New Age 65902 User manual

1

www.newageproducts.com

DSB -INSTL-01-Rev.03

OUTDOOR KITCHEN

DOUBLE SIDE BURNER

STOP

Use two or more people to move, assemble, or

install the burner to avoid back injury. Do not

leave children unattended near a burner, grill

or cabinets. For assistance, call 1.877.306.8930;

for U.K 0800.031.4069: e-mail at info@

newageproducts.com.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

ATTENTION: Is your burner damaged?

Need help or spare parts? For fastest service,

contact NewAge Products at 1-877-306-8930;

Do not return to the retailer.

Warning! Excessive weight

hazard!

!

16”STAINLESS STEEL DUAL SIDE BURNER - MODEL 65902

NEWAGE INSERT DUAL SIDE BURNER CABINETS ;

65012- 16”STAINLESS STEEL INSERT DSB CABINET

65212- 16”GREY ALUMINUM GLASS INSERT DSB CABINET

65412- 16”COASTAL GRAY ALUMINUM INSERT DSB CABINET

65609- 16”STAINLESS STEEL GROVE INSERT DSB CABINET

ALL CABINETS LISTED ABOVE WERE DESIGNED

SPECIFICALLY TO FIT THE 16”DUAL SIDE BURNER.

SEE SHOPNEWAGE.COM FOR MORE INFORMATION.

NEWAGE PRODUCTS INC.

111 CREDITVIEW ROAD, 2nd FLOOR ,VAUGHAN, ONTARIO,

CANADA L4L-9T1

2www.newageproducts.com

WARNINGS

!

1. Shut o all gas supply lines to the burner.

2. Extinguish any open ames.

3. Open the lid to the side burner.

4. If gas odor persists, vacate the area near the burner and contact your

gas supplier or your re department immediately.

DANGER

IF YOU SMELL GAS:

Failure to follow these instructions could result in re or explosion which

could cause property damage, personal injury or death.

!

1. Never Operate this appliance unattended.

2. Never opperate this appliance within 10 ft (3.0) of any structure,

combusttible material or other gas cylinder.

3. Never operate this appliance within 25 ft(7.5m) of any fammable liquid.

4. Never allow oil or Grease to get hotter than 400 F (200 C )or if oil begins to

smoke, immediately turn burner or gas supply o.

5. Heated liquids remain at scalding temperatures long after the cooking

process. Never touch cooking appliance until the liquids have cooled to 115

(45C) r less.

6. If a fire should occur, keep away from the appliance and immediately call your

fire department. Do not attempt to extinquish an oil or grease fire with water.

Failure to follow these instructions could result in re or explosion which

could cause property damage, personal injury or death.

DANGER

3

www.newageproducts.com

!

!

!

1. DO NOT store or use products with ammable liquids or vapors in the

vicinity of the NEWAGE Double Burner Cabinet, NEWAGE Outdoor Kitchen

cabinets or any appliances.

2. DO NOT store a spare LP cylinder in or near the NEWAGE Double Burner

Cabinet, NEWAGE Outdoor Kitchen Cabinets, or any other appliances.

1. The burning of gas cooking fuel generates some by-products which are on the

list of substances which are known by the State of California to cause cancer or

reproductive harm.

2. California law requires businesses to warn customers of potential exposure to

such substances. To minimize exposure to the substances, always operate this unit

according to the use and care instructions found in this manual. Be certain to pro-

vide adequate ventilation when cooking.

WARNING! CALIFORNIA PROPOSITION 65

WARNINGS

DANGER

DANGER

Read and follow the instructions in this manual fully and completely before

installing, servicing or operating the gas appliance to reduce the risk of :

1. Fire

2. Personal injury or property damage

3. Improper installation

THIS PRODUCT IS DESIGNED FOR OUTDOOR USE ONLY. Do not install or

operate indoors, in a garage, in a screened in porch, gazebo, or any other

enclosed area. This outdoor cooking gas appliance is not intended to be

installed in or on recreational vehicles , boats or in a non-ventilated room.

Failure to operate this product in a well ventilated area can cause property

damage, injury or death. Keep the area surrounding the grill clear and free

from combustionable materials, gasoline and other ammable vapors and

liquids. Do not obstructed ventilation openings of the cylinder enclosure.

Keep openings free from debris!

This instruction manual contains important information necessary for the

proper assembly and safe use of the appliance

4www.newageproducts.com

!

!

!

WARNING

WARNING

1. Always maintain the required clearances from combustible

construction as detailed. The grill is designed for outdoor use only.

Never use in a garage, building, shed, breezeway or other

enclosed area. This grill shall not be used under any unprotected

overhead combustible construction.

2. Gas grills are not design certied for and are not to be installed in

or on recreational vehicles, portable trailers, boats or any

other moving installation.

3. Keep any electrical supply cord and the fuel supply hose away from

any heated surfaces. Electrical cords should be placed away

from walkways to avoid creating a tripping hazard.

4. Do not repair or replace any part of the grill unless specically

recommended in this manual. Other service should be performed by

a qualied technician.

5. All gas lines must have a shut-o that is readily and easily accessible.

Be sure the owner knows where the shut-o is located. If you smell

gas, check for gas leaks immediately. Check only with a soap and

water solution. Never check for gas leaks with an open ame.

(See INDEX: “Leak Testing”for further details.)

1. The outdoor cooking gas appliance and its individual shuto valve

must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 0.5 psi

(3.5 kPa).

2. The outdoor cooking gas appliance must be isolated from the gas

supply piping system by closing its individual manual shuto

valve during any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psi (3.5 kPa).

1. Massachusetts requires all gas be installed using a plumber or gas

tter carrying the appropriate Massachusetts license.

2. All permanently-installed natural gas or propane installations require

a“T” handle type manual gas valve be installed in the gas supply line

to this appliance.

3. This does not apply to portable propane installations using a 20 pound

cylinder.

WARNING! STATE OF MASSACHUSETTS

5

www.newageproducts.com

TABLE OF CONTENTS

WARNINGS 2-4

TABLE OF CONTENTS 5

GUIDELINES 6

UNPACKING/ PARTS SUPPLIED 7

TOOLS NEEDED 8

WARRANTY 9

NATURAL GAS INSTALLATION 10

CONVERTING FROM NATURAL GAS TO PROPNE 11

PROPANE INSTALLATION 12

CUT-OUT DIMENSIONS 13

CARE AND MAINTENANCE 14

GAS CONNECTIONS 15

GENERAL INFORMATION 16

LP PROPANE CONNECTIONS 17-18

NATURAL GAS CONNECTIONS 19

INSTRUCTIONS FOR INSTALLERS 20-21

OPERATION OF GRILL

SAFE OPERATING PRACTICES 22 -23

PRE-GRILL CHECKLIST 24

LEAK TESTING 25-26

ELECTRICAL CONNECTIONS 27

LIGHTING THE GRILL 28-29

GRILL MAINTENANCE AND CLEANING 30-31

TROUBLESHOOTING 32

SPARE PARTS 33

WIRING DIAGRAM 34

NEWAGE CUSTOMER SERVICE 34

6www.newageproducts.com

Double Side Burner

Dimensions

Weight

Capacity

16” Double Side

Burner

9.9 Inches

16 Inches

15 lbs.

Guidelines

7

www.newageproducts.com

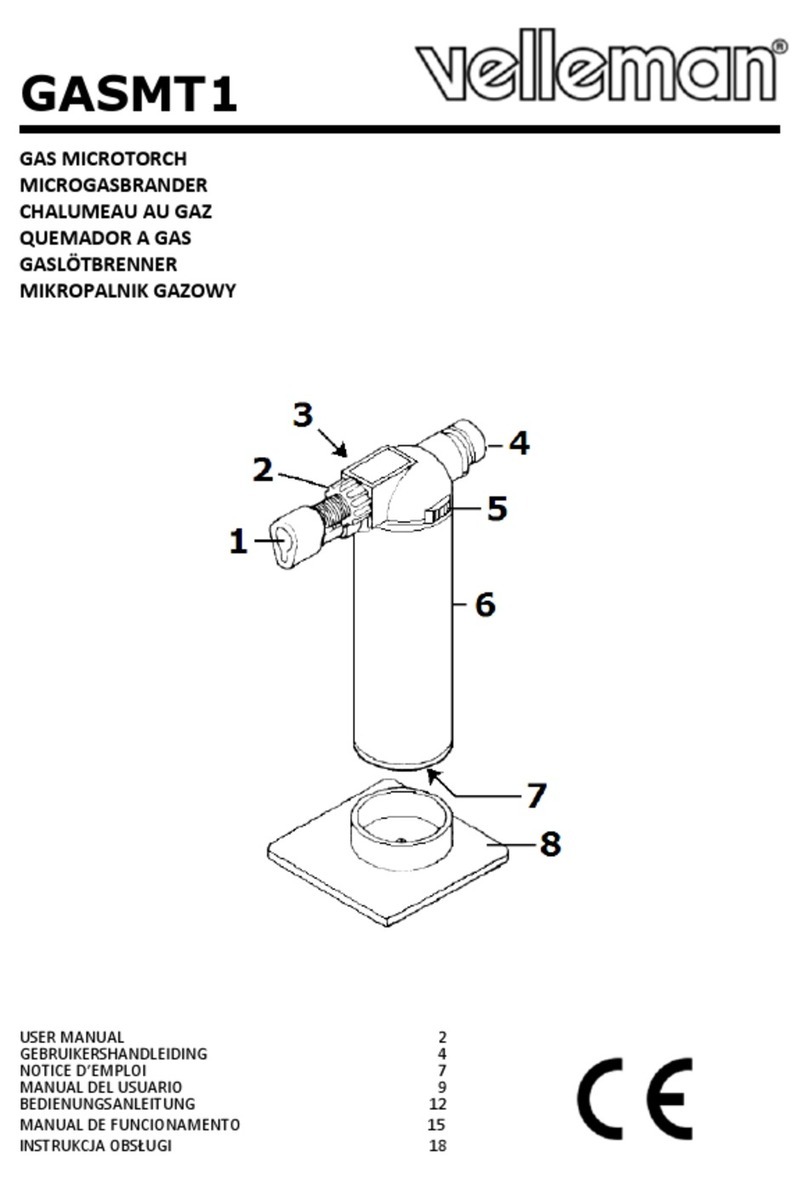

1 x Natural Gas

Hose

1 x QCC1 Type

Regulator

1 x SS Grate

Parts Supplied

Quantity

SS Grate 1

Natural Gas Hose with Disconnect 1

QCC1 Regulator 1

Hex Bolt (M6 x 1”) 4

Injector Orifices 2

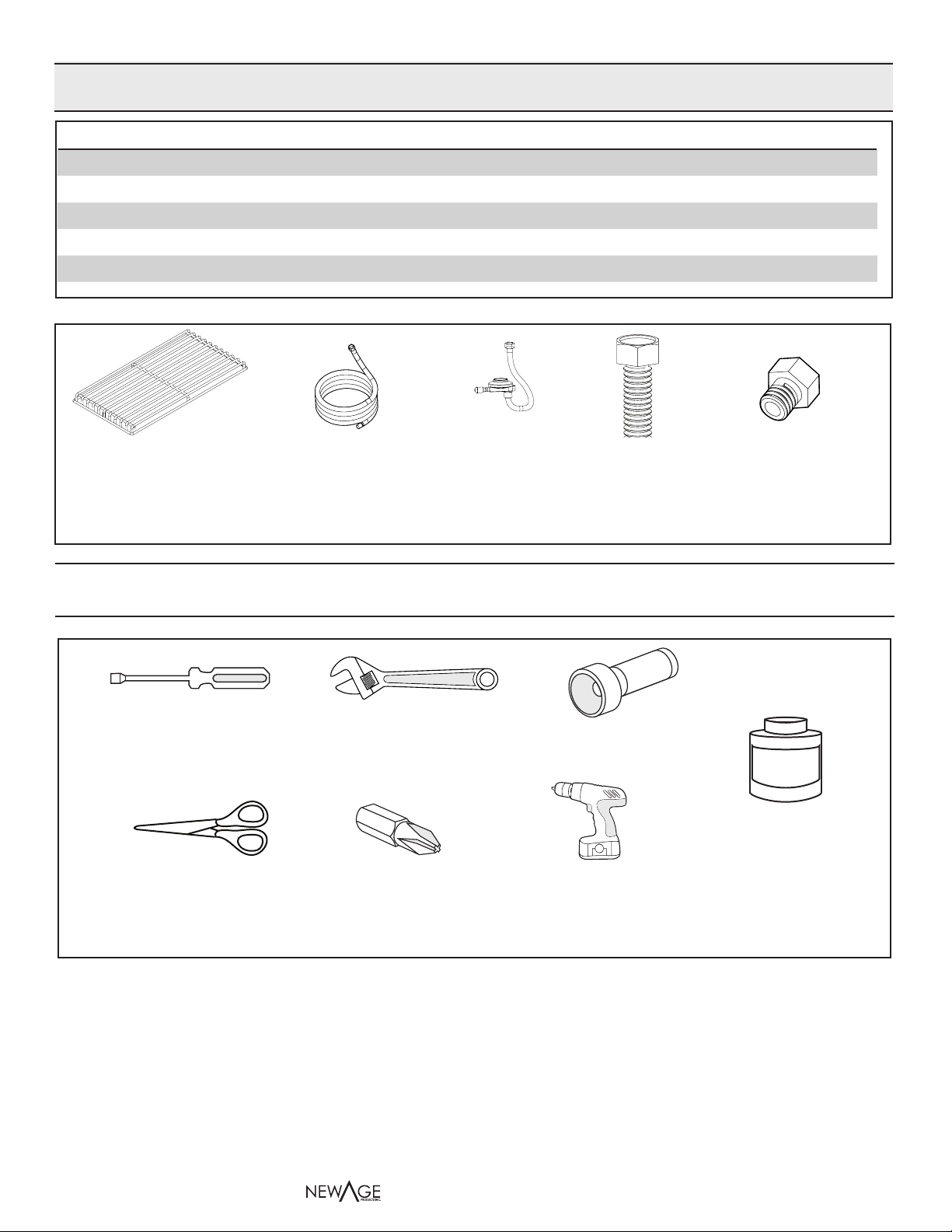

Flashlight

6mm Nut Driver

(Optional)

#2 Phillips Bit

(Optional)

Scissors

Gas Line

Pipe Dope

(Optional)

Cordless Power Drill

Pipe Dope -

Thread Sealant

Adjustable wrench

Tools Needed

4 x Hex Bolt

(M6 x 1”) 2 x Orices

8www.newageproducts.com

Warranty

All products must be installed, operated, and maintained in accordance with the instructions included with the products.

