NewLine Venta Vanity User manual

Important!

July 2020

1. When you receive your Newline Vanity package please check for any freight

damage.

2. If damage has occurred, advise your supplier within 8 hours.

3. Do not install any faulty product as this will invalidate later claims.

Venta Vanity

Wall Hung & Floor Standing

INSTRUCTION MANUAL

2

VENTA HANDLE VANITY INSTALLATION

WE RECOMMEND A TRADESMAN FAMILIAR WITH THIS TYPE OF INSTALLATION

PLEASE READ CAREFULLY!

WARRANTY

1. This covers faulty product. Check www.newline.co.nz for full details of warranty.

2. Any breakage on site will not be covered.

3. The installation must conform to these instructions for the warranty to apply.

4. Compliance with NZ Building code clause G4 on ventilation is required in a bathroom.

5. Aftercare details in these instructions must be adhered to.

HEALTH AND SAFETY

• Some vanities are heavy and two-man lifting is recommended. Provide support under wall

hung units to simplify installation process.

• Determine positioning of wiring and piping within cavity walls. Mark their position to ensure

you are protected and services are not damaged.

INSTALLATION TYPE

Wall Hung Vanity Installation: Page 3

Floor Standing Vanity Installation: Page 4

MATERIALS REQUIRED

• Masking tape

• Bathroom Silicone (wide adhesion features including plastics)

