New Leader L3020G4 Configuration guide

IMPORTANT: READ THE SAFETY GUIDELINES AND ALL INSTRUCTIONS CAREFULLY BEFORE OPERATING

HIGHWAY EQUIPMENT COMPANY –NEW LEADER DIVISION

1330 76TH AVE SW, CEDAR RAPIDS, IOWA 52404-7052

PH. (319) 363-8281 www.highwayequipment.com FAX (319) 632-3081

HIGHWAY EQUIPMENT COMPANY

GENERAL MANUAL FOR MODEL

L3020G4

SAFETY GUIDELINES

INSTALLATION

OPERATION

MAINTENANCE

TROUBLESHOOTING

PARTS LIST

Dealer Sticker

This unit may have been built with

SPECIAL FEATURES. Provide

SERIAL NUMBER when ordering

parts.

SERIAL NO. _________________

MODEL L3020G4

UNIT SERIAL NUMBER__________________

MANUAL NUMBER: 97372-B

EFFECTIVE:6/2006

Starting with Serial No. 122208

HIGHWAY EQUIPMENT COMPANY

1330 76TH AVE SW

CEDAR RAPIDS, IOWA 52404-7052

PHONE (319) 363-8281 FAX (319) 632-3081

www.highwayequipment.com

BUILDING THE BEST SINCE 1939

Copyright 2003 Highway Equipment Company, Inc.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

2

97372-B

Page Rev. A

TABLE OF CONTENTS

Warranty..................................................................................................4

Preface .....................................................................................................5

Safety.......................................................................................................6

Safety Decal Installation and Maintenance................................................ 8

Safety Decal Illustrations ........................................................................... 9

General Description.................................................................................17

Dimensions & Capacities .......................................................................18

Installation Instructions............................................................................19

Pump & PTO Requirements....................................................................... 19

Truck Requirements ................................................................................... 20

Hydraulic Pump Installation....................................................................... 21

Hydraulic Pump Drive Shaft Installation................................................... 21

Radar & Controller Installation.................................................................. 21

Mounting Spreader Body ........................................................................... 22

Spinner........................................................................................................ 25

Inverted V................................................................................................... 25

Fender Installation...................................................................................... 26

Electric Dump Valve Control..................................................................... 26

Hydraulic Hose Installation........................................................................ 27

Electrical Connections................................................................................ 30

Light Installation ........................................................................................ 30

Spinner Sensor............................................................................................ 30

Filling Hydraulic System............................................................................ 30

Checking Installation.................................................................................. 30

Initial Start-Up.........................................................................................31

Field Testing............................................................................................32

General Operating Procedures.................................................................33

Lubrication & Maintenance.....................................................................34

Hydraulic System ....................................................................................... 34

Hydraulic Hose........................................................................................... 35

Conveyor Chain.......................................................................................... 36

Conveyor Belt Maintenance....................................................................... 37

High-Temperature Belting.......................................................................... 37

Conveyor Gear Case................................................................................... 37

Lubrication of Bearings.............................................................................. 38

Clean Up..................................................................................................... 38

Fasteners..................................................................................................... 38

Lubricant & Hydraulic Oil Specifications...............................................39

Lubrication & Maintenance Chart...........................................................40

Troubleshooting.......................................................................................41

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

3

97372-B

Page Rev. A

TABLE OF CONTENTS CONTINUED

Torque Chart............................................................................................44

Instructions for Ordering Parts ................................................................45

Legend for Parts List Symbols.................................................................45

Parts List

Mounting Angles ..............................................................................46

Swinging Rear Endgate ....................................................................47

Feedgate and Jack .............................................................................48

Conveyor Chain ................................................................................50

Chain Shields ....................................................................................52

Conveyor Idler ..................................................................................54

Conveyor Drive .................................................................................55

Encoder..............................................................................................56

Conveyor Chain Oiler .......................................................................57

Wipers................................................................................................58

Fenders ..............................................................................................60

Inverted V .........................................................................................66

Cab Shield .........................................................................................67

Ladders ..............................................................................................68

Hillside Flow Divider .......................................................................69

Material Divider ................................................................................70

Spinner Guards & Shields .................................................................71

24” Hydraulic Fans............................................................................72

Spinner Sensor...................................................................................74

Reservoir ...........................................................................................75

Hydraulics

Raven Control..............................................................................76

Mark Series Control.....................................................................80

Manual Dual Control...................................................................83

Twin Spinner Hydraulics ..................................................................86

Pump Hydraulics................................................................................88

Gear Case ..........................................................................................89

Spinner Motor ...................................................................................90

Conveyor Motors ..............................................................................92

Control Valve ....................................................................................94

Lights ................................................................................................95

Decals ...............................................................................................96

Mark V Valve....................................................................................98

G4 Spread Pattern....................................................................................Tab

INSERT

NEW LEADER (NL)

WARRANTY

TAB

SAFETY

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

5

97372-B

Page Rev. A

PREFACE

PLEASE ! ALWAYS THINK SAFETY FIRST !!

