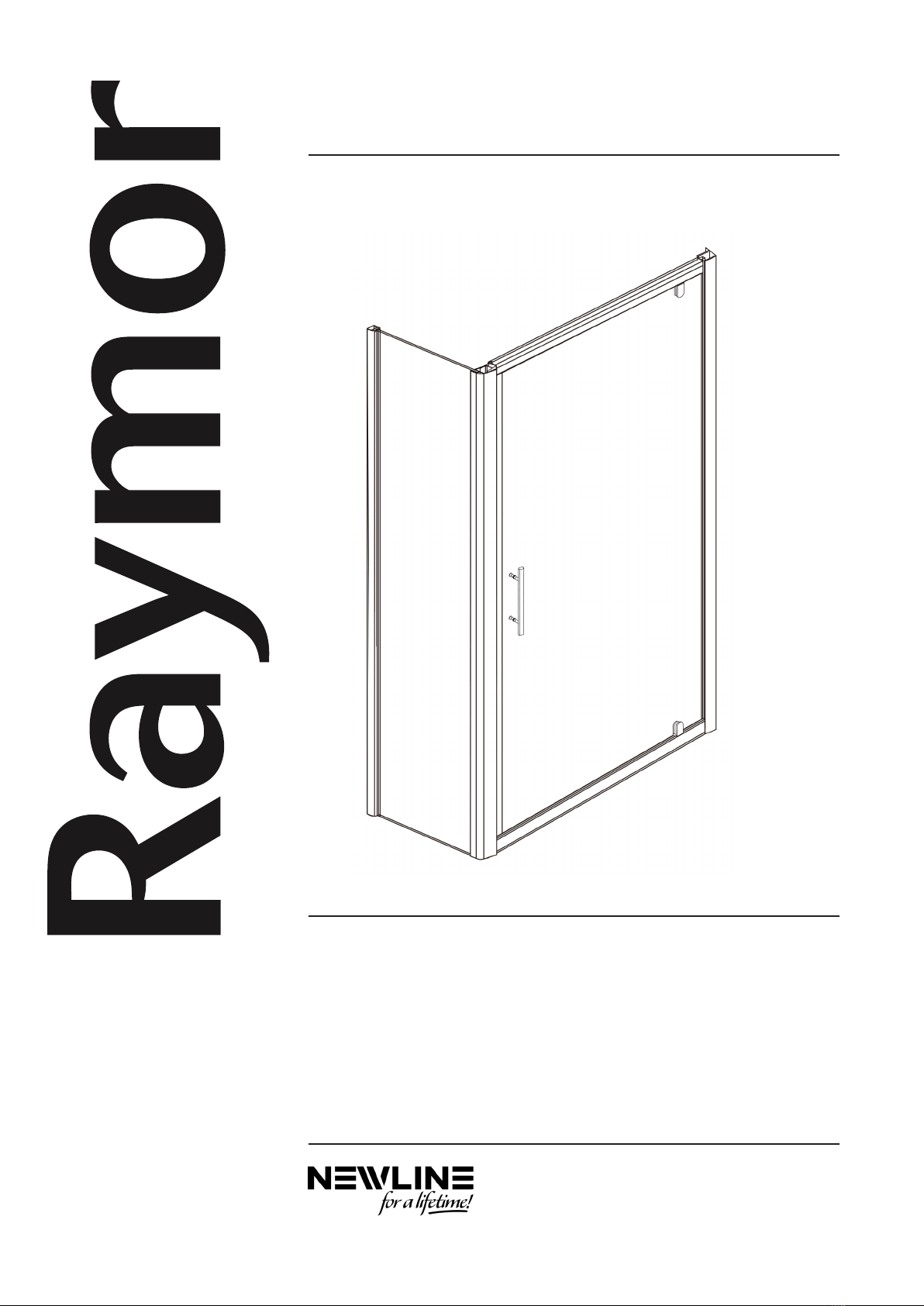

NewLine RAY900CHR-PIVOT User manual

PIVOT DOOR SET

INSTRUCTION MANUAL

PRODUCT CODES:

RAY900CHR-PIVOT

RAY900WHT-PIVOT

RAY1000CHR-PIVOT

INSTRUCTION MANUAL VERSION: 16/0003

RAY1000WHT-PIVOT

RAY1200CHR-PIVOT

RAY1200WHT-PIVOT

Newline Group Limited

Freephone 0508 639 5463 | www.newline.co.nz

PLEASE READ THROUGH AND UNDERSTAND ALL INSTRUCTIONS BEFORE

INSTALLATION AND USE.

