Newport Electronics INFINITY MICRO-INFINITY ICN77000 Series User manual

Counters

Frequency Meters

PID Controllers

Clock/Ti ers

Printers

Process Meters

On/Off Controllers

Recorders

Relative Hu idity

Trans itters

Ther ocouples

Ther istors

Wire

Rate Meters

Ti ers

Totalizers

Strain Gauge Meters

Volt eters

Multi eters

Soldering Iron Testers

pH Pens

pH Controllers

pH Electrodes

RTDs

Ther owells

Flow Sensors

NEWPORT Electronics, Inc.

®

Additional Products fro

THE NEW STANDARD FOR QUALITY

It is the policy of NEWPORT to co ply with all worldwide safety and EMC/EMI regulations that apply. NEWPORT is constantly pursuing certification of its products to the

European New Approach Directives. NEWPORT will add the CE ark to every appropriate device upon certification.

The infor ation contained in this docu ent is believed to be correct but NEWPORT Electronics, Inc. accepts no liability for any errors it contains, and reserves the right to

alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

TRADEMARK NOTICE:

a

®

,,, newportUS.com, , , , , and

the “Meter Case Bezel

Design”

are trade arks of NEWPORT Electronics, Inc.

PATENT NOTICE: The “Meter Case Bezel Design” is a trade ark of NEWPORT Electronics, Inc., registered in the U.S. This product is covered by one or ore of the following

patents: U.S. Pat. No. D336,895; 5,274,577/ FRANCE BREVET No. 91 12756/ UK PATENT No. GB2 248 954; GB2 249 837/ SPAIN 2039150; 2048066/ ITALY 1249456;

1250938/ CANADA 2052599; 2052600/ GERMANY DE 4134398 C2. OTHER U.S. AND INTERNATIONAL PATENTS PENDING OR APPLIED FOR.

NEWPORT

®

NEWPORT

®

This device is arked with the international caution sy bol. It is i portant to read the Setup Guide before installing or co issioning this device as it contains i portant

infor ation relating to safety and EMC.

For Immedi te Assist nce

In the U.S.A. nd C n d : 1-800-NEWPORT

®

In Mexico: (95) 800-NEWPORT

SM

Or c ll your loc l NEWPORT Office.

Internet e-m il

NEWPORTnetSM On-Line Service

www.newportUS.co

Downloaded from Elcodis.com electronic components distributor

To Order Model ICN77000 SERIES CONTROLLER (Specify Model Number)

PROCESS CONTROLLER, DUAL DISPLAY FOR THERMOCOUPLE, RTD, VOLTAGE OR CURRENT INPUTS IN A 1/16 DIN CASE

Ordering Ex mples:

1.) ICN77R322-C2 is a NEMA 1 bezel case with 1.75 inch round hole ounting adaptor, dual SSR control outputs and RS232 co unications output.

2.) ICN77330 is a NEMA 12 bezel case with 1/16 DIN ounting and single Relay control output.

3.) ICN77544-A2 is a NEMA 4 bezel case with 1/16 DIN ounting, dual pulse control outputs, and a SPST 3A Alar relay.

Model No. Description

ICN77 Dual displays for si ultaneous display of easured value and setpoint.

Selectable preset tune, adaptive tune, autotune, PID, PI, PD control odes. The

dual control outputs can be configured for a variety of control and alar

applications such as heat, heat/cool, heat/alar , cool or cool/alar . The ra p to

setpoint feature allows the user to define the rate of rise to setpoint, ini izing

ther al shock to the load during start-up. Maxi u ra p ti e 99.59 (HH.MM),

Soak: 00.00 to 99.59 (HH.MM),Da ping: 1 to 8 in unit steps. Input types

J,K,T,E,R,S,B,N,J-DIN°C, RTD 100Ω 0.00385, 100Ω & 1kΩ 0.00392, 0 to 20 A,

4 to 20 A, 0 to 100 V, 0 to 1V, 0 to 10Vdc. Alar 1 output includes SPST relay,

3A @ 120Vac, 3A @ 240Vac.

NOTE: The Controller ust be ordered co pletely configured. Options are not field installable.

