5

!

• Should a hydraulic hose ever rupture, burst or

need to be disconnected, immediately shut off the

pump and release all pressure. Never attempt to

grasp a leaking pressurized hose with your

hands.The forceofescaping hydraulic fluidcan

inflict injury.

•Do not subject the hose to potential hazard such

as fire, sharp objects, extreme heat or cold, or

heavyimpact.

•Do not allow the hose to kink, twist, curl, crush,

cut or bend so tightly that the fluid flow within the

hose is blocked or reduced. Periodically inspect

the hose for wear, because any of these

conditions can damage the hose and possibly

result in personal injury.

•Do not pull, position or move setup by the hose.

Doing so can damage the hose and possibly

causepersonal injury.

•Hose material and coupler seals must be

compatible with hydraulic fluid used. Hoses also

must not come in contact with corrosive materials

suchas battery acid,creosote-impregnated

objects and wet paint. Hose deterioration due to

corrosive material can result in personal injury.

Neverpainta coupler or hose.

•Theusermust be a qualified operatorfamiliar with

thecorrect operation, maintenance, anduseof

rams. Lack of knowledge in any of these areas

can lead to personal injury.

•Useonlyapprovedaccessoriesandapproved

hydraulicfluid.

•Do not exceed the rated capacity of the ram.

•Inspect each ram and coupler before each use to

preventunsafeconditions from developing.

•Do not use rams if they are damaged, altered or

inpoor condition.

•Do not use rams with bent or damaged coupler or

damagedthreads.

•Under certain conditions, the use of an extension

with a hydraulic ram may not be advisable and

couldpresent a dangerouscondition.

•Avoid pinch points or crush points that can be

created by the load or parts of ram.

•To help prevent material fatigue if the ram is to

be used in a continuous application, the load

should not exceed 85% of the rated capacity.

•Ram must be on a stable base which is able

to support the load while pushing or lifting.

•Ensure ram is fully engaged into/onto adapters,

extension accessories.

•Tohelp prevent personalinjury, useshims,friction

materialor constraints topreventslippage of the

base or load.

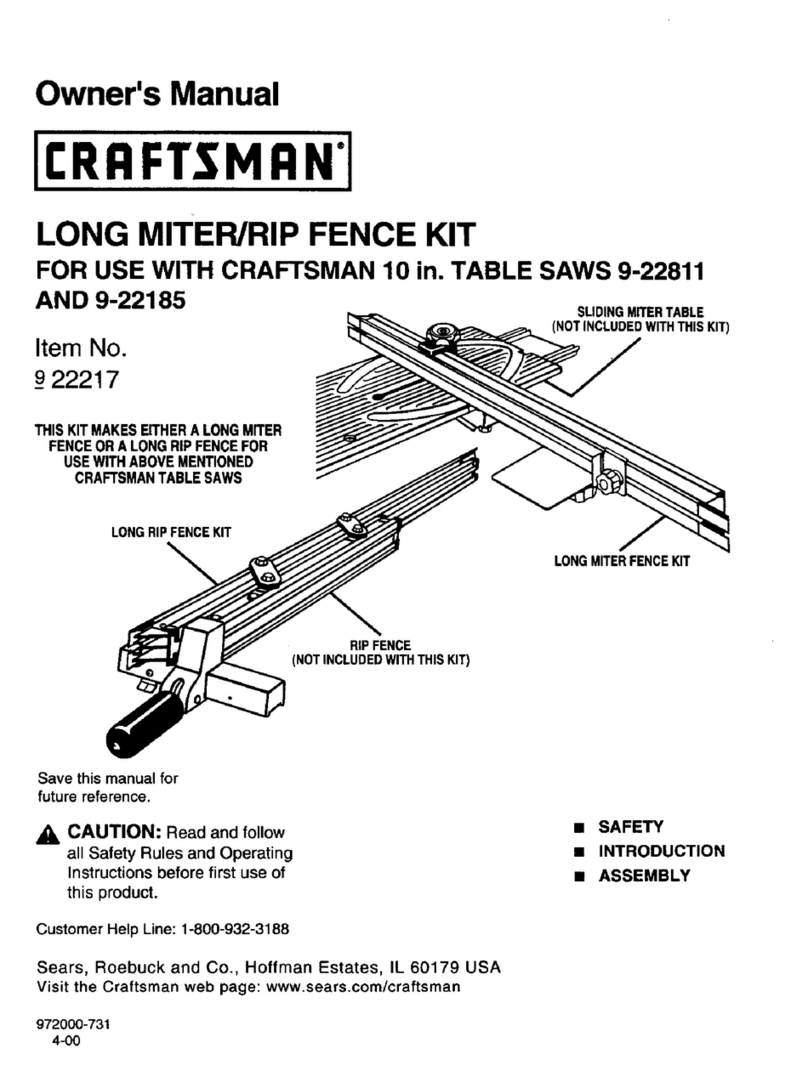

•Do not off-center loads on a ram. The load can tip

or the ram can "kick out" and cause personal

injury.

