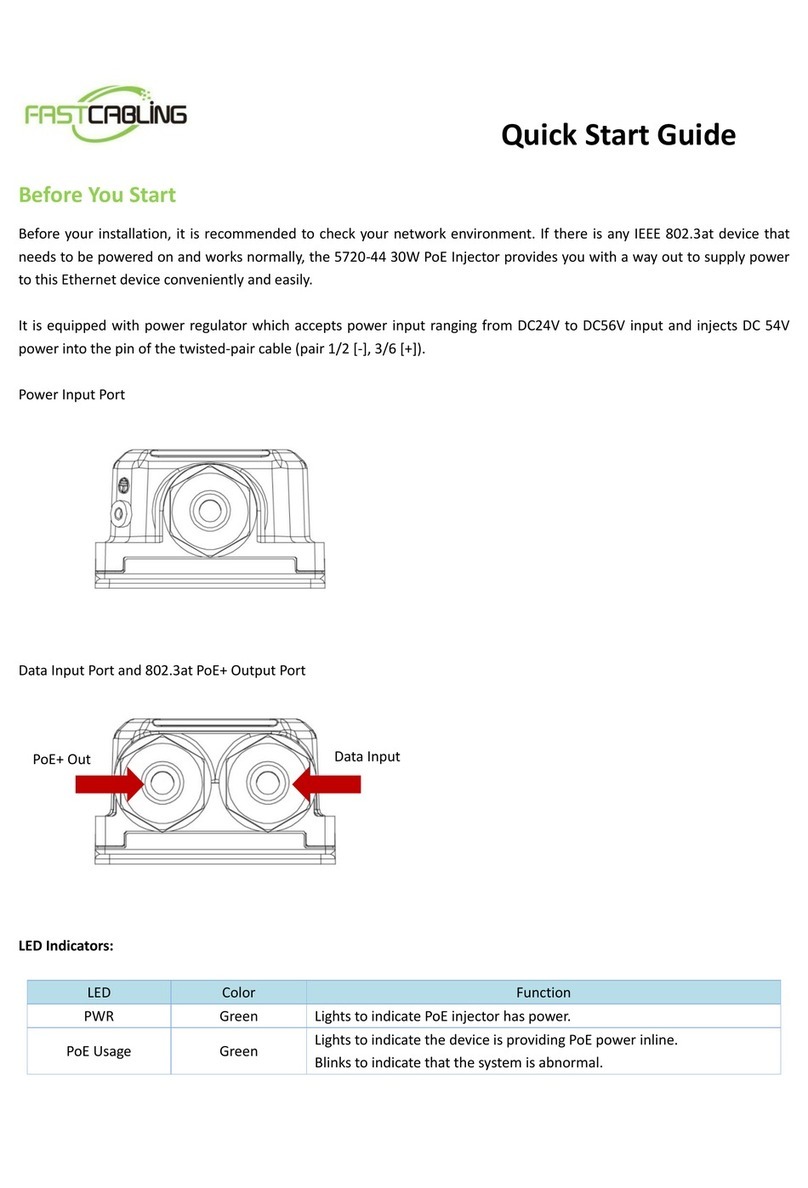

Notes on the Use of this Manual

In this manual, the symbols described below are used to simplify orientation.

NOTE!

This sets particularly important information apart from the

rest of the text.

ATTENTION!

These instructions must be followed exactly to avoid injury

to the user and damage to the instrument.

This symbol refers to more detailed information which can

be found elsewhere, e.g. in the Software Manual.

The tools listed after this symbol are required for the

installation or modification of your instrument.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 3

Basic Safety Information

State-of-the-Art Your instrument has been produced with state-of-the-art

technology and is safe to operate.

Authorized

Operation

Any operation of the instrument other than as authorized

requires consultation with NETZSCH.

Any use exceeding the (expanded) authorized operation is

considered unauthorized. The manufacturer will not be liable

for any damage resulting from such use.

Manufacturer's

Requirements

Authorized operation of the instrument includes compliance

with manufacturer's requirements regarding installation,

commissioning, operation and maintenance.

Training of

Personnel

Your instrument may only be operated and maintained by

authorized, trained and individually instructed personnel who

have been informed of possible sources of danger.

Responsibility Responsibility for commissioning, operation and maintenance

must be clearly defined and compliance must be ensured. The

resulting responsibilities can be clearly resolved under the

aspect of safety.