The Raymor Pivot Door Set can be installed as a 2-Sided shower enclosure or

installed as a door only option for an Alcove (3-Sided) shower. This instruction

manual contains information on installing both 2-Sided and Alcove shower

enclosures. Please ensure you are referring to the correct Layout Procedure and

installation steps for your shower conguration before commencing installation.

CONTENTS PAGE

Important Information ... 1

Preparation Checklist ... 2

Supplied Components / 900 and 1000 Showers ... 3

Supplied Components / 1200 Showers ... 4

Layout Procedure / 2-Sided Congurations ... 5

Installation Steps / 2-Sided Congurations ... 6

Layout Procedure / Alcove (3-Sided) Congurations ... 8

Installation Steps / Alcove (3-Sided) Congurations ... 9

Newline Group Limited | Freephone 0508 639 5463 | www.newline.co.nz

CONTENTS

Page 1

Raymor Showers / Pivot Door Set

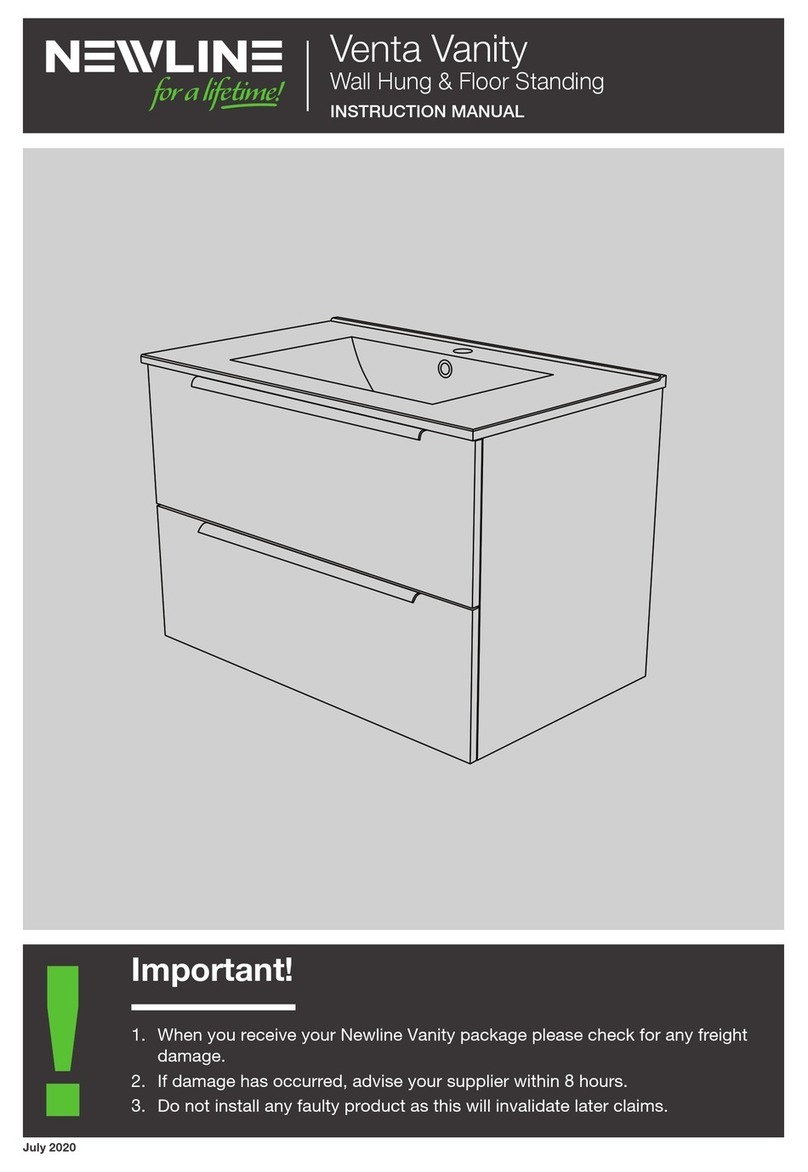

PIVOT DOOR SET / Important Information

IMPORTANT

Firstly check all items have been received.