•As the load is lifted, use blocking and cribbing to

guardagainsta falling load.

•Neverallowpersonnel to work on, underor around

a load before it is properly supported by appropri-

ate mechanical means. Never rely on hydraulic

pressurealoneto support load.

•Allpersonnel must beclearbefore lowering.

•Never try to disassemble a hydraulic cylinder,

Referrepairstoqualified,authorizedpersonnel.

IMPORTANT

•Keep ram clean at all times.

•When the ram is not in use, keep the piston(s)

fullyretracted.

•Useanapproved, high-grade pipe threadsealant

to seal all hydraulic connections. Teflon tape can

be used if only one layer of tape is used and it is

applied carefully (two threads back) to prevent the

tape from being introduced into hydraulic system.

A piece of tape could travel through the system

andobstructthe flow of fluidand adverselyaffect

function.

•Never attach ANY component not authorized by

Sears.

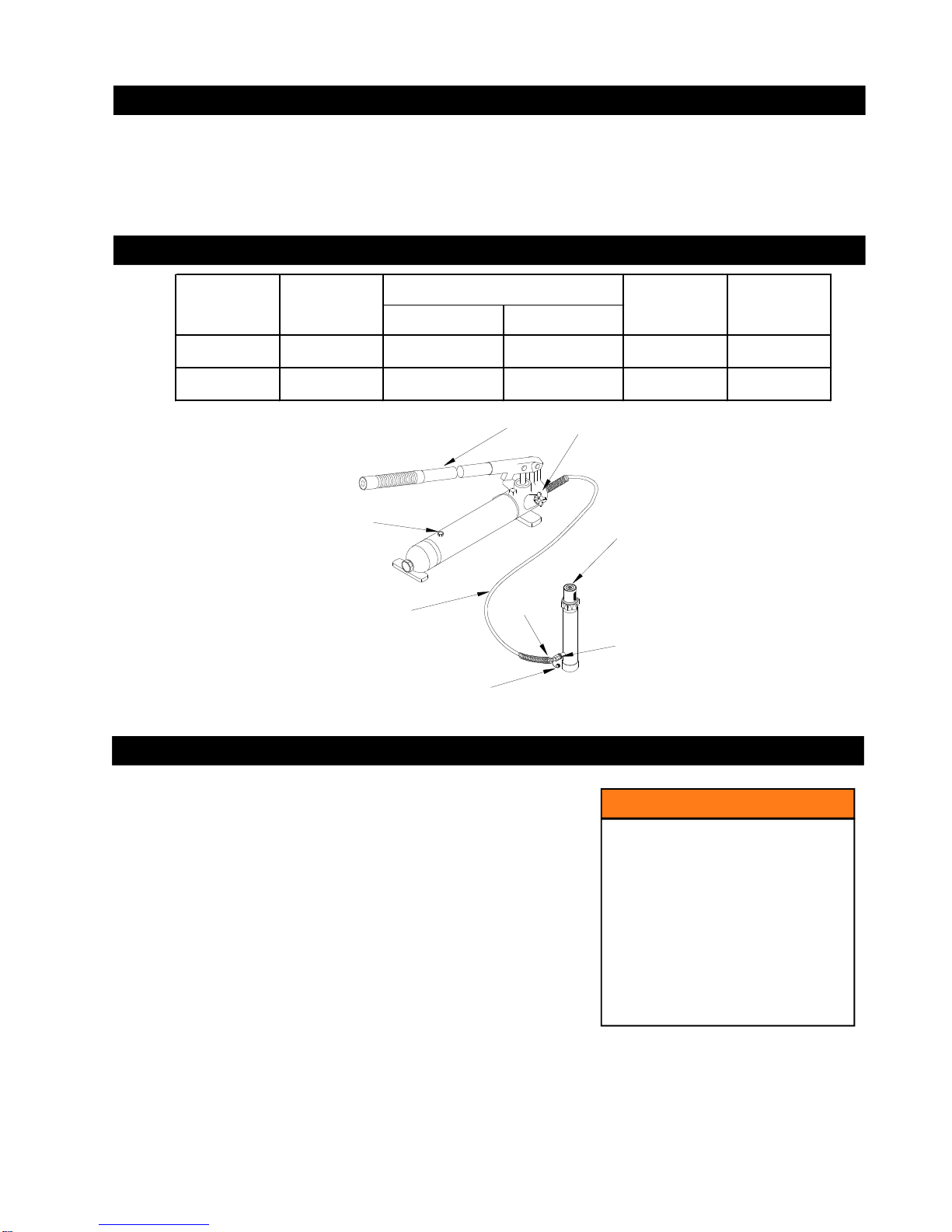

KNOW YOUR SYSTEM

Your ram, hose(s), couplings and pump all must be

ratedforthesame maximum operating pressure,

correctly connected and compatible with the

hydraulic fluid used.An improperly matched system

can cause the system to fail and possibly cause

serious injury. If you are in doubt, consult Sears.

!

Center loads on ram

!WARNING !WARNING

SAFETY INSTRUCTIONS (cont.)

© Sears, Roebuck and Co.