Unauthorized Access

The operator must make sure that only trained personnel work

on the instrument.

Improper Operation Any type of operation which reduces the safety of the user and

the operability of the instrument should be avoided.

Unauthorized

Changes to the

System

Unauthorized modifications and changes which effect the

safety of the instrument are not permitted.

Obligation to Report

Changes to the

System

The user is obligated to immediately report to the operator in

charge any changes to the instrument which effect the safety of

the system.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 4

Maintenance

Obligation

The operator of the system must ensure that the instrument is

operated in perfect condition at all times.

Proper Set-up of the

Work Stations

The operator must guarantee the openness and cleanliness of

the work stations at the instrument through appropriate

instruction and inspections.

Shut-down For all maintenance work, the instrument must be switched off

and unplugged.

Removal of

Protective Devices

Protective devices may only be removed when the instrument is

switched off and unplugged. It is imperative that the

protective devices be replaced before starting the instrument.

Checks following

Maintenance or

Repair Work

After maintenance or repair work, a check should be made to

ensure that all protective devices are in place and operate

properly. Only then should the instrument be started.

Industry-specific

Accident Prevention

Regulations

The operator must observe the relevant regulations and

protective measures when handling the required gases. In

addition, possible reactions with the materials used must be

considered. At operating temperatures above 55°C, protective

gloves must be worn. In any case, the industry-specific and local

accident prevention regulations are also valid for the

instrument.

Disposal of

Production Materials

Production materials are to be disposed of according to local

regulations.

Maintenance or

Repair

Products sent in for maintenance or repair should, to the extent

possible, be free of harmful substances (e.g. radioactive, toxic,

caustic or microbiological materials). Otherwise, the type of

contamination must be declared. Products not explicitly

declared to be "free of harmful substances" will be

decontaminated at the expense of the sender.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 5

Operating

Instructions

Using the Operation Manual, the operator should prepare

operating instructions which specify the actions and tasks

required for safe operation.

The operating instructions should be placed in a suitable

location in the work place and complied with by the employees.

Gases Observe the relevant regulations and protective measures when

handling the required gases.

Consider possible reactions with the materials.

Warning signs should be hung in the appropriate places in

accordance with national and regional regulations.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 6

Safety regulations for handling liquid nitrogen LN2

It is imperative that you observe the safety regulations for

handling nitrogen.

FIRE AND EXPLOSION HAZARDS

Neither gaseous nor liquid nitrogen are flammable and do not in

themselves constitute a fire or explosion risk. However, both

gaseous and liquid nitrogen are normally stored under pressure

and the storage vessels, whether gas containers or liquid tanks,

should not be located in areas where there is a high risk of fire or

where they may normally be exposed to excessive heat. Vessels

containing compressed gaseous nitrogen may rupture violently if

overheated as a result of exposure to fire.

Oil-lubricated compressors operated continuously on nitrogen

supply for a prolonged period should not be switched to air supply

without thorough cleaning. Otherwise there is a danger that

unoxidized pyrophoric deposits which may have formed in the

machine will explode violently on contact with compressed air.

At equal pressures, the boiling point of liquid nitrogen is lower

than that of liquid air. Air will condense on the external surfaces

of vessels or pipework containing liquid nitrogen at an equilibrium

pressure less than 1.5 bars absolute if the vessels are either not

lagged, or are lagged with a porous cellular-type insulator. The

liquid air produced can result in oxygen enrichment of the

atmosphere local to the equipment. Special precautions must

therefore be taken with regard to the insulation of the vessel

before any maintenance or repair work is started, particularly

where the use of open flames or other potential sources of

ignition is intended.

MATERIAL HAZARDS

Certain steels, such as carbon steel, and some other materials are

unsuitable for use at sub-zero temperatures because they lose

impact strength and become extremely brittle. Carbon steel

cannot be used safely at temperatures below -30°C (-20°F) and is

obviously unsuitable for use with liquid nitrogen. Materials

normally suitable for use at low temperatures are the austenitic

stainless steels, aluminum and copper and its alloys. In an area

where liquid nitrogen spillage can occur, care should be taken to

ensure that the liquid does not come into contact with vulnerable

steel structures and vehicle tires.