If there is freight damage damage, faults or an incorrect component supplied advise your

supplier within 12 hours. Do not proceed with installation as this will invalidate any claims.

WARRANTY

Faulty goods are covered under warranty. Visit www.newline.co.nz for warranty information.

Breakages incurred during installation are not covered under warranty.

HEALTH AND SAFETY

Toughened Glass:

• Do not rework precut glass panels. Cutting or altering a glass panel will cause it to

explode without warning.

• Unpack all glass assemblies. Stand glass on soft packaging when it is on the oor

and against a wall. Care must be taken not to strike any edge or corner against a hard

surface as this will chip and destroy the glass panel.

Installation:

• Glass panels and assemblies are heavy. Two man lifting is recommended for handling

and installation.

• Determine positioning of wiring and piping within wall cavities before shower installation.

Mark their positions to ensure electrical and piping areas are avoided.

• Wear appropriate protective clothing and eye protection during installation.

TOOLS REQUIRED

Spirit Level Soft pencil Masking Tape

Electric Drill and Bits Tape measure

Square headed Screwdrivers Cleaning Materials and Rags

MATERIALS REQUIRED

Sika Silaex NG translucent Silicone.

AFTERCARE

The shower must be thoroughly cleaned weekly with a microber cloth, mild detergent and

water. Rinse with clean water and squeegee and wipe dry. Note: Glass panels are factory

pretreated with EnduroShield glass coating protection. Please visit enduroshield.com to

register your warranty and view cleaning and warranty requirements.

WE RECOMMEND THAT A PROFESSIONAL SHOWER INSTALLER IS USED FOR

INSTALLATION OF THIS PRODUCT TO ENSURE THE VERY BEST OUTCOME

Page 2

Raymor Showers / Pivot Door Set

PROJECT MANAGEMENT / Preparation Checklist

ENSURE YOU TICK THE SPECIFIC BOXES THAT APPLY AS YOU PROGRESS

2 Sided Shower: Ensure the oor is level and the walls are plumb and at.

Position all framing for solid xing for the shower tray, shower and plumbing ttings

(refer to the specic tray, liner and shower instruction manual at www.newline.co.nz).

Ensure all plumbing items have been installed prior to the lining being attached.

Alcove Shower: Critical that the walls are constructed plumb and at within the

specications of the specic shower being installed.

ACRYLIC TRAY AND LINER OPTION

• Detailed installation instructions are packed with the shower tray for tray and lining

installation.

• Shower waste and supply ttings must be installed by a registered plumber.

TILE INSTALLATION OPTION WITH STANDARD PROFINISHTM TILE TRAY

• The “ProFinishTM Tile Tray” must be installed as per the ProFinishTM installation

instructions with the packaged product.

• The leak proof waste and supply ttings must be installed by registered plumber.

• Waterproong must be undertaken by certied applicator and a Producer Statement

provided. There is a list of 14 proven systems listed in the back of these instructions.

• Tiling:

1. Manufacturers waterproong cure times must be adhered to.

2. The notched trowel lines for the tile mortar must be vertical on walls & leading to the

waste outlet on the oor.

3. Ensure tiles are laid according to the falls in the tray.

4. The boundary line where the shower screen sits must be level.

5. Tile adhesive cure times must be allowed before commencing shower installation.

Page 3

Raymor Showers / Pivot Door Set

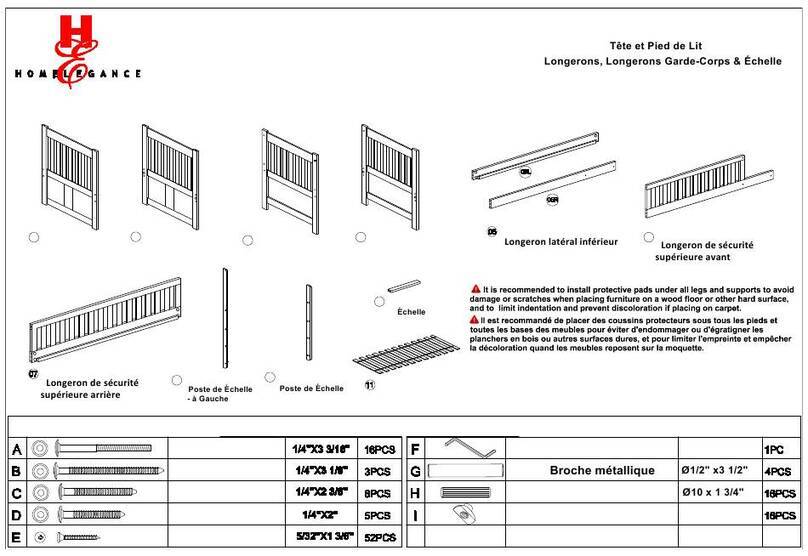

PARTS LIST / 900 and 1000 Showers

Ref Description Parts Number Qty

2 Wall Posts 2

3 Screws M4x35mm FASTE 16

4 Screws M4x8mm 12

5 Screw Cover Caps 20

6 Return Panel 1

7 Bottom Horizontal Rail 1

8 Pivot 2

9 Top Horizontal Rail 1

10 Door Panel 1

11 Handle Set 1

12 Bottom Door Gasket 1

13 Posts 2

14 Magnectic Door Strip 1

FASTENING PACK

Page 4

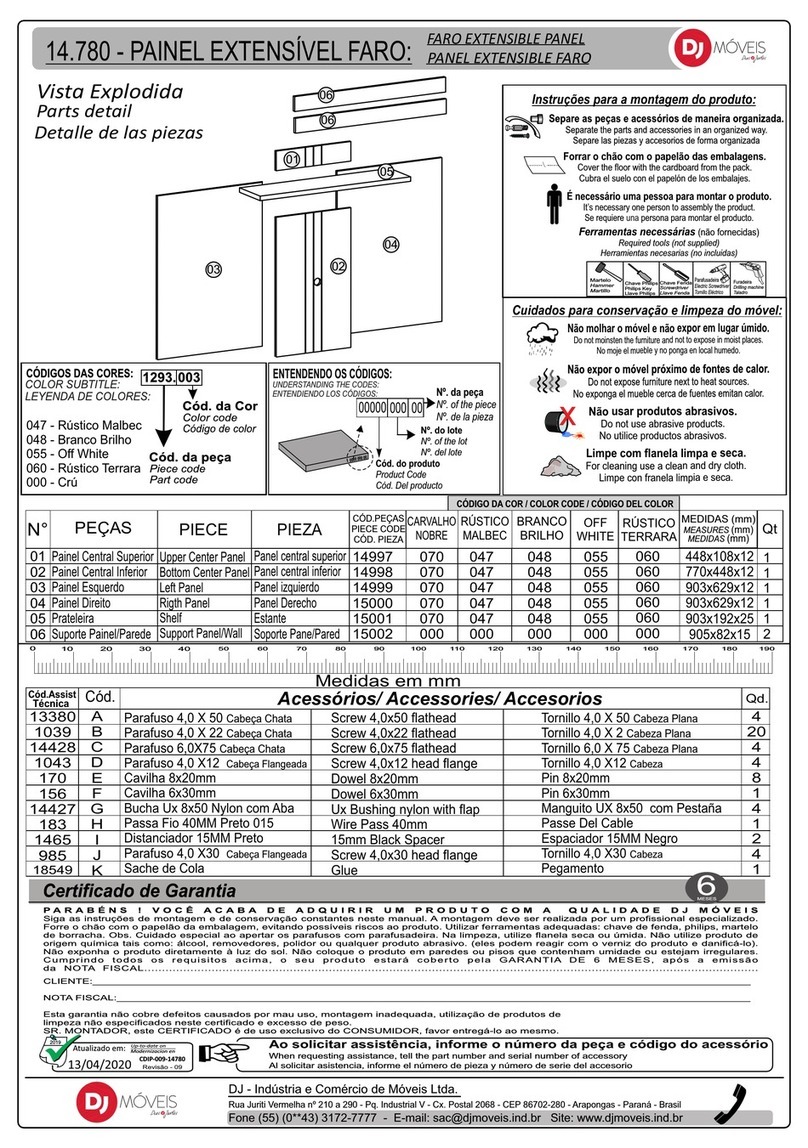

Raymor Showers / Pivot Door Set

PARTS LIST / 1200 Showers

Ref Description Parts Number Qty

2 Wall channels 2

3 Screws M4 x 35mm 8

4 Screws M4 x 8mm 12

5 Screw cover caps 12

6 Return panel 1

7 Bottom horizontal rail 1

8 Pivot 2

9 Top horizontal rail 1

10 Door panel 1

11 Handle set 1

12 Bottom door gasket 1

13 Fixed panel 1

14 Screws M4 x 10mm 2

15 Glass clamp 2

16 Door post 1

17 Magnetic Door Seal Strip 1

[17]

