Neway LSZ13 Operating instructions

XL-PS20053RM-en-US Rev A

Control Arm and Bushing

LSZ13/20 Repair Manual

2XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Contents

Contents Page

Introduction......................................................................... 2

Warranty.............................................................................. 2

Notes, Cautions, and Warnings ............................................. 2

Section 1 – Safety Instructions ............................................. 3

Service Repair Kits ............................................................... 4

Section 2 – LSZ13 Remove Lower Control Arm ..................... 8

Section 3 – LSZ13 Remove Upper Control Arm...................... 8

Section 4 – LSZ20 Remove Lower Control Arm ..................... 9

Section 5 – LSZ20 Remove Upper Control Arm...................... 9

Section 6 – LSZ13/20 Replacing Bushings........................... 10

Contents Page

Section 5 – LSZ20 Remove Upper Control Arm...................... 9

Section 6 – LSZ13/20 Replacing Bushings........................... 10

Section 7 – LSZ13 Install New or Rebushed

Lower Control Arm........................................... 10

Section 8 – LSZ13 Install New or Rebushed

Upper Control Arm........................................... 12

Section 9 – LSZ20 Install New or Rebushed

Upper Control Arm........................................... 13

Section 10 – LSZ20 Install New or Rebushed

Lower Control Arm......................................... 14

Section 11 – Torque Specification ....................................... 15

Notes, Cautions, and Warnings

Before starting any work on the unit, read and understand all

the safety procedures presented in this manual. This manual

contains the terms “NOTE”, “IMPORTANT”, “CAUTION”, and

“WARNING” followed by important product information. These

terms are defined as follows:

NOTE: Includes additional information to enable accurate

and easy performance of procedures.

IMPORTANT: Includes additional information that

if NOT followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Introduction

This manual provides the necessary information for the

maintenance, inspection, and safe operation of the NEWAY®

LSZ Series Auxiliary Air Suspension.

NOTE: To assist with installation, customer inspection

drawing LSZ13_TAB_CI is required and is included

in the literature kit.

Read this manual before using or servicing this product and

keep it in a safe location for future reference. Updates to this

manual, which are published as necessary, are available on

the internet at www.safholland.us.

When replacement parts are required, SAF-HOLLAND®highly

recommends the use of only SAF-HOLLAND Original Parts.

A list of technical support locations that supply SAF-HOLLAND

Original Parts and an Aftermarket Parts Catalog are available

on the internet at www.safholland.us or contact Customer

Service at 888-396-6501.

Warranty

Refer to the complete warranty for the country in which

the product will be used. A copy of the written warranty

is included with the product or available on the internet

at www.safholland.com.

3

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

General Safety Instructions

Operational and Road Safety Instructions

Before operating vehicle, ensure that the maximum permissible

axle load is NOT exceeded and that the load is distributed

equally and uniformly and in accordance with state and

federal bridge laws.

Make sure that the brakes are NOT overheated from

continuous operation.

Failure to minimize the use of brakes during

overheating conditions could result in

deterioration of brake efficiency which, if not

avoided could result in death or serious injury.

Observe the operating recommendation of the truck

manufacturer for off-road operation of the installed axles.

IMPORTANT: The definition of OFF-ROAD means driving

on non-asphalt/non-concrete routes, e.g.

gravel roads, agricultural and forestry tracks,

on construction sites and in gravel pits.

IMPORTANT: Off-road operation of axles beyond

the approved application design could

result in damage and impair suspension

system performance.

Follow the recommended routine maintenance and inspections

described in this manual. These procedures are designed so

that optimum performance and operational safety are achieved.

The suspension springs should ALWAYS be operated with

a static operating pressure between 20 psi (1.38 bar)

and 107 psi (7.38 bar).

Failure to operate the air springs with a

proper static operating pressure could

cause premature component failure and

loss of vehicle control which, if not avoided,

could result in death or serious injury.

In the event of suspension air pressure loss, quickly reduce

speed as safely as possible and remove the vehicle from

traffic. If unable to remove vehicle from traffic, follow DOT

safety requirements regarding emergency situations.

Contact a qualified towing and/or service company to assist

in repairing the vehicle or to move it to a qualified repair facility.