Care should be taken to ensure that liquid nitrogen and cold

nitrogen vapor are not trapped in a closed system without any

form of automatic pressure relief. Otherwise, pressures well in

excess of the equipment working pressure will be generated as the

system warms up, thus creating a possible rupture hazard.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 7

HEALTH HAZARDS

Asphyxia

Nitrogen, although non-toxic, can constitute an asphyxiation

hazard through the displacement of the oxygen in the

atmosphere. The potential for this type of hazard is significant

because of the widespread use of nitrogen as a purging or

blanketing gas in chemical, metallurgical, and other industrial

operations and because neither nitrogen gas nor oxygen depletion

are detectable by the normal human senses. Unless adequate

precautions are taken, persons can be exposed to oxygen-deficient

atmospheres if they enter equipment or areas which have

contained or have been purged with nitrogen.

Oxygen is required to support life and its volume concentration in

the atmosphere is normally 21%. At normal atmospheric pressure

(760 mm Hg), persons may be exposed to oxygen concentrations

of 18% by volume (equivalent to a partial pressure of 135 mm Hg),

or even less, without adverse effects. However, the response of

individuals to oxygen deprivation varies considerably. The

minimum oxygen content of breathing atmosphere should be 18%

by volume (at normal atmospheric pressure), but to ensure a wider

margin of operational safety, it is recommended that persons not

be exposed to atmospheres in which the oxygen concentration is,

or may become, less than 20% by volume.

Symptoms of oxygen deprivation, such as increased pulse and

breathing rate, fatigue and abnormal perceptions or responses,

may be apparent at an oxygen concentration of 16%.

Permanent brain damage or death may result from breathing

atmospheres containing less than 10% oxygen. Initial symptoms

include nausea, vomiting and gasping respiration. Persons

exposed to such atmospheres may be unable to help themselves or

warn others of their predicament. The symptoms are an

inadequate warning of the hazard.

BREATHING A PURE NITROGEN ATMOSPHERE WILL PRODUCE

IMMEDIATE LOSS OF CONSCIOUSNESS AND ALMOST IMMEDIATE

DEATH.

Cold burns

Liquid nitrogen and cold nitrogen vapors or gases can produce

effects on the skin similar to a burn. Unprotected parts of the

body coming into contact with uninsulated parts of the equipment

may also stick fast (because all available moisture is frozen) and

the flesh may be torn on separation.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 8

Frostbite

Severe or prolonged exposure to cold nitrogen vapor and gas can

cause frostbite. Local pain usually gives warning of freezing, but

sometimes no pain is experienced. Frozen tissues are pain-free

and appear waxy with a pallid yellowish color. Thawing of the

frozen tissues can cause intense pain. Shock may also occur if the

frostbite is at all extensive.

Effects of cold on lungs

Prolonged breathing of extremely cold atmospheres may damage

the lungs.

Hypothermia

Low environmental temperatures can cause hypothermia and all

persons at risk should wear warm clothing. Hypothermia is

possible in any environmental temperature below 10°C (50°F), but

susceptibility depends on time, temperature and the individual.

Older persons are more likely to be affected. Individuals suffering

from hypothermia may find their physical and mental reactions are

adversely affected.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 9

PRECAUTIONS

Operations and maintenance

It is essential that operations involving the use of gaseous or liquid

nitrogen, particularly where large quantities are used, are

conducted in well-ventilated areas to prevent the formation of

oxygen-deficient atmospheres.

Ideally, nitrogen should be vented into the open air well away

from areas frequented by personnel. Nitrogen should NEVER be

released or vented in enclosed areas or buildings where the

ventilation is inadequate.

Before entering areas, vessels or other equipment for maintenance

or other purposes in which the atmosphere is, or may become

deficient in oxygen, action should be taken to make the

equipment safe. Preparatory work will include equipment

isolation from hazardous processes, purging and continued

ventilation with air as appropriate. Equipment in service with

flammable gases should be purged with nitrogen prior to purging

with air to avoid the formation of flammable mixtures.

NEVER USE OXYGEN AS A SUBSTITUTE FOR AIR AS A PURGING

MEDIUM. Prior to entry, the atmospheres should be tested with a

portable oxygen analyzer (calibrated before use) to ensure that

the oxygen lies between 20% and 22% by volume. The use of a

safety work permit system is strongly recommended (Note: The

latter two recommendations need not apply when entering a

Cryo-Guard vehicle for normal loading or unloading purposes. For

details see Cryo-Guard Drivers Instruction Manual).