If a product is properly installed, operated, and maintained; and fails to meet the below specied warranty, NewAge

Products, Inc (“NewAge”) will replace the defective product or parts.

Newage is proud to oer a complete product warranty for a period of (one year from the date of purchase. )Subject to the

limitations and disclaimers set forth below or in other product documentation, NewAge provides the following additional

warranties to the initial customer;

Length of

Warranty from

date of purchase

Warranty Covered Items Cost to NewAge Cost to Customer

10 year Stainless steel grill hood / burner box/ Interior Brackets Materials Shipping

5 years Rotisserie Forks and Stake, Rotisserie Rollers, Grill grates,

Grease Trays, Ceramic Rotisserie Burner, Ceramic Sear Burner, U

shaped Burner and Side Burners

Materials Shipping

This warranty is limited to product replacement only. In no event will NewAge be liable for special, indirect, or

consequential damages.

This warranty is available to the initial purchaser only and is not transferable. Proof of purchase and additional information

regarding the defect may be required at NewAge’s discretion. The warranty is made only to products sold in the United

States, Canada.

ALL OTHER WARRANTIES DISCLAIMED:

ALL OTHER WARRANTIES ARE DISCLAIMED TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW. WITHOUT

LIMITING THE GENERALITY OF THE FORGOING, NEWAGE EXPRESSLY DISCLAIMS ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

NEWAGE PRODUCTS INC. WILL NOT PAY FOR:

1. Service calls or labor costs.

2. Products damaged by accident, misuse, abuse, re, ood, improper installation, acts of God, neglect,

corrosion, improper maintenance or cleaning, modication, mishandling or not following

care instructions.

3. Products damaged by improperly loading beyond the specied maximum weight capacity outlined

in the instructions provided with the product.

4. Defects results from use in excess of normal residential use.

5. Cosmetic damage that occurs after customer purchasing the product, including scratches, dings,

dents, corrosion, or stains in the material that does not aect the structural or functional capability

of the product.

6. Loss of product contents.

OTHER NOTES TO CONSUMER:

Discoloration due to the high heat, for example beside a grill, is a trait of stainless steel and is not covered. Surface rust

resulting from acid rain or environmental chemicals are not covered. (Please see maintenance information to combat

surface rust). NewAge outdoor powder coated nishes are designed to withstand weathering and are UV stable.

The 304 stainless steel material used in the construction of NewAge Outdoor Kitchen Cabinets is highly rust resistant,

however, chlorine in the air from swimming pools or the salt from sea air may cause surface rust to appear and even create

some pitting corrosion if left on the product. We suggest cleaning all stainless steel surfaces at least every two weeks to

keep your cabinets in prime condition. The chemical reaction from salt is easy to prevent however it is more dicult when

left on the surface.

Additional product information is available at

http://www.newageproducts.com/outdoor-kitchen-warranty

9

www.newageproducts.com

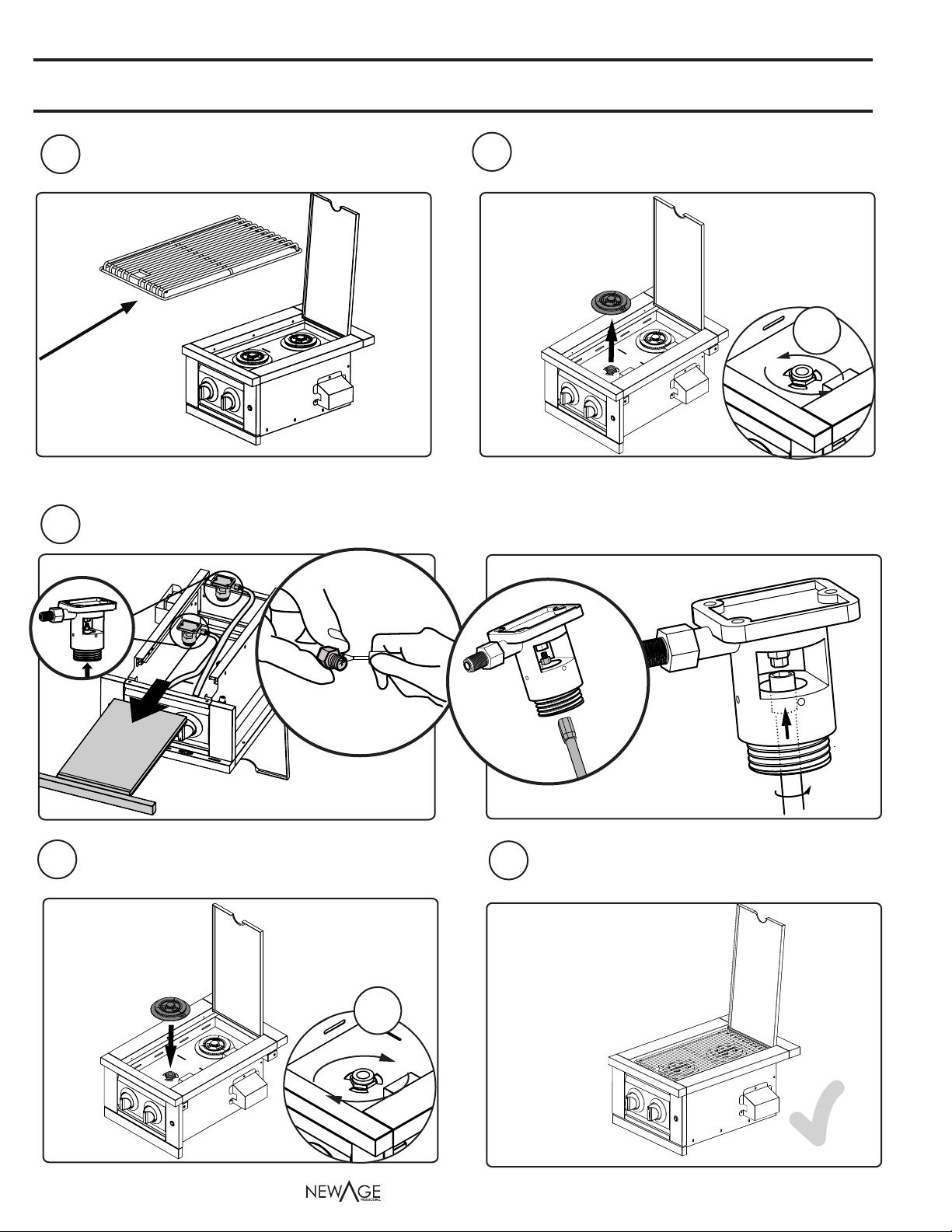

Unpacking Instructions

Take o rst layer of EPS foam packaging, and

next remove the DSB.