DO NOT operate the vehicle in the absence of suspension

air pressure; however in the event of an air system failure

while in service, an internal rubber bumper built into the

air spring will make it possible to temporarily operate the

vehicle at reduced speed determined by road conditions.

Operating the vehicle without proper air

pressure can cause tire failure, fire, or loss of

vehicle control which, if not avoided could

result in death or serious injury.

The suspension MUST be lifted when the vehicle is moving

in reverse.

Failure to lift axle when in reverse could

result in tire or axle damage.

1. Safety Instructions

General and Servicing Safety Instructions

Read and observe all Warning and Caution hazard alert

messages. The alerts provide information that can help prevent

serious personal injury, damage to components, or both.

Failure to follow the instructions and safety

precautions in this manual could result in

improper servicing or operation leading

to component failure which if not avoided

could result in death or serious injury.

All installations should be performed by a properly

trained

technician using proper/special tools, and safe procedures.

NOTE: In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act (OSHA). Equivalent laws could

exist in other countries. This manual is written based

on the assumption that OSHA or other applicable

employee safety regulations are followed by the

location where work is performed.

Properly support and secure the vehicle from unexpected

movement when servicing the unit.

Failure to properly support and secure the

vehicle and axles prior to commencing work

could create a crush hazard which, if not

avoided, could result in death or serious injury.

Service both roadside and curbside of an axle. Worn parts

should be replaced in sets. Key components on each axle’s

braking system, such as friction material, rotors and drums

will normally wear over time.

Follow all manufacturer’s instructions on spring pressure

and air pressure controls.

Failure to follow manufacturer’s instructions

regarding spring pressure or air pressure

control could allow unexpected release of

energy which, if not avoided, could result

in death or serious injury.

The wheel contact surfaces between the wheel and hub/drum

MUST NOT be additionally painted.

IMPORTANT: The wheel contact surfaces MUST be clean,

smooth and free from grease.

Failure to keep wheel and hub contact surfaces

clean and clear of foreign material could

allow wheel/hub separations which, if not

avoided, could result in death or serious injury.

Only the wheel and tire sizes approved by SAF-HOLLAND

can be used.

Tire clearance between tires and the suspension MUST be

regularly monitored and maintained.

Failure to maintain tire clearance between

tires and the nearest point of contact on

the suspension or vehicle could cause

fire or loss of vehicle control which, if not

avoided, could result in death or serious injury.

4XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Service Repair Kits 13k

SRK 48100557: LOWER CONTROL ARM KIT 13K

ITEM DESCRIPTION PART NUMBER QTY.

1Control Arm Assembly 90517255 1

2Flat Washer, Lock-Out 93600566 4

4 Nut,Hex,Lock .75"-10 GR C 93400494 2

5 Washer, Flat, Narrow, .75" 93600156 4

6Cap Screw, Hex .75"-10 x 6" GR 8 93003659 2

9

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

10

Crossmember Service Bulletin

(not shown) XL-PS20037SB-en-US 1

11 Cap Screw, Hex .75"-10 x 6.5" GR 8 93003671 1

12 Shim, .005" Thick 90036302 2

13 Shim, .010" Thick 90036303 2

14 Shim, .020" Thick 90036304 2

SRK 48100557

1

2

2

2

4

4

5

5

5

5

6

6

11

12

13

14

2

SRK 48100558

1

SRK 48100608: UPPER CONTROL ARM KIT 13K

ITEM DESCRIPTION PART NUMBER QTY.

1Control Arm Assembly 90517255 1

2Flat Washer, Lock-Out 93600566 4

3Cap Screw, Hex, .75"-10 x 6.75" GR 8 93003677 1

4Nut, Hex, Lock .75"- 10 GR C 93400494 2

5 Washer, Flat, Narrow, .75" 93600156 4

6Cap Screw, Hex .75" - 10 x 6" GR 8 93003659 1

9Cap Screw, Hex, .75"-10 x 7" GR 8 93003683 1

10

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

11

Crossmember Service Bulletin

(not shown) XL-PS20037SB-en-US 1

12 Shim, .005" Thick 90036302 2

13 Shim, .010" Thick 90036303 2

14 Shim, .020" Thick 90036304 2

SRK 48100558: UPPER CONTROL ARM KIT 13K

ITEM DESCRIPTION PART NUMBER QTY.

1Bearing/Bushing Tool 50544017 1

2

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

3

Crossmember Service Bulletin

(not shown) XL-PS20037SB-en-US 1

SRK 48100608

1

2

2

2

4

4

5

5

5

5

6

6

11

12

13

14

2

5

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Service Repair Kits 13k

SRK 48100553

SRK 48100607

SRK 48100553: LOWER BUSHING KIT 13K

ITEM DESCRIPTION PART NUMBER QTY.

1 Bushing 90008280 4

2 Core Pin-Coated 90038544 4

3Flat Washer, Lock-Out 93600566 8

4Nut, Hex, Lock .75"-10 GR C 93400494 4

5Cap Screw, Hex .75" - 10 x 6" GR 8 93003659 4

6 Washer, Flat, Narrow, .75" 93600156 8

7Cap Screw, Hex .75" - 10 x 6.5" GR 8 93003671 2

8

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

11

Crossmember Service Bulletin

(not shown) XL-PS20037SB-en-US 1

12 Shim, .005" Thick 90036302 2

13 Shim, .010" Thick 90036303 4

14 Shim, .020" Thick 90036304 4

SRK 48100607: UPPER BUSHING KIT 13K

ITEM DESCRIPTION PART NUMBER QTY.

1 Bushing 90008280 4

2 Core Pin-Coated 90038544 4

3Flat Washer, Lock-Out 93600566 8

4Nut, Hex, Lock .75"-10 GR C 93400494 4

5Cap Screw, Hex .75" - 10 x 6" GR 8 93003659 2

6 Washer, Flat, Narrow, .75" 93600156 8

7Cap Screw, Hex .75" - 10 x 6.75" GR 8 93003677 2

9

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

11

Crossmember Service Bulletin

(not shown) XL-PS20037SB-en-US 1

12 Cap Screw, Hex, .75"-10 x 7" GR 8 93003683 1

13 Shim, .005" Thick 90036302 4

14 Shim, .010" Thick 90036303 4

15 Shim, .020" Thick 90036304 4

1

1

2

2

4

5

3

3

3

3

6

6

64

6

5

12

13

14

7

1

1

2

2

4

5

3

3

3

3

6

6

64

6

5

12

13

14

7

6XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Service Repair Kits 20k

SRK 48100618

SRK 48100631

SRK 48100618: LOWER CONTROL ARM KIT 20K

ITEM DESCRIPTION PART NUMBER QTY.

1Control Arm Assembly, Lower 90517309 1

2 Washer, Lock-Out 93600566 4

3Cap Screw, Hex .875 - 9 x 6.5 GR C 93003892 1

4Nut,Hex Lock .875 - 14 GR C 93400499 2

5 Washer, Flat, Narrow, .88" 93600160 4

6Cap Screw Hex, .875 - 14 x 6 GR 8 93003870 1

7

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

SRK 48100631: UPPER CONTROL ARM KIT 20K

ITEM DESCRIPTION PART NUMBER QTY.

1Control Arm Assembly 90517308 1

2 Washer, Lock-Out 93600566 4

3Cap Screw, Hex .875 - 9 x 6.5 GR C 93003894 1

4Nut,Hex Lock .875 - 14 GR C 93400499 2

5 Washer, Flat, Narrow, .88" 93600160 4

6Cap Screw Hex, .875 - 14 x 6 GR 8 93003870 1

7

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

1

2

2

2

4

4

5

5

5

5

6

6

2

1

2

2

2

4

4

5

5

5

5

6

6

2

7

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Service Repair Kits 20k

SRK 48100615

SRK 48100630

SRK 48100615: LOWER BUSHING KIT 20K

ITEM DESCRIPTION PART NUMBER QTY.