It should be recognized that although nitrogen is slightly lighter

than air at equal temperatures, liquid nitrogen and cold nitrogen

vapor are denser than air and can accumulate in low-lying areas

such as pits and trenches. Where large spills of liquid nitrogen

occur, a fog is formed in the vicinity of the spill caused by the

condensation of water vapor in the surrounding air. The fog, in

addition to severely reducing visibility, may contain oxygen

concentrations appreciably lower than those of air, thus

presenting a local asphyxiation hazard.

IF IT IS NECESSARY FOR A PERSON TO ENTER AN OXYGEN-

DEFICIENT ATMOSPHERE FOR MAINTENANCE OR OTHER

PURPOSES, IT IS ESSENTIAL THAT HE/SHE WEAR, AND BE TRAINED

IN THE USE OF, A SELF-CONTAINED BREATHING APPARATUS.

Persons entering an oxygen-deficient area are advised to wear a

safety belt with a manned safety line attached. Standby personnel

should have ready access to self-contained breathing apparatus

should emergency assistance be required.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 10

Personnel protection

It is recommended that persons handling gas containers wear

safety glasses, safety footwear and clean, sturdy gloves.

Persons handling equipment in service with liquid nitrogen should

wear protective face shields, loose fitting leather or insulated

gauntlets.

EMERGENCIES

In the event of accident or emergency, the instructions below

should be implemented without delay. After emergency action

has been taken, contact your nearest Air Products PLC Sales Office

(see list at the back) for further advice.

Asphyxiation

Persons showing symptoms of oxygen deprivation should be

moved immediately to a normal atmosphere. Persons who are

unconscious or not breathing must receive immediate first aid.

Medical assistance should be summoned without delay and first

aid measures include inspection of the victim's airway for

obstruction, artificial respiration and simultaneous administration

of oxygen. The victim should be kept warm and quiet.

It is important to note that personnel carrying out rescue

operations must minimize the risk to themselves. A RESCUER

SHOULD NOT ATTEMPT TO ENTER AN OXYGEN-DEFICIENT

ATMOSPHERE WITHOUT USING SUITABLE SELF-CONTAINED

BREATHING APPARATUS; OTHERWISE HE MAY HIMSELF BE

OVERCOME. Many double fatalities have occurred in industry as a

result of personnel who, with the best intentions but without

proper breathing apparatus and equipment, have entered an

oxygen-deficient atmosphere in an attempt to rescue a colleague.

Treatment of cold burns and frostbite

Cold burns should receive medical attention as quickly as possible.

However, such injuries are not an everyday occurrence and

doctors, hospital staff or on-site first aid personnel may not be

aware of the basic methods of treatment. The following notes

describe the first aid treatment and recommended advice for

further treatment to be given by a medical practitioner or a

hospital.

First Aid

In severe cases, summon medical attention at once. Flush affected

areas of skin with copious quantities of tepid water to reduce

freezing of tissue. Loosen any clothing that may restrict blood

circulation. Move the victim to a warm place but not to a hot

environment and do not apply direct heat to the affected areas.

Every effort should be made to protect the frozen areas from

infection and further injury. Dry, sterile bulky dressings may be

used but should not be applied so tightly that blood circulation is

restricted.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 11

Treatment by medical practitioner or hospital

a) Remove any clothing that may constrict the circulation to the

frozen area. Remove patient to sick bay or hospital.

b) Immediately place the part of the body exposed to the

cryogenic material in a water bath which has a temperature of not

less than 40°C (104°F) but not more than 45°C (113°F). (See below

for exceptions to this recommendation.) NEVER USE DRY HEAT OR

HOT WATER. Temperatures in excess of 45°C will superimpose a

burn upon the frozen tissue.

c) If there has been massive exposure to the super-cooled material

so that the general body temperature is lowered, the patient must

be re-warmed gradually. Shock may occur during rewarming,

especially if this is rapid.

d) Frozen tissues are pain-free and appear waxy with a pallid

yellowish color. They become painful, swollen and very prone to

infection when thawed. Therefore, do not re-warm rapidly if the

accident occurs in the field and the patient cannot be transported

to a hospital immediately. Thawing may take from 15 to 60

minutes and should be continued until the blue, pale color of the

skin turns to pink or red. Morphine or some other potent

analgesic is required to control the pain during thawing and

should be administered under professional medical supervision.

e) If the frozen part of the body has thawed by the time medical

attention has been obtained, do not re-warm. Under these

circumstances, cover the area with dry sterile dressings with a large

bulky protective covering.