• Cleaning materials

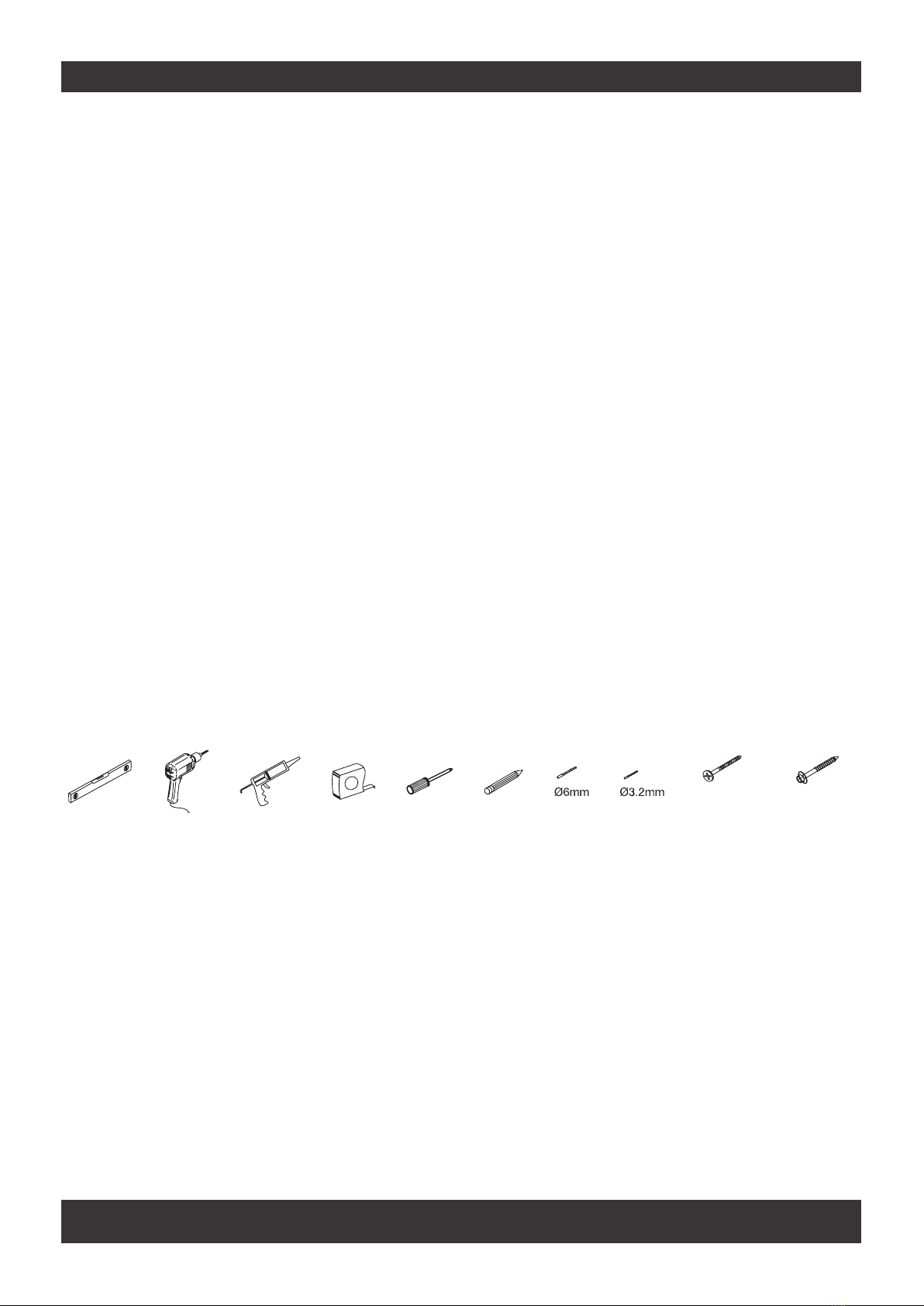

TOOLS & FASTENINGS REQUIRED

IMPORTANT: INSTALLATION NOTES

• Newline Vanities are water resistant but

not waterproof. Exposure to moisture

vapour will greatly reduce the life a Vanity.

Compliance with NZ Building code clause

G4 on ventilation is required.

• Avoid any distortion to the Vanity due to

the walls or floor being out of plumb or

level. This will cause the fit of the drawers

and doors to be misaligned.

• All tiling must be completed prior to Vanity

installation. The warranty does not include

restoration of tiling or wall finishing.

• Ensure that the hot water supply is

regulated to 55 degrees C.

• Fit water flow restrictors to small vanity

tops to avoid splashing/overflows.

• Use a registered plumber for the plumbing

connections.

WARRANTY WILL BE VOID IF THE ’INSTALLATION NOTES’ ARE NOT COMPLIED WITH.

75mm

Countersunk

Screws

(Floor Mounted

Vanities)

75mm Coach

Screws

(Wall Hung

Vanities)

3

WALL HUNG VANITY INSTALLATION

Mark the height (from 800mm to 900mm - owners choice) and locate top and bottom

frame points to secure the unit.

FASTENING TO THE WALL: A wall hung vanity needs solid fixing for attachment to the

wall. Provide this prior to fixing the wall lining. In some cases, existing framing may be

sufficient (Fig 1).

1

2

For installation of pipes it is easier to remove the doors and the drawers. Store them

carefully and number their locations (drawer removal and reinstall, page 5).

3

Mark and drill holes required for the water and waste fittings.

4

Support the unit level at the desired height. Fasten into the frame with 75mm coach

screws. Ensure no distortion occurs when fastening as this effect draw alignments. The

height adjustment disc (Page 5) offers a little adjustment.

5

Install the plumbing fittings to meet industry standards. Water test the fittings. Use a

registered plumber to complete this task.

6

Fit the top in place. This should be flush at the back with even overlaps on each side.

Check for any rocking movement to the cabinet (mostly applies to VC tops). Support this

movement and apply a bead of silicone to bond these together (Note: There is a 5mm

tolerance in VC tops).

7

SEAL ALL JOINS OF UNIT WITH SILICONE: Vanity top onto cabinet, top and cabinet

to wall and any joints susceptible to water penetration. To achieve an even and tidy finish

use masking tape each side of the join.

9

Replace and adjust the doors and drawers. Reference Page 5 if “Soft Close” needs

reactivating.

8

DO NOT USE FOR 24 HOURS UNTIL SILICONE BOND HAS CURED.

Fig 1

NOTE: Warranty claims will be invalid if water damage occurs after installation.

4

FLOOR STANDING VANITY INSTALLATION

Check the walls and floors are plumb, level and flat. Take remedial action or compensate

for existing discrepancies in the installation process.

1

Locate the necessary framework in the wall to fasten the cabinet securely.

2

For installation of pipes it is easier to remove the doors and the drawers. Store them

carefully and number their locations (drawer removal and reinstall, page 5).

