Newgy Industries Robo-Pong 2055 User manual

www.newgy.com

Robo-Pong 2055 and Robo-Pong 1055

OWNER'S MANUAL

•2055 Quick Start ......... 2

•1055 Quick Start ............. 4

•Operation .......................6

•Robot Positions ......... 18

•Misc. Adjustments ..... 19

•Drill Diagrams ..............21

•Speed Calib. Target . . 27

•RP.2.PC ......................... 28

•Important Notices .... 34

•Take-Down, 2055 ......35

•Maintenance ................37

•Chip Replacement ... 38

•Exploded Views ........ 39

•Parts List ...................... 44

•Warranty & Repair ... 46

2

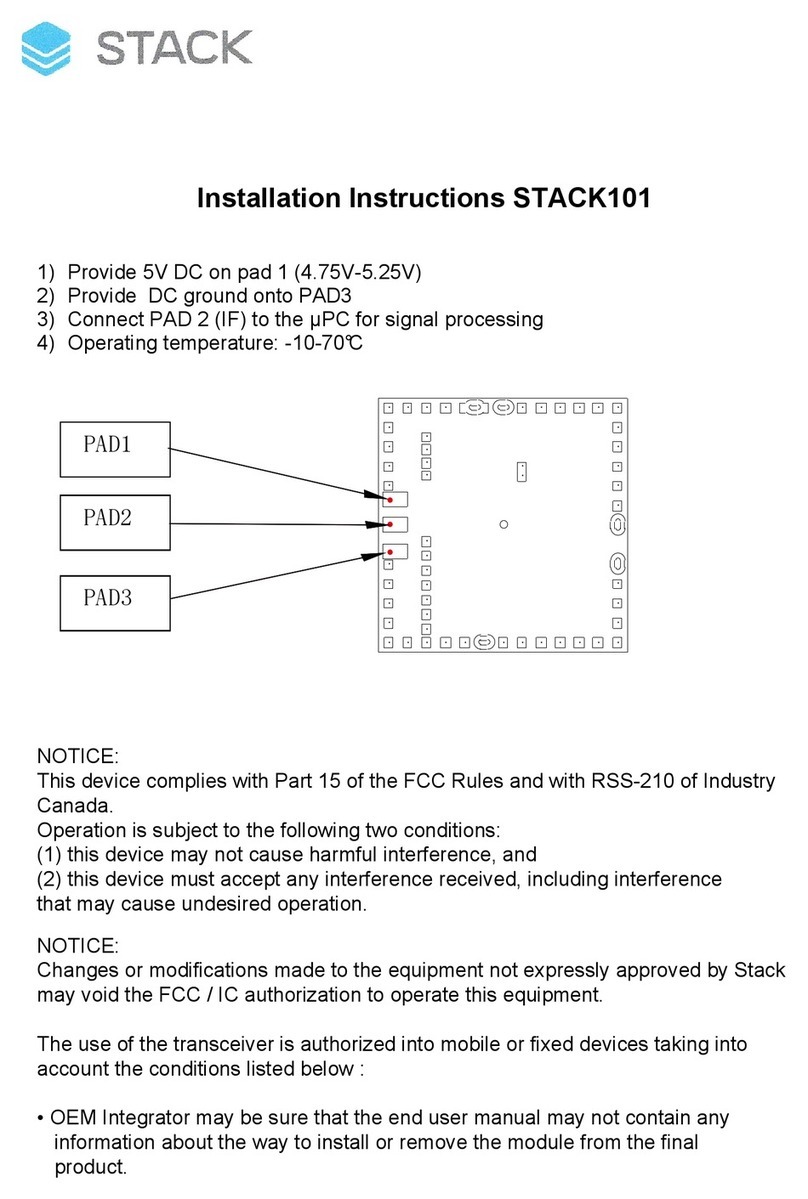

2055 QUICK START

Pull down support legs

Place the robot on the table with the

open front side facing you. Pull the curved

black metal support legs toward you.

Spread Support Legs Apart

Spread out the sup port legs to their

fully open position.

Join Net Support Tubes

Turn the robot around 180° so the Net

Support Tubes are now facing you.

Grasp the second

tube from your

right and pull up,

removing it from its

storage hole. Place

the bottom of this

tube into the top

of the first tube

on your right as

shown. Repeat on

the left side.

Gently Lower Ball Trays

Grasp one of the Ball Return Trays,

lift straight up to unlock it, grasp the

adjacent Net Support Tube, and slowly

lower them into position. Be careful

not to let the tray or support tube slam

down. Repeat on the other side.

Verify All Parts

Unpack all the parts and check that all

are present. If unable to identify a part,

look for a small silver label with the part

name. If a part is missing, please contact

Newgy. You may want to keep your box

and styrofoam pieces in case you need to

ship your robot.

1

5

2

3

4

Pong Pal

(U.S. Only)

3

Attach the Robot to the Table

Pick up the robot by the center base

and secure it to the table by angling

it downward and against the table.

The support legs should be as wide as

possible before they go underneath the

table and the front support triangle sits

on top of the table.

Attach the Side Nets

Attach the side nets to your table tennis

table net by slipping the red flexible

band over your table net’s support

base and looping it over the table net’s

clamp screw.

Adjust Head Angle

Tilt the head downward as far as

possible by loosening the Brass Knob

and then re-tighten

after moving head.

Verify that the

word “topspin” is at

the top of the ball

discharge hole.

Place Balls* in Bucket

Open the bag(s) of balls. Wash and dry

them, and then place in the Ball Tray.

Add any additional new table tennis balls

that have been washed and dried, or any

used balls with a worn surface. All balls

must be 40mm or 40+mm in diameter.

(*Included with U.S. robots only.) Do not

mix 40mm and 40+mm balls.

6

8

9

10

11

7

Connect Cable to Robot

Plug one end of the Connec tor Cable into

the 5-Pin Connector on the back of the

robot as shown. Take

the other end of the

cable to the player's

end of the table.

Attach Bracket to Control Box

Turn Control Box upside down on the

table. Take the Mounting Bracket and

align the hole in the mount ing arm with

the threaded insert of the Control Box.

Secure bracket with Mounting Screw.

Leave Control Box

laying face down.

12

13

Connect Cables to Control Box

Bring the free end of the Connector

Cable to the pla yer’s end of the table.

Plug the Connector Cable into the 5-pin

socket on the bot tom of the Control

Box. Then insert

the Transformer’s

pin into the power

jack of the Control

Box.

Adjust Bracket to Top

Thickness

Pick up the Control Box and looking

across the round rubber pad of the

Adjustment Screw, raise or lower the

height of the rubber pad so it aligns

with the nearest mark on the bracket's

label that corresponds with the

thickness of your table's top.

Attach Control Box To Table

Angle the opening be tween the two

rub ber pads of the Mount ing Brac k et

towards the bot tom of your table's

apron. Slip the bracket onto the table.

The rectangular rubber pad of the

bracket should sit flat on the table's

top surface. If it is not flat, loosen or

tighten the Adjustment Screw until the

pad lays flat. This

is not a clamping

mechanism—do

not overtighten!

14

4

1055 QUICK START

15 17

Position Your Control Box

Place the Control Box on the side of the

table about one foot from the end. If you're

right-handed, place it on the left side of the

table. If you're left-handed, place it on the

right side. Plug

the Transformer

into any suitable

electrical socket.

Get Ready To Play!

If not already on, turn the Control Box

on by pressing the Power button.

Adjust the Ball Speed to 8 by pressing

the + button. Pick up your paddle and

press the Stop/Start button. The balls

will start loading into the robot. It

takes about 15 seconds before the

first ball is shot out. It will be

delivered down the centerline of the

table with Topspin.

16 To Connect Control Box to PC

(Optional)

If you want to connect your robot to

a PC, connect any USB-A to USB-B

Printer cable (not included) to both the

control box and your Windows® PC.

Detach Robot Body

Loosen the two Wing Nuts holding

your robot body onto the Ball Bucket.

Ro tate the black,

rectangular Clip

Washers 180˚. Pull

the Robot Body

off the bucket.

Verify All Parts

Unpack all the parts and check that all are

present. If unable to identify a part, look for a

small silver label with the part name. If a part is

missing, please contact Newgy. You may want to

keep your box and styrofoam pieces in case you

need to ship your robot.

1 2

Warranty &

Tell-A-Friend

Flyer

Quick Start

Guide

Pong Pal

(U.S. Only)

Attach Bucket Extender

Slide the Bucket Ex ten der onto the top

of the bucket so that the hooks on the

bottom of the Extender capture the

top lip of the Bucket. Stop when the

hook on the front of the Extender grabs

the front lip of the Bucket. It may be

nec es sary to lift the bottom rear of the Ex-

ten der over the Locating Tab protruding

above the rear lip of the Bucket. Reattach

the Robot Body to the Bucket by reversing

step 2.

