10

Head Oce: 3 Hynds Road, Greerton, Tauranga 3112

Freephone: 0508 639 5463 Phone: 09 444 2053 Fax: 09 443 0044

www.newline.co.nz

COMPANY PRIMER PRODUCTS CONTACT WARRANTY

ARDEX Prep: Wipe down with

damp cloth - No primer

1. ARDEX WPM 155 Rapid

(1 Part Poly- Acrylic)

2. Ardex Superex WPM 002 (2Part)

3. ARDEX WPM 750 WeldTec

Undertile Sheet Membrane*

Ronald Rose 027 838 5691

15years

*20years

DAVCO

Tilemax Ltd

Davco Primex 1. Davco K10 Plus - Polyurathane

(Coat Primex within 24 hrs)

2. Davco K10 Rapid

Isaac Gordan 022 127 7694

15 years

DRIBOND

CONSTRUCTION

CHEMICALS

Primax Bonding slurry -

Kemcrete mixed 50/50

with cement or Gripex

1. Hydrathane

2. Liquid Flash 2- Pack

3. Reomat b/breaking Tapes

Steve Plester 022 1205416

15years

LADICRETE

GLOBAL TILE

Prep: as instructions

No Primer

Hydro Ban SBR Chris Anderson 021 784 162

15years

MAPEI Ecoprim Grip (1part)

Magelastic SP (2 part)

1. Mapelastic AquaDefence

2. Mapegum WPS

3. Mapelastic Smart (2part)

Heidi Clark 027 6455 122

15 years

SIKA (NZ) Per Instructions Sikalastic-152 Andy Williams 09 820 2900

021 421 084

15 years

Tiling Trade

Supplies

T/A Technokolla NZ

Prep: Clean and Vac

surface.

Technokolla 101

1. Technokolla RL80 SeamTape joins

Rasolastic Advance. Two Part

2. Strataex & Rasogum over laps

Dave Boyes 0275 635 891

15 years

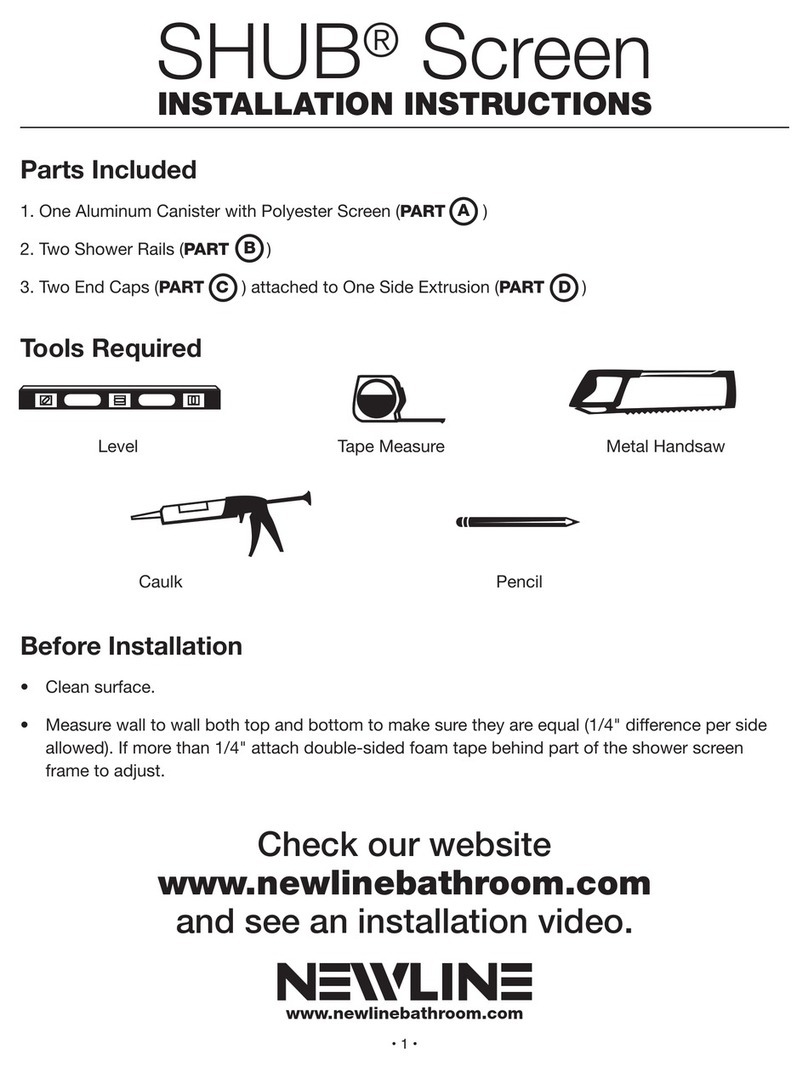

WATERPROOFING

• The Independent Waterproong Companies listed below have tested their systems and

procedures on Newline Pronish Tile Trays. This represents years of proven track record.

• At the time of publication all Waterproong Systems hold a BRANZ Appraisal.

• All the Waterproong Systems listed have an aligned Tiling Systems. You must use the associated

Waterproong & Tiling system for compatibility, performance and accountability.

• A Producer Statement must be provided to the Council Authority and Owner detailing the

Waterproong applicator ID or Code. As an appendage also include the tiling system utilised.

• Applicators must be trained and hold current Accreditation with the respective system being

utilised for the Warranty to be valid. We advise you to ask for these credentials.

• Newline warrants the performance and integrity of the Pronish Tile Shower Base for 20 years.

Non-conformity to installation instructions has the risk of failure.

• All Waterproong and Tile Installation must be installed as per manufactures Specications as any

deviation from the instructions may result in a performance failure.

• All Tiling must follow BRANZ Good Tiling Practice.

Tile Tray Waterproong

* This document is current as of 9 May 2018.