3

Screw through the cabinet back panel to wall framing. Ensure no distortion occurs when

fastening as this effect draw alignments. The height adjustment disc (Page 5) offers a little

adjustment.

4

Fit the top in place. This should be flush at the back with even overlaps on each side.

Check for any rocking movement to the cabinet (mostly applies to VC tops). Support this

movement and apply a bead of silicone to bond these together (Note: There is a 5mm

tolerance in VC tops).

5

Install the plumbing fittings to meet industry standards and water test the fittings. Use a

registered plumber to complete this task.

6

Replace and adjust the doors and drawers. Reference Page 5 if “Soft Close” needs

reactivating.

7

SEAL ALL JOINS OF UNIT WITH SILICONE: Cabinet to floor, upstand to wall, cabinet

and top to wall and any joints susceptible to water penetration. To achieve an even and

tidy finish use masking tape each side of the join.

8

DO NOT USE FOR 24 HOURS UNTIL SILICONE BOND HAS CURED.

NOTE: Warranty claims will be invalid if water damage occurs after installation.

5

REMOVAL OF DRAWER

FOR SPECIFICATIONS PLEASE GO TO NEWLINE.CO.NZ

2

3

In production there has been two means of fastening the sliding rails to end of draw.

1. Option A - a small countersunk screw is used as indicated on drawing.

2. Option B - if no screw is in place slide both plastic lugs to centre to release.

3. Lift drawer up to clear front pin location.

4. Carefully pull draw forward and out.

REINSTALL DRAWER

To reinstall drawer, make sure front and rear pins are

engaged. Then reposition lugs into draw body.

Note: if drawer stops short of closing, this is due to

the “soft close” mechanism needing reactivation.

Push the drawer shut gently until it clicks. The soft

close should now be fully active.

Height adjustment disc

under this bracket.

OPTION B

OPTION A

OPTION B

OPTION A

6

AFTERCARE INTRUCTIONS: VANITIES

To comply with warranty requirements, please ensure the following aftercare procedures are

regularly performed. Failure to comply to Warranty Aftercare Instructions will void warranty.

VITREOUS CHINA BASINS AND VANITY TOPS

• Use warm soapy water or mild detergent and a soft or microfiber cloth. Rinse with clean

water. This must be done on a weekly basis or more often when needed.

POLYMARBLE VANITY TOPS

• Use warm soapy water and a clean microfiber cloth followed by drying off with absorbent

cloth. This must be done on a weekly basis or more often when needed.

• For minor scuffs on the surface use plastic polish.

• Scratches: If this is minimal use as the process for minor scuffs but in the case of a deeper

scratch start with 2000 grit wet and dry paper. Use this wet to take out most of the scratch

following on with plastic polish to finish. Note: Deep scratches and chips are best left to a

specialised repairer.

VANITY CABINETS

• Laminated or lacquer painted surfaces are water resistant. However constant and excessive

exposure to water will enter joins in the assembly and the subsequent damage will be

irreversible.

• Ensure the water pressure is regulated and balanced to the size of the basin to control water

splash.

• The water temperature must be at a maximum of 55 degrees Celsius.

• The waste connections have been correctly installed by a licenced plumber.

• Any joins in the cabinet that are susceptible for water ingress must be sealed with silicone

including cabinet to wall.

• The bathroom must have a suitable ventilation system to remove moisture vapour.

• All cleaning of surfaces: Use a damp microfiber cloth with warm soapy water followed up by

drying off with an absorbent cloth.

• Do not use abrasive or aggressive cleaners.

• Installation must comply with instructions to be under warranty.

• Always wipe up any spills immediately.

GENERAL

• A list of chemicals to avoid contact with the surfaces of your product: hair dyes or lacquers,

mineral turps, white spirits, insecticides, nail polish or cleaner, bleaches, shoe polish,

mercurochrome, iodine, solvents, alcohol, citrus based chemicals, bath oils, bath salts,

kerosene. This is by no means comprehensive but indicative of chemical harm that must be

avoided.

For further details please refer to the warranty details, available at www.newline.co.nz

3 Hynds Road, Greerton, Tauranga 3112

P: 0508 639 5463 | 09 444 2053

www.newline.co.nz

Table of contents

Other NewLine Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual