Page 5 of 6

CAUTION

Failure to support loose receiver tube may allow it to fall,

resulting in minor injury or property damage.

Fig. 13 - Removed receiver tube

9. Remove the receiver tube and continue to operate the

hydraulic actuator until the pivot bushing is completely

drawn into the receptacle.

10. Disassemble and remove the installation tool.

11. Check the spring center and readjust as needed using

dead blow mallet.

Fig. 14 shows a spring center of 1300 mm, for example.

Dual tyre standard measurements:

940mm Intra disc

960 Intra drum

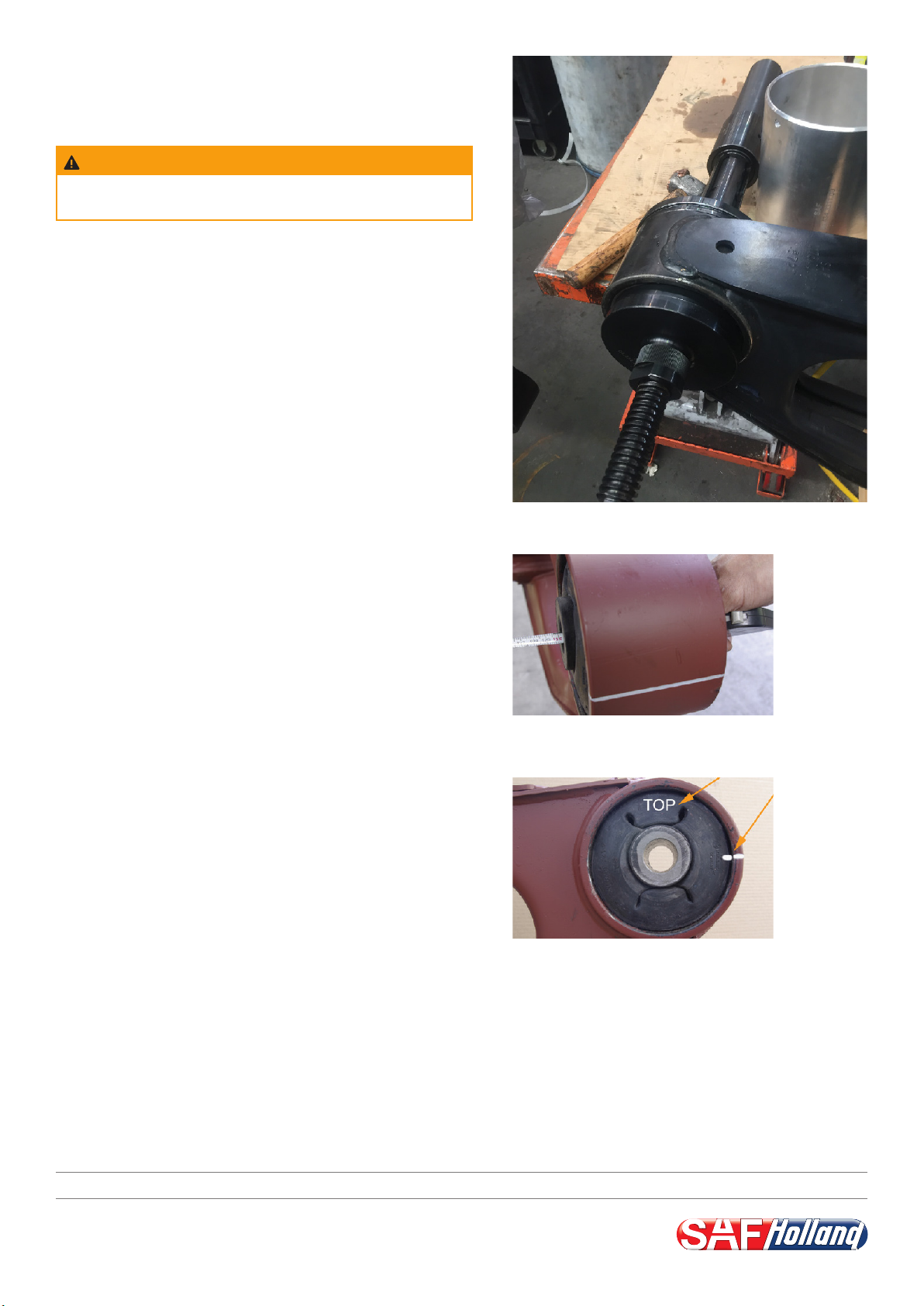

12. Check the proper orientation of the pivot bushing.

Make sure that the orientation index marked “TOP”

(in white colour for illustration purposes) faces upward

and that the bushing position locator of the replacement

bushing is aligned with the bushing orientation line

drawn on the outside of the receptacle

(Fig. 15). If the replacement pivot bushing is not installed

properly, remove and reinstall it.

Remove the pivot bushing on the opposite axle side as

described earlier and install a replacement pivot bushing

as outlined.

8. Operate the Hydraulic pump until the drive nut (6)

and the pivot bushing are completely drawn into the

receptacle (5) and the receiver tube becomes loose and

can be removed (Fig. 13).

Fig. 14 - Checking spring center

Fig. 15 - Checking installation position

FINAL STEPS

Upon replacement of the pivot bushing, perform the

following final steps in compliance with the relevant

operating instructions and the associated repair and

maintenance manual. Observe the relevant safety

instructions and the specified tightening torques:

1. Lift the axle ensuring new wear mounts are installed.

2. Install and slightly tighten new pivot bolts and nuts.

3. Install the shock absorber using new nuts.

4. Remove the axle supports.

5. Apply air pressure to the air suspension system.

6. Remove the wheel chocks.

7. Adjust the ride height.

8. Check the axle alignment of the trailer.

9. Tighten the pivot bolt, referring to the appropriate

tightening instructions and specifications on the

following page.

SAF-HOLLAND (Aust.) Pty. Ltd. · www.safholland.com.au

Group