The purpose of this manual is to familiarize the person (or persons) using this unit with the

information necessary to properly install, operate, and maintain this system. These instructions

cannot replace the following: the fundamental knowledge that must be possessed by the installer or

operator, the knowledge of a qualified person, or the clear thinking necessary to install and operate

this equipment. Since the life of any machine depends largely upon the care it is given, we suggest

that this manual be read thoroughly and referred to frequently. If for any reason you do not

understand the instructions, please call your authorized dealer or our Cedar Rapids, Iowa, Product

Support Department at (319) 363-8281.

It has been our experience that by following these installation instructions, and by observing the

operation of the spreader, you will have sufficient understanding of the machine enabling you to

troubleshoot and correct all normal problems that you may encounter. Again, we urge you to call

your authorized dealer or our Cedar Rapids Product Support Department if you find the unit is not

operating properly, or if you are having trouble with repairs, installation, or removal of this machine.

We urge you to protect your investment by using genuine HECO parts and our authorized dealers for

all work other than routine care and adjustments.

Highway Equipment Company reserves the right to make alterations or modifications to this

equipment at any time. The manufacturer shall not be obligated to make such changes to machines

already in the field.

This Safety Section should be read thoroughly and referred to frequently.

ACCIDENTS HURT !!!

ACCIDENTS COST !!!

ACCIDENTS CAN BE AVOIDED !!!

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

6

97372-B

Page Rev. A

SAFETY

In this manual and on the safety signs placed on the unit, the words “DANGER,” “WARNING,”

“CAUTION,” and “IMPORTANT” are used to indicate the following:

DANGER

Indicates an imminently hazardous situation that, if not avoided,

WILL result in death or serious injury. This signal word is to be

limited to the most extreme situations and typically for machine

components that, for functional purposes, cannot be guarded.

WARNING

Indicates a potentially hazardous situation that, if not avoided,

COULD result in death or serious injury, and includes hazards that

are exposed when guards are removed. It may also be used to alert

against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided,

MAY result in minor or moderate injury. It may also be used to

alert against unsafe practices.

IMPORTANT! Is used for informational purposes in areas which may involve

damage or deterioration to equipment but generally would not

involve the potential for personal injury.

The need for safety cannot be stressed strongly enough in this manual. At Highway Equipment

Company, we urge you to make safety your top priority when operating any equipment. We firmly

advise that anyone allowed to operate this machine be thoroughly trained and tested, to prove they

understand the fundamentals of safe operation.

The following guidelines are intended to cover general usage and to assist you in avoiding accidents.

There will be times when you will run into situations that are not covered in this section. At those

times the best standard to use is common sense. If, at any time, you have a question concerning these

guidelines, please call your authorized dealer or our factory at (319) 363-8281.

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT

THIS MANUAL IS USED TO CALL YOUR ATTENTION TO

INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY AND THAT

OF OTHERS. FAILUR

E TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN INJURY OR DEATH.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

7

97372-B

Page Rev. A

SAFETY

AVOID ACCIDENTS

Most accidents, whether they occur in industry, on the farm, at home, or on

the highway, are caused by the failure of some individual to follow simple

and fundamental safety rules or precautions. For this reason, most

accidents can be prevented by recognizing the real cause and doing

something about it before the accident occurs.

Regardless of the care used in the design and construction of any type of

equipment, there are many conditions that cannot be completely

safeguarded against without interfering with reasonable accessibility and

efficient operation.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN

ACCIDENT. THE COMPLETE OBSERVANCE OF ONE SIMPLE

RULE WOULD PREVENT MANY THOUSAND SERIOUS INJURIES

EACH YEAR. THAT RULE IS:

NEVER ATTEMPT TO CLEAN, OIL OR ADJUST A

MACHINE WHILE IT IS IN MOTION.

NATIONAL SAFETY COUNCIL

If spreader is used to transport chemicals, check with your chemical

supplier regarding DOT (Department of Transportation) requirements.

