Neware BVIR User manual

1

BVIR User Manual

2

Attention and warning

Note:“Note”says can help you better use

the main information of the equipment.

Notice:“Notice”says might damage the

hardware or lead to loss of data, and tell

you how to avoid such problem.

Warning :“ Warning ”says may cause

property damage, personal injuries or

even death.

Introduction:In order to better use and play system performance ,please read the instruction before using this

system, , due to the system constantly upgraded, this instruction sheet for reference only and is subject to

change without prior notice.

© 2010 NEWARE。All rights reserved, re-print reserved。

November, 2010 VERSION: 2.0

3

To Customers,

Thanks for your great support to NEWARE products!

In order to better use and play system performance ,please read the instruction before using

this system, , due to the system constantly upgraded, this instruction sheet for reference only.

The company is committed to provide first-class battery formation, capacity grading, testing

equipment and power management system. Development of the company for over ten years,

the product performance index is in the industry advanced level,passed strictly examination

of national quality inspection department and obtained multiterm certificates. Currently

business partners reached more than 8000 customers, spread over hundreds of famous

companies, universities, research institutes and quality inspection department both in

domestic and foreign area, is going to be one of most competitive battery test system

suppliers.

Our company registered trademark is “NEWARE”, passed the quality management system

certification of ISO9001. We adopt the world-leading SAP system for the management of

business process. Our company always pursuing to meet the various needs of customers with

the advanced technology and perfect service, to realize enterprise sustainable development.

The company adopts advanced integrated R&D project management systems, software

maturity reach CMMI 3 grades. This ensures the consistency of the R&D production, can

rapidly solve customer special requirements.

The free service telephone:

800-830-8866,

provide pre-sales, after-sales technical support and

free training service, sincerely welcome to our company to visit and investigate.

More choice of models, software updates/downloads and information consultation, please

visit our website: http://www.neware.com.cn.

Battery Voltage and Internal Resistance Tester User Manual

4

CONTENTS

1 Introduction..........................................................................................5

1.1 Inspection........................................................................................................................... 5

1.2 Safety.................................................................................................................................. 5

1.3 Overpressure Classification............................................................................................. 5

1.4 Prevention.......................................................................................................................... 6

2 Summarize............................................................................................. 7

2.1 Product Summarize.......................................................................................................... 7

2.2 Function..............................................................................................................................7

2.3 Characteristics...................................................................................................................7

2.4 Technical Specification..................................................................................................... 7

3 BVIR Composition Structure and Function.................................... 9

3.1 Operation Keys..................................................................................................................9

3.2 LCD Screen......................................................................................................................10

3.3 LEDs Indicator Light......................................................................................................10

4 Testing Process...................................................................................11

4.1 Prepare Measurement.....................................................................................................11

4.2 Standard Testing Process................................................................................................12

4.3 Comparing Function.......................................................................................................12

4.4 Open/Close Buzzer Function......................................................................................... 14

4.5 Keep Function..................................................................................................................14

4.6 Historical Data Checking............................................................................................... 14

4.7 Calibration....................................................................................................................... 15

4.8 Low Battery Display....................................................................................................... 16

4.9 Auto Power-Off Function...............................................................................................16

Appendix…………………………………............................................ 17

Caution..................................................................................................................................... 17

Maintenance.............................................................................................................................17

After sales service....................................................................................................................17

Service Items............................................................................................................................17

Exception..................................................................................................................................17

Exchange.................................................................................................................................. 17

Customer Obligations............................................................................................................. 18

Contact NEWARE...................................................................................................................20

Battery Voltage and Internal Resistance Tester User Manual

5

Chapter 1 Introduction

Thanks for using “NEWARE BVIR” voltage internal resistance equipment, in order to make

full use of equipments’ function, please carefully read this user manual before you operate the

testing equipment.

1.1 Inspection

Check the equipment carefully to see weather it was broken during the transportation when

you receive it. Specially, check accessories, panel buttons and connector wire. If there is obviously

damage or can not work in accordance to instructions, please contact NEWARE sales engineer.

Accessories

User manual

A 4-wire Watch pen or polymer battery fixture

One charger

A 100mΩ standard resistance

Transportation

In order to avoid any unnecessary damage during the shipment, please try your best to make use of

our original packing materials.

1.2 Safety

Dangerous

This product is designed according to relevant safety standards, and passed the

safety test before the transport. But, wrongly use this instrument will harm the human

body, also damage the equipment. Please confirm your operation is according to the

specifications instructions and using environment before using it. We don't accept any

complaint and feedback of property or personnel damage caused by non-instrument

problem.

Safety Tips

Following instructions in the manual are the relatively important notice and warnings.

“Dangerous” if operation is incorrect, may cause the user very serious injury or death.

“Warning” if operation is incorrect,may cause the user very serious injury or death.

“careful” if operation is incorrect ,may cause the user very serious injury or broke the

equipment.

“Attention” helps improve the performance of the proposed project or the correct operation

of the product of the steps.

1.3 Overpressure Classification

This product meets the class I over-pressure testing product standards。In order to ensure the

safe operation of testing products,IEC 60664 established a safety standards for all types of electric

environment , from the CAT I to CAT IV is divided into 4 categories,called overpressure standard.

They are defined as follows:

CAT I :The secondary circuit through a transformer or similar circuit connected in AC

socket.

CAT II: The circuit directly connected to the AC power output devices on the circuit

(portable tools, home appliances, etc)

CAT III: The circuit connected to the distribution box on heavy equipment, direct circuit

from distribution box to AC socket.

CAT IV: From lead-in line to aerial lead-in line, electric meter, leakage current protection

equipment (distribution box).

The higher level classification, the corresponding instantaneous electric energy is high also,

so if design a CAT III environmental standard equipment, the instantaneous electric energy it bears

should exceed CAT II standards. There will be a serious accident if testing equipment is over-used

in a higher standard environment, which must be avoided.

Battery Voltage and Internal Resistance Tester User Manual

6

1.4 Prevention

Dangerous

1. The following content is to make sure that the operations is safe,under these

conditions, all of functions could be used .The maximum voltage between

input voltage and ground is 20V AC/DC. Don’t attempt to test the ground

voltage which is more than 20V.

2. When test the battery, you should ensure adequate ventilation. Sometimes the

electrode and the battery electrode contact may produces sparks, can produce

flammable gases such as hydrogen.

Warning

1. Make sure the correct terminal connections of the power terminals and testing

terminal. View chapters to see the details about the connection.

2. To avoid damage of the equipment, do not try to test AC/DC voltage exceed

20V.

3. Do not try to add a voltage between SOURCE+, SENSE+,SOURCE-,and

SENSE+,this will damage the equipment.

Careful

1. This equipment doesn’t have waterproof or dustproof function 。To avoid

damage of the equipment,please do not use in wet and dusty environment.

2. Before using the equipment,please confirm the wires of insulating layer is not

damaged, and watch- pen is not unusual naked,using equipment in this case

will cause accident,please change a new watch-pen.

3. Do not use under the sun, heat, moisture and atomization condition,products

may damage ,and the deterioration of the insulation using the product ,the

performance of products no longer meet the design requirements.

4. Do not use the equipment in strong magnetic interference or the place with the

electrostatic charge, they can cause error testing results.

Warning

1. It is basically impossible to implement accurate measurement in a place with

strong magnetic interference,like the transformer accessories,high current or

strong electromagnetic place (such as radio stations).

2. Use of distribution watch- pen or measurement fixture.

Service

1. When the first use of the equipment, check whether equipment works properly,

to confirm that the equipment is not damaged during the transportation. If

found any damaged, please contact NEWARE sales representative.

2. When return the equipment to mend, please take the battery out to prevent

damage during the transportation. Add cushions in the box to prevent shaking.

Confirm that contains the detailed product problems, we will not bear the loss

incurred during the transportation.

Battery Voltage and Internal Resistance Tester User Manual

7

Chapter 2 Summarize

2.1 Product Summarize

BVIR battery voltage and internal resistance tester is mainly for testing the internal resistance

and open-circuit voltage of Secondary batteries, Lead-acid batteries, Ni-Cd batteries, Ni-MH

batteries, Li-ion batteries, etc.

2.2 Function

Complex comparison functions: can make the comparison of the current measured resistance,

voltage value and pre-set voltage, resistance upper (lower) limit.

Data View:The equipment can save 99999 group measurement data, the user can view the

data.

Correction function:Include the zero point correction and full-scale correction.

Automatic power-off:By default the last half-hour operation automatic power-off, to save

power.

Electricity shortage hint: When the battery is insufficient, the resistance tester will give some

hints information.

USB connector:USB 2.0 Full Speed(full version)for battery charging.

2.3 Characteristics

Accurate measurement:Using AC four-terminal method to measure the internal resistance of

the battery ,can provide accurate results after the elimination of the contact resistance and

lead resistance ;the provided standard watch-pen can be easily connected to the battery

electrodes,allows precise measurement of the four-terminal,quickly and directly measure the

internal resistance of the battery exchange.

Automatically switch:Can automatically switch resistance、voltage range,no shift,without

changing the function, shows the battery internal resistance and voltage.

Measurement range:Suit to measure cell and module battery, which voltage is equal or below

20V.

High stability: Simple circuit ,high integration, anti-interference ability,used for measuring

constant ac current is less than 20mA, stable and reliable performance.

Note:Working environment must be 23℃±5℃,humidity must be 80%RH or below it(no

water vapor),zero adjustment before measuring,and preheat at least 10 minutes.

2.4 Technical Specification

Index Project

Index Parameter

Measuring methods

AC 4-terminal resistance test method

Voltage

Voltage range

0~20V

Accuracy

0.1%

Resistance

Resistance

measuring range

20mΩ\200mΩ\2000mΩ automatic/manual switch

Points range range

and accuracy

0~200mΩ

1%

200mΩ~2000mΩ

3%(does not include 200mΩ)

A/D mode

SAR 12digit successive comparative way

Frequency

Measuring

frequency

1KHz

Sampling rate

1000times/S

Rising time

Display update 5times/S

Open terminal voltage

AC5V(effective value)

Battery Voltage and Internal Resistance Tester User Manual

8

Index Project

Index Parameter

Over the input range

To show “﹍﹍”

Comparator

Manually operation on/off

The number of comparators

10 group voltage and internal resistance limit

Comparator buzzer setting

Resistance measurement mode:when Hi、Lo or IN,buzzer ring

Save function

Save show

Resistance voltage

measurement range

When PASS or FALL,buzzer ring

Zero function

Induce voltage by using circuit and the test line compensation

View function

Test value with the comparator value asynchronous display

Buzzer function

When use the comparator, can undertake the buzzer on/of

setting

Data store

10milion set of test data can be local view

External control terminal

extension

Extensible test automation

USB I/F

USB 2.0 Full Speed(full version)

Pressure resistance

20V

Preheat

Above 3min

Equipment Working Environment

Index Project

Index Parameter

Operating temperature range

10℃~40℃

Storage temperature range

10℃~45℃

Operating environment

relative humidity range

30% ~ 80% RH(no water vapor)

Storage environment relative

humidity range

30% ~ 90% RH(no water vapor)

Operation place

Both indoor or outdoor, easy to carry

Fixtures and Equipment Size Specification

Index Project

Index Parameter

Accessories

Polymer fixture and probe

Volume

W*D*H: 120*75*25(mm)

Weight

About200g

Battery Voltage and Internal Resistance Tester User Manual

9

Chapter 3 BVIR Composition Structure and Function

BVIR consists of operation keys, LCD screen, LEDs indicator light.

3.1 Operation Keys

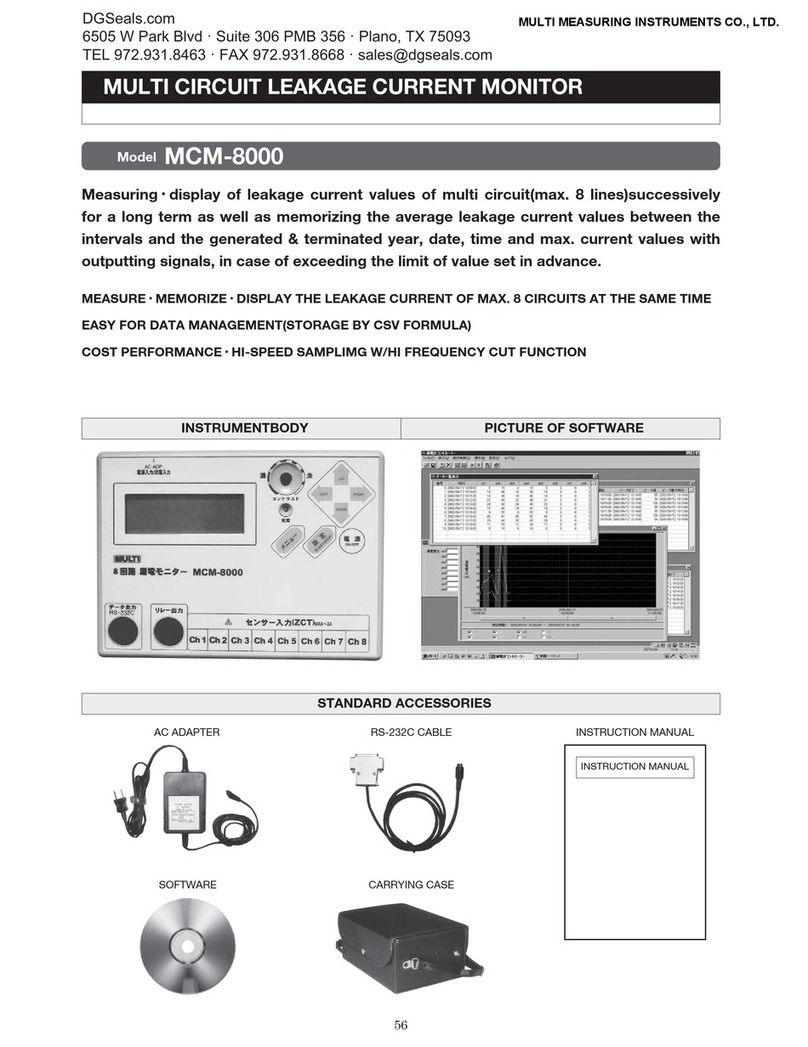

Picture 1 Internal Resistance and Voltage Tester Appearance

1 Battery resistance display

Shows the measured internal resistance of the battery and

history data

2 Battery voltage display

Shows the measured battery voltage of the battery and voltage

history data

3 LEDs light

Shows battery passed testing

4 Holding key

Lock the current contents of the screen and historical data

query

5 Buzzer key

Buzzer open and close

6 Cursor movement key

Move the cursor to the left

7 Anode “sense” port

Watch-pen positive “sense” port

8 Cathode “source” port

Watch-pen negative “ source” port

9 Value increment buttons

Increase the current value

10Comparing function key

Comparison function switch ,change the current mode to

comparative parameter setting mode

11 Calibration key

Calibration adjustment key

Battery Voltage and Internal Resistance Tester User Manual

10

12 LEDs key

Battery passed testing

13 Record data group number

Display historical data records and group number setting of

comparing function

3.2 LCD Screen

The LCD screen shows the measured internal resistance or voltage values, Show the current

total record measuring amount, under the page of comparison setup ,shows the maximum and

minimum value of internal resistance or voltage ,and present comparative parameter group array

number.

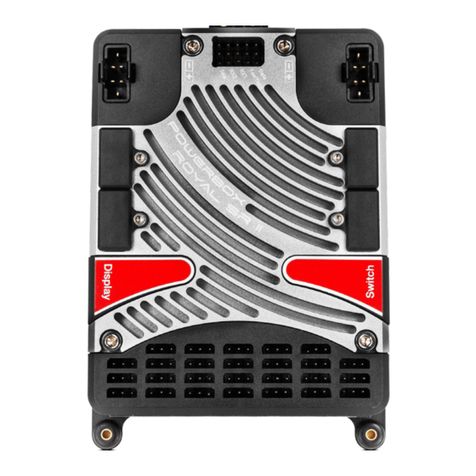

Picture 2 BVIR LCD Screen

As shown, ①indicates that the battery internal resistance, ② indicates battery voltage, ③

indicates the number of recording data,“

m

” is the internal impedance measurement unit,“V”

is the voltage measurement unit, “HOLD”appears when the screen lock and historical data

query ,appears when open the buzzer, is the battery capacity scaleplate, “min” and

“max” appears when set the parameter of comparison function,“MEMO” appears when set the

parameter of comparison function.

3.3 LEDs Indicator Light

√ Battery smoothly passed the inspection, battery meet the set comparative conditions

× Battery didn't pass the inspection; battery doesn't meet the set comparative conditions

Battery Voltage and Internal Resistance Tester User Manual

11

Chapter Four Testing Process

4.1 Prepare Measurement

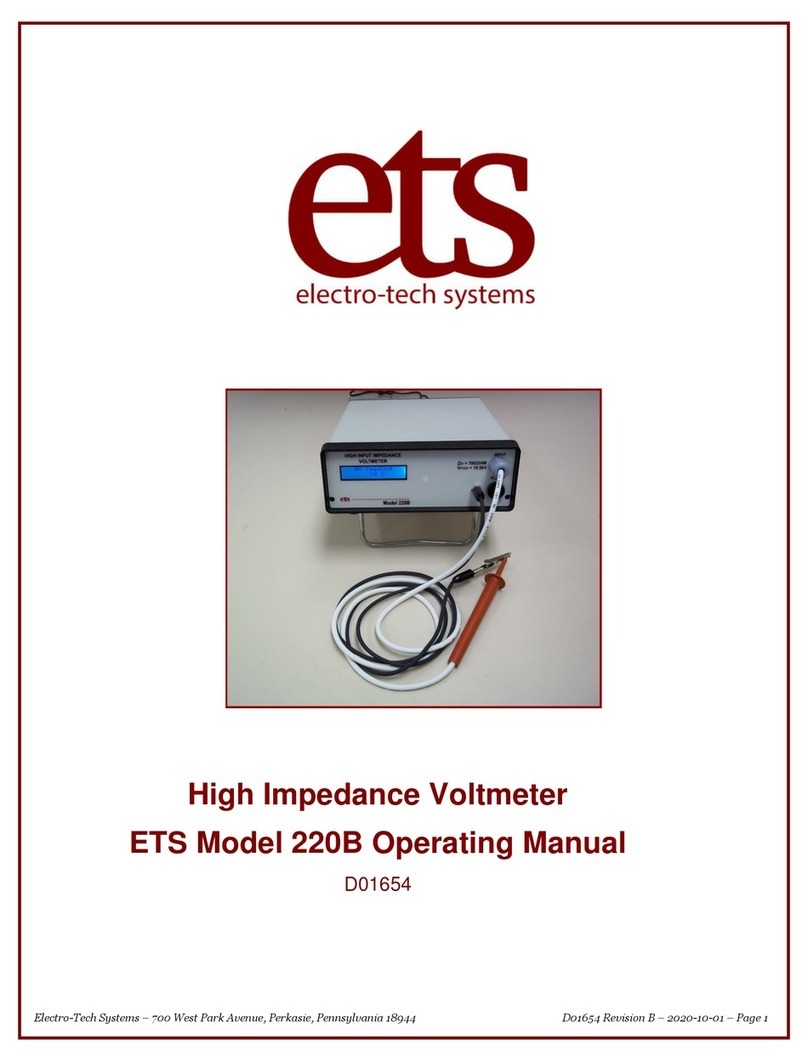

Picture 3 Screen Shown after Startup

1. The content shows as Picture 3 within 3 seconds after press “POWER” key, the content

shows as Picture 4 after 3 seconds,at this time, voltage is jumpy, after 3 minutes preheating,

screen voltage is stability, after startup can adjust through“↑”,“↓”,change group, and check

historical data.