1 Bushing 90008280 4

2Core Pin-Coated-7/8" Fastners Coated 90038584 4

3Flat Washer, Lock-Out 93600566 8

4Nut, Hex, Lock .875 - 14 GR C 93400499 4

5Cap Screw, Hex .875 - 14 x 6" GR 8 93003870 2

6 Washer, Flat, Narrow, .88" 93600160 8

7Cap Screw, Hex .875 - 14 x 6.5" GR 8 93003882 2

8

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

SRK 48100630: UPPER BUSHING KIT 20K

ITEM DESCRIPTION PART NUMBER QTY.

1 Bushing 90008280 4

2Core Pin-Coated-7/8" Fastners Coated 90038584 4

3Flat Washer, Lock-Out 93600566 8

4Nut, Hex, Lock .875 - 14 GR C 93400499 4

5Cap Screw, Hex .875 - 14 x 6" GR 8 93003870 2

6 Washer, Flat, Narrow, .88" 93600160 8

7Cap Screw, Hex .875 - 14 x 7" GR 8 93003894 2

8

LSZ13/20 Repair Manual, Control

Arm and Bushing (not shown) XL-PS20053RM-en-US 1

1

1

2

2

4

5

3

3

3

3

6

6

64

6

7

1

1

2

2

4

5

3

3

3

3

6

6

64

6

7

8XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Removal

LSZ13/20 Control Arm and Bushing

The instructions below pertain to all procedures and must be

performed prior to replacing bushings or control arms.

1. With the vehicle unloaded and/or trailer disconnected on

a level surface, set parking brakes and chock drive tires

to prevent the vehicle from rolling forward or backward.

2. Place suspension in the in-service position. Exhaust air

pressure in the suspension air springs. Remove the air

pressure using the air pressure regulator or control valve.

2. LSZ13 Remove Lower Control Arm

Required Tools:

1-1/8" socket and wrench

Small pry bar

3/8" open-end wrench

3/4" wrench and socket

1/2" socket

Small hydraulic press or NEWAY bushing/bearing tool

Torque wrench capable of 250 ft.-lbs.

Roll of masing tape (optional)

NOTE: DO NOT remove and replace control arms on both

sides at the same time. Remove one side at a time.

1. Remove and discard two (2) 3/4" lock nuts and two (2)

3/4" washers from both lower 3/4" pivot bolts.

2. Remove and discard lower two (2) 3/4" pivot bolts and

two (2) 3/4" washers.

3. Remove the lower control arm, retain if NOT replacing.

Discard four (4) wear washers.

Servicing the upper control arm, go to Section 3

Replacing bushings in lower control arm, go to Section 6

Installing new lower control arm, go to Section 8

3. LSZ13 Remove Upper Control Arm

NOTE: DO NOT remove and replace control arms on both

sides at the same time. Remove and replace one

side at a time.

1. Record the position of all four (4) crossmember spacers

(if equipped).

2. Disconnect supply tubing to SuperChamber by depressing

release collar with 3/8" open-end wrench on fitting at

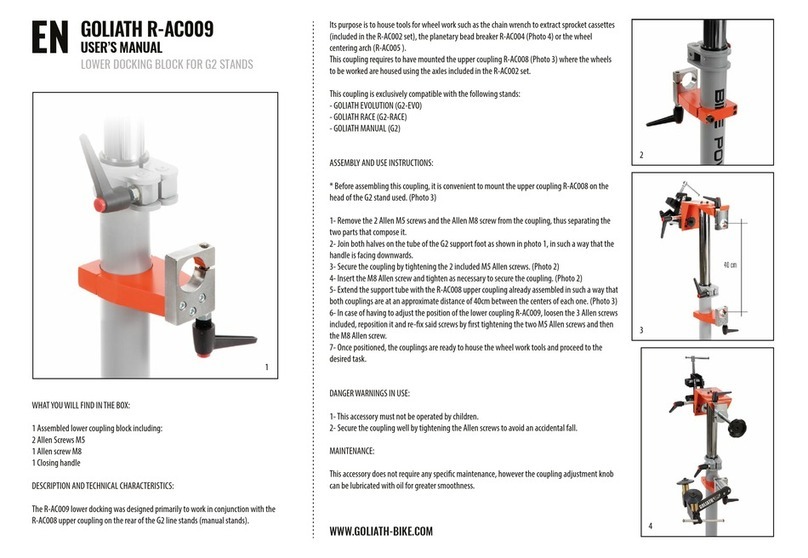

same time pulling on supply tubing (Figure 1).