3

5

Place Balls* In Bucket

Open the bag(s) of balls. Wash and dry

them, and then place in the Ball Bucket.

Add any additional new table tennis balls

that have been washed and dried, or any

used balls with a worn surface. All balls

must be 40mm or 40+mm in diameter.

(*Included with U.S. robots only.) Do not

mix 40mm and 40+mm balls.

Adjust Head Angle

Tilt the head downward as far as possible

by loosening the Brass Knob and then

re-tighten after moving head. Verify

that the word “topspin” is at the top of

the ball discharge hole.

5

4

Position Robot On Table

Position the robot

in the center of the

table close to the

end line as shown.

The robot’s head

should be in line

with the centerline

of the table.

Connect Cables To Control Box

Bring the free end of the Connector

Cable to the pla yer’s end of the table.

Plug the Connector Cable into the

5-pin socket on

the bot tom of

the Control Box.

Then insert the

Transformer’s

pin into the

power jack of

the Control Box.

Attach Bracket To Control Box

Turn Control Box upside down on the

table. Take the Mounting Bracket and

align the hole in the mount ing arm with

the threaded insert of the Control Box.

Secure bracket with

Mounting Screw.

Leave Control Box

laying face down.

Connect Cable To Robot

Plug one end of the Connec tor Cable into

the 5-Pin Connector

on the back of the

robot as shown. Take

the other end of the

cable to the player’s

end of the table.

6

8

9

10

7

Adjust Bracket to Top Thickness

Pick up the Control Box and looking

across the round rubber pad of the

Adjustment Screw, raise or lower the

height of the rubber pad so it aligns

with the nearest mark on the bracket's

label that corresponds with the

thickness of your table's top.

11 Attach Control Box To Table

Angle the opening be tween the two

rub ber pads of the Mount ing Brac k et

towards the bot tom of your table’s

apron. Slip the bracket onto the table.

The rectangular rubber pad of the

bracket should sit flat on the table’s

top surface. If it is not flat, loosen or

tighten the Adjustment Screw until the

pad lays flat. This is not a clamping

mechanism—do not overtighten!

12 Position Your Control Box

Place the Control Box on the side of

the table about one foot from the end.

If you’re right-handed, place it on the

left side of the table. If you’re left-

handed, place it on

the right side. Plug

the Transformer into

any suitable electrical

socket.

6

CONTROL BOX FEATURES (ALL MODELS)

All robot functions are controlled electronically by the

Control Box. It uses a powerful programmable micropro-

cessor to run motors, monitor sensors, execute programs,

and display information on an easy to read LCD. You con-

trol it with 8 color coded buttons to navigate through the

menus and adjust values of each function. Figures 1A and

1B point out the button, connections, and features of the

digital Control Box.

1. LCD—Displays the menus, messages, and settings

for your robot in one of 6 different languages.

2. Power (

|

/) Button—Colored orange, this button

turns your Control Box on or off.

3. Test (✓)Button—Colored yellow, this button has

various functions depending upon the currently selected

mode. These functions are detailed under the Mode sec-

tions starting on page 7.

4. Stop/Start (■/▶)Button—Colored red and green,

this button starts and stops ball delivery. After pressing

this button, there will be a 3 second start up beeping

sequence to allow time to ready yourself for the first shot.

5 & 6. Minus (–) & Plus (+)Buttons—Colored gray

and shaped like arrows pointing left and right, press to

increase or decrease values or otherwise allow selection of

the parameters available for the selected function.

7 & 8. Up (⬆)& Down (⬇)Buttons—Colored gray and

shaped like arrows pointing up and down, press these but-

tons to navigate up and down through the menus.

9. OK/MENU Button—Colored white and square-

shaped, press this button to go to the Main Menu and

select the Mode.

10. Power Jack—Plug the transformer in here to con-

nect the robot to an electrical source.

11. 5-Pin Connector—Plug the gray Connector Cable

in here to connect the Control Box to the main robot body.

12. Female USB Connector—Plug the USB cable (user

supplied) in here to connect the robot to a PC.

13. Male DB-9 Connector—Plug the Linking Cable

from the Pong-Master Scoreboard in here. Pong-Master is

an optional accessory.

14. Mounting Screw Insert—Screw the black-knobbed

Mounting Screw in here to secure the Control Box to the

Control Box Mounting Bracket.

OPERATION OF YOUR ROBOT

CONTROL BOX

TOP VIEW

FIGURE 1A

1

2

3

4

56

7

8

9

10

11

12

13

14

CONTROL BOX

BOTTOM VIEW

FIGURE 1B

13 14

To Connect Control Box to PC

(Optional)

If you want to connect your robot to

a PC, connect any USB-A to USB-B

Printer cable (not included) to both the

control box and your Windows® PC.

Get Ready To Play!

If not already on, turn the Control Box

on by pressing the Power button.

Adjust the Ball Speed to 8 by pressing

the + button. Pick up your paddle and

press the Stop/Start button. The balls

will start loading into the robot. It takes

about 15 seconds before the first ball is

shot out. It will be delivered down the

centerline of the table with Topspin.

7

BALL SPEED 00

L POSITION 10

R POSITION 10

WAIT 01.00s

BALL SPEED sets how fast the Ball Speed Motor spins.

This determines both how fast the ball is discharged and how

much spin is placed on the ball. The higher this setting the

more speed and spin. Setting of 0 means the motor is off and

will result in balls falling out of the discharge hole. Maximum

setting is 30. (Tip: for top ball speed, clean the Discharge Wheel

and Friction Block before using.See page 37.)

BALL SPEED 00

L POSITION 10

R POSITION 10

WAIT 01.00s

L POSITION sets the leftmost position to which a ball is

delivered. A setting of 0 correlates with an extreme angle off

the left sideline; 5–6 with the middle of the left court; 10 with

the centerline of the table; 14–15 with the middle of the right

court; and 20 with an extreme angle off the right sideline.

Figure 2 below illustrates all of the 21 possible positions (0–20).

20

0

10

812

614

416

218

9

711

513

315

117 19

OSCILLATOR POSITIONS

FIGURE 2

CONTROL BOX MENU SYSTEM (ALL MODELS)

All functions of the Control Box are accessible through its

menu system. The menu system is displayed on its LCD

screen. Since the screen is limited to showing a maximum

of 4 lines of 16 characters, most menus will have more than

1 page. Additional pages of a menu are indicated by a

downward arrow on the bottom line of the display or an

upward arrow on the top line. This menu system functions

very much like the menu system on many cell phones.

To navigate the menu system, simply press the Down

Button to select the next line. As lines are selected they

reverse colors with a black background and white charac-

ters. When deselected, a line will have black characters on

a white background. If you navigate to a bottom line that

contains a downward arrow (as shown at the end of the

WAIT line of the L POSITION illustration to the right),

pressing the Down Button will reveal the next page with

up to 4 new functions.

You may also go upward through a menu by pressing

the Up Button. And if you arrive at a top line with an

upward arrow (as shown in the COUNT illustration on the

next page), pressing the Up Button will reveal a new page of

functions.

Once you have selected a function, you change the val-

ues for that function by using the – and + Buttons. If the

values are numerical, the – Button will decrease the value

while the + Button increases the value. A single quick but-

ton press will change the value by one increment. Holding

the button down will accelerate the rate at which the val-

ues change until you release the button.

MAIN MENU (ALL MODELS)

The Main Menu serves as the access control to the 4 oper-

ating modes. It can be accessed by pressing the OK/Menu

Button. When that button is pressed, the Main Menu is dis-

played. The Main Menu consists of a single page. This

menu has 4 selections: (1) NORMAL, (2) DRILL, (3) PC,

and (4) SETUP. To enter one of these modes, select one and

then press the OK/Menu Button.

NORMAL

DRILL

PC

SETUP

Tip: Press OK/Menu once in any mode to instantly return

to the Main Menu. The robot will cease any action it's currently

performing and wait for your next instruction. This is especially

helpful if you get "lost" in the menu system.

NORMAL MODE (ALL MODELS)

NORMAL Mode is used when the player wants to set

each function manually. This is most like how other robots

typically function. Normal Mode is also the default mode

when the Control Box is first plugged into power. This

mode has 3 pages of functions.

Tip:If ever you want to return to Normal Mode, press the

OK/Menu Button twice from any menu to go to Normal Mode.

8

A position setting is really a line of direction coming

from the robot. Selecting a position number results in a ball

being thrown somewhere along the dotted line that corre-

sponds with the number. The Head Angle, Ball Speed, and

Spin determine where a ball is delivered along that line.

If the robot is not positioned at the center of the endline,

these trajectories will change accordingly. See Positioning

Your robot & Controls on page 18 for more info.

When L POSITION is set, it automatically sets R

POSITION. If both positions are the same, the ball will

be thrown to only one position. If L POSITION and R

POSITION are different, then balls are alternately thrown

first to one position and then to the other position.

BALL SPEED 00

L POSITION 10

R POSITION 10

WAIT 01.00s

R POSITION sets the rightmost position to which a

ball is delivered. This setting can be changed without affect-

ing the L POSITION. However, if L POSITION is changed,

R POSITION will need to be reset. Remember, when L & R

settings are the same, balls are delivered to only one posi-

tion. When they are different, balls are delivered alternately

between the two positions.

BALL SPEED 00

L POSITION 10

R POSITION 10

WAIT 01.00s

WAIT is the amount of time (interval) between one shot

and the next shot in seconds. An easy way to remember this

setting is to think, "How long do I want to wait before the

next shot?" If the pace seems too slow and you want to wait

less, decrease WAIT and ball delivery becomes more rapid.

If the pace is too fast and you want to wait more, increase

WAIT and ball delivery will slow down.

WAIT can be changed in 0.05 second increments from

0.35 to 50 seconds. However, the minimum setting is dyna-

mically linked to L POSITION and R POSITION settings.

The larger the difference between L and R, the longer the

robot must wait before delivering the next ball. This is

because it takes a minimum amount of time for the robot to

change positions. For every difference of 2 in the settings

between L & R, another 0.05 is added to WAIT.

For example, if L & R are both set to 5 (no oscillation), the

minimum WAIT is 0.35 seconds. But if L is set to 0 and R to 20

(a difference of 20), 0.50 is added to the minimum WAIT to

allow time for the robot's head to sweep from the far left side-

line to the far right sideline. In this example, the minimum

WAIT would change from 0.35 to 0.85 seconds with a differ-

ence of 20 in L & R positions. This ensures that a ball is not

shot out until the robot has swept to the correct position.

Please be aware that WAIT is not absolute. This setting

may vary a little due to a number of factors, but in general,

it is accurate to within ±10%. WAIT also is involved in the

calculations for TIME (explained after COUNT).

COUNT 0000

TIME 0:00:00

OSC RANDOM OFF

SPEED RANDOM 00

COUNT indicates the number of balls that the robot

delivers before it stops automatically. If COUNT is set to 0,

COUNT is ignored and the robot will keep throwing balls

until the Stop/Start Button is pressed.

If COUNT is more than 0, it will decrement by 1 every

time a ball is thrown until it reaches 0. If Stop/Start Button is

pressed before COUNT reaches 0, delivery will stop.

Pressing the Stop/Start button a second time will resume the

COUNT where it was when it was stopped. Once COUNT

reaches 0, it must be reset to a new number before it

becomes active.

COUNT is synced with TIME (discussed next). As

COUNT is changed, TIME dynamically changes to reflect a

multiplication of COUNT times WAIT. For example, with

WAIT set to 1 second and COUNT to 61, TIME would show

0:01:01 (1 minute, 1 second).

COUNT 0000

TIME 0:00:00

OSC RANDOM OFF

SPEED RANDOM 00

TIME shows how long the robot will continue throw-

ing balls until it stops automatically. TIME is displayed in

HR:MIN:SEC format. A display of 1:01:01 indicates 1 hour, 1

minute, and 1 second.

TIME is restricted to increments of WAIT rounded to

the next second. For example, if WAIT is 1.50 seconds and

TIME is set to 0:00:03, COUNT would show 2. If TIME is set

to 0:01:30, COUNT would show 60. However, TIME cannot

be set to something like 0:00:05 because that time is not an

even increment of WAIT.

TIME is similar to COUNT—a setting of 0 deactivates

this function and more than 0 causes the robot to keep run-

ning until the value becomes 0. Interrupting TIME by press-

ing the Stop/Start Button simply pauses the countdown

until the Stop/Start Button is pressed a second time.

Having TIME and COUNT dynamically linked together

makes it easy to regulate your training routine by number of

balls thrown or by overall time. If you're used to doing a par-

ticular routine for 100 balls, set COUNT to 100 and the robot

automatically calculates the time it takes to throw 100 balls. If

you prefer to regulate your workouts by time, set TIME to

0:03:00, for example, to do your routine for 3 minutes before

the robot stops automatically. If you don't want to use TIME

or COUNT to stop ball delivery, set them to 0 and you can

control ball delivery manually by pressing the Stop/Start but-

ton.

TIP: Since TIME and COUNT can be set to very high num-

bers, there is a trick to greatly speed up the rate at which the

value changes. Press and hold the – or + Button and then press

the OK/Menu Button. Values will change much more rapidly.

9

COUNT 0000

TIME 0:00:00

OSC RANDOM OFF

SPEED RANDOM 00

OSC RANDOM turns the oscillator randomization fea-

ture on and off. It requires L POSITION and R POSITION

to be set to different numbers for it to have any effect.

When off, balls are thrown alternately to the left and right

positions. When on, balls are thrown randomly between the

left and right positions.

For example, if L POSITION is 5, R POSITION is 10, and

OSC RANDOM is OFF, balls are delivered alternately to posi-

tions 5 and 10. However, if OSC RANDOM is changed to ON,

then balls will be placed anywhere between positions 5 and

10; i.e., positions 5, 6, 7, 8, 9, or 10. The robot will pick one of

these numbers and throw a ball to the position it chooses.

COUNT 0000

TIME 0:00:00

OSC RANDOM OFF

SPEED RANDOM 00

SPEED RANDOM varies the BALL SPEED so balls are

thrown to different depths on the table. The value entered

is added to the value for BALL SPEED to give a range of

numbers from which the robot can randomly pick.

For example, BALL SPEED is set to 12 and SPEED

RANDOM is set to 6. This gives a range of ball speeds from

12 (very short, close to the net) to 18 (very deep, close to the

endline). The robot will randomly pick a number from

within this range—12, 13, 14, 15, 16, 17, or 18—and throw a

ball at that speed.

A value of 00 means no randomization. Maximum val-

ue is 10. Be cautious about using too high of a value as it

could cause balls to be thrown off the end of the table.

Tip: Set the BALL SPEED to the slowest desired speed first,

say 15. Then, without changing the head angle, experiment to see

what BALL SPEED setting will throw a ball just past the end of

the table, say 19. Subtract 1 from this larger number to find the

maximum speed that still lands the ball on the table—in this case,

18. Subtract the slowest ball speed, 15, from this maximum speed,

18, to give the maximum SPEED RANDOM setting—3.

WAIT RANDOM0.00

WAIT RANDOM causes the WAIT setting to vary by a

certain amount of time. The entered value is added to the

WAIT time to provide a range of time for the interval

between two consecutive shots. Like WAIT, this setting can

be changed in increments of 0.05 seconds. Maximum WAIT

RANDOM is 1.00 seconds. A setting of 0.00 means no ran-

domization is added to the wait time.

For example, WAIT is 1.00 seconds and WAIT RANDOM

is 0.20. These settings would provide a range of wait times

between 1.00 and 1.20 seconds. The robot could pick any time

among the following—1.00, 1.05, 1.10, 1.15, or 1.20 seconds.

Using WAIT RANDOM makes it difficult to develop a

rhythm and predict when the next ball will be delivered.

This encourages the user to maintain a good ready position

between each shot and only move after the ball is shot out

from the robot.

Also be aware that the greater the WAIT RANDOM is,

the less and less accurate TIME and COUNT become. This

is because the amount of time between each ball can no lon-

ger be accurately calculated since the interval between each

shot is constantly changing.

You can use 1, 2, or all 3 randomization controls at once.

Combining them together can make for very unpredictable

ball deliveries. It is recommended that you use controlled

randomization. Add randomness in small increments only

after consistency is attained without randomization. As

technique improves, gradually increase the amount of ran-

domization to more closely simulate live play.

In Normal Mode, the yellow Test Button is used to give

1 or more balls to test your settings. Press Test once and 1

will appear on screen. After a brief delay, 1 ball will be

thrown using the current BALL SPEED and last position

settings. If you hold the Test Button down, the number

shown on screen will keep advancing in increments of 1

until you release the button. Then, that number of balls will

be thrown. Please be aware that test balls thrown will not

reflect any random settings chosen (random position, speed,

or wait).

DRILL MODE (ALL MODELS)

NORMAL

DRILL

PC

SETUP

DRILL Mode allows access to the 64 drills that come

pre-programmed with your robot. Select Drill Mode by

going to the Main Menu, selecting DRILL and pressing OK.

There are 2 pages of functions in Drill Mode.

The 64 drills have been carefully selected to offer a variety

of drills for all playing levels, and to demonstrate how drills

can be created for training footwork, forehand-backhand tran-

sitions, serve return, and attack of high balls or backspin balls.

Each drill is diagrammed in the drill diagraMs section

starting on page 21. It is recommended that you keep these

diagrams next to your table tennis table when using Drill

Mode to quickly refer to the diagrams and select a drill for

training a particular aspect of your game. These diagrams

also provide information on what type of shots the player is

expected to use during the drill and what spin and head

angle settings to use. Create your own drill diagrams by

downloading a blank drills diagram page from the Down-

loads page of www.newgy.com, printing it off and using

hand notations on those printed diagrams.

TIP: You can often create "new" drills by simply changing the

HAND setting. So, for instance, if you are right handed and have RIGHT

selected, Drill 52 will give two backhands and one forehand. By changing

RIGHT to LEFT, this same drill will give you 2 forehands and 1 backhand.

10

DRILL# 01

SPIN TOP

HEAD ANGLE 02.0

WAIT ADJUS 000%

The first 3 lines of each drill are reserved for settings

that are predefined for each drill. Except for selecting

another drill, these values cannot be changed. Press the +

Button to select a drill with a higher ID number and the –

Button for a lower numbered drill.

Once a drill is selected, you need to verify that the Spin

(see page 16) and Head Angle (see page 15) are correctly set

before starting a drill. Failure to do so will normally cause

the drill to not run correctly and landing spots will be dif-

ferent than the way the drill was designed.

Regarding Head Angle, the angle indication mecha-

nism is not precise. Therefore, it is recommended that if

balls within a drill are not landing in the correct spot, that

you first try slightly nudging the head angle either up or

down to see if this corrects the problem. For instance, if a

drill starts with a short serve, and the serve often hits the

net, raise or lower the head angle slightly so that the serve

still lands short, but it clears the net without touching it.

DRILL# 01

SPIN TOP

HEAD ANGLE 02.0

WAIT ADJUS 000%

WAIT ADJUS is used to increase or decrease the wait

time between each shot. The value can be changed from

-100% to +900% in 10% increments. Since WAIT is adjusted

by percentage, even drills that have different WAITS pro-

grammed within the drill will still run correctly. Players of

many different levels can use the same drill without need-

ing to rewrite the drill.

For example, let's say a drill has a WAIT of 1 second

between the 1st and 2nd ball and a WAIT of 0.80 seconds

between the 2nd and 3rd ball. If WAIT ADJUS is set to +010%,

the 1st WAIT would be changed to 1.1 seconds and the sec-

ond WAIT to 0.88 seconds. The drill would run slower so

the player has more time between each ball.

On the other hand, if WAIT ADJUS is set to -010%, the

1st WAIT is reduced to 0.90 seconds and the 2nd one to 0.72

seconds. This causes the drill to run at a faster pace, reduc-

ing the time the player has between every ball.

Except for the 5 Beginner level drills, the drills that

come with your Robo-Pong are written to simulate real-time

rallies. This means that wait times were selected to closely

approximate the actual wait times in a rally between two

players. If you are unable to keep up with the pace, add a

positive WAIT ADJUS until you can maintain the pace for

several minutes. Your goal should be to gradually and sys-

tematically decrease the WAIT ADJUS to 0.

And once you can keep pace with a drill in real time,

then strive to practice the drill at faster than real time by

decreasing WAIT ADJUS to a negative value. By using this

principle of progressive overloading, you can train your

movements to flow smoothly at faster and faster speeds.

You will react faster to the ball in actual game rallies and

you may start dominating rallies simply because you are

quicker than your opponent.

SPEED ADJUST 0

# OF REPS 0000

TIME 0:00:00

SPEED ADJUST increases or decreases the BALL SPEEDS

that are preset in a drill. The values range from -9 to +9. The

value is added to the BALL SPEED for each ball in a drill.

For instance, a drill has 2 balls in it, one with a BALL

SPEED of 14 and the other, 16. If SPEED ADJUST is set to

+2, the speed of the 1st ball changes to 16 and the 2nd ball

to 18. If set to -2, 1st ball changes to 12 and the second to 14.

SPEED ADJUST should be used sparingly, especially

on drills that have both short balls and long balls. Adjusting

the speed upward on such a drill would likely make the

short ball land too deep and the deep ball get thrown off

the table. Adjusting the speed downward would likely

make the short balls fall into the net and the deep balls land

in the middle of the table.

SPEED ADJUST is best used for drills having a single

BALL SPEED. These drills have all balls landing at the

same depth on the table. Check Preview (see beginning of

page 10) to see if all balls in a drill are thrown at the same

depth. Decrease SPEED ADJUST to make balls land shorter

on the table and increase it to get deeper balls.

SPEED ADJUST is also handy when used in conjunc-

tion with Head Angle. If the specified Head Angle results in

a ball that has a higher trajectory than you prefer, simply

lower the Head Angle and use a positive SPEED ADJUST

to have the ball land at the desired depth on the table.

Again, this works best on drills that have a consistent BALL

SPEED set for the entire drill.

SPEED ADJUST 0

# OF REPS 0000

TIME 0:00:00

# OF REPS is similar to COUNT of Normal Mode. It

automatically stops ball delivery after the specified number

of drill repetitions are completed. For instance, if set to 5,

and there are 3 balls in the drill, the robot would run the

drill 5 times (15 balls total) before stopping. Also a setting

of 0 deactivates this function and drills can only be stopped

by manually pressing the Stop/Start Button.

If a drill is paused (by pressing the Stop/Start Button),

before # OF REPS equals 0, the drill will resume at the start

of the repetition at which it was paused when the STOP/

START button is pressed again. For example, # OF REPS is

set to 5 and the drill is paused in the middle of the 3rd rep.

When resumed, the drill would repeat the 3rd repetition

since it did not completely finish when interrupted.

11

SPEED ADJUST 0

# OF REPS 0000

TIME 0:00:00

TIME stops a drill automatically after the specified

amount of time has elapsed. Like Normal Mode, where

TIME is dynamically linked to COUNT, in Drill Mode,

TIME is dynamically linked to # OF REPS. You can increase

or decrease TIME in increments of the estimated time it

takes to complete 1 full repetition of a drill.

For example, if it takes approximately 5 seconds to

complete 1 repetition of a drill, TIME would go up and

down in increments of 5 seconds. If a drill contains variable

WAIT times, this approximation will become less precise.

Also see TIME (for Normal Mode) on page 8 for further

explanation of this function.

PC MODE (ALL MODELS)

NORMAL

DRILL

PC

SETUP

PC Mode is used whenever you want to connect your

Robo-Pong to your Windows®PC to read drills from or

write them to the Control Box and to run drills directly

from the PC. This Mode consists of a single page:

PC MODE

MAKE CONNECTION

TO PC

RUN ROBO-SOFT

After seeing this screen, please verify that your PC is

connected properly via the USB port on the bottom on the

Control Box. This connection routine is discussed in more

detail on page 28. After making the connection, start up

your PC and then launch the RP.2.PC program that can be

be downloaded from Newgy.com.

After RP.2.PC is launched, it takes several seconds to

establish communications with the Control Box (be patient).

Once the launch routine completes, it confirms the connec-

tion by displaying a message at the top of the program's

main window.

Once the connection is confirmed, RP.2.PC can be used

to read from and write to the Control Box, and run drills

direct from your PC. If you switch out of PC Mode after

connecting, the check mark will disappear and you'll need

to reestablish communication once you return to PC Mode

by using the AutoConnect command. Please read the

RP.2.PC section (page 28) for more info.

Please be aware that a connection between your PC and

the Control Box does not need to be established if you only

want to open, work on, or save drills stored on your comput-

er's hard drive (or external drive connected to your comput-

er). A connection is only necessary whenever you desire to

communicate with the Control Box via RP.2.PC.

The yellow Test Button does not have any function

associated with PC Mode.

SETUP MODE (ALL MODELS)

NORMAL

DRILL

PC

SETUP

SETUP Mode provides access to a variety of calibration

routines, user interface settings, and personal preferences. It

consists of 2 pages. We recommend that you write these set-

tings down. When you update the firmware or restore fac-

tory defaults, these settings will be erased. Writing them

down will save time if you need to re-enter the values.

CONTRAST 15

HAND RIGHT

LANGUAGE EN

OSC CALIB 25

CONTRAST adjusts the contrast of the screen to im-

prove visibility under a variety of lighting conditions. The

range is from 00 to 30. Default setting is 15, which should

work best for most lighting conditions. However, if so

desired, the user can lighten or darken the screen by chang-

ing the value. Going down in value provides a lighter

screen; whereas, going up in value darkens the screen.

If this setting is changed to either extreme value, it may

appear that the screen is completely dark or that no infor-

mation is displayed. But by adjusting your viewing angle

and/or the amount of light hitting the screen, you may see

feint outlines of letters and/or numbers. Adjust the value

accordingly to make the screen more readable.

CONTRAST 15

HAND RIGHT

LANGUAGE EN

OSC CALIB 25

HAND is one of the unique features of the digital

Robo-Pong robots. It lets the user select their dominant

hand so that drills run correctly with regards to backhand/

forehand strokes. Values are Right (default) or Left. Select

the one that matches your dominant playing hand.

Since drills are normally written for right-handed play-

ers, who are the vast majority of players, this switch allows

a left-handed player to use drills written for a right-handed

player without needing to rewrite the drill. We recommend

that all drills be written for right-handed players so that

this switch works properly.

HAND only affects drills run from either DRILL Mode

or directly from your PC in PC Mode. It has no effect on

NORMAL Mode.

RP.2.PC

12

CONTRAST 15

HAND RIGHT

LANGUAGE EN

OSC CALIB 25

LANGUAGE allows selection of the desired language

for displaying the menu system and messages. Values are

EN (English), DE (German), FR (French), ES (Spanish), CN

(Chinese), or JP (Japanese). EN is the default. After selecting

the desired language, any press of another button will acti-

vate that language and all information displayed on the

LCD screen will be shown in that language.

If the menu system is displayed in a language that can-

not be read, another language can be chosen by using the

Language Selection Special Function (see page 13).

CONTRAST 15

HAND RIGHT

LANGUAGE EN

OSC CALIB 25

OSC CALIB is used to calibrate a position setting of 10

with the centerline of your table tennis table (see page 7 for

explanation of positions). Once position 10 is calibrated to the

centerline, all other positions will be properly calibrated as

well. Range of values is from 00 to 50. Default is set to 25.

Decreasing the value results in the ball's landing spot

shifting toward the left and increasing the value results in it

shifting to the right. To see if your oscillation needs calibrat-

ing, set the Spin to Topspin and the Head Angle to 8. Then

press the yellow Test Button once.

5 Balls will be shot out from the robot. Carefully

observe the landing spots of these 5 balls in relation to the

centerline. If the balls land in a cluster around the center-

line, no adjustment is necessary. However, if the 5 balls

cluster consistently to the right of the centerline, decrease

OSC CALIB until the 5 balls cluster around the centerline.

Similarly, increase OSC CALIB if the test balls consistently

land to the left of the centerline.

It is normal for balls to land slightly to the left or right

of the centerline, but of the 5 test balls thrown, there should

be roughly equal numbers that are thrown left or right of

the centerline. If balls are always thrown either on the cen-

terline or to the right, for example, go ahead and decrease

OSC CALIB to shift the cluster slightly to the left.

Before changing OSC CALIB, check to be sure the robot

is properly centered on the end of the table. The center sup-

port rib of the triangular shaped Front Support Plate (Key

#5 on page 44) should align with the centerline of the table.

SENSOR CALIB 10

ALARM CALIB 10

SPEED CALIB 10

255 255 255

SENSOR CALIB corrects poor ball feed performance.

Be cautious about changing this from the default value

until you have eliminated other causes, discussed below.

The Ball Sensor (#40, Figure H, page 45) detects when a

ball should be thrown out and is responsible for accurate

ball counting. If your robot begins to throw 2 balls at once,

doesn't throw out a ball when it is supposed to, or seems to

often hesitate immediately before a ball throw, you may

need to calibrate the Ball Sensor.

Values range from 00 to 20 with 10 being the default

value. Decreasing the value advances a ball's position in the

ball channel so the ball is sensed "earlier". Increasing the

value causes the ball to be sensed "later".

You would decrease the value if the robot doesn't throw a

ball out when it's supposed to or seems to often hesitate

immediately before ball throws. Increase the value if you often

get two balls thrown instead of 1 ball.

Before adjusting SENSOR CALIB, please eliminate other

more likely causes. It is normal for an occasional hesitation

before a ball throw, but this should not happen on regular

basis. This is caused by the pickup mechanism missing a ball

pickup and rapidly accelerating the feed wheel to "make up"

for the missed pickup. There will be a slight hesitation before

the ball feed mechanism can "catch up" after a missed pickup.

Also if the chip loosens from its chip holder, the Ball Sensor

will not work.

A common cause of missed ball pickups is that there are

not enough balls immediately in front of the ball pickup

mechanism. Add more balls to your robot to prevent this. If

several balls are not in contact with the Pickup Fingers (#46,

Figure I, page 43), they cannot be picked up. This mimics incor-

rect ball sensor calibration, but the true cause is simply there

are not enough balls for the pickup mechanism to work prop-

erly or something is preventing balls from rolling down into

the pickup mechanism.

Something else that can cause the ball sensor to not sense

balls correctly is that the steel lever attached to the sensor does

not protrude far enough into the ball channel. The lever needs

to protrude far enough into the channel that a ball cannot pass

by it without activating the sensor (you should hear a clicking

sound as the lever is depressed). If necessary, carefully bend

this lever inward so it detects balls properly.

Undersized balls may also cause this behavior. Please ver-

ify that all balls are 40mm in diameter (see page 17 for using a

Ball Dam2to check ball diameters). Robo-Pong 2055 and 1055

cannot utilize 38mm balls.

Lastly, something that causes double ball throws is a bro-

ken Ball Discharge Spring (#58, Fig. D, pg. 44). If this part is

broken, missing, or deformed, it is likely the culprit and

should be replaced before adjusting SENSOR CALIB. Forcing

the head angle to less than 1 can also cause this.

If you have eliminated other more likely causes, adjust

SENSOR CALIB by setting the head to Backspin and to Angle

7. Then press the yellow Test Button. The robot will begin

shooting balls into the table net and the balls will roll back into

the net system. If balls aren't being thrown into the table net,

adjust the Head Angle until they are.

Balls will be delivered to positions 12 and 16. Watch the

head carefully to be sure that one and only one ball is thrown

out each time the head completes its sideways travel. It likely

will take numerous balls to be thrown before a problem is

detected. Press any button to stop the test. If SENSOR CALIB

needs adjusting, select a new value and then repeat the test

until the problem disappears.

13

SENSOR CALIB 10

ALARM CALIB 10

SPEED CALIB 10

255 255 255

ALARM CALIB effects the sensitivity of the Ball Jam

Alarm. This alarm is activated whenever the resistance of

the Ball Feed Motor rises above a preset level. This causes

the alarm to sound and power to the Ball Feed Motor is cut

until the problem is resolved. This prevents damage to the

Ball Feed gears and other parts. For most users, this feature

will never be needed and should be kept at default value.

Dirty, broken, or oversized balls are the most likely

causes for this alarm to activate. Other causes are foreign

objects or anything else that would prevent balls from

being pushed smoothly through the ball channel.

The alarm has a range of adjustment to allow the user

to make it activate sooner or later than "normal". The range

is from 0 to 20 with 10 being the default value. If you desire

more sensitivity, you can increase the value. If you want

less sensitivity, decrease the value.

A likely scenario where you may consider decreasing

the sensitivity would be if the balls get very dirty and the

alarm starts activating. Instead of stopping and washing

the dirt off the balls, the user wants to continue playing

with dirty balls. Although not guaranteed, decreasing

ALARM CALIB may allow dirty balls to be used until such

time that they can be properly cleaned.

SENSOR CALIB 10

ALARM CALIB 10

SPEED CALIB 10

255 255 255

SPEED CALIB is used to fine tune the BALL SPEED.

For drills that have been created on a different Robo-Pong

to work correctly on your robot, it is important that BALL

SPEEDS on the two machines be calibrated so that a value

of, for instance 15, results in the same landing spot on both

robots. This problem would most likely be caused by com-

ponents wearing or aging.

Values range from 0 to 20 with 10 being default value.

Increasing the value results in more speed being added to

the ball; decreasing the value, in less speed. However, there

is an upper limit to this effect—no balls set at BALL SPEED

25 or higher will be affected by SPEED CALIB. So don't

think that increasing this value will result in faster top

speeds. BALL SPEED 30 is already set at the maximum for

the motor and the electronics controlling that motor. So set-

ting SPEED CALIB to 20 and using a BALL SPEED of 30

would not result in even more speed being applied to the

ball. As a matter of fact, it would cause the robot to run

worse, possibly resulting in an over-voltage situation where

power is cut off to the Control Box and causing it to reset.

SPEED CALIB should only be used as a last resort

when all other possible solutions do not resolve the prob-

lem. The first thing you should check if balls are not land-

ing where they should, is to check that the robot is level

and the Head Angle is set properly.

As discussed previously, the Head Angle Adjustment

Mechanism is not precise, so a Head Angle Setting should

be used as a general guideline, not as an absolute. In gener-

al, for any given head angle, the acceptable tolerance is

±0.25. So if the given Head Angle is 8, the acceptable range

for that setting is 7.75 to 8.25. Many times, speed "problems"

can be resolved simply by adjusting the head angle.

Another common cause of slower ball speeds is that the

rubber Discharge Wheel and/or Friction Block are dirty.

Dirt buildup on these two parts can cause a substantial

reduction in ball speeds. Clean these parts regularly to

maintain top speeds. See page 37 for recommended clean-

ing procedures.