2. Connect watch-pens or polymer fixture to the red port to the positive electrode port of

“SOURCE” and “SENSE” of the equipment, the black port connects to the negative port of

“SOURCE” and “SENSE”. Picture 4 is the state without access to the battery.

Picture 4 Screen Shown after Stability

3. When the screen appears“ ”, indicates that the battery power is very low,please charge

the battery;If internal battery loss efficiency, need change the battery. After changed,

automatic power-off will automatically set to in idle for 30 minutes, and buzzer open; If

storage time is more than a week,please power save after charging batteries two case.

4. When charge,“ ”will keep flashing,when appears“ ”, indicates that the battery is

full-charged.

5. After charging completes, disconnect chargers and utility first, then disconnect the

equipment.

Battery Voltage and Internal Resistance Tester User Manual

12

4.2 Standard Testing Process

Warning:In order to avoid equipment damage, don’t try testing voltage over 20VAC/DC;

don’t test voltage of constant voltage source;After testing high voltage battery, when

continue testing low voltage battery, should short-press the watch-pens, this will make

watch-pens connected AC coupling capacitance discharge.

1. Connect watch-pens, connect four terminals,SOURCE+/- and SENSE+/-.

2. Press “Power” key to open the equipment and start testing, when open the equipment, need

two minutes preheating time to make circuit stabilized.

3. Connect the red watch-pens to the battery positive electrode, the black watch-pens to the

battery negative electrode, the external connector post connect to the “SOURCE” terminal,

the internal connector post connect to the “SENSE” terminal. When the watch-pens connect

battery electrodes, downward press the watch-pens to make the internal connector post shrink

to the watch-pen inside, and all connector post of “SOURCE” and “SENSE” connect well.

4. After testing completes, disconnect battery, close the equipment power.

Note :When testing, screen shows “OF”, indicates that internal resistance or

voltage exceed the range of the equipment; When resistance shows “ - - - - ” ,

indicates that testing can’t continue, there might be circuit breakers could exist, or

watch-pens and equipment terminal didn’t connect well, or contact resistance relative to the

testing range is too big; Please do not press “POWER” key and other keys at the same time

except set automatic shut-off mode, in case press “POWER” key and other keys at the same

time, please press “POWER” key immediately to close the equipment, continue operating

may lead to the loss of calibration information, and can’t do exact testing any longer; When

watch-pens is open, an reaction voltage will display on the equipment, this is not the

problem of the equipment.

4.3 Comparing Function

Comparing function is to make the comparison of the current measured resistance、voltage

and pre-set upper or lower limit of voltage and resistance. If compare failure ,the red light

“×”on, if with buzzer open, there will be buzzer tip; If successful, the green light“√”on.

Enter the testing interface without access to the battery, press“COMP”key to open and close

comparing function,“COMP”shows on the above screen indicates that this function is open.

If want to change parameter, such as upper or lower limit of voltage and resistance, please

operate as the follow methods:

1. Into the comparative parameter settings interface

Press “ COMP” key,and maintain at least 3 seconds, then the equipment into the comparative

parameter settings interface.

Battery Voltage and Internal Resistance Tester User Manual

13

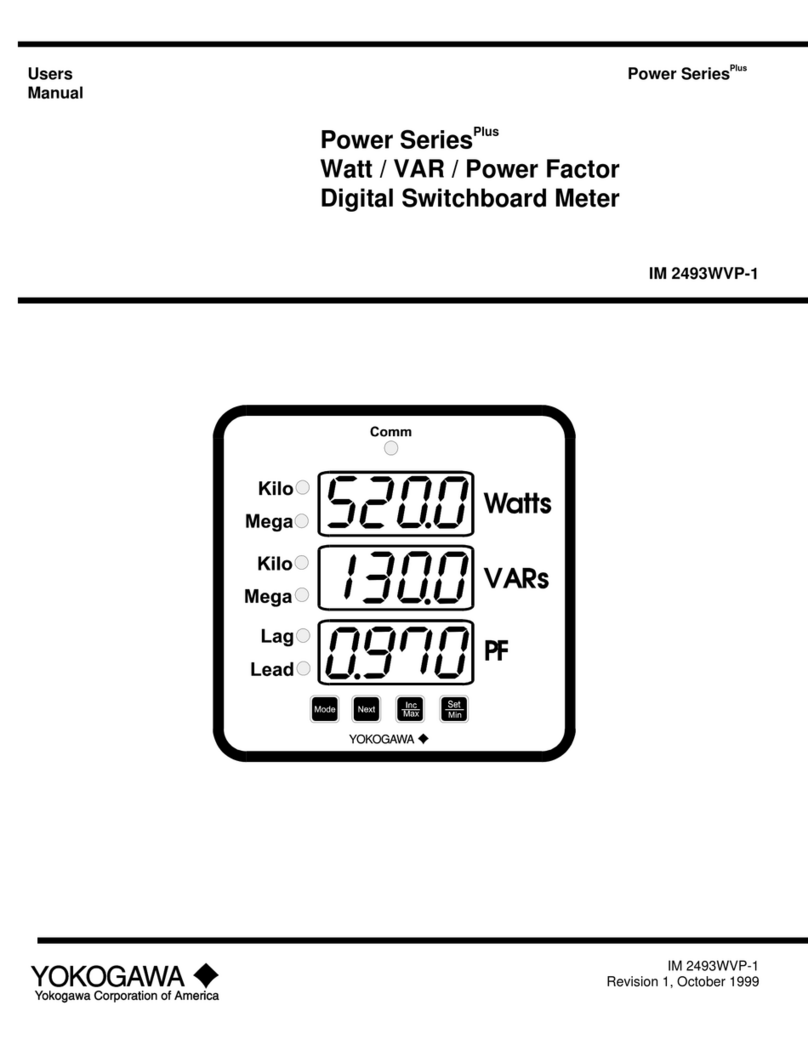

Picture 5 Comparative Parameter Setting

The content shows as Picture 5 when into the comparative parameter settings interface,

①is the upper limit of internal resistance, ②is the lower limit of internal resistance, ③

indicates that what you set is about upper (lower) limit of internal resistance, ④ is the current

comparative parameter group number.

2. Set Comparative Parameter Group Number

Under the setting interface, press “←”,“→” to move the twinkle cursor to ④, press“↑”,

“↓” to change the comparative parameter group number, the maximum group number is

10,and the minimum is 1.

3. Set Voltage Upper(Lower) Limit

a. Press “→”, first display that the available setting is voltage limit, LCD screen as Picture

6, move the twinkle cursor to the top digit of maximum voltage, V shows that voltage

limit is under setting, as shown;

b. Press “←”,“→” key, switching among each set value, press “↑”,“↓” to change value,

the voltage range is from 0V to 20V;

c. Can change comparative parameter group number, continue setting parameter of other

comparative parameter groups, the data of the last group number of will automatically

be saved into memory.

Picture 6 Voltage Limit Setting

4. Set Internal Resistance Limit

a. Continue press “→” key,move the twinkle cursor to the top digit of maximum internal

resistance, mΩ shows that internal resistance limit is under setting, as Picture 7 ;

b. Press “←”,“→” key, switching among each set value, press “↑”,“↓”to change value,

the internal resistance range is from 0mΩ to 2000mΩ.

Battery Voltage and Internal Resistance Tester User Manual

14

Picture 7 Internal Resistance Setting

Note:Setting of the upper limit valueshould be equal or greater than the lower limit value,,

the logical conditions of voltage and internal resistance value in comparing function is

"and" relationship .

5. Finish Setting

After all the settings completes, press “COMP” key back to the interface state before

setting, if this setting is invalid, press “POWER” key exit the setting interface. Access to the

battery after setting, if user forget to press “COMP” key or close the equipment, the equipment

will back to the interface state before setting after in idle for one minute.

Note:Before exit the interface by pressing “COMP”, all of the data is saved in memory,

only after press “COMP” key ,can the data be saved in nonvolatile memory, other exit

ways will make this setting invalid, please exit by pressing “COMP” key to save the

data.

4.4 Open/Close Buzzer Function

Buzzer function is only valid towards comparing function, after opening buzzer function, if

comparison result failure, will make a buzz alerts, will not work after closing. Open or close

buzzer by pressing buzzer key, when “ ”appears on the above screen, indicates that buzzer

function is opened; If doesn’t appear, indicates that buzzer function closed.

.

Note :No matter buzzer open or closed, when press the key, buzzer will make short

buzzing.

4.5 Keep Function

“Keep function” make screen keep current measurements showed unchanged till the function

closed. When press HOLD key ,“HOLD” appears on the screen, indicates that the screen is

locked; “HOLD” disappears on the screen, indicates that back to normal state.

Screen into the locked state after no operating in a few minutes , other keys will be no

response except POWER key,HOLD key, press “HOLD” back.

Note :When the screen locked, there will be no response by pressing other keys except

POWER key,HOLD key,“↑” key and “↓” key. By pressing HOLD key also means entered

the check function of historical data.

4.6 Historical Data Checking

The equipment can store 99999 group testing data, user can check and edit data. Operating as

follows:

1. First press HOLD key under testing page, enter historical data checking interface, as

Battery Voltage and Internal Resistance Tester User Manual

15

Picture8:

Picture 8 Historical Data Checking

2. Press “↑” ,“↓”key ,screen data increase/decrease a numbers, Picture 9 for no records of

historical data shown in groups;

Picture 9 Not Measured Data Group Display

3. After the user completes the checking and editing function, short -press HOLD key, then

back to the normal testing surface.

4.7 Calibration

Calibration function includes zero adjustment and full scale adjustment. Zero adjustment is

balancing survey internal resistance zero and the voltage zero; The full scale adjustment is

adjusting the internal resistance and the voltage measurement value when full scale. Adjusting two

times is a circulation, the first time is zero adjustment, the second time is full scale adjustment, the

third time starts circulating. The full scale adjustment need the full scale resistance and full scale

voltage adjustment one time and needs circulate adjusts two times.

Zero adjustment steps as follows:

1. Make the two SOURCE and two SENCE watch-pens short-pressed.

2. Press the ADJ key, release it until the character 0.Adj appears on the screen, says system

being zero correction.

3. Until 0.Adj characters on the screen disappears, if the PASS light flashed, indicates a

successful zero calibration; If the FALL light flashes with buzzer ring, indicates

calibration failure.

Full-scale adjustment steps as follows:

1. Connect the watch-pens to the standard distribution of resistance of 100 mΩ at both

ends.

2. Press the ADJ key, release it until the character F. Adj appears on the screen, says system

being full-scale correction.

3. Until F. Adj characters on the screen disappears, if the PASS light flashed, indicates

success of full-scale correction, if the lights FALL flashed with buzzer ring, indicates

calibration failure.

Battery Voltage and Internal Resistance Tester User Manual

16

Note: Access to full-scale calibration resistance is 100mΩ, the correction is the resistance of

full scale; access to the 20V DC voltage source, the correction is the full scale voltage. During

the process of zero point correction, ensure that four watch-pens in a good short-connected.

Only SOURCE and SENSE watch-pens well short-connected then will show 0.

4.8 Low Battery Display

When the battery power is low, the battery capacity gauge to top of the screen

displays" ", then you need to recharge or replace the external power supply equipment to

ensure the equipment work properly.

4.9 Auto Power-Off Function

The default shutdown time of tester is 30 minutes, the user can turn off the automatic shut

down or reduce the automatic shutdown time, follow these steps:

1. Turn the power off;

2. Press the POWER key and the HOLD key;

3. Continued to press HOLD for a while to enter into automatic shutdown time setting

interface, as shown in Picture 10;

4. Press the HOLD key again, in order to select the auto-off time 15 minutes or 30 minutes;

If you want to turn off the automatic shutdown settings, when the screen display is 30

minutes, press the button to turn off automatically shutdown;

5. Press the POWER key to shut down, then press the POWER key again to starting up,

thus setting off the automatic shutdown.

Picture 10 Auto Power-Off Interface

Battery Voltage and Internal Resistance Tester User Manual

17

Appendix

Caution

When you use NEWARE product, please note the following:

The maximum voltage between input and ground is 20V AC / DC, do not try to measure the

voltage on the ground more than 20V.

When measuring the battery, make ensure adequate ventilation, and sometimes during the

measurement electrodes and the battery electrode contact will produce sparks, can produce

flammable gases, such as hydrogen.

Do not attempt disassemble circuit board to avoid communication error or equipment

damage.

Do not try to plus a voltage to the power positive terminal (SOURCE +) and measuring

positive terminal (SENSE +) or power negative terminal (SOURCE-) and measuring negative

terminal (SENSE-) which can damage equipment.

The instrument has not waterproofed and dustproof functions, in order to avoid damage, do

not use it in wet and dusty environments.

Before using this product, make sure the wire insulation is not damaged and no abnormal

bare table pen, if is you should stop using and replace a matched table pen.

Do not store and use the instruments in the sun, heat, humidity and aerosol environment. The

product may be damaged and the insulation of products be deteriorated that product

performance will no longer meet the design requirements

Do not use the products in strong electromagnetic interference or electrostatic charge of the

place that will cause erroneous results.

Maintenance

The device you are using is a product of superior design and craftsmanship and should be

treated with care. The following suggestions will help you protect your warranty coverage.。

Please use the device in this guide, do not try other methods;.

Keep the device dry. Rain, humidity and all types of liquids or moisture can corrode

electronic circuits;

Equipment should be kept clean, not in dusty, dirty areas or the use or storage. This will

damage its moving parts and electronic components;

Do not store the device in hot areas, high temperature can shorten the life of electronic

devices;

Do not store the device in cold areas, or when the device returns to its normal temperature,

moisture can form inside and damage the circuit board;

Do not knock or shake the device. Rough handling can break internal circuit boards and fine

mechanics;

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean equipment;

When replacing the parts, can only use the supplied or approved parts. Unauthorized parts,

modifications, or attachments could affect device performance and even damage the

equipment;

Proper use and maintenance of equipment can help you play better product performance. Our

long-term customer surveys and service practice has shown that equipment failure in many cases

is due to improper operation or maintenance method inadvertently caused, if the device does not

work, we recommend that you carefully read the product manual or contact the customer service

the new Viagra consultation.

After Sales Service

Service Items

Free Technical Training: The company offers a free pre-and post-sales technical training,

specialized technical engineers at your service, sincerely welcome you to visit;

NEWARE Phone Support: When in the use of new products, users who encounter difficult

Battery Voltage and Internal Resistance Tester User Manual

18

problems, you can call the company service hotline, consulting time, according to

NEWARE’s schedule.

Trouble-Shooting Support: receiving a customer about the product failure or abnormal

operation of the notice, if not corrected by NEWARE telephone support, NEWARE will solve

the problem as soon as recovered to the proper functioning of product components to make

correction, repair or adjust or replace;

Response Time: NEWARE should efforts to place qualified personnel dispatched reasonably,

and related maintenance personnel must arrive within the time promised to customers. The

time should be calculated from the maintenance decision to supply trouble shooting service

except other regulation, or time calculated by hour only covers normal work time, that is 9am

to 6pm from Monday to Friday, and 9am to 4pm Saturday. (Public holidays and NEWARE

regulation holiday is accepted).

Our products provide one year of free maintenance, long tracking service. And to provide free

software upgrades to ensure that equipment is in top working condition.

The company opened free service hotline: 800 -830-8866.After receiving a service request, if

customer needs on-site maintenance, our technical staff will be rushed to the site to ensure that the

user produces normally.

Exception

NEWARE’s services do not include neglect or fault NEWARE caused by any reason other than the

necessary support. Such reasons include but are not limited to:

customer or its employees or agents or any third party accident, transportation, neglect,

misuse, abuse or breach of contract;

failure of any products or parts not provided by NEWARE;

Any fault of products or components not provided by NEWARE or any products trouble by

loading non-NEWARE software.

natural disasters, lightning, fire damage, flood, war, violence or any similar event;

NEWARE personnel or authorized person or any person outside NEWARE authorized by the

contractor to implement the change, repair or repairs;

Providing services outside the workplace of product, except NEWARE’s explicit consent.

Exchange

NEWARE reserves the right that replace NEWARE’s products or any of the parts or more

considered to be defective. Namely, failure or just need to be investigated is a product

component of NEWARE. ( any products or spare parts fault not done with NEWARE, the

customer their own solute)

When replacing parts, NEWARE keep the right of supplying parts in function and appearance

of new goods, but have used the same or re-adjust the right parts. NEWARE should ensure

that the products used for replacement parts should have the same or at least equivalent basic

structure as the failure products of NEWARE. NEWARE reserves the right to supply any

person at any time that the products of any component

Spare parts provided for the replacement of new products should become owner of NEWARE

property. Any one or more parts removed should be property of NEWARE.

The warranty period of spare parts for maintenance ("Replacement Part") is for 1 year from

NEWARE's products or their products into new prestige of the remainder of the warranty

period (choose the longer one). For avoid doubting, the warranty period in its repair or

replacement does not extend. Customers do not delivered exchanged parts to NEWARE

within ten days after the parts returning to customer, NEWARE’s customers should pay for

replacement parts. The price of replacement parts should be implemented as the latest price

list.

Customer Obligations

In order to receive service and support customers should be responsible for compliance with the

following:

Explain the problem to the technician: Customers should specify the problems encountered.

Battery Voltage and Internal Resistance Tester User Manual

19

Make sure the technician to understand the content of the failure report and its emergence

time, as well as troubleshooting measures have been taken;

Cooperation with the technician: technical staff must listen carefully to the explanation in

accordance with its instructions actions.

Technical staff can not resolve the problem by phone, customers will be proposed next steps

Note: Customer must comply with the above procedures, NEWARE may send technical

support personnel provide on-site maintenance.

Allow NEWARE technical support staff to access to products and safely and timely, to fulfill its

obligations under this article.

Provide adequate working space around products and provide test equipment and components

required by technical staff at any time request and care facilities for storage of all parts reasonably.

In order to effectively provide services to ensure NEWARE technical support staff to keep abreast

of the problem situation, workers should be received by a customer and during the maintenance

period always accompanied by a staff familiar with customers and customer sites, and shall

endeavor to provide familiar clients and operations staff.

Provide reasonable and necessary communication facilities.

Service related content are the latest version of the "after-sales service provisions", if in doubt,

please contact our service department, we will be happy to serve you.

Battery Voltage and Internal Resistance Tester User Manual

20

Contact NEWARE

Thanks for using NEWARE products, we hope that NEWARE products become to your profit

assistant in process of using it. We provide you with a variety of ways of self-service to help you

be more efficient equipment operation to solve the various problems encountered in the process.

For fast, effective solution to the problem, we suggest you contact us promptly according to the

following ways when there is a problem.

Email:chenmin@neware.com.cn

Website:www.newaredevice.com.

Bus available:N9,15,44,45,60,67,102,201,210,216,218,222,324,328,374,

388 Bus to Meilin station

ZIP:518049

Other manuals for BVIR

1

Table of contents

Other Neware Measuring Instrument manuals