3. Remove and retain two (2) 1/2" bolts, two (2) 1/2" lock

washers, and lower air spring support plate (if equipped)

that attach air spring piston to axle.

Figure 1

AIR SUPPLY TUBING

4. Remove and discard the two (2) 3/4" lock nuts and two

(2) 3/4" washers from both upper pivot bolts.

5. Extend SuperChamber™clevis to allow removal of clevis

pin and hardware. Retain the clevis pin and hardware

(Figure 1).

6. Remove and discard (2) 3/4" pivot botls and two (2) 3/4"

washers from both upper pivots.

7. Remove and retain one (1) 3/4" bolt and one (1) 3/4"

washer from lower lift bracket.

8. Remove and retain two (2) 1/2"bolts, two (2) 1/2" lock

nuts and four (4) 1/2" washers that attach lift assembly

to upper control arm.

9. Remove and discard two (2) 3/4" pivot bolts two (2) 3/4"

washers from both upper pivots.

10. Remove and retain two (2) crossmember spacers (if equipped).

11. Remove upper control arm, retain if NOT replacing.

Discard four (4) wear washers.

Installing new bushings, go to Section 6.

Replacing upper control arm, go to Section 7 discard

upper control arm.

9

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Removal

4. LSZ20 Remove Lower Control Arm

Required Tools:

1-5/16" combination wrench

1-5/16" socket

3/4" socket

3/4" wrench

3/8" open-end wrench

Small hydraulic press

Roll of masking tape (optional)

Torque wrench capable of 400 ft.-lbs.

NOTE: DO NOT remove and replace control arms on both

sides at the same time. Remove and replace one

side at a time.

1. Remove and discard two (2) 7/8" lock nuts and two (2)

7/8" washers from both lower 7/8" pivot bolts.

2. Remove and discard lower two (2) 7/8" pivot bolts and

two (2) 7/8" washers.

3. Remove the lower control arm, retain if NOT replacing.

Discard four (4) wear washers.

Servicing upper control arm, go to Section 5.

Replacing bushings in lower control arm, go to Section 6.

Replacing lower control arm, go to Section 10.

5. LSZ20 Remove Upper Control Arm

NOTE: DO NOT remove both upper and lower control

arms on both sides. Remove one side at a time.

1. Remove and retain two (2) 1/2" bolts and two (2) 1/2"

lock washers that attach the air spring piston to the axle.

2. Disconnect supply tubing to SuperChamber by depressing

release collar with 3/8" open-end wrench on fitting at

same time pulling on supply tubing (Figure 1).

3. Remove and discard two (2) 7/8" lock nuts and two (2)

7/8" washers from both upper 7/8" pivot bolts.

4. Remove and retain one (1) 3/4" bolt, (1) 3/4" lock nut

and two (2) 3/4" washers from lift assembly.

5. Remove and retain lift assembly and stop tube (Figure 2)

6. Remove and discard upper two (2) 7/8" pivot bolts and

two (2) 7/8" washers from both upper pivots.

7. Remove upper control arm, retain if NOT replacing.

Discard four (4) wear washers.

Replacing bushings in control arms, go to Section 6.

Replacing control arms, go to Section 9.

Figure 2

STOP TUBE

10 XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Figure 5

LOCK-OUT

WASHER

LOCK-OUT

WASHER

CHAMBER ATTACHMENT BORES

TOWARDS FRAME BRACKET

Bushing Replacement

6. LSZ13/LSZ20 Replacing Bushings

Required Tools:

Small hydraulic press or NEWAY bushing/bearing tool

1. Remove four (4) wear washers from both the bushings

within lower control arm.

2. Using a small hydraulic press or a NEWAY bushing/

bearing tool, remove both bushings from control arm

(Figure 3).

3. Clean control arm bushing bores using a piece of emery

cloth or a wire brush to remove any rust or attached rubber.

IMPORTANT: DO NOT use any type of petroleum-based

product such as oil or grease for pressing

in bushings.

4. Using an approved lubricant such as P-80 rubber lube, press

in two (2) new bushings into control arms. Use Figure 4 to

properly clock the bushing.