FASTENING PACK

Page 5

Raymor Showers / Pivot Door Set

LAYOUT PROCEDURE / 2Sided Conguration

Shower Type Door Assembly Return Panel

900mm x 900mm 855mm (min) to 875mm (max) 855mm (min) to 875mm (max)

1000mm x 1000mm 955mm (min) to 975mm (max) 955mm (min) to 975mm (max)

1200mm x 900mm 1155mm (min) to 1175mm (max) 855mm (min) to 875mm (max)

22mm

A

A

OTHER APPLICATIONS

This table is for shower installations outside of the package installation being outlined.

MINIMUM TO MAXIMUM GUIDE

ACRYLIC TRAY APPLICATION

• It is recommended that the position of the wall channels

is 22mm o the tray edge (refer Diagram A). This

measurement will allow for walls out of plumb up to

8mm.

• Greater variances to plumb than 8mm at the wall must

be assessed and adjusted because this impacts on the

boundary line.

• Equalize door and return panel on the nal marking out.

PROFINISHTM TILE TRAY WITH HOB APPLICATION

• The desired position for the boundary line is

approximately in the centre of the hob to 5mm

inwards.

• Adjust the boundry line to t using the minimum to

maximum guide.

• Variances to plumb at the wall must be assessed and

adjusted because this impacts on the boundary line.

22mm

Page 6

Raymor Showers / Pivot Door Set

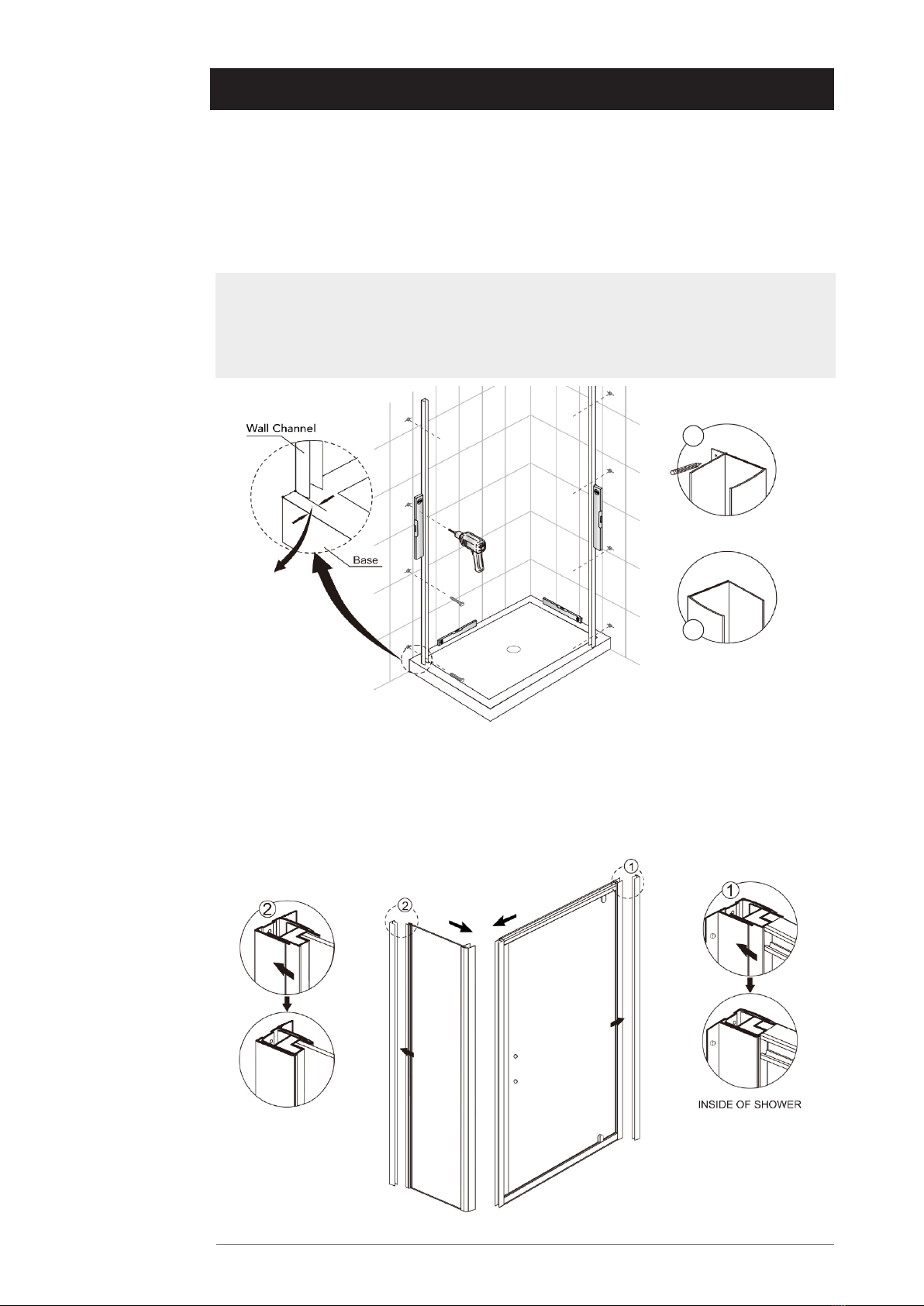

INSTALLATION STEPS / 2Sided Conguration

STEP 1

1. Referring to the Assembly Layout Plan (Page 5), set up and plumb Wall Channels on

boundary line.

2. Apply silicone to back of wall channels and fasten to the wall ensuring that they remain

plumb.

Tiling Note: Some authorities do not allow the waterproof layer to be penetrated. In this

instance we recommend using Bostik V60 to x Wall Channels. Allow to cure as per

manufacturers instructions before proceeding with shower installation.

STEP 2

Slide door assembly and Return Panel into the Wall Channels. Place the two panel

assemblies together at the corner.