To use SPEED CALIB, make a 6 x 6 inch paper target.

One is provided on page 27, but instead of cutting that tar-

get out, we recommend making a copy and using the copy.

Then follow the instructions as given on the target.

SPECIAL FUNCTIONS (ALL MODELS)

There are 4 special functions that can be accessed by press-

ing a combination of buttons on the Control Box: (1)

Language Selection, (2) Ball Unloading, (3) Self Diagnostics,

and (4) Factory Default Restoration. All special functions

begin by pressing and holding the OK/Menu Button until

the screen goes blank. Release the OK/Menu Button and

after a brief moment, the screen turns completely black.

Then press one of the gray arrow-shaped buttons as given

in the following descriptions:

Language Selection is particularly useful if the menu

system is displayed in a language that the user cannot read.

Press and hold the OK/Menu Button until the screen goes

blank and then release. Momentarily, the screen turns com-

pletely black. Now press and hold the Up Button. The fol-

lowing message appears in the currently selected language:

RELEASE BUTTON

WHEN YOU SEE

YOUR LANGUAGE

It will then begin cycling through all the languages,

one at a time, with a short pause before each one. When

you see the language you prefer, let go of the Up Button

and the menus will stay in that language. Press any button

to exit Special Functions mode and resume normal opera-

tions.

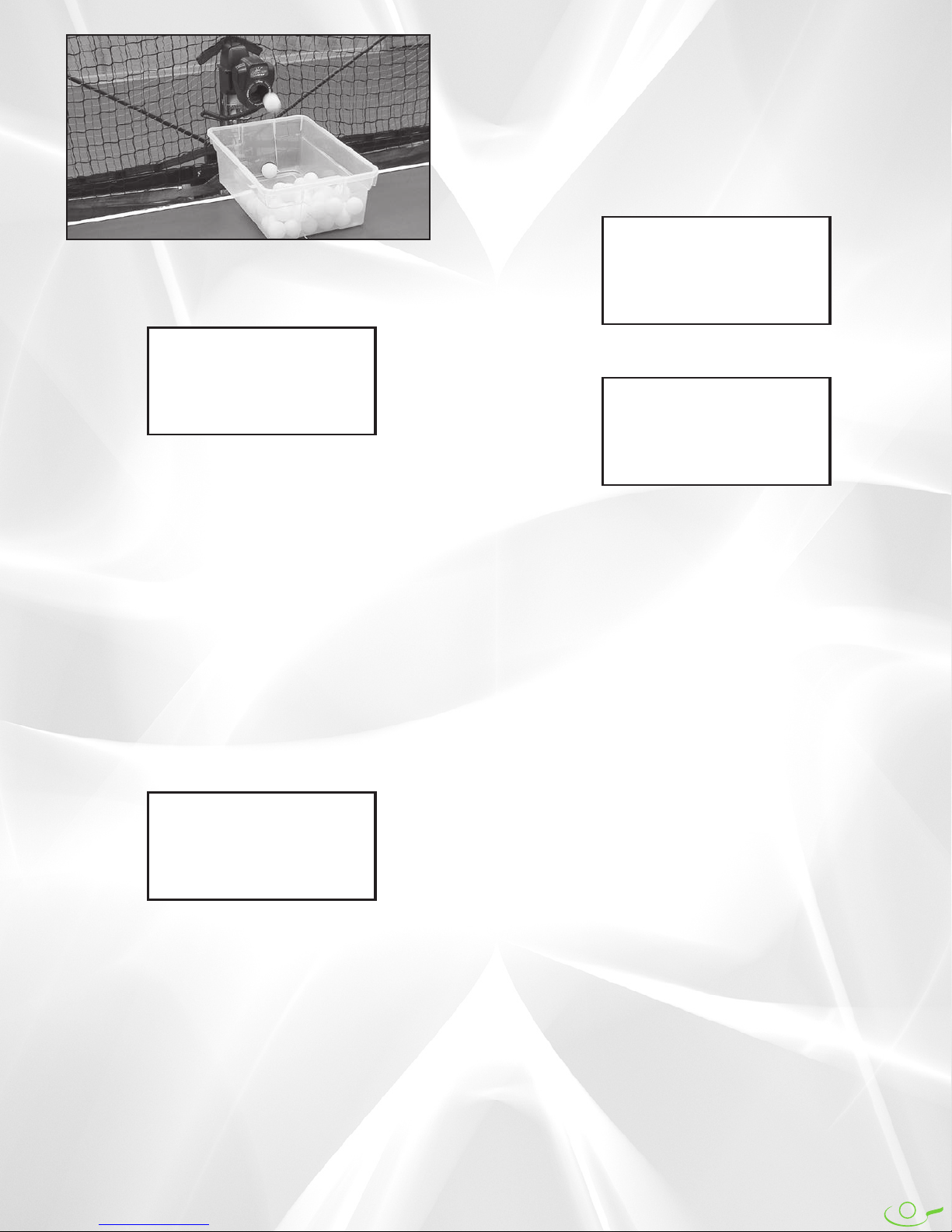

Ball Unloading is used when you want to quickly

empty balls out of the robot's trays2or bucket1. This is typi-

cally done when the user wants to practice serves by gath-

ering all balls from the robot and placing them into a bin.

Before using this function, get a medium-sized plastic

bin (available at many department & hardware stores). If

you have a Robo-Caddy, it's convenient if the plastic bin is

sized to fit into the caddy's tray.

14

overwritten during this procedure. As mentioned previous-

ly, it is handy to write down all values for functions in the

SETUP Mode, so you can quickly reenter them after you

use Factory Default Restoration. We have included a space

on the back cover to record your settings.

Like the other Special Functions, begin by holding

down the OK/Menu button until the screen goes blank and

then release that button. When the screen turns all black,

press the – Button. You will then see the following screen:

RESTORING

FACTORY

DEFAULTS

And after a moment, the screen will confirm that the

procedure completed successfully:

FACTORY

DEFAULTS

RESTORED

A few seconds later, the above screen disappears and

the system reboots and you are taken automatically to page

1 of the default Normal Mode.

Place the plastic bin under the robot's head. Then press

and hold the OK/Menu Button until the screen goes blank

and then release. After the screen turns completely black,

press the Down Button. The following message appears:

BALL UNLOADING

PLACE TRAY UNDER

ROBOT HEAD

In a moment, balls will start dropping out of the robot's

head at maximum frequency, landing in the plastic bin placed

underneath. In a short amount of time, all balls will be pulled

from the trays2or bucket1and deposited into the bin. Place the

bin on the top of the table or into the top of the Robo-Caddy

on the server's end of the table. Now practice your serves and

use the robot's net system to capture and collect your serves:

Self Diagnostics is used to help troubleshoot the robot

when having problems with the robot. This should be used

principally with a trained service technician who can prop-

erly interpret the codes provided. Always perform a

Factory Default Restoration (described next) before using

Self Diagnostics.

To activate, use the same routine described previously

for making the screen go black. Then press the + Button.

The screen will display the following message and then

generate a series of numbers in the last line:

TESTING SYSTEM

GIVE ERROR #S

TO TECHNICIAN

0123456789

Write down these numbers and give them to a service

technician. These codes may assist the technician with trou-

bleshooting the problem.

Factory Default Restoration is handy when you suspect

that a setting may be causing the robot to behave in a

strange manner. Restoring all settings to factory default

means that all values are set back to the default value for

each function This is a handy step to take when you suspect

that the robot is malfunctioning and should always be done

before calling for service help. It may clear up the problem

by itself.

Please remember to recalibrate your robot after using

Factory Default Restoration as any custom setting is

15

BALL TRAJECTORY (ALL MODELS)

The trajectory of a ball is regulated by adjusting the angle of

the robot head. The angle can be changed from low to high.

At its lowest setting (1), the ball will be delivered so it first

strikes the robot's side of the table, bounces over the net,

and lands on the player's side of the table (just like a serve).

At its highest setting (13), the ball will be delivered in a

high arc over the net (like a lob return).

The trajectory is adjusted by tilting the head up or

down. If the head will not tilt, loosen the Brass Knob on the

right side of the robot head. If the head does not stay at the

desired angle, tighten the Brass Knob slightly (see Figure 3).

For reference, there are head angle indicators next to

the Brass Knob numbered 1 to 13 (see Figure 4). These

indicators are not precise, so you may need to nudge the

head slightly up or down from a setting when a particular

head angle is provided.

WARNING: DO NOT adjust the head angle when the

head is moving side to side. Failure to follow these instructions

may result in broken parts and may void your warranty.

BALL SPEED directly influences the ball trajectory set-

ting. When the head is set so the ball first strikes the robot's

side of the table (robot “serving”—see Figures 5C & 5D),

maximum BALL SPEED is in the range of 10–15. As BALL

SPEED is increased, the head must be angled up to deliver

the ball so it first strikes the player's side of the table (robot

“returning”—see Figures 5A & 5B). As BALL SPEED is

increased even more, adjust the head angle down to pre-

vent the ball from being thrown off the end of the table.

INCORRECT ROBOT HEAD ANGLE,

ROBOT “RETURNING”

FIGURE 5A

HEAD ANGLE INDICATORS

FIGURE 4

CORRECT ROBOT HEAD ANGLE,

ROBOT “RETURNING”

FIGURE 5B

INCORRECT ROBOT HEAD ANGLE,

ROBOT SERVING

FIGURE 5C

CORRECT ROBOT HEAD ANGLE,

ROBOT SERVING

FIGURE 5D

Robot head is tilted too high, resulting

in ball being thrown off the end of the

table.

Same ball speed as Figure 5A, but

now robot head is tilted down so the

ball lands on the table.

When robot is set to serve onto its

side of table first, and the head angle

is too severe, the ball will rebound

abnormally high.

Same ball speed as Figure 5C, but

head angle has been raised slightly

so ball stays low to the net. With robot

serving, maximum ball speed is

limited to 10-15 before ball is thrown

off the end of table.

Robot Head

70

Angle Pointer

69

Brass Knob

Robot Head

Robot Head

Robot Head

If necessary, loosen

knob (69) to adjust

angle of head up or

down. Tighten knob

if head will not stay

in position.

ADJUSTING HEAD ANGLE

FIGURE 3

Head Angle Indicators

16

BALL SPIN (ALL MODELS)

Robo-Pong robots are capable of putting any type of spin

on the ball. Topspin, backspin, sidespin, and even combina-

tion spins can easily be selected. To change the spin, simply

rotate the head of the robot until the desired spin is at the

top of the Ball Discharge Hole (see Figure 6).

For combination spins, move the head until one of the

rotational arrows is at the top of the Ball Discharge Hole.

For instance, if the arrow between Topspin and R. Sidespin

is selected, the robot will deliver a ball containing both top-

spin and right sidespin. Likewise, if the arrow between

Backspin and L. Sidespin is selected, the robot will deliver

a combination backspin/left sidespin ball.

Before discussing how to return spins, it's important to

know that your robot simulates the play of a modern table

tennis professional using inverted sponge rubber. With

Robo-Pong robots, there is always some kind of spin on the

ball. To learn how to produce your own spin and return an

opponent’s (or the robot’s) spin, it is important to use the

correct equipment—a quality inverted or pips out sponge

rubber racket. Using old-style paddles such as hard rubber

or sandpaper will make it more difficult to control spin.

Each spin has a different effect on the ball and how the

ball reacts when you strike it with your paddle. Following

are some brief pointers to help you return the different

spins. More detail is available in the newgY robo-Pong

training Manual which is included with your robot if

bought in the U.S., or as a download from Newgy.com.

The secret to returning spin is to angle your paddle

correctly when contacting the ball. Any spin can easily be

returned if you angle your paddle properly. Set your pad-

dle angle at the beginning of your stroke and maintain the

same angle until your stroke ends. Avoid changing your

paddle angle during your stroke (see Figure 7).

Topspin causes the ball to dip downward as it travels

through the air. When you strike the ball with your paddle,

it has a tendency to pop up high in the air. To compensate

for topspin, angle your paddle face down as you stroke

through the ball in a forward and upward direction. Con-

tact the top surface of the ball (see Figure 7A).

Backspin causes the ball to rise upward and float as it

travels through the air. When you strike the ball with your

paddle, it has a tendency to go straight down into the table.

To compensate for backspin, angle your paddle face up-

ward as you push your paddle straight forward. Contact

the bottom surface of the ball (see Figure 7B).

Sidespin makes the ball curve sideways through the

air. Left sidespin makes the ball rebound off your paddle to

your right; right sidespin to the left. To compensate for left

sidespin, angle the paddle face to the left and contact the

right side of the ball. To compensate for right sidespin,

angle your paddle face to the right and contact the left sur-

face of the ball (see Figures 7C &7D).

Combination spins take on the characteristics of both

spins, although to a lesser degree than the pure spins. To

compensate for topspin/right sidespin, you must angle

your paddle face down and to the right and contact the top

left surface of the ball. Likewise, a backspin/left sidespin

ball is best returned by angling your paddle face up and to

the left and contacting the ball on its bottom right surface.

Spins are intensified by increasing the Ball Speed (see

page 7). You intensify both speed and spin every time you

turn up BALL SPEED. It is not possible to adjust Robo-

Pong robots to deliver a slow ball with lots of spin, for

instance. It is also impossible for Robo-Pong robots to

deliver a no-spin ball. Additionally, since backspin causes

the ball to rise, the maximum setting for BALL SPEED

when the robot is set on Backspin is approximately 15–17.

Rotate Head So

Desired Spin Is

Listed In Upright

Position

CAUTION:

Do Not Twist Power

Cord Around Head.

Rotate No More

Than 180° In Either

Direction From

Position Shown

FIGURE 6 PADDLE ANGLE ADJUSTMENTS

FOR VARIOUS SPINS

FIGURE 7

AB

CD

SPIN SELECTION

17

BALL DAMS (2055 ONLY)

Robo-Pong 2055 comes with a pair of Ball Dams. They serve

three functions: (1) they keep balls inside the Center Trough

when the robot is folded up, (2) they keep balls from enter-

ing the Center Trough when you want to remove the robot

body, and (3) they serve as a ball gauge for determining if a

ball is the proper size and whether it should be used in the

robot.

The Ball Dams, when used for functions 1 or 2, fit into

two retaining slots at the top of the Center Trough. When

not in use, the Ball Dams fit into their storage slots on the

side of the Center Trough (see Figure 8).

To use the Ball Dams when preparing the robot for stor-

age or transport, remove the Ball Dams from their storage

slots by pulling slightly up on the trays to reveal the stor-

age slots (see Figure 10). Then push all the balls into the

Center Trough and insert the Ball Dams into their retaining

slots (see Figure 9). To use the Ball Dams for function #2,

push the balls up into one of the Ball Return Trays and

quickly insert the Ball Dam into its retaining slot before the

balls can roll down into the Center Trough. The balls will be

out of the way and you can easily loosen the two wing nuts

and two clip washers, then pull up on the robot body to

remove it.

The hole in a Ball Dam serves as a handy ball checking

feature. The hole is exactly 40.6mm in diameter, which is the

largest allowable size for a table tennis ball. Robo-Pong 1055

and 2055 can use only 40mm or 40+mm balls. Do not use

38mm, 44mm, or any other ball size than 40mm or 40+mm.

Do not mix 40mm and 40+mm size balls. Use the hole to

test the roundness and size of balls used in the robot.

If you suspect a ball is out of round or too large, as indi-

cated by balls jamming within the robot, insert the suspect

ball into the ball checker hole. With your fingers, rotate it

around inside the hole to check all possible diameters of the

ball. The ball should have equal clearance through the hole

on all diameters. The ball should fit through the hole with-

out binding. It is also possible that a ball is too small. In this

case, you will notice a considerable gap between the ball

and the edge of the hole.

Note: Be aware that plastic balls (also called poly balls) are

identified with the marking 40+. They were introduced in 2014

and are approximately 0.5mm larger in diameter than the aver-

age celluloid ball (40mm), which is the material that has histori-

cally been used for table tennis balls. Plastic balls are marked

with 40+ instead of 40 that is used on celluloid balls. When

using the ball checker hole, there should be considerable more gap

when measuring celluloid balls than when measuring plastic

balls.

Ball Dam

Retainer Slot

Ball Dam

Storage Slot

Ball

Checker

Hole

15

Ball Dam

1

Center

Trough

BALL DAM & CENTER TROUGH

(2055 ONLY)

FIGURE 8

INSERTING BALL DAM

(2055 ONLY)

FIGURE 9

REMOVING BALL DAM

(2055 ONLY)

FIGURE 10

CHECKING BALL WITH BALL DAM

(2055 ONLY)

FIGURE 11

➥

➨

➨

Rotate Ball Inside

Hole To Check All

Diameters Of The

Ball. Ball Should

Pass Easily Through

Hole On All

Diameters.

18

POSITIONING YOUR ROBOT AND CONTROLS (ALL MODELS)

Robo-Pong robots are versatile in how they are positioned in

relation to the table. The 1055 normally sits on top of the table

as shown in robot positions 1–4 in Figure 12. They can also be

mounted in the optional Robo-Caddy and placed behind the

table like positions 5 & 6. The 2055 is typically mounted to

the end of the table at position 5, but can alternatively be

mounted in the Robo-Caddy just like the 1055.

Some positions offer certain advantages while other

positions compromise some of the robot’s functions. By

placing the robot in various positions you can achieve a

variety of angles and trajectories to simulate almost any

type of shot you would encounter in a regular game. The

following paragraphs explain this further.

Position 1—Robot positioned square to the table where

the centerline and endline of the table meet. This is the only

on the table position in which the 1055’s oscillator positions

will be accurate (see Figure 2, page 7). Also, this is the

desired starting position when first setting up the 1055.

Position 2—Robot positioned at the far left corner and

angled cross-court. This position will skew the 1055’s oscil-

lator positions toward the player’s right side of the table.

This position would be the preferred direction when simu-

lating typical right-handers’ forehand to forehand rallies.

Position 3—Robot positioned at the far right corner and

angled cross-court. Setting the robot in this position will

skew the 1055’s oscillator positions toward the player’s left

side of the table. Typical backhand to backhand play for

right-handers would be ideally simulated with the robot in

this position.

Position 4—A robot placed in this position has the

advantage of offering slower and faster ball speeds because

it is closer to the landing spot of the ball. At a Ball Speed

setting of 1, the ball is very slow and with light spin, but is

delivered deep on the player’s end. At a Ball Speed setting

of 30, the ball speed is very fast and simulates the angle

from which a typical kill shot would be hit. However, the

1055’s oscillator range is narrower than if the robot had

been positioned at the endline like Positions 1–3. This posi-

tion also is similar to the ball release point that most coach-

es use when doing multi-ball drills with a student.

Position 5—This is the normal position of the 2055

when it is attached to the end of the table, and its net system

would function normally. The 1055 would have to be

mounted in the Robo-Caddy to be in this position.

Positioned here, the 2055’s and 1055’s oscillator ranges

would be accurate.

Position 6—Mounted in a Robo-Caddy, both models

can be freely moved around in back of the table. The Robo-

Caddy also permits lowering or raising the height of the

robot. This is great for simulating deep shots such as chops,

lobs and loops. However, the oscillator ranges for the 1055

and 2055 are not accurate and the 2055’s net system is usu-

ally not effective at capturing balls when in this position.

Additionally, you need to purchase a Shielded Connector

Extension Cable to extend the length of the Connector

Cable from 11 to 22 feet. This permits the Control Box to

stay within reach of the player.

Robot

Pos. 1

Robot

Pos. 2

Robot

Pos. 3

Robot

Pos. 4

Robot

Pos. 5

Robot

Pos. 6

Right Hand

Player Left Hand

Player

Control Box

AB

These positions are only a few of the ones possible, but

they will give you a good idea of the pluses and minuses of

placing the robot in a particular position.

IMPORTANT NOTE: Even though the oscillator range

may not be accurate as described in Figure 2 on page 7 when the

robot is in certain positions, you should be able, with experimen-

tation, to find the correct settings to permit ball delivery over any

particular part of the table.

Figure 12 also illustrates the ideal positions for the Control

Box. If you’re right-handed, Position A is the preferred location

for the controls. If you’re left-handed, Position B is preferred.

Locating the controls in these suggested positions permits the

controls to stay within easy reach of the player’s free hand.

Since a player has a longer reach on the forehand side, it is

suggested that you position your body as shown. The over-

whelming majority of tournament level players use their back-

hand to cover about one-third of the table and their forehand to

cover the other two-thirds of the table.

ROBOT AND CONTROL BOX

POSITIONS

FIGURE 12

19

LEVELING ADJUSTMENT (2055 ONLY)

Robo-Pong 2055 is designed to sit level when attached to

the table. In proper position (Figure 13), the CT Support

Legs fit underneath the table and the CT Front Support

Plate sits on top of the table. If the robot does not sit level,

balls will not feed properly. If this condition occurs, it is

necessary to make some leveling adjustments. The first

adjustment is to level the table top by placing shims under

the table legs until the table top is level.

If this does not cause the robot to sit level, then it will be

necessary to make adjustments to the robot itself. The

Support Legs come with 3 sizes of Rubber Tips and 4 rubber

spacer-washers to accommodate different table top thick-

nesses, and cause the Center Trough to sit level. The Rubber

Tips are marked on their top with the table thickness they

are used with. The longest is used for 1/2″(13mm) tops. The

mid-size one is used on 3/4″(19mm) tops and comes pre-

installed. The shortest tip is used for 1″(25mm) tops.

In addition to these different sized tips, there are 4 rub-

ber spacer-washers which are used with the Rubber Tips

for finer adjustments. Either one or two of these spacer-

washers (depending on how much adjustment you need)

are placed inside the Rubber Tips before the tips are placed

on the end of the Support Legs.

Another reason why your robot may not sit level is that

it is not properly seated on the locating tab. When seated

correctly, the Support Flange of the Back Panel sits flush on

the Locating Tab that protrudes from the top of the Center

Trough or Ball Bucket (see Figure 14). Your robot serial num-

ber is located on top of this Support Flange.

TIP: If it is possible to adjust the level of the robot’s half of

the table independently from the player’s half, you may choose to

purposely give a slight slope to the robot’s half so balls that end

up on the table roll into the robot’s trays. If you make the table

unlevel, make sure the robot sits level by adjusting the Rubber

Tips as described above. In this case, it may be necessary to use

the Rubber Tip one size larger than normal and/or the rubber

spacer washers to level the robot.

ADJUSTING NET TENSION (2055 ONLY)

The Ball Return Trays should sit level at or just below the

level of your table top. If the tension of the Main Net is too

tight, the trays will be pulled up into a slight “V” shape

with the top edge of the trays above the level of the table

top. To correct this situation, loosen the adjustment straps

shown in Figure 15 until the trays sit level. If this adjust-

ment is insufficient, stretch the net by grabbing it with two

hands and pulling gently apart to relax the net fabric.

The Trap Net (the black net with large holes) slows

down your returns so more of them are captured. The size

of the holes is slightly smaller than the diameter of a ball.

Hard hit shots force the ball through the net and the ball

becomes trapped between the Trap Net and the Main Net.

When slowly hit balls contact the Trap Net, they do not

have enough force to go through the net, so they immedi-

ately drop down into the trays.

MISCELLANEOUS ADJUSTMENTS (2055 ONLY)

CENTER TROUGH ATTACHMENT

(2055 ONLY)

FIGURE 13

ADJUSTING MAIN NET TENSION

(2055 ONLY)

FIGURE 15

ADJUSTING TRAP NET TENSION

(2055 ONLY)

FIGURE 16

Table Tennis

Table

Back Of Robot

To Control

Box

Velcro

Straps

Robot

8,9

CT Support

Legs

92

Connector

Cable

Serial #

Located

Here

10, 11, 12

CT Support

Leg Rubber

Tip—Come

In 3 Sizes

So Center

Trough Will

Sit Level.

Support Flange Of Robot Sits

Fully Down On Locating Tab Of

Center Trough2or Ball Bucket1

15

Ball Dam

In Storage

Position

5

CT Front

Support Plate

32

Wing

Nut

1

Center Trough

(Should Be Level)

SUPPORT FLANGE ALIGNMENT

& SERIAL # (2055 ONLY)

FIGURE 14

Velcro

Straps

20

The Trap Net is normally hung loosely to increase its

energy-absorbing capability. If you are practicing hard hit

shots like smashes or fast loops, you may find that a tighter

Trap Net captures more of your shots. The tension of the

Trap Net is adjusted by tightening or loosening the velcro

straps at the sides of the Trap Net (see Figure 16).

Side Nets block off the sides of the table and direct

wide angled shots into the main net. The Side Nets have a

red flexible band sewn at the narrow end of the net. This

flexible band is used to attach the Side Net to either the

clamp assembly for the table’s net (the net that separates

the two halves of the table—see Figure 17) or to a clip that

is attached to the table surface (see Figure 18C). Further-

more, you can adjust the tension of the Side Nets by modi-

fying the flexible bands (see Figures 18B and 18E).

If the table net has a clamp screw, pass the flexible band

of the Side Net over the top of the net support and wrap it

around the clamp screw as shown in Figure 17.

If your table net does not have a clamp screw, use the

Plastic Clips included with your robot. Clean the table sur-

face with isopropyl alcohol along the sideline about 1–3

inches before the table net. After the alcohol dries, remove

the backing on the bottom of a clip and press it onto the

table top along the sideline about an inch from the net. The

open end of the clip should face away from the robot (18A).

Create a knot close to the centerpoint of the flexible band

(18B). Insert the band into the clip where the knot is located

(18C). Side Net should look like 18D.

The flexible bands were designed to provide the proper

tension for the side nets in most installations. If you require

more tension to hold the side nets in place, then simply

knot the band as shown in 18B to shorten the band length

and then reattach. Be careful to never use so much tension

that you pull the main net with sufficient force that the Ball

Return Trays are lifted up. If you need less tension, then

you can lengthen the band by tying a hair band of the

required size (available at many stores) to the side net’s

flexible band (see Figure 18E).

When first used, the netting material is taut. The materi-

al will relax over time by itself. If there is sufficient gap