NOTE: Make sure the bushing is centered in the control arm

7. LSZ13 Install New or Rebushed

Upper Control Arm

1. Position new or re-bushed upper control arm assembly

with four (4) wear washers with lift bracket mounting holes

towards frame bracket (Figure 5).

2. If equipped with spacers install one (1) 3/4" bolt, one

(1) 3/4" washer, crossmember with two (2) crossmember

spacers and shelf bracket. Ensure spacers are re-installed

as recorded in Section 3 Step 1.

3. If equipped with wrapper and shelf bracket install one (1)

3/4" pivot bolt and one (1) 3/4" washer into wrapper

and shelf bracket.

4. Install one (1) new 3/4" upper pivot bolt and 3/4"

washer at axle enough to be flush with the outboard face

of the bushing core pin (Figure 6). Install shims to fill

the gap using the three (3) thicknesses of shims, .020",

.010" and .005" between the bushing core pin and the

clevis face (figure 6). Once gap is reduced as much as

possible, push pivot bolt all the way to allow installation

of one (1) 3/4" nut and one (1) 3/4" washer.

NOTE: To install new 3/4" lock nut and new 3/4" flat

washer at upper axle pivot connection, the thread

portion of bolt can be reached from bottom of

axle knuckle, If successful installing one (1) 3/4"

lock nut and one (1) 3/4" washer skip optional

procedures below.

Figure 3

BUSHINGS

3/4"BOLT

3/4"WASHER

3/4"WASHER

3/4"WASHER

3/4"LOCK NUT

3/4"WASHER

Figure 4

15˚15˚

11

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of SAF-

HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Installation

Optional procedure to install 3/4" nut and washer:

Using a pair of needle nose pliers install the 3/4" flat

washer onto the 3/4" bolt at the upper control rod

pivot on the axle. Install the nut by rotating the bolt

and using the pair of needle nose to start the 3/4"

lock nut onto the 3/4" pivot bolt.

Optional procedure to install 3/4" nut and washer:

Using a 1-1/8" box end wrench with tape to retain

the lock nut, rotate the 3/4" upper pivot bolt to install

the 3/4" lock nut onto the upper 3/4" bolt at the axle.

5. Install lift assembly on control arm with two (2) 1/2"

bolts and two (2) 1/2" washers into lift bracket mounting

holes on upper control arm. Install two (2) 1/2" lock

nuts and two (2) 1/2" washers. Torque two (2) 1/2" bolts

according to specifications in Section 11.

6. Plug in supply tubing into fitting on SuperChamber.

7. Re-install two (2) 1/2" bolts, two (2) 1/2" lock washers,

and lower air spring support plate (if equipped) that

attach air spring piston to axle. Torque the 1/2" bolts

according to specifications in Section 11.

8. Install lower lift bracket onto the upper one (1) 3/4" pivot

bolt at the frame bracket. Rotate the lower lift bracket to

allow the installation of the clevis pin. Secure clevis pin

using one (1) 5/16" bolt and one (1) 5/16" lock washer.

Torque 5/16" bolt according to specifications in Section 11.

9. Extend chamber clevis to allow installation of the lower

one (1) 3/4" lower lift bracket bolt and 3/4" washer into

frame bracket and lower lift bracket (Figure 1).

10. Install one (1) 3/4" lock nut and one (1) 3/4" flat washer

onto the lower one (1) 3/4" lower lift bracket bolt with

one (1) 3/4" lock nut and one (1) 3/4" flat washer onto

upper one (1) 3/4" pivot bolt. Torque all 3/4" hardware

according to specifications in Section 11

Figure 6

SHIM

12 XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Installation

Figure 7

Figure 8

SHIM

LOCK-OUT

WASHER

LOCK-OUT

WASHER

CHAMBER ATTACHMENT BORES

TOWARDS FRAME BRACKET

8. LSZ13 Install New or Rebushed

Lower Control Arm

NOTE: Make sure all four (4) wear washers are installed

onto bushings prior to lower control arm

installation (Figure 7).

IMPORTANT: The lift bracket mounting holes in lower

control arm MUST be installed towards the

frame bracket (Figure 7).