2

1

Page 7

Raymor Showers / Pivot Door Set

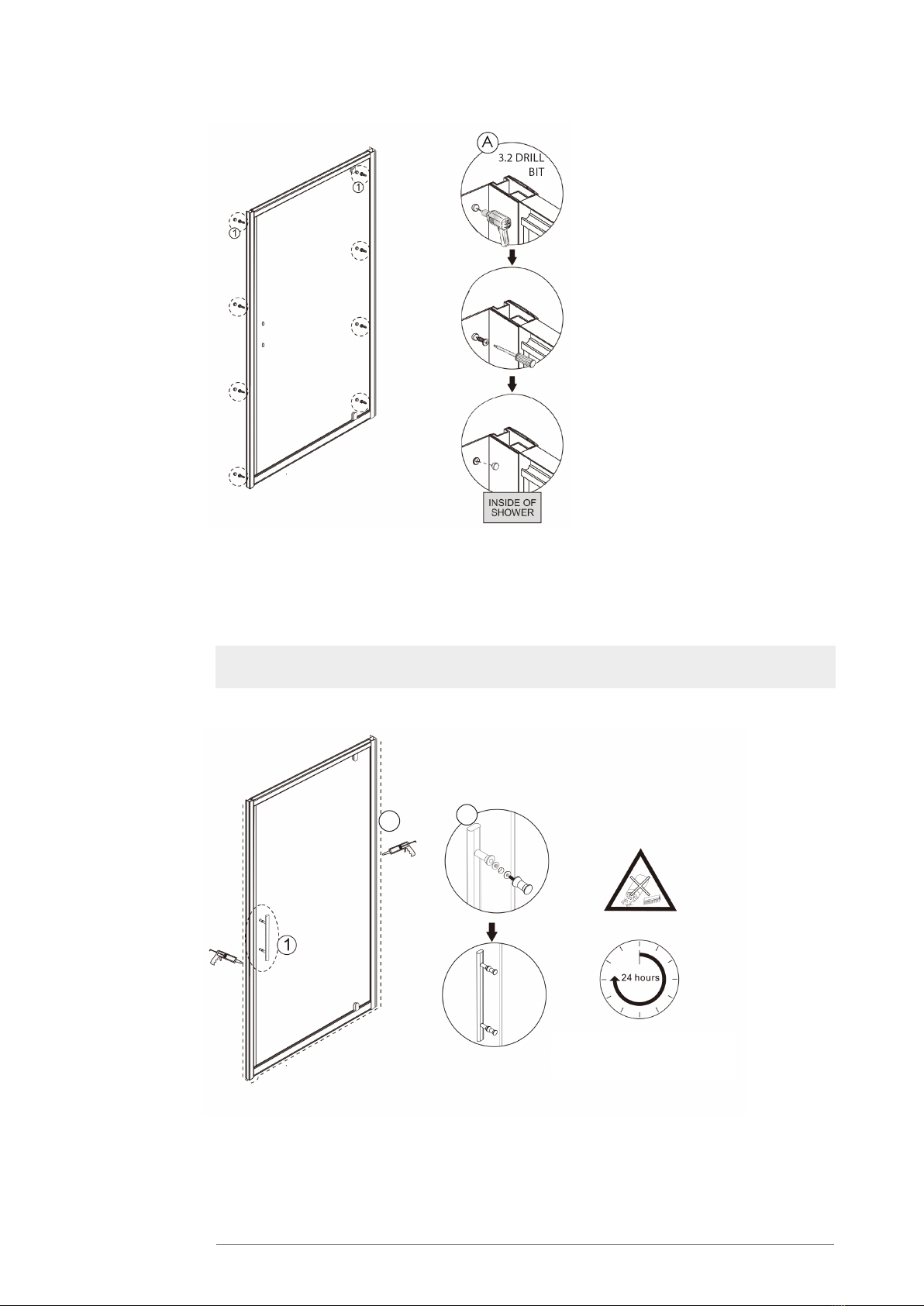

STEP 3

1. Adjust the Door and Return Panels evenly on the tray and into the Wall Channels.

2. Bring the corner joint together and drill and fasten this point (A1, A2 and A3).

3. Align the Door Assembly and Return Panel evenly to the walls and tray.

4. Square up the door frame and door and ensuring the magnetic door catch is in line.

5. Fasten as detail in diagram below (B1, B2 and B3).

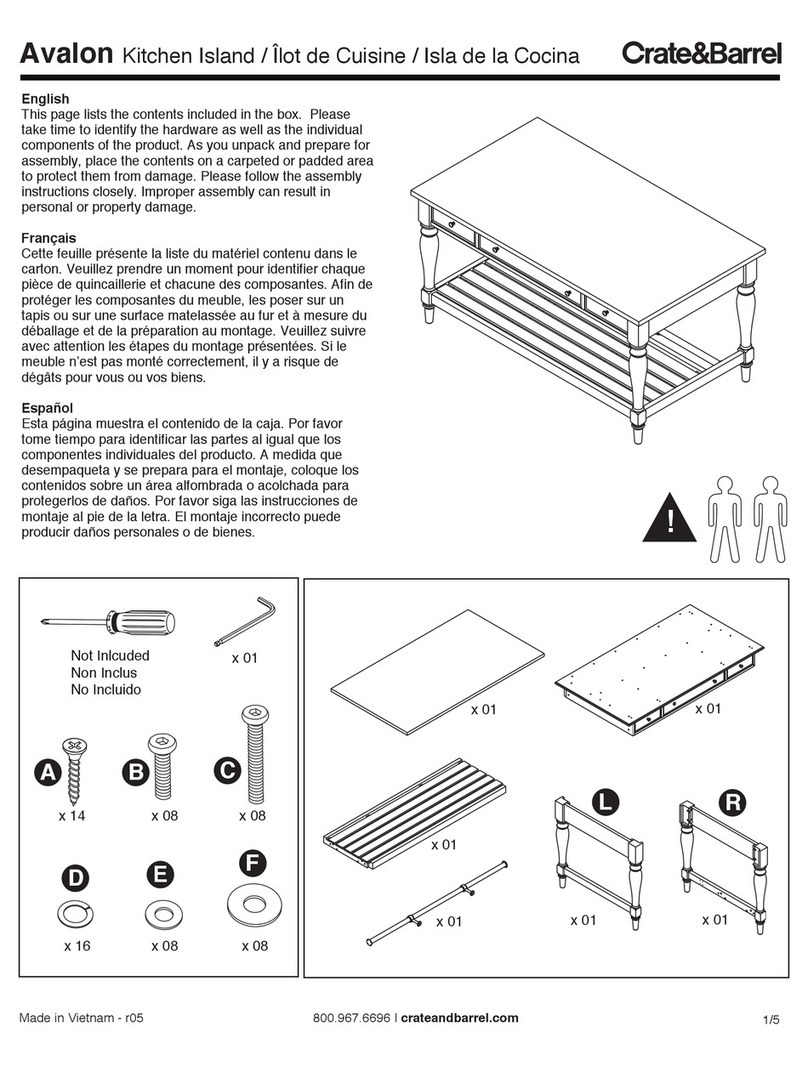

STEP 4

1. Fasten the handle in place (A).

2. Apply silicone to the outer boundaries as indicated with dotted lines (B).

Note: Sealing on the inside of the shower will void the warranty.

ALLOW 24 HOURS FOR

SILICONE TO DRY BEFORE

USE

A

B

3.2 DRILL

BIT

A1 B1

A2 B2

A3 B3

A

B

B

Page 8

Raymor Showers / Pivot Door Set

LAYOUT PROCEDURE / Alcove Conguration

Shower Door Minimum Maximum

900mm x 900mm 842mm 882mm

1000mm x 1000mm 942mm 982mm

1200mm x 900mm 1142mm 1182mm

ProFinishTM Tray ProFinishTM Tray Sizes

900 Tray 885mm (W) x 900mm (D)

1000 Tray 985mm (W) x 1000mm (D)

1200 Tray 1185mm (W) x 900mm (D)

OTHER APPLICATIONS

This table is for shower installations outside of the package installation being outlined.

MINIMUM TO MAXIMUM GUIDE

ACRYLIC TRAY APPLICATION

• Frame to precisely t the specic tray you are using.

• Mark out the outside boundary line at 15mm in from the

outside of the tray. Plumb up the walls.

PROFINISHTM TILE TRAY WITH HOB APPLICATION

• Standard Raymor Pivot Alcove“ProFinishTM Tray” sizes

detailed in the table below.

• The table below provides the nished measurement of

the framed and lined Alcove with GIB Aqualine® 10mm

or similar wall board.

