342 |

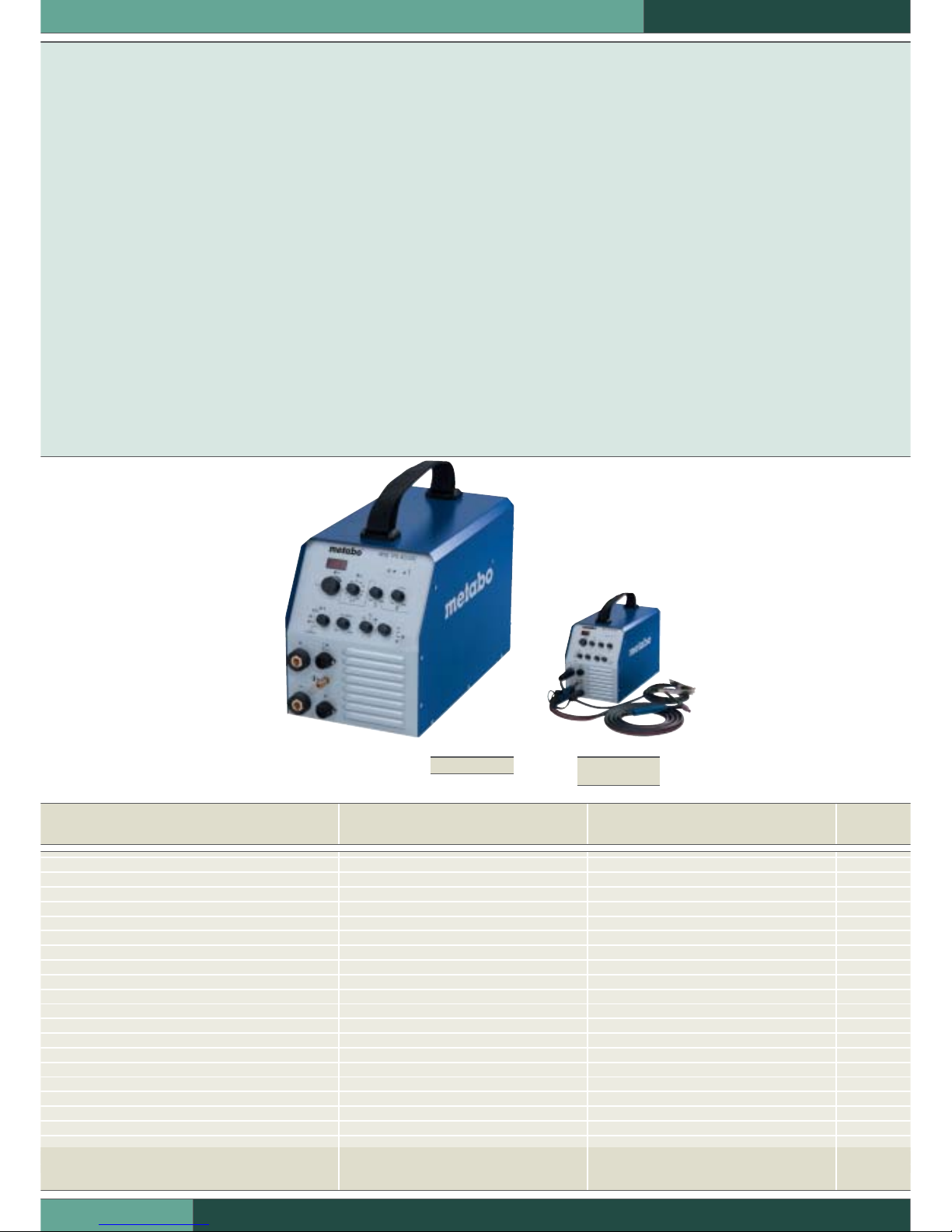

MIG/MAG

170/30 XTC

Comparative device characteristics

Mains voltage 230/400 V 230/400 V

Maximum power input at 400 V 6,7 kVA 6,7 kVA

Setting range (400 V) 60 - 170 A 60 - 170 A

Regulation 6 levels each 6 levels each

Weldable wire 0,6 - 0,8 mm 0,6 - 0,8 mm

Weldable material thickness 0,5 - 6 mm 0,5 - 6 mm

Maximum duty cycle at 25 °C 30 % 30 %

Maximum duty cycle at 40 °C 20 % 20 %

100% duty cycle at 25 °C 90 A 90 A

100% duty cycle at 40 °C 60 A 60 A

Fuse protection for 400 V T 16 A T 16 A

Dimensions L x W x H 854 x 338 x 782 mm 854 x 338 x 782 mm

Weight 68,5 kg 68,5 kg

Standard equipment Torch SB 15/3 m, earth cable,

protective shield, wire brush, torch spray,

pressure reducer with content and flow

manometer, connection adapter 230 V/400 V

Torch SB 15/3 m, earth cable,

protective shield, wire brush, torch spray,

pressure reducer with content and flow

manometer, connection adapter 230 V/400 V,

welding wire 0.8 mm/5 kg (G3Si1), adapter

for 5 kg, gas bottle 10 litres mixed gas

Type MIG/MAG 170/30 XTC MIG/MAG 170/30 XTC Set

Order no. 0021031900 0021901900

COMMON FEATURES

MIG/MAG

170/30 XTC Set

Inert Gas Welding System

MIG/MAG 170/30 XTC

Inert Gas Welding System

MIG/MAG 170/30 XTC Set

MIG/MAG WELDING SYSTEMS

....5 year warranty

on main transformer

"Smart Intelligence": state-of-the-art processor control

for easy operation and ideal welding results

Gasless and currentless welding wire threading - comfortable,

gas-loss-free and safe

Soft start for easy electric arc start

Adjustable burn back time for practical electric arc restart

2/4-cycle control for practical operation

Adjustable automatic point system for even welding results

Large, ergonomic and protected control elements

for optimum adjustment even with gloves

Electronics dust-proof rough applications

Unique: switchable three-wire electrical socket 230 V -

ideal for angle grinder etc.

Metal 2-roller wire feed for safe wire transport even with

long hose packets

Vertical wire roller guide with angular torch and wire

outlet for optimum and even wire transport

Operation at 230 V and 400 V for universal use

"Cooling duct": high duty cycle due to optimum cooling

Robust welding housing construction (chassis)

"Multigriff": for easy transportation of device and practical

storage of welding site equipment

Large device transport wheels for easy and safe transport

Rubber-coated storage area - practical for accessories

Variable gas bottle holder

Removable torch and earth cable

"S-mark": approved for welding in narrow welding

spaces with increased electrical danger

5 year warranty on main transformer

CE-inspected