[ ] CASE TYPE

R3 NEMA 1, 1.89 x1.89" (48 x 48 ) bezel and 1.75" ROUND cutout

R5 NEMA 1, 2.1 x 2.1" bezel and 1.75” ROUND cutout

3 NEMA 12 bezel for

1

/

16

DIN panel cutout 45 x 45 (1.772 x 1.772")

5 NEMA 4 bezel for

1

/

16

DIN panel cutout 45 x 45 (1.772 x 1.772")

[ ] CONTROL OUTPUT #1 (Direct or Reverse Acting)

2 Solid State Relay SSR : 1A @ 120/240Vac continuous

3 Relay: For “C” 5A @ 120Vac, 3A @ 240Vac

4 Pulsed 10Vdc @20 A (for use with external SSR)

5 Non-Isolated 1 to 10Vdc or 0-20 A @500Ω ax

[ ] CONTROL OUTPUT #2 (Direct or Reverse Acting)

0 Insert “0” if second output is not desired

2 Solid State Relay SSR: 1A @ 120/240Vac continuous

3 Relay: For “C” 5A @ 120Vac, 3A @ 240Vac

4 Pulsed 10Vdc @20 A (use for external SSR)

Model No. Description cont.

[ ] OPTIONAL OUTPUTS

*none (no entry required)

-A2 SPST relay, 3A@ 120Vac, 3A @ 240Vac (Alar 2)

-C2 Isolated RS232, 300 to 19.2k baud

-C4 Isolated RS485, 300 to 19.2k baud

-PV Isolated Analog Output

-RSP Re ote Setpoint Selection

[ ] POWER SUPPLY

*90 to 240 Vac/dc, 50 to 400Hz (no entry required)

NEMA 1/UL Type 1: Intended for indoor use, to provide a degree of

protection against contact with the enclosed equip ent and against li ited

a ount of falling dirt.

NEMA 4/UL Type 4: Intended for indoor use, to provide a degree of

protection against splashing water, windblown dust and rain, and hose

directed water and unda aged by the for ulation of ice on the enclosure.

Testing-Hosedown:Enclosure is subjected to a strea of water fro a

hose which has a 1" dia eter nozzle and which delivers at least 65 gallons

per inute fro a distance of 10 to 12 feet for a ini u of 5 inutes.

NEMA 12/UL Type 12: Intended for indoor use, to provide a degree of

protection against circulating dust, falling dirt, and dripping non-corrosive

liquids. Testing-Drip:Enclosure is subjected to a drip pan which produces

both splashing and dripping. Testing-Atomized ater:Enclosure is

subjected to a spray of ato ized water by using a nozzle that produces a

3" round dia eter spray, 12" fro enclosure. The air pressure is at 30psi.

For harsh environ ents, we reco end installation of the controller for

square panel cutouts.

Downloaded from Elcodis.com electronic components distributor

P rt 1: Introduction

1.1 S fety Consider tions .........................................................................1

1.2 Before You Begin..................................................................................2

P rt 2: Setup

2.1 Mounting the Controller.......................................................................4

2.2 Front P nel View ..................................................................................7

Front Panel Annunciators.......................................................................7

2.3 Re r P nel View....................................................................................8

Rear Panel Connector Labels ................................................................9

2.4 Mech nic l Inst ll tion ......................................................................10

Dip Switch Configuration ......................................................................10

Dip Switch Settings...............................................................................11

2.5 Electric l Inst ll tion .........................................................................12

Input Connection Examples .................................................................13

2.5.1 Ther ocouple.......................................................................................13

2.5.2 Two/Three/Four Wire RTD ...................................................................14

2.5.3 Process Current ...................................................................................15

2.5.4 Process Voltage ...................................................................................15

T

ABLE OF

C

ONTENTS

i

Downloaded from Elcodis.com electronic components distributor

P rt 3: Oper tion: Configur tion Mode

3.1 Introduction........................................................................................16

Turning Your Controller on for the First Time .............................................16

Function in Configuration Mode................................................................17

3.2 Menu Configur tion...........................................................................18

ID Number .............................................................................................19

Set Points ..............................................................................................20

Input Type (Thermocouple) ......................................................................24

Input Type (RTD) ....................................................................................25

Input Type (RTD Value)...........................................................................26

Input Type (Process) ...............................................................................27

Reading Configuration.............................................................................29

Alarm 1..................................................................................................33

Alarm 2..................................................................................................36

Loop Break Alarm...................................................................................38

Output 1 ................................................................................................42

Output 2 ................................................................................................52

Ramp & Soak.........................................................................................58

3.3 Av il ble Options...............................................................................60

Analog Output Option..............................................................................61

Communication Option............................................................................64

T

ABLE OF

C

ONTENTS

ii

Downloaded from Elcodis.com electronic components distributor

T

ABLE OF

C

ONTENTS

iii

Configur tion Mode Cont.