Administer a tetanus booster after hospitalization.

Hypothermia

Persons suspected to be suffering from hypothermia should be

wrapped in blankets and moved to a warm place. Slow

restoration of temperature is necessary and forms of locally

applied heat should not be used. Summon medical attention.

Fire fighting

Nitrogen is not flammable and no special fire fighting precautions

or equipment are needed. If an outbreak of fire occurs in the

vicinity of nitrogen storage equipment, the local fire department

should be summoned at once. Unless vessels containing

compressed gaseous nitrogen can be removed safely to an

unaffected area, every effort should be made to keep them cool

by spraying them with large quantities of water.

Liquid nitrogen spillage

If large spills of liquid nitrogen occur, large quantities of water

should be used to increase the rate of liquid vaporization.

Vehicles involved in a heavy liquid spillage should not be moved as

the tires may be frozen to the ground and the rubber will be

brittle.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 12

GAS CONTAINERS

The content of the container is primarily identified by a label

attached to the container shoulder and secondarily by the color of

the container. The Air Products identification colors for containers

containing nitrogen are:

Body: French gray; shoulder and guard: black (BS 349: 1973)

The following practices are recommended for safe handling and

storage of high-pressure gases including nitrogen containers.

General

−Only trained persons should handle compressed gases.

−Observe all regulations and local requirements regarding the

storage of containers.

−Do not remove or deface labels provided by the supplier for the

identification of the container contents.

−Ascertain the identity of the gas before using it.

−Know and understand the properties and hazards associated

with each gas before using it.

−Establish and implement plans to cover any emergency

situations that might arise.

−When doubt exists as to the correct handling procedure for a

particular gas, contact the supplier.

Handling and Use

−Wear stout gloves.

−Never lift a container by the cap or guard unless the supplier

states it is designed for that purpose.

−Use a trolley or other suitable device or technique for

transporting heavy containers, even for a short distance.

−Leave valve protection caps or guards (where provided) in place

until the container has been secured against a wall or bench or

placed in a stand and is ready for use.

−Where necessary, wear suitable eye and face protection. The

choice between safety glasses, chemical goggles, or full face

shield will depend on the pressure and nature of the gas being

used.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 13

Storage and handling

−Where necessary for toxic gases, see that self-contained positive

pressure breathing apparatus or a full face air line respirator is

available in the vicinity of the working area.

−Check for gas leaks using a suitable method. Flammable and

toxic gas monitors are available. Where a gas is toxic, check

special procedures specified by the supplier.

−Ascertain that an adequate supply of water is available for first

aid, fire fighting, or dilution of corrosive material in the event

of leakage.

−Employ suitable pressure regulating devices on all containers

when the gas is being emitted to systems with a lower pressure

rating than that of the container.

−Before connecting the container for use, ensure that back feed

from the system into the container is prevented.

−Ascertain that all electrical systems in the area are suitable for

service with each gas.

−Never use direct flame or electrical heating devices to raise the

pressure of a container. Containers should not be subjected to

temperatures above 45°C.

−Never re-compress a gas or a gas mixture from a container

without consulting the supplier.

−Never attempt to transfer gases from one container to another

unless expressly agreed beforehand with the supplier.

−Do not attempt to increase liquid draw-off rate by pressurizing

the container without first checking with the supplier.

−Do not use containers as rollers or supports, or for any other

purpose than to contain the gas as supplied.

−Never permit oil, grease or other readily combustible substances

to come into contact with valves of containers containing

oxygen or other oxidants.

−Keep container valve outlets clean and free of contaminants,

particularly oil and water.

−Do not subject containers to abnormal mechanical shocks which

may cause damage to their valves or safety relief devices.

−Never attempt to repair or modify container valves or safety

relief devices. Damaged valves should be reported immediately

to the supplier.

−Close the container valve whenever gas is not required, even if

container is still connected to equipment.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 14

−Replace outlet caps or plugs and container caps (where

provided) as soon as container is disconnected from equipment.

Storage

−Containers should be stored in a well-ventilated area. Some

gases will require a specially built area.

−Store containers in a location free of fire risk and away from

sources of heat and ignition. Designation as a "No smoking"

area may be desirable.

−The storage area should be kept clear and access should be

restricted to authorized personnel only. The area should be

clearly marked as a storage area and appropriate hazard

warning signs displayed (flammable, toxic, radio active etc.).

−Containers in storage should be properly secured to prevent

toppling or rolling.

−Vertical storage is recommended where the container is so

designed.

−Container valves should be tightly closed and, where

appropriate, valve outlets should be capped or plugged.

−Container valve protection guard or cap should be in place and

properly secured.

−Protect containers stored in the open against rusting and

weather extremes. Containers should not be stored in

conditions likely to encourage corrosion.

−Store full and empty containers separately and arrange full

containers so that the oldest stock is used first.

−Gas containers should be segregated in the storage area

according to the various categories (toxic, flammable, oxidant,

etc.).

−The amounts of flammable or toxic gases in storage should be

kept to a minimum.

−Flammable gases should be stored away from other

combustible materials.

−Containers held in storage should be periodically checked for

general condition and leakage.

General Information

LFA 447

TM

01/09 J:\LFA447\CHAPTER1.DOC 15

LIQUID STORAGE CONTAINERS

−Liquid nitrogen is stored and transported either in purpose

built storage tanks or dewar flasks. Storage quantities vary

from a few liters for dewar flasks to several thousands of liters

for storage tanks. The storage tanks are pressurized, insulated

containers which are installed in accordance with established

codes of practice. All liquid storage areas should be kept clean

and free of flammable materials.

−Unlike a liquid nitrogen tank, a vaccum-jacketed dewar flask is

essentially a non-pressurized container.

−Recommendations for handling and storage are as follows:

−The protective caps on dewar flask fill/ drain outlets should be

kept closed when not in use to prevent contamination and

ensure that blockage by frost does not occur. Check caps

regularly to ensure that they have not become sealed by frost

accumulating on the surface. Formation of frost may be

removed by warming gently with air.

−DO NOT USE SOURCES OF EXCESSIVE HEAT SUCH AS STEAM OR

OPEN FLAMES.

−Dewar flasks should be stored in well-ventilated areas where

they are protected against weather extremes, particularly heavy

rain.

01/09 J:\LFA447\CHAPTER2.DOC

Chapter II

Installation

LFA 447

TM

Installation

LFA 447

TM

01/09 J:\LFA447\CHAPTER2.DOC

Contents

INSTALLATION.............................................................................................1

PACKING AND DELIVERY ............................................................................1

LOCATION REQUIREMENTS ..........................................................................2

INSTALLATION SCHEMATICS.........................................................................3

CONNECTING THE COMPUTER SYSTEM ................................................................. 4

CONNECTING THE THERMOSTAT .......................................................................... 5

Installation

LFA 447

TM

01/09 J:\LFA447\CHAPTER2.DOC 1

Installation

In most cases, your LFA 447 is set up and commissioned by

one of our customer service engineers.

If you would like to set up your instrument yourself, please

read the following sections.

Packing and Delivery

We deliver all components in separate cartons. The

measuring unit, electronics, computer system etc. are packed

in form-molded foam to protect against damage during

transport.

We recommend keeping the original cartons. Should repairs

or an extension of the system become necessary, the cartons

can be reused, thus ensuring a relatively safe return to the

manufacturer.

Prior to shipping, we carefully test all components of the

system for mechanical and electrical operability.

After unpacking, please check all delivered components for

possible transport damage and compare the individual items

against the delivery note supplied.

Should an item be missing, please contact us immediately.

Table of contents

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific Sorvall RC6 Plus instruction manual

IKA

IKA Lab disc manual

Thermo Scientific

Thermo Scientific Sorvall Legend X1R instruction manual

Thermo Scientific

Thermo Scientific iCAP RQ ICP-MS Pre-installation requirements guide

Diesse

Diesse MINI-CUBE user manual

Neuation

Neuation iSWIX JR. NXT Product user manual

Kodak

Kodak X-Omat MULTILOADER 300 Plus Service manual

Wasatch Photonics

Wasatch Photonics Cobra OCT Getting started guide

TAN Bead

TAN Bead Smart LabAssist Series user manual

SIGNALCORE

SIGNALCORE SC5511A Operating & programming manual

Heidolph

Heidolph MR Hei-Standard operating manual

ibidi

ibidi 11920 instruction manual