12(2) control knobs and (2) Aluminum burners

are packaged seperately inside main box.

Attach control knobs by pushing straight in,

lower aluminum burners and grate into position.

3

• Dispose / recycle all packaging materials.

• Verify all the contents in the box and gather the required tools. See“Parts Supplied” and“Tools Needed” list.

10 www.newageproducts.com

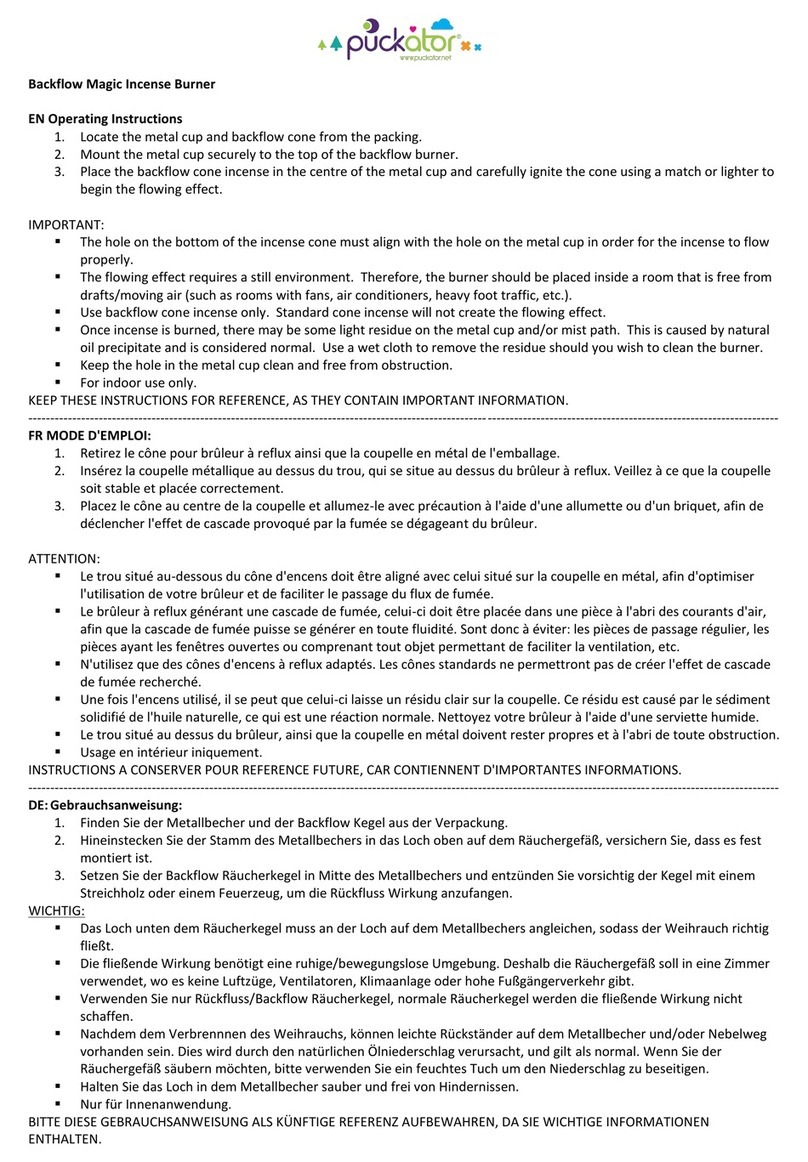

Natural Gas Installation

Open the doors of the cabinet, and from the

inside of the cabinet feed the Natural Gas hose

through cutout hole on back panel.

.

3

12

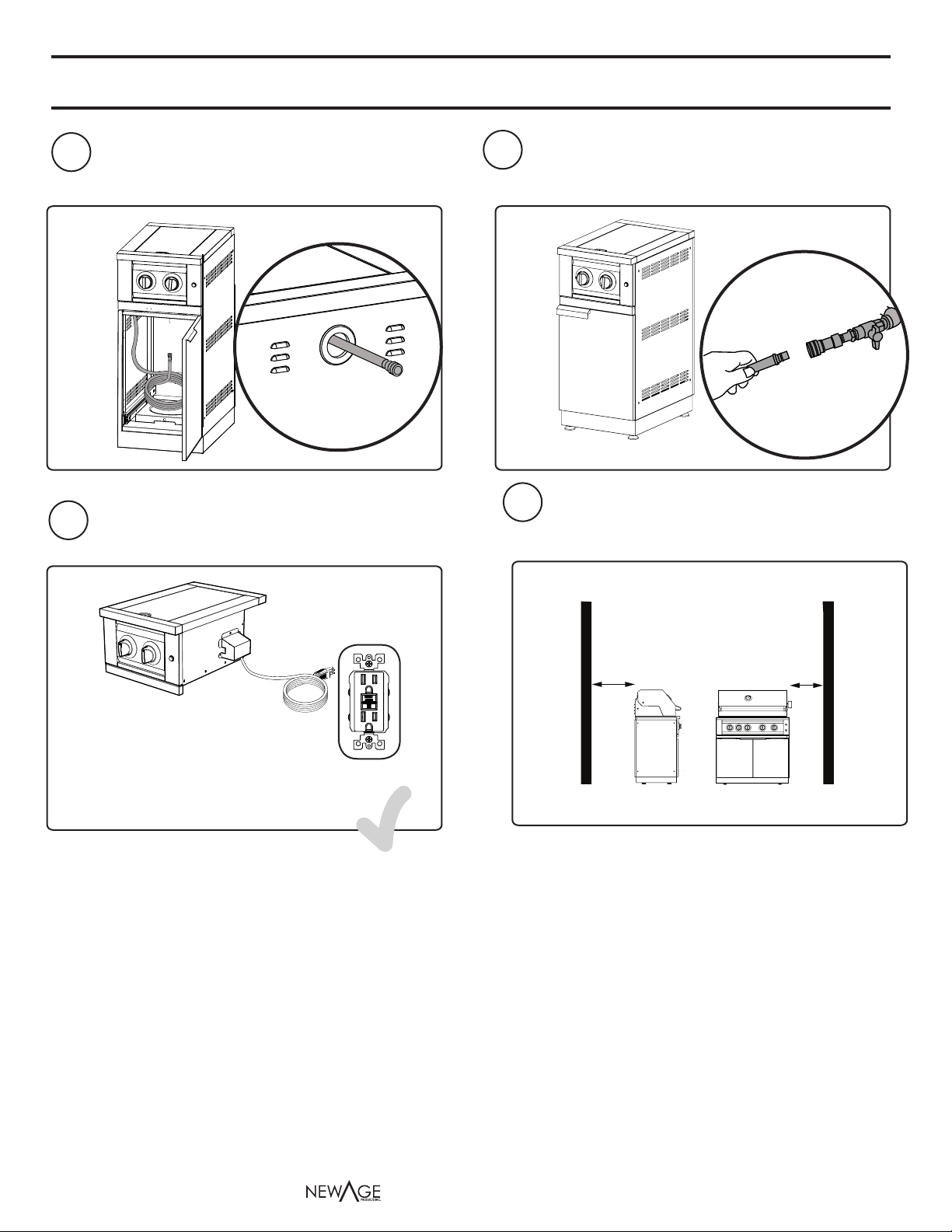

WARNING! The grill and cabinet must have a

minimum clearance from combustible materials.

Refer to below gure for dimensions.

Side - 10”Clearance

Rear - 18”Clearance

18 Inches 10 Inches

* The outdoor cooking gas appliance

shall not be used under overhead

combusible construction

5

!

GFCI

Note: The Double Burner must be plugged into

a GFCI outlet, installed by an electrician.

5

!

Connect to Natural Gas supply line using the

quick disconnect tting.

BURNER ELECTRICAL REQUIREMENTS: 110 VAC 60 Hz

11

www.newageproducts.com

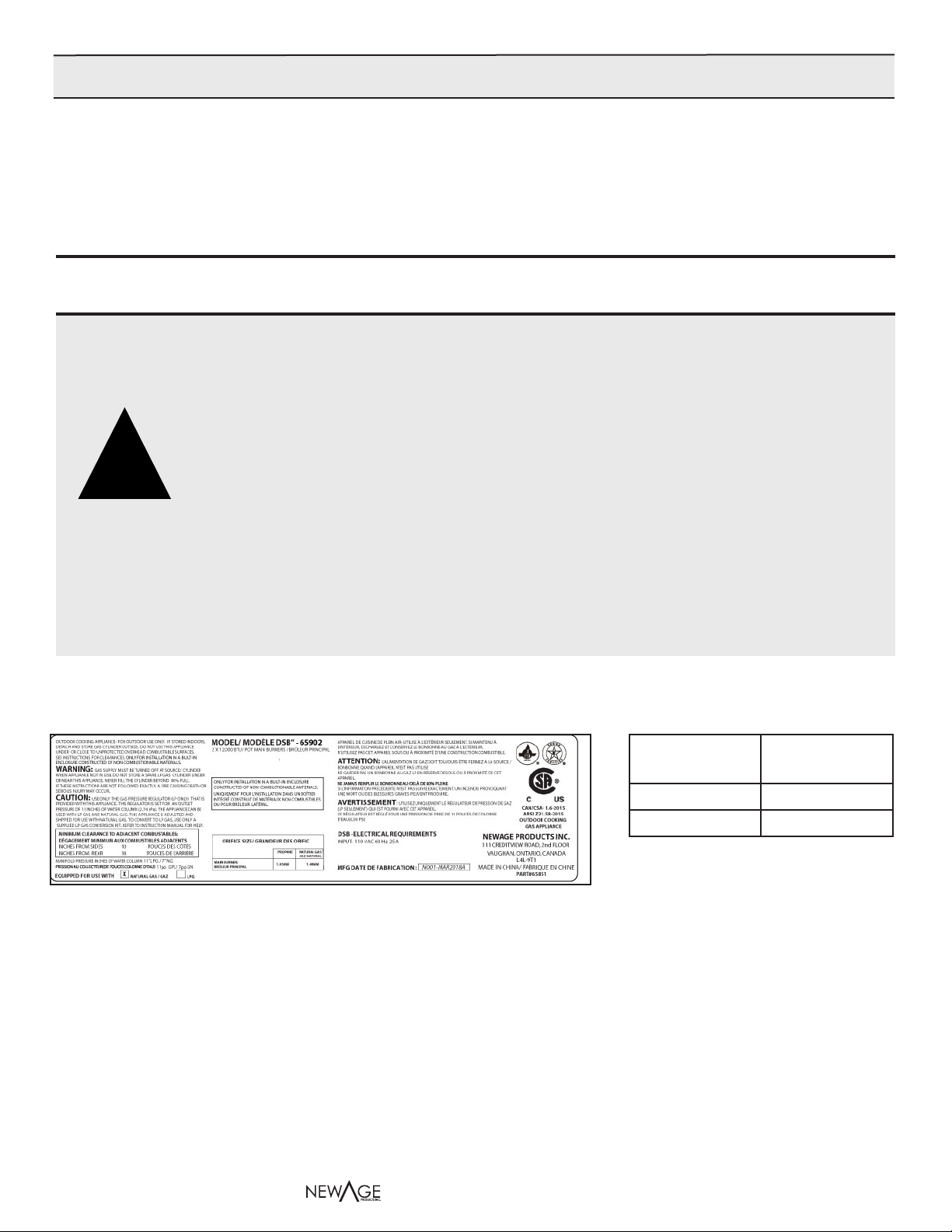

Converting from Natural Gas to Propane

Flip unit upside down. Remove grease tray. Locate burner castings. Apply pipe dope to the thread of

the propane injector jet, being careful of not getting any dope into or near the end of the injector.

Install oriface with a 6mm nut driver. Push threaded casting end up through hole in burner pan.

Remove the grill grate. Lift each burner o and locate burner

retention nuts(A). Remove nuts and burn-

ers will drop down into holes .

3

1

3

2

45

5

Tighten burner retention nuts (A) and

replace burners back in original position.

Install grate back in original position.

A

A

12 www.newageproducts.com

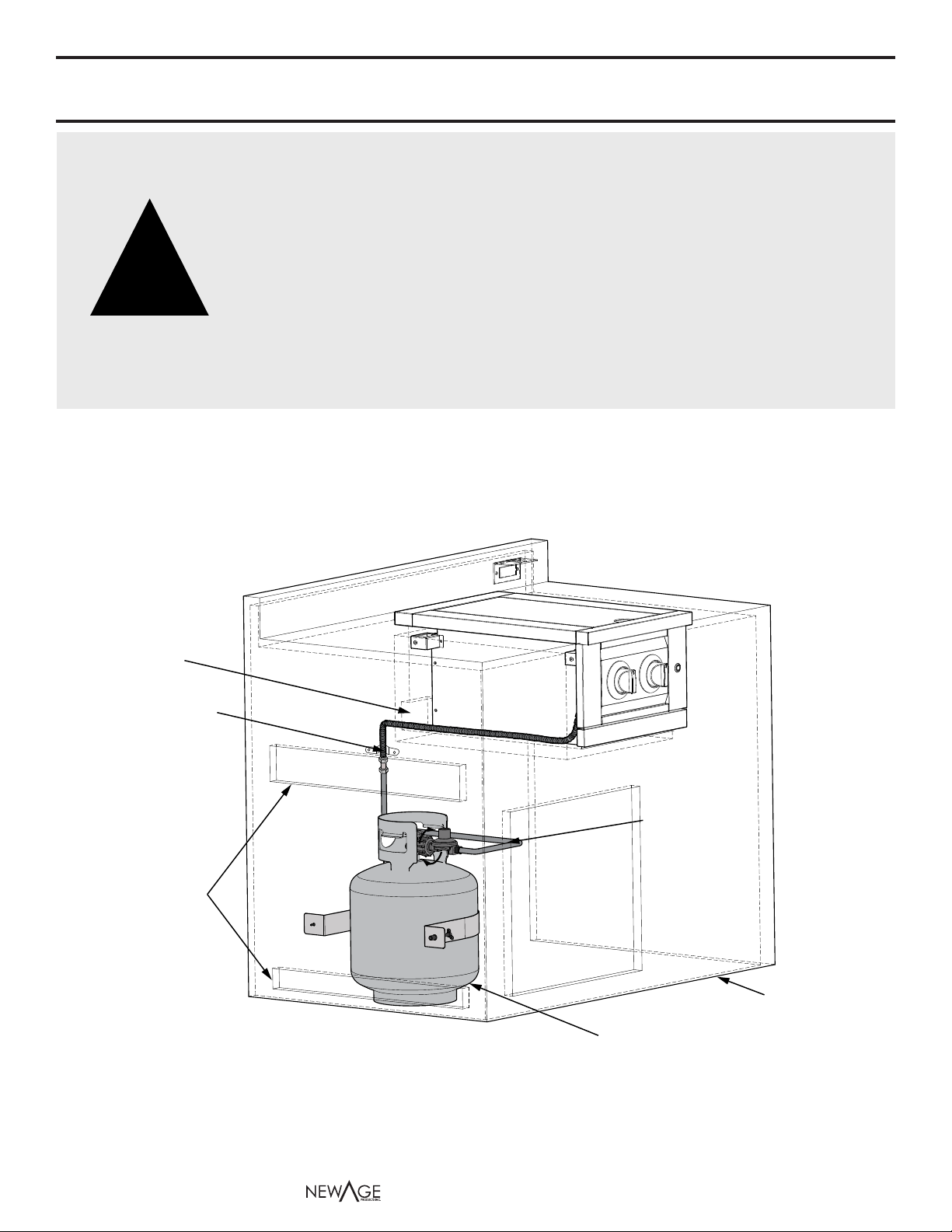

Propane Installation

Open the doors of the cabinet, and pull out

the propane tray.

Place and secure a 20 lb. LP tank into pullout

tray ring and tighten wing bolt to engage tank

clamp on to base of propane tank.

12

Rotate clock wise

shown from below

for clairity

Connect brass tting on Type 1 regulator hose

to gas inlet on Double Burner manifold.

3

Attach regulator hand wheel to the tank.

Clockwise to tighten, counter-clockwise to

loosen.

34

WARNING!The grill and cabinet must have a

minimum clearance from combustible materials.

Refer to below gure for clearance dimensions.

Side - 10”Clearance

Rear - 18”Clearance

18 Inches 10 Inches

* The outdoor cooking gas appliance

shall not be used under overhead

combusible construction

55 !!

GFCI

Note: In order for the LED lights to be

operational, the Double Side Burner needs to

be plugged into a GFCI outlet installed by an

electrician.

GRILL ELECTRICAL REQUIREMENTS:

110 VAC 60 Hz

13

www.newageproducts.com

The installation must conform with local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, Storage

and Handling of Liqueed Petroleum Gases, ANSI/NFPA 58; or Natural

Gas and Propane Installation Code, CSA B149.1; Propane Storage and

Handling, CSA B149.2; or the Standard for Recreational Vehicles,

ANSI A119.2/NFPA 1192; and Recreational Vehicle Code,

CSA Z240 RV Series, as applicable.

The appliance, when installed,

must be electrically grounded in

accordance with local codes or, in

the absence of local codes, with

the National Electrical Code, ANS

/NFPA 70, or the Canadian

Electrical Code, CSA C22.1.

!

WARNING

Note to Installer:

A built-in appliance for use with

a remote LP gas supply system

where the installer constructs the

propane cylinder enclosure. The

installer must provide detailed

instructions and diagrams that

comply with clauses 4.6.1-4.6.5

of the ANS Z223.1 Code.

All built-in appliances must use

rigid pipe, semi-rigid tubin, or a

connector complying with the

standard for Connectors for Gas

Appliances, ANS Z21.24. CSA 6.10,

or Standard for Connectors for

Outdoor Gas Appliances and

Manufactured homes, ANS Z21.75.

CSA 6.27, for the appliance which

are connected to xed fuel piping

system (Natural Gas).

!

A propane tank can not

be stored below the gas grill.

Only 1 tank in service should

be used with the grill.

!

WARNING

!

WARNING

Cabinet frame, cabinet side panels and

counter top must be made from

non-combustionable material.

MODEL

W D H

65902

14 1/4"

362mm

21

1/4"

540mm

10 3/8"

264mm

OPENING DIMENSIONS

SIDEBURNER 16"

153mm

MINIMUM 10 SQ IN (65 SQ CM)

OF VENTILATION REQUIRED ON

EACH END OF CABINET.

5"

127mm

5"

127mm

MAXIMUM

GAS INLET OPENING

OUTDOOR GFI ELECTRICAL OULET

RECOMMENDED - LOCATE ON SAME SIDE

OF GRILL AS ROTISSERIE BRACKET.

D

H

W

2 3/4”

70mm

34"

864mm

RECOMMENDED

ELECTRICAL OPENING

MINIMUM 10 SQ IN (65 SQ CM)

OF VENTILATION REQUIRED ON

EACH END OF CABINET.

5"

127mm

MAXIMUM

1"

25.4mm

MAXIMUM

Cutout Dimensions for Built-in

Secure 20 lbs propane tank to

interior of built in cabinet.

Allow access in order to

connect or disconnect

propane hose regulator to

propane tank.

14 www.newageproducts.com

Care and Maintenance of your

Stainless Steel Grill

Perform Regular Maintenance

Wash regularly with clean fresh water, mild detergent and a micro ber cloth. After washing rinse in clean

water and wipe the surface dry with your cloth remembering to go with the grain on brushed stainless steel.

Generally you should wash your stainless steel every three months. Coastal areas or next to a

chlorine pool more frequently every 2 weeks. Do not use abrasive cleaners or a scouring pad of any type as

they will cause excessive wear and dull the nish. Stainless steel nishes in coastal environments may show

tea staining if not washed regularly. For better protection use a thin coating of protectant on the surface. We

do not recommend using this coating for food prep areas.

List of common conditions that cause corrosion or discoloration of

stainless steel and should be avoided:

1. Chloride containing cleansers – this includes bleach and any cleaners containing bleach

2. Muriatic acid (hydrochloric acid) – commonly used to clean up after tile/concrete installation

3. Concentrated soap residue – chemical additives will cause discoloration and some dried soaps

actually look like rust

4. Water with high iron content – can leave a rusty residue, especially if allowed to drip continuously

5. Contact with iron materials – including steel wool, iron residue/dust from installation or cleaning of other

steel products

6. Dont’allow trapped moisture between the product and cover – rubber mats, metal cans or cleaning

products trap moisture - allow cabinets to completely dry before covering.

7. Salts – contain chlorides

8. Extreme Heat by Flame

9. Do not permit citrus or tomato juice to remain on stainless steel surfaces.

10. No abrasive cleaners, steel wool pads, or abrasive cloths as they will scratch the finish.

!

1. DO NOT store or use products with ammable liquids or vapors in the

vicinity of the NEWAGE Grill Cabinet,NEWAGE Outdoor Kitchen cabinets or

any appliances.

2. DO NOT store a spare LP cylinder in or near the NEWAGE Grill Cabinet,

NEWAGE Outdoor Kitchen Cabinets, or any other appliances.

WARNING!

WARNING!This grill is designed for non-combustible enclosures only, and must be

installed and serviced by a qualied installer to local codes.

WARNING! As indicated on the rating plate, this gas grill is designed to operate with

supply pressures of 11”WC for Propane and 7”WC for Natural Gas. For installations where

the gas supply pressure exceeds these requirements, a regulator must be installed

upstream of the grill’s components. If the gas supply pressure is lower than these require-

ments, the unit will be under-red and will not reach the maximum temperatures. Ensure

that the supply line size complies with local and/ or national installation codes.

!

WARNING!

15

www.newageproducts.com

!

WARNING

Gas Connections

The Double Side Burner is factory set to use natural gas (NG). The Side Burner can be converted to use

propane gas. See :Converting from Natural Gas to Propane on page 11. It is critical that the gas you use

matches that which the grill was set up for. You can verify that by checking the rating plate.

The rating plate will be attached to the Double Burner by chain.

• Remove the drip tray, and locate rating plate inside of cabinet.

Ensure that the gas supplied meets with the minimum pressure requirements. Do not operate the Burner on

any gas other than that for which the grill has been set.

Both the regulator and the manifold orices have been tuned for the type of gas specied on the rating

plate. Converting to a dierent type of gas requires a conversion kit, supplied from NewAge and must be

installed by a qualied technician. All installation and all installation parts must conform to local codes

with the National Electrical Code, ANSI Z223.1/ NFPA 70 latest edition and the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 in the U.S. and CGA-B149.1/.2 in Canada. Canadian installations must conform to

CGA-B149.1/.2 natural gas/propane installation code. (Canada)

Rating Plate - Lists serial numbers, model numbers, and gas type

Water Column Requirements

Fuel WC Min Under

Full Load

NAT GAS 7 in WC

LP 11 in WC

Never connect a gas line directly to the gas appliance. A pressure regulator must

be installed on all gas equipment. All local codes require a pressure regulator

and NewAge supplies the correct regulator with your gas appliance. Removing or

failing to install the pressure regulator can result in re, and serious personal injury

and will void the warranty. This gas appliance is designed for non-combustible

enclosures only, and must be installed and serviced by a qualied installer to local

codes.

As indicated on the rating plate, this gas appliance is designed to operate with gas

supply pressures of 11”WC for Propane and 7”WC for Natural Gas. For installations

where the gas supply pressure exceeds these requirements, a regulator must be

installed upstream of the grill’s components. If the gas supply pressure is lower than

these requirements, the unit will be under-red and will not reach the maximum

temperatures. Ensure that the supply line size complies with local and/or national

installation codes.

OXIDIZATION Removal

If you have oxidation there are a few steps to take to bring your stainless steel cabinets back to “as new”

condition. Apply clean water with a cleaning sponge and rub gently in the direction of the grain. If the mark

won’t shift, it may be necessary to use a stainless steel cleaner, in which case apply the cleaner and rub

gently. After cleaning it is important to rinse the stainless steel with clean fresh water and buff with a soft

cloth. Remember to always rub with the grain, NEVER across as you will ruin the fi nish, and the stainless can

lose its shine. If you must use a scourer, usea plastic scrub pad with no metal content.

16 www.newageproducts.com

General Information

This Gas Barbecue Is Certied Under Canadian And American National Standards, CSA 1.6b-2012 and ANSI

Z21.58b-2012 respectively for Outdoor Gas Grills and should be installed to conform with local codes. In

absence of local codes, install to the current CAN B149.2 Natural Fuel Gas Code and the Propane Installation

Code, CSA B149.1 Propane Installation Code in Canada or to the National Fuel Gas Code, ANSI Z223.1/NFPA

54 the National Fuel Gas Code the Natural Gas and Propane Installation Code, CSA B149.2.

If a rotisserie motor is used, it must be electrically grounded in accordance with local codes or, in absence

of local codes, with the current CSA C22.1 Canadian Electrical Code in Canada or the National Electrical

Code, ANSI/NFPA 70 the Canadian Electrical Code, Part 1, CSA 22.1.

California proposition 65: The burning of gas fuel creates by-products, some of which are on the list as

substances known by the State of California to cause cancer or reproductive harm. When cooking with

gas, always ensure adequate ventilation to the grill.

Propane Cylinder Specications

If the gas appliance is being supplied with propane from a portable cylinder, a regulator specied by the

manufacturer must be used. The regulator must supply a pressure of 11 inches water column (0.39 PSI) to

the gas grill and have a QCC1 type tting. Cylinders to be used with this unit must be supplied with a QCC1

cylinder valve. A QCC1 cylinder has a positive seating connection, which will not allow gas ow until a

positive seal has been achieved. It is also equipped with an excess ow device. In order to attain full ow

to the grill, the valves must be in the o position when the cylinder valve is turned on.

A dented or rusty cylinder may be hazardous and should be checked by your propane supplier. Never

use a cylinder with a damaged valve. Use only a propane supply cylinder constructed and marked in

accordance with the specications for LP-gas cylinders of the National Standard of Canada, CAN/CSA-b339,

Cylinders, Spheres and Tubes for Transportation of Dangerous Goods; and Commission, as applicable or

the Specications for LP-Gas Cylinders of the U.S. Department of Transportation (D.O.T.). Cart models have

been designed for use with a 20 lb (9.1 kg) size propane cylinder only (not supplied).

The propane cylinder must be provided with a cylinder connection device compatible with the connection

for outdoor cooking appliances. The propane cylinder must be provided with a shut-o valve terminating

in a propane cylinder valve type QCC1, and a safety relief device having direct communication with the

vapor space of the cylinder. The cylinder supply system must be arranged for vapor withdrawal and the

cylinder shall include a collar to protect the cylinder valve. The cylinder shall incorporate a listed OPD

(overll protection device). Do not store a spare LP-gas cylinder under or near this appliance. Never ll

the cylinder beyond 80 percent full. If the preceding information is not followed exactly, a re causing

death or serious injury may occur

17

www.newageproducts.com

Do not change the regulator/hose assembly or use any other assembly than

the one supplied with your NewAge gas appliance.

Do not attempt to use a 5LP-A equipped regulator/hose assembly with a

standard 510 POL cylinder/valve assembly.

Do not store a spare LP-gas cylinder under or near this appliance.

Never ll the cylinder beyond 80 percent full.

If the information above is not followed exactly, a re causing death or serious

injury may occur.

!

WARNING

LP Gas Connection

Propane Tank

(Not Supplied)

Non-Combustible

Construction

Propabe Hose and

Regulator

Flexible Gas Line

With Regulator

(Supplied)

Venting

Flexible Corrogated Gas Hose

(Not Supplied)

Secure Flexible

Gas Line to

Cabinet structure

(Not Supplied

18 www.newageproducts.com

LP connections

Make sure the LP cylinder valve is fully closed. It is possible for the valve to be open without releasing gas

but, as soon as you start connecting the regulator, gas will leak from the connection.

Insert the regulator inlet into the cylinder valve and turn the black coupler clockwise until the coupler is

hand tight. Do not over-tighten this connection. See Figure 1

To disconnect the coupler, rst make sure the main cylinder valve is turned o. Grasp the coupler and turn

counter clockwise. The inlet will then disengage.

Always leak-test the connection after relling or exchanging LP cylinders. (See Leak Testing on Page 25.)

Dust Cap - Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type

of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs

may result in leakage of propane.)

Propane cylinder must include a collar to protect the cylinder valve

Coupling Nut

Figure 1.

Figure 2.

Cylinder Valve Pressure Relief Valve

LP Tank (not included)

LP Dust Cap

(used when in storage or transportation.)

LP Regulator

(included)

Hand tighten to ensure proper

seal for correct gas flow.

19

www.newageproducts.com

LP cylinder requirements

The LP cylinder must be constructed and marked in accordance with the specications for LP gas cylinders

of the U.S. Department of Transportation (DOT) and designed for use with a Type 1 system only.

Cylinders of free standing grills must be secured using the provided cylinder retention system to avoid

accidental movement.

When exchanging your cylinder for a rell, exchange only for a Type 1 20lb cylinder with an over-ll

protection device.

Never use a cylinder with a damaged valve.

A dented or rusty LP cylinder may be hazardous and should be avoided. If in doubt, have it checked by your

LP supplier.

Always check for leaks after every LP cylinder change. (See Leak Testing instructions on Page 25.)

Always shut o the LP-gas supply at the cylinder when the gas appliance is not in use.

Cylinders must be stored outdoors in a well-ventilated area out of the reach of children. If your gas appliance

is stored indoors, the LP cylinder must be stored outside.

The Double Side Burner is set up for Natural Gas. Converting to propane requires a conversion kit, supplied

from NewAge and must be installed by a qualied technician. The Burner comes equipped with an LP hose/

regulator assembly for connection to a standard 20 lb. LP cylinder. (Type 1). All ttings necessary to attach

the assembly to the gas appliance are included.

Never connect an unregulated gas line to the gas appliance.

20 www.newageproducts.com

Grill Intake

Manifold

Threaded

nipple

Flexible

Corrugated Gas

Hose

Flexible Gas

Hose

Quick

Disconnect

Threaded

nipple

Quick

Disconnect

Coupler

Main shut-off valve Gas supply line

from home

NewAge recommends that only qualied professionals perform the required

plumbing on this product.

To ensure satisfactory performance, the gas supply line must be sized to

accommodate the total BTU/h requirements of all the gas-red equipment that will

be connected to that line.

In no case should pipe less than 3/4”inside diameter or 1”outside diameter ever be

used to connect this product.

• Calculate the total BTU output of all equipment and refer to Gas Supply Line Runs for allowable run

distances for ¾ inch pipe. Failure to meet these minimum requirements may reduce performance of the grill

and any other appliances running on that supply line.

• Always keep supply line runs as short as possible.

• A gas shut-o valve must be installed in an easily accessible location by a qualied licensed gas tter.

• The outdoor cooking gas appliance and its individual shut-o valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of 0.5 psi (3.5

kPa).

•The outdoor cooking gas appliance must be isolated from the gas supply piping system by closing its

individual manual shut-o valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

• Keep threading compound o of the rst two pipe threads to avoid having any small pieces of compound

break loose and clog a burner valve or orice. Do not use threading compound on any are ttings.

For built-in installations, it is recommended that any exible pipe used be kept as short as possible.

For freestanding units using natural gas, NewAge strongly recommends using a quick disconnect kit.

This Quick Disconnect kit, is included with purchase.

NOTE:This product must be installed by a licensed plumber or gas tter when installed within the State of

Massachusetts.

Natural Gas Connection

!

WARNING

Natural Gas connections

Table of contents

Languages:

Popular Burner manuals by other brands

Planika

Planika FLA 2 E 4 user manual

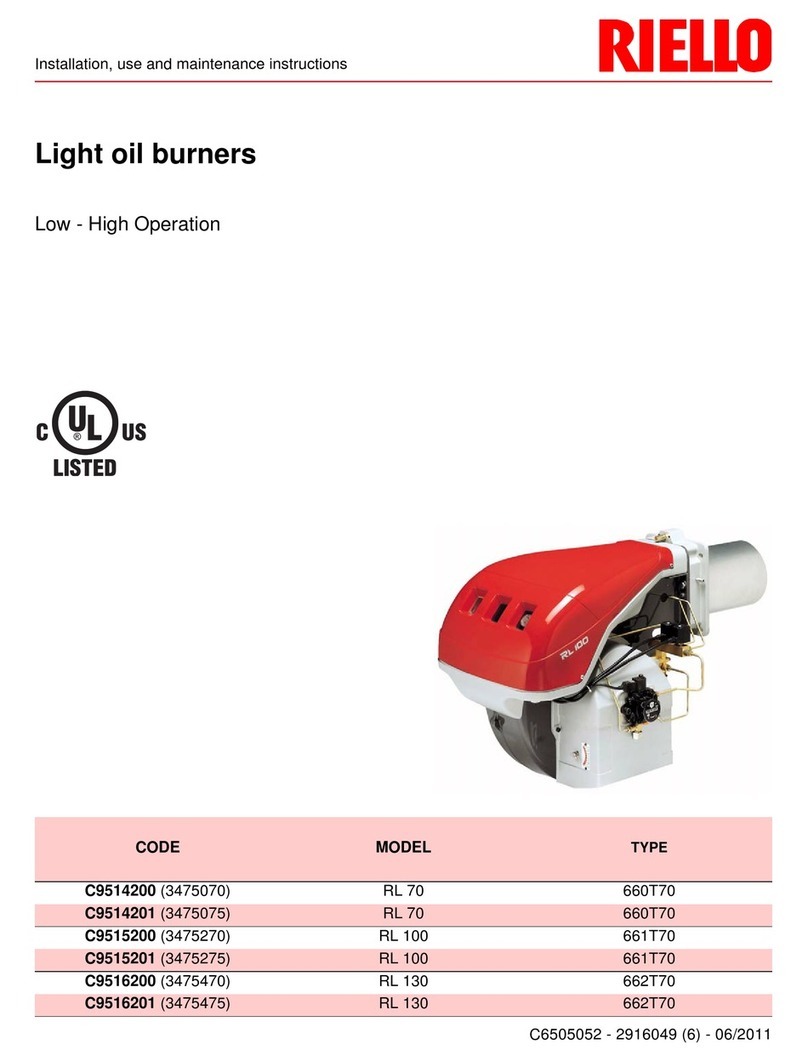

Riello

Riello Gulliver RG4D Installation, use and maintenance instructions

Riello

Riello GI/EMME 1400 Installation, use and maintenance guide

Anderson

Anderson FFO57 Operation manual

Riello

Riello G20 Installation, use and maintenance instructions

Broil King

Broil King DPSBSS owner's manual

Beckett

Beckett AFG Oil Burner 240V Product sheet

Riello

Riello RL 70 Installation, use and maintenance instructions

baltur

baltur COMIST 26SP INSTALLATION, USE AND MAINTENANCE INSTRUCTION MANUAL

Nu-Way

Nu-Way XGN Series Handbook

Riello

Riello RL 300/B MZ Installation, use and maintenance instructions

NOVO

NOVO ALTA ALTADBLSBNG manual