1. Position new or re-bushed upper control arm assembly

with four (4) wear washers with chamber attachment

bores towards frame bracket (Figure 7).

2 If equipped with spacers install one (1) 3/4" bolt, one (1)

3/4" washer, crossmember, two (2) crossmember spacers

and shelf bracket.

3. If equipped with wrapper and shelf bracket install one

(1) 3/4" pivot bolt and one (1) 3/4" washer into wrapper

and shelf bracket.

4. Install new one (1) 3/4" lock nut and one (1) 3/4" washer

at lower pivot at frame bracket.

5. At axle using one (1) new 3/4" lower pivot bolt and

one (1) new 3/4" washer, install pivot bolt enough to

be flush with the outboard face of the bushing core pin

(Figure 8). Install shims to fill the gap using the three

(3) thicknesses of shims, .020", .010" and .005" between

the bushing core pin and the inside clevis face. Once the

gap is reduced as much as possible, push pivot bolt all

the way to allow installation of one (1) new 3/4" nut

and one (1) new 3/4" washer. Torque the 3/4" pivot bolts

according to specifications in Section 11.

5 Repeat on opposite side if needed, if not go to step 6.

6. Remove wheel chocks from drive tires.

13

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of SAF-

HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Installation

9. LSZ20 Install New or Rebushed

Upper Control Arm

1. Position new or re-bushed upper control arm assembly

with four (4) wear washers with lift bracket mounting holes

towards frame bracket (Figure 7).

2. Install new one (1) 7/8" pivot bolt and one (1) new 7/8”

washer at upper frame bracket pivot, spacer wrapper,

shelf bracket and crossmember.

3. Re-install lift assembly onto one (1) 7/8” upper pivot bolt

at frame bracket. Install lower lift assembly one (1) 3/4"

bolt, one (1) 3/4" lock nut and one (1) 3/4" washers.

Torque the one (1) 3/4" bolt according to specifications

in Section 11.

4. Plug in supply tubing into fitting on lift assembly.

5. Install at axle one (1) 7/8" upper pivot bolt and one (1)

7/8" washer.

6. Using your hand thru window within front face of

knuckle, install one (1) 7/8" nut and one (1) 7/8" washer

(see optional procedure below). Torque 7/8" pivot bolts

according to specifications in Section 11.

Optional procedure to install 7/8" nut and 7/8"

washer: Using a 1-5/16" box end wrench with tape

to retain the lock nut, rotate the one (1) 7/8” upper

axle pivot bolt to install the one (1) 7/8" lock nut.

Torque 7/8" pivot bolts according to specifications

in Section 11.

7. Re-attach air spring to axle using two (2) 1/2" bolts with

two (2) 1/2" lock washers to air spring mounting plate on

axle. Torque two (2) 1/2" bolts according to specifications

in Section 11.

14 XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Control Arm Installation

10. LSZ20 Install New or Rebushed

Lower Control Arm

1. Position new or re-bushed lower control arm assembly

with four (4) wear washers into axle and frame bracket.

NOTE: Make sure all four (4) wear washers are installed

onto bushings prior to lower control arm installation.

2 Install one (1) new 7/8" lower pivot bolt, one (1) new 7/8"

washer, shelf bracket and spacer wrapper at frame bracket.

3 Install one (1) 7/8" lower pivot bolt and one (1) 7/8"

washer at axle.

4 Install two (2) 7/8" lock nuts and two (2) 7/8" washers

onto two (2) lower 7/8" pivot bolts. Torque two (2) lower

7/8" pivot lock nuts to torque specified in Section 11.

5 Repeat on opposite side if needed.

6. Remove the wheel chocks from drive tires.

15

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY, SAF, and logos are trademarks of SAF-

HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Torque Specifications

11. Torque Specifications

NOTE: Torque specifications listed in this section are with clean

lubricated/coated threads, supplied by SAF-HOLLAND.

IMPORTANT: The use of special lubricants with friction

modifiers, such as Anti-Seize or Never-Seez®,

without written approval from SAF-HOLLAND

Engineering, will void warranty and could

lead to over torquing of fasteners or other

component issues.