Command Formats ...........................................................................................................72

Reading Scale .............................................................................................................................86

Reading Offset .................................................................................................................87

Remote Setpoint Option ....................................................................................................88

P rt 4 Specifc tions

.........................................................................................91

List of Figures

Figure 2.1 a. — Mounting the Square Mount Controller .................................................................5

Figure 2.1 b. — Mounting the Round Mount Controller ..................................................................6

Figure 2.2 — Front Panel Display ...................................................................................................7

Figure 2.3 — Typical Rear Connector Label and Possible Labels of Different Models ..................8

Figure 2.4 — Dip Switch Location.................................................................................................10

Figure 2.5.1 — Power Wiring Hookup...........................................................................................12

Figure 2.5.2 — Ther ocouple Wiring Hookup..............................................................................13

Figure 2.5.3 — Two-wire RTD Hookup, Three-Wire RTD Hookup, Four -Wire RTD Hookup ......14

Figure 2.5.4 — Process Current Wiring Hookup...........................................................................15

Figure 2.5.5 — Process Voltage Wiring Hookup...........................................................................15

Figure 3.1 — Flowchart for ID and Set Point Menus ....................................................................18

Figure 3.2 — Flowchart for Input Type..........................................................................................23

Figure 3.3 — Flowchart for Reading Configuration.......................................................................28

Downloaded from Elcodis.com electronic components distributor

List of Figures Cont.

Figure 3.4 — Flowchart for Alar 1 and Alar 2..........................................................................32

Figure 3.5 — Flowchart for Loop Break ........................................................................................37

Figure 3.6 — Flowchart for Output 1.............................................................................................41

Figure 3.7 — Flowchart for Output 2.............................................................................................51

Figure 3.8 — Flowchart for Ra p & Soak ....................................................................................57

Figure 3.9 — Flowchart for Analog Output Option ........................................................................61

Figure 3.10 — Flowchart for Co unication Option....................................................................64

Figure 3.11 — Flowchart for Re ote Setpoint..............................................................................88

List of T bles

Table 3.1 — Co unication Co ands..................................................................................... 72

Table 3.2 — Co and Letters and Index .................................................................................. 76

T

ABLE OF

C

ONTENTS

iv

Downloaded from Elcodis.com electronic components distributor

1.1 S fety Consider tions

This device is arked with the international caution sy bol. It is

i portant to read this anual before installing or co issioning

this device as it contains i portant infor ation relating to Safety

and EMC (Electro agnetic Co patibility).

This instru ent is a panel ount device protected in

accordance with Class I of EN 61010 (115/230 AC power

connections). Installation of this instru ent should be done by

qualified personnel. In order to ensure safe operation, the

following instructions should be followed.

This instru ent has no power-on switch. An external switch or

circuit-breaker shall be included in the building installation as a

disconnecting device. It shall be arked to indicate this

function, and it shall be in close proxi ity to the equip ent

within easy reach of the operator. The switch or circuit-breaker

shall eet the relevant require ents of IEC 947–1 and IEC

947-3 (International Electrotechnical Co ission). The switch

shall not be incorporated in the ain supply cord.

Further ore, to provide protection against excessive energy

being drawn fro the ain supply in case of a fault in the

equip ent, an overcurrent protection device shall be installed.

• Do not exceed voltage rating on the label located on the

top of the instru ent housing.

• Always disconnect power before changing signal and

power connections.

• Do not use this instru ent on a work bench without its

case for safety reasons.

• Do not operate this instru ent in fla able or explosive

at ospheres.

• Do not expose this instru ent to rain or oisture.

• Unit ounting should allow for adequate ventilation to

ensure instru ent does not exceed operating te perature

rating.

• Use electrical wires with adequate size to handle

echanical strain and power require ents. Install without

exposing bare wire outside the connector to ini ize

electrical shock hazards.

EMC Consider tions

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the sa e conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the

instru ent if EMC proble s persist.

F ilure to follow ll instructions nd w rnings m y result in injury!

I

NTRODUCTION

part

1

1

Downloaded from Elcodis.com electronic components distributor

part

1

I

NTRODUCTION

2

1.2 Before You Begin

If you need assistance, please contact the nearest Custo er Service Depart ent,

listed in this anual.

Re ove the packing slip and verify that you have received everything listed.

Inspect the container and equip ent for signs of da age as soon as you receive

the ship ent. Note any evidence of rough handling in transit. I ediately report

any da age to the shipping agent. The carrier will not honor da age clai s

unless all shipping aterial is saved for inspection. After exa ining and re oving

the contents, save the packing aterial and carton in the event reship ent is

necessary.

The latest Operation and Co unication Manual as well as free configuration

software are available fro the website listed in this m nu l or on the CD-ROM

enclosed with your shipment.

For first-ti e users: Refer to the QuickStart Manual for basic operation and set-up

instructions.

If you have the Serial Co unications Option you can easily configure the

controller on your co puter or on-line.

Manuals, Software:

nspecting Your Shipment

Customer Service

Downloaded from Elcodis.com electronic components distributor

I

NTRODUCTION

part

1

3

TO DISABLE OUTPUTS

Standby ode is useful during setup of the controller or when aintenance of the

syste is necessary. When the controller is in standby, it re ains in the ready

condition but all outputs are disabled. This allows the syste to re ain powered and

ready to go.

PUSH ENTER TWICE to disable the syste during an EMERGENCY.

When the controller is in "RUN" Mode, push ENTER

twice to dis ble ll outputs nd l rms.

It is now in "STANDBY" Mode. Push ENTER once

ore to resu e "RUN" Mode.

Downloaded from Elcodis.com electronic components distributor

part

2

S

ETUP

6

Round Mount Micro Controller Mounting Instructions

1. Separate the display fro the eter by squeezing the case (where shown) and then

unplugging the cable fro the eter.

2. Slide the retainer over the rear of the case, but do not engage serrations on

case.

3. Pass the cable (fro the display) thru a 1 3/4"dia eter hole in the ounting

panel and connect to the eter (take care to center the

connector on the ating pins). While squeezing the case,

press the display and eter squarely together

until they connect.

4. Check the display and gasket for proper

align ent, then slide the retainer tight against

the backside of the ounting panel.

Figure 2.1b — Mounting the Round Mount Controller

Round Mount

Downloaded from Elcodis.com electronic components distributor

S

ETUP

part

2

Fro t Pa el A u ciators

SP1 OUT1/Setpoint 1 indicator.

SP2 OUT2/Setpoint 2 indicator.

AL1 Alar 1 indicator.

AL2 Alar 2 indicator.

°C °C unit indicator.

°F °F unit indicator.

PV Upper display shows the Process Value

SV Lower display shows the Setpoint Value

MENU Changes display to Configuration Mode and advances thru enu ite s*

/MAX Used in progra ode and peak recall*

/MIN Used in progra ode and valley recall*

ENTER Accesses sub enus in Configuration Mode and stores selected values*

* See Part 3 Operation:Configuration Mode

Figure 2.2 Front Panel Display

2.2. Front P nel View

7

Downloaded from Elcodis.com electronic components distributor

S

ETUP

part

2

9

Rear Pa el Co ector Labels

POWER AC Power Connector: All odels

INPUT Input Connector: All odels

TC, PR (Process)

RTD

ALARM 1 ALARM 1 relay SPST, progra able: All odels

OUTPUT 1 Control Output 1: Based on one of the following odels.

Relay SPDT Voltage and Current

Solid State Relay Pulse

OUTPUT 2 Control Output 2: Based on one of the following odels:

Relay SPST Nor ally Open

Solid State Relay

Pulse

OPTION Based on one of the following odels:

RS-232C Isolated Analog Out

RS-485 Alar 2 Relay SPST, progra able

Re ote Setpoint

Downloaded from Elcodis.com electronic components distributor

part

2

S

ETUP

10

2.4. Mech nic l Inst ll tion

The settings of the DIP switch must be verified or set to comply with your

selection t the Input/Type menu (see Section 3.0 for Input/Type). The DIP

switch is accessible through an opening on the side of the case or ay be accessed

by re oving the controller fro the case, see Section 2.1 for instructions. Locate the

dip switch (see Figure 2.4) and set the switches according to the following tables.

Figure 2.4 Dip Switch Location — switch settings are shown in OFF position

Dip Switch

Configuration

opening in case

Unit installed in case. Unit re oved fro case.

Downloaded from Elcodis.com electronic components distributor

part

2

S

ETUP

12

2.5. Electric l Inst ll tion

POWER CONNECT ON EXAMPLES

The figure below shows the power wiring hookup.

Fuse Connector Output Type 115 V c 230 V c

Fuse 1 Output 1 Relay 5 A(T) 3 A(T)

Fuse 2 Output 1 Relay 5 A(T) 3 A(T)

SSR 0.5 A(T) 0.5 A(T)

Fuse P Power N/A 100 A(T) 100 A(T)

Fuse A Alar 1/2 Relay 3 A(T) 3 A(T)

Note: Values shown are ini u reco endations for the

protection of the controller. For a specific load, consult the respected

electrical specifications to select a suitable fuse.

The Protective Conductor termin l must be

connected for s fety re sons.

The Safety European Standard EN61010-1 for easure ent, control, and laboratory

equip ent requires that fuses ust be specified based on IEC127. This standard

specifies for a Ti e-lag fuse, the letter code “T”. The above reco ended fuses are

of the type IEC127-2-sheet III. Be aware that there are significant differences

between the require ents listed in the UL 248-14/CSA 248.14 and the IEC 127 fuse

standards. As a result, no single fuse can carry all approval listings. A 1.0 A p IEC

fuse is approxi ately equivalent to a 1.4 A p UL/CSA fuse. It is advised to consult

the anufacturer’s data sheets for a cross-reference.

Use copper conductors only for power

connections

Figure 2.5.1 Power Wiring Hookup

Note ☞

For SSR wiring hook-up exa ples, refer to Specification Section.

Downloaded from Elcodis.com electronic components distributor

Table of contents

Other Newport Electronics Controllers manuals

Popular Controllers manuals by other brands

Carel

Carel ir33+ FMC quick guide

YASKAWA

YASKAWA Motoman DX200 instructions

Becker

Becker Centronic UnitControl UCS520 operating instructions

omal automation

omal automation Rackon RK10 instruction manual

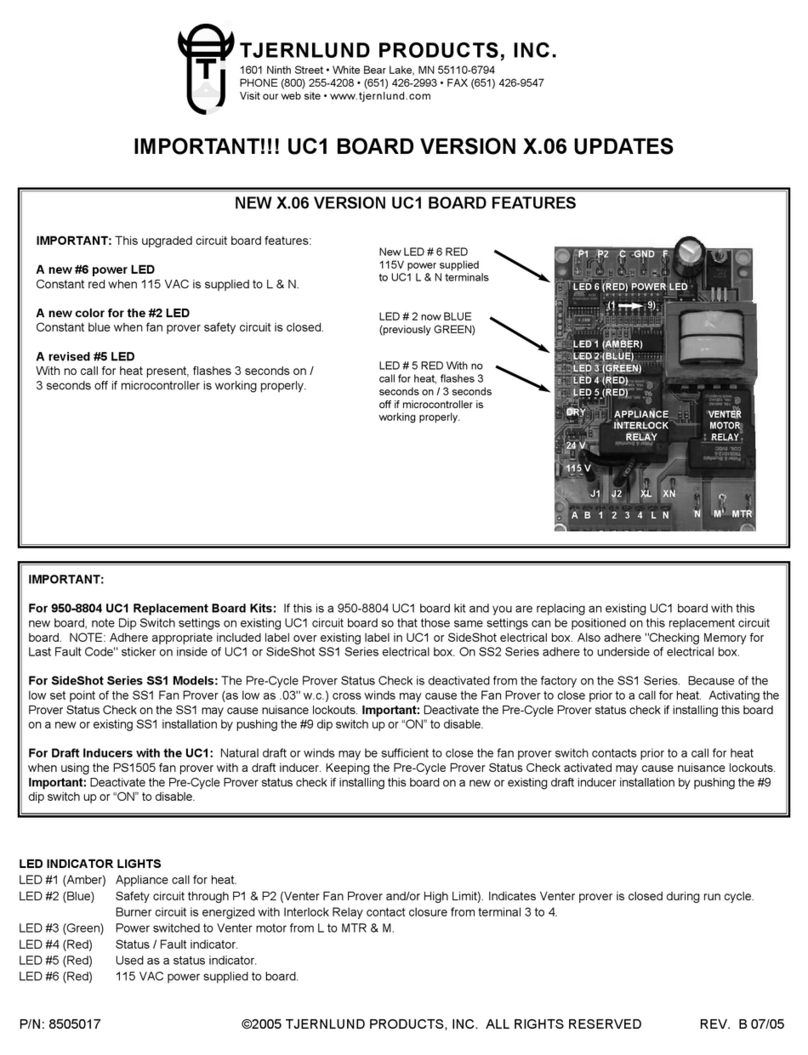

TJERNLUND

TJERNLUND 950-8804 UC1 UNIVERSAL CONTROL BOARD KIT (VERSION X.04) 8505017 REV A... manual

Gemini

Gemini 2 quick start guide