• Mark the outside boundary line at the centre position on

the hob of the installed and tiled ProFinishTM Tray.

Dotted Line

Indicates Outside

Boundary

Page 9

Raymor Showers / Pivot Door Set

INSTALLATION STEPS / Alcove Conguration

STEP 1

1. Mark out the Wall Channels up the wall as indicated to establish the outside boundary line.

Tiling Note: Some authorities do not allow the waterproof layer to be penetrated. Use Bostik V60

to x Wall Channels and allow to cure as per manufacturers instructions.

STEP 2

1. Slide the Wall Channels onto each side of the door assembly.

2. Install the door assembly complete with Wall Channels into position.

3. Apply silicone to the back of the Wall Channels and fasten at the boundary line.

4. Even out the door frame within each wall channel.

5. Square up the door frame, door and ensure the magnetic door catch is in line.

15mm

Wall Channel Final Position

Page 10

Raymor Showers / Pivot Door Set

STEP 3

Drill and fasten as detail (A)

STEP 4

1. Fasten the handle in place (A1).

2. Apply silicone to the outer boundaries as indicated by dotted line (A2).

Note: Sealing on the inside of the shower will void the warranty.

3.2 DRILL

BIT

ALLOW 24 HOURS

FOR SILICONE TO DRY

BEFORE USE

A1

A2

This manual suits for next models

5

Table of contents

Other NewLine Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

OriginLiving

OriginLiving Ultimate Setup Gaming Desk manual

Crate&Barrel

Crate&Barrel Avalon manual

BluDot

BluDot Woodrow Bed Assembly notes

Twoey inside

Twoey inside Reading Corner Seat 1 4050 Assembly instructions

DHP

DHP 4188439WE manual

Hillsdale Furniture

Hillsdale Furniture Brandi Youth JR Loft 2001 Assembly instructions