General Information

The torque specifications listed throughout the manual are

applied to the lock nut and NOT the bolt.

IMPORTANT: Most of the fasteners used in this suspension

are Grade 8 bolts and Grade C lock nuts.

These fasteners have the strength and

hardness properties required for their

particular function. They MUST be replaced

with fasteners of the same grade, size and

form as the original in order to prevent

failure (Figure 10).

Failure to use the proper fasteners when

servicing the suspension could cause

component failure which, if NOT avoided,

could result in death or serious injury.

Failure to properly torque all fasteners

will result in component failure which,

if NOT avoided, could result in death or

serious injury.

All fasteners MUST be re-torqued after the first 100 hours

of service or 5,000 miles (8,000 km).

Refer to vehicle OEM for torque specifications for vehicle

frame fastener hardware.

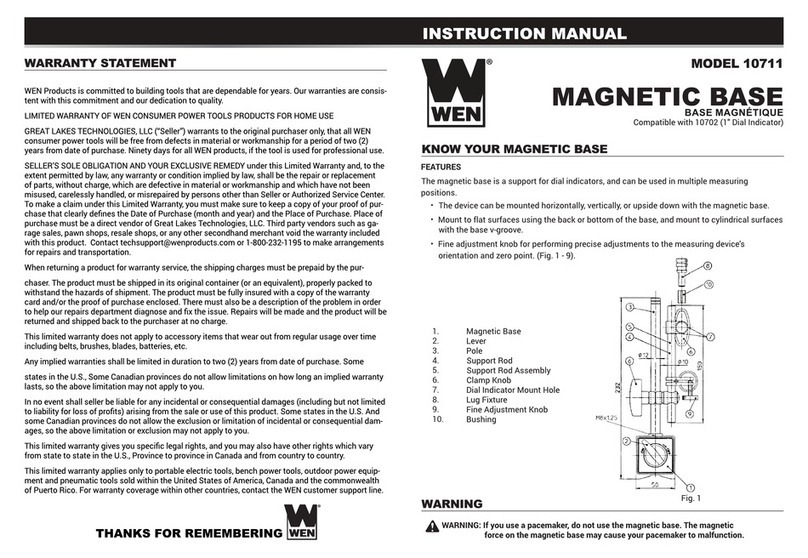

COMPONENT TORQUE RANGE SIZE

Clevis Pin Assembly

18-24 ft-lb

24-33 N•m 5/16"-18

Chamber Bracket

37-50 ft-lb

50-68 N•m 1/2"-13

LSZ13 Pivot Connections

200-250 ft-lb

271-339 N•m 3/4"-10

LSZ20 Pivot Connections

330-370 ft-lb

447-502 N•m 7/8"-14

Table 1

GRADE 1 OR 2

BOLT GRADE MARKINGS

LOCK NUT GRADE MARKINGS

3 DOTS

LOCK NUT

GRADE B

LOCK NUT

GRADE C

6 DOTS

GRADE 5 GRADE 8

Figure 10

SAF-HOLLAND USA · 888.396.6501 · Fax 800.356.3929

www.safholland.us

SAF-HOLLAND CANADA · 519.537.3494 · Fax 800.565.7753

WESTERN CANADA · 604.574.7491 · Fax 604.574.0244

www.safholland.ca

SAF-HOLLAND MEXICO · 55.55.5362.8743 · Fax 52.55.5362.8743

www.safholland.com.mx

From fifth wheel rebuild kits to suspension bushing repair kits,

SAF-HOLLAND Original Parts are the same quality components used

in the original component assembly.

SAF-HOLLAND Original Parts are tested and designed to provide

maximum performance and durability. Will-fits, look-alikes or, worse

yet, counterfeit parts will only limit the performance potential and

could possibly void SAF-HOLLAND’s warranty. Always be sure to spec

SAF-HOLLAND Original Parts when servicing your

SAF-HOLLAND product.

SAF-HOLLAND INC.

1950 Industrial Blvd., Muskegon, MI 49442

www.safholland.com

XL-PS20053RM-en-US Rev A · 2017-10-06 · Amendments and Errors Reserved © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, NEWAY,SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Other manuals for LSZ13

1

This manual suits for next models

1

Table of contents