CAUTION

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

8

97372-B

Page Rev. A

SAFETY DECALS

MAINTENANCE INSTRUCTIONS

1. Keep safety decals and signs clean and legible at all times.

2. Replace safety decals and signs that are missing or have become illegible.

3. Replaced parts that displayed a safety sign should also display the current sign.

4. Safety decals or signs are available from your dealer's Parts Department or our Cedar Rapids factory.

INSTALLATION INSTRUCTIONS

1. Clean Surface

Wash the installation surface with a synthetic, free-rinsing detergent. Avoid washing the surface

with a soap containing creams or lotion. Allow to dry.

2. Position Safety Decal

Decide on the exact position before application. Application marks may be made on the top or

side edge of the substrate with a lead pencil, marking pen, or small pieces of masking tape.

NOTE: Do not use chalk line, china marker, or grease pencil. Safety decals will not adhere to

these.

3. Remove the Liner

A small bend at the corner or edge will cause the liner to separate from the decal. Pull the liner

away in a continuous motion at a 180-degree angle. If the liner is scored, bend at score and

remove.

4. Apply Safety Decal

a. Tack decal in place with thumb pressure in upper corners.

b. Using firm initial squeegee pressure, begin at the center of the decal and work outward in all

directions with overlapping strokes. NOTE: Keep squeegee blade even—nicked edges will

leave application bubbles.

c. Pull up tack points before squeegeeing over them to avoid wrinkles.

5. Remove Pre-mask

If safety decal has a pre-mask cover remove it at this time by pulling it away from the decal at a

180 degree angle. NOTE: It is important that the pre-mask covering is removed before the decal

is exposed to sunlight to avoid the pre-mask from permanently adhering to the decal.

6. Remove Air Pockets

Inspect the decal in the flat areas for bubbles. To eliminate the bubbles, puncture the decal at one

end of the bubble with a pin (never a razor blade) and press out entrapped air with thumb moving

toward the puncture.

7. Re-Squeegee All Edges.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

9

97372-B

Page Rev. A

SAFETY DECALS CONTINUED

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

10

97372-B

Page Rev. A

GENERAL SAFETY RULES

Operation Section

1. Before attempting to operate this unit, read and be sure you understand the operation and

maintenance manual. Locate all controls and determine the use of each. Know what you are

doing!

2. When leaving the unit unattended for any reason, be sure to:

a. Take power take-off out of gear.

b. Shut off conveyor and spinner drives.

c. Shut off vehicle engine and unit engine (if

so equipped).

d. Place transmission of the vehicle in

“neutral” or “park”.

e. Set parking brake firmly.

f. Lock ignition and take keys with you.

g. Lock vehicle cab.

h. If on steep grade, block wheels.

These actions are recommended to avoid

unauthorized use, runaway, vandalism, theft and

unexpected operation during start-up.

3. Do not read, eat, talk on a mobile phone or take

your attention away while operating the unit.

Operating is a full-time job.

4. Stay out of the body while conveyor is operating.

If it is necessary to get into the body for any

reason, be sure all power is shut off, vehicle

brakes are set, and the engine starting switch is

locked and keys removed. All controls should be

tagged to prohibit operation and tags should be

placed and later removed only by the person who

was working in the body.

5. Guards and covers are provided to help avoid

injury. Stop all machinery before removing

them. Replace guards and covers before starting

spreader operation.

6. Stay clear of any moving members, such as

shafts, couplings and universal joints. Make

adjustments in small steps, shutting down all

motions for each adjustment.

7. Before starting unit, be sure everyone is clear and

out of the way.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

11

97372-B

Page Rev. A

GENERAL SAFETY RULES

Operation Section

8. Be careful in getting on and off this unit,

especially in wet, icy, snowy or muddy

conditions. Clean mud, snow or ice from steps

and footwear.

9. Do not allow anyone to ride on any part of unit

for any reason.

10. Keep away from spinners while they are turning:

a. Serious injury can occur if spinners touch

you.

b. Rocks, scrap metal or other material can be

thrown off the spinner violently. Stay out of

discharge area.

11. Inspect spinner fins, spinner frame mounting and

spinner fin nuts and screws every day. Look for

missing fasteners, looseness, wear and cracks.

Replace immediately if required. Use only new

SAE grade 5 or grade 8 screws and new self-

locking nuts.

12. Inspect all bolts, screws, fasteners, keys, chain

drives, body mountings and other attachments

periodically. Replace any missing or damaged

parts with proper specification items. Tighten all

bolts, nuts and screws to specified torques

according to the torque chart in this manual.

13. Shut off engine before filling fuel and oil tanks.

Do not allow overflow. Wipe up all spills. Do

not smoke. Stay away from open flame. FIRE

HAZARD!

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

12

97372-B

Page Rev. A

GENERAL SAFETY RULES

Operation Section

14. Starting fluids and sprays are extremely flammable.

Don’t smoke. Stay away from flame or heat!

15. All vehicles should be equipped with a serviceable

fire extinguisher of 5 BC rating or larger.

16. Hydraulic system and oil can get hot enough to

cause burns. Before working on the system, wait

until oil has cooled.

17. Wear eye protection while working around or on

unit.

18. Read, understand and follow instructions and

precautions given by the manufacturer or supplier

of materials to be spread. Improper selection,

application, use or handling may be hazardous to

people, animals, plants, crops or other property.

19. Cover all loads that can spill or blow away. Do not

spread dusty materials where dust may create

pollution or a traffic visibility problem.

20. Turn slowly and be careful when traveling on

rough surfaces and side slopes, especially with a

loaded spreader. Load may shift causing unit to

tip.

21. Read and understand the precautionary decals on

the spreader. Replace any that become defaced,

damaged, lost or painted over. Replacement decals

can be ordered from your dealer or from Highway

Equipment Company by calling (319) 363-8281.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

13

97372-B

Page Rev. A

GENERAL SAFETY RULES

Maintenance Section

1. Maintenance includes all lubrication,

inspection, adjustments (other than operational

control adjustments such as feedgate openings,

conveyor speed, etc.) part replacement, repairs

and such upkeep tasks as cleaning and painting.

2. When performing any maintenance work, wear

proper protective equipment—always wear eye

protection—safety shoes can help save your

toes—gloves will help protect your hands

against cuts, bruises, abrasions and from minor

burns—a hard hat is better than a sore head!

3. Use proper tools for the job required. Use of

improper tools (such as a screwdriver instead of

a pry bar, a pair of pliers instead of a wrench, a

wrench instead of a hammer) not only can

damage the equipment being worked on, but

can lead to serious injuries. USE THE

PROPER TOOLS.

4. Before attempting any maintenance work

(including lubrication), shut off power

completely. DO NOT WORK ON RUNNING

MACHINERY!

5. When guards and covers are removed for any

maintenance, be sure that such guards are

reinstalled before unit is put back into

operation.

6. Check all screws, bolts and nuts for proper

torques before placing equipment back in

service. Refer to torque chart in this manual.

7.

Some parts and assemblies are quite heavy.

Before attempting to unfasten any heavy part or

assembly, arrange to support it by means of a

hoist, by blocking or by use of an adequate

arrangement to prevent it from falling, tipping,

swinging or moving in any manner which may

damage it or injure someone. Always use lifting

device that is properly rated to lift the equipment.

Do not lift loaded spreader. NEVER LIFT

EQUIPMENT OVER PEOPLE.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

14

97372-B

Page Rev. A

GENERAL SAFETY RULES

Maintenance Section

8. If repairs require use of a torch or electric welder, be

sure that all flammable and combustible materials are

removed. Fuel or oil reservoirs must be emptied,

steam cleaned and filled with water before attempting

to cut or weld them. DO NOT weld or flame cut on

any tank containing oil, gasoline or their fumes or

other flammable material, or any container whose

contents or previous contents are unknown.

9. Keep a fully charged fire extinguisher readily

available at all times. It should be a Type ABC or a

Type BC unit.

10.

Cleaning solvents should be used with care.

Petroleum based solvents are flammable and present

a fire hazard. Don’t use gasoline. All solvents must

be used with adequate ventilation, as their vapors

should not be inhaled.

11. When batteries are being charged or discharged, they

generate hydrogen and oxygen gases. This

combination of gases is highly explosive. DO NOT

SMOKE around batteries—STAY AWAY FROM

FLAME—don’t check batteries by shorting terminals

as the spark could cause an explosion. Connect and

disconnect battery charger leads only when charger is

“off”. Be very careful with “jumper” cables.

12. Batteries contain strong sulfuric acid—handle with

care. If acid gets on you, flush it off with large

amounts of water. If it gets in your eyes, flush it out

with plenty of water immediately and get medical

help.

13. Hydraulic fluid under high pressure leaking from a

pin hole are dangerous as they can penetrate the skin

as though injected with a hypodermic needle. Such

liquids have a poisonous effect and can cause

serious wounds. Get medical assistance if such a

wound occurs. To check for such leaks, use a piece

of cardboard or wood instead of your hand. The

fine spray from a small hydraulic oil leak can be

highly explosive—DO NOT SMOKE—STAY

AWAY FROM FLAME OR SPARKS.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

15

97372-B

Page Rev. A

GENERAL SAFETY RULES

Installation Section

1. The selection of the vehicle on which a

spreader body is to be mounted has

important safety aspects. To avoid

overloading:

a. Do not mount spreader on a chassis

which, when fully loaded with

material to be spread, will exceed

either the Gross Axle Weight

Rating (GAWR) or the Gross

Vehicle Weight Rating (GVWR)

for the chassis.

b. Do install the spreader only on a

vehicle with cab-to-axle dimension

recommended for the spreader body

length shown.

2. Follow mounting instructions in the

Installation section of this manual. If

mounting conditions require deviation

from these instructions refer to factory.

3. When making the installation, be sure that the lighting meets Federal Motor Vehicle Safety

Standard (FMVSS) No. 108 and all applicable local and state regulations.

4. When selecting a PTO to drive hydraulic pump, do not use a higher percent speed drive than the

Truck-PTO-Pump Match Graph indicates in the Installation section of this manual. Too high a

percent PTO will drive pump at excessive speed, which can ruin the pump, but more importantly,

will overheat the hydraulic oil system and increase the possibility of fire.

5.

When truck frame must be shortened, cut off only the

portion that extends behind rear shackle in accordance with

the truck manufacturer’s recommendations. If

a torch is

used to make the cut, all necessary precautions should be

taken to prevent fire. Cuts should not be made near fuel

tanks and hydraulic oil reservoirs, fuel, brake, electric or

hydraulic lines and such lines should be protected from

flame, spark

s or molten metal. Tires should be removed if

there is any chance of their being struck by flame, sparks or

molten metal. Have a fire extinguisher handy.

Please Give Part No., Description and Unit Serial No.

HIGHWAY EQUIPMENT COMPANY

16

97372-B

Page Rev. A

GENERAL SAFETY RULES

Installation Section

5. Do not weld on vehicle

frame as such welding

can lead to fatigue

cracking and must be

avoided. When drilling

holes in frame member,

drill only through the

vertical web portions−do

not put holes in top or

bottom flanges. Refer to

truck manufacturer’s

recommendations.

6. Be sure that welds between mounting bars and sill or between mounting angles and spreader cross

sills are sound, full fillet welds. Center mounting angles so that good fillet welds can be made on

three sides—an edge bead weld is not a satisfactory weld for this service. Use dry, E6013 or E7018

rod for normal steels. On stainless steel bodies use SAE grade 5 bolts—welding is recommended if

type 308 welding rod is available.

7. Install controls so they are located for convenient use. Position them so they do not interfere with

any vehicle control and they do not interfere with driver or passenger or with access to or exit from

the vehicle.

8. Check for vehicle visibility, especially toward the rear. Reposition or add mirrors so that adequate

rearward visibility is maintained.

9. Add Caution, Warning, Danger and Instruction decals as required. Peel off any label masking

which has not been removed.

10. Install all guards as required.

11. Check installation completely to be sure all fasteners are secure and that nothing has been left

undone.

TAB

OP & MAINT

Table of contents

Other New Leader Spreader manuals

New Leader

New Leader L5034G4 AGCO User manual

New Leader

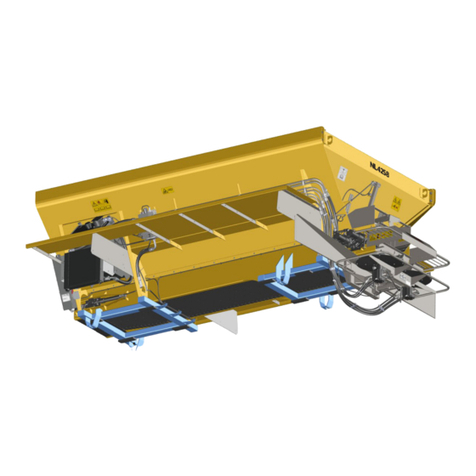

New Leader AGCO NL4258G4 User manual

New Leader

New Leader NL5000G5 AGCO User manual

New Leader

New Leader Hi-Way SUPER P User manual

New Leader

New Leader L5034G4 AGCO User manual

New Leader

New Leader L5034 G4 User manual

New Leader

New Leader L4000G4 User manual

New Leader

New Leader L5034G4 AGCO User manual

New Leader

New Leader AGCO NL5258G5 User manual

New Leader

New Leader NL4500G4 User manual