TDI TURBOTWIN T100-VE User manual

From Tech Development

6800 Poe Ave. Dayton OH 45414

Tel: (937) 898-9600 Fax: (937) 898-8431

Website: tdi-turbotwin.com

Publication T1-932

Dated: May 20, 2016

INSTALLATION AND OPERATING

MANUAL

MODEL: T100-VE

TURBOTWIN Engine Air Starters

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932

Page: i Issued May 20, 2016

TABLE OF CONTENTS

SECTION SUBJECT PAGE

1.0 General Information...............................................................................1

1.1 Description.............................................................................................1

1.2 Product Identification.............................................................................1

1.3 Physical Characteristics.........................................................................2

1.4 Performance ..........................................................................................2

2.0 Orientation of the Starter .......................................................................2

3.0 Installing the Starter...............................................................................2

3.1 Supply Line Installation..........................................................................3

3.2 Inlet Pressure Port.................................................................................3

3.3 Exhaust Piping.......................................................................................4

3.4 Soft Start Valve & Filter Fitting ..............................................................4

3.5 Natural Gas Installation .........................................................................4

3.6 Piping System........................................................................................4

3.7 Atex Applications...................................................................................4

3.8 Best Installation Practices......................................................................5

4.0 Starter Operation...................................................................................6

4.1 Basic Operation .....................................................................................6

4.2 Automated Start Panel...........................................................................7

4.3 Best Operating Practices.......................................................................7

5.0 T00-VE Warranty...................................................................................7

6.0 Operator’s Troubleshooting Guide ........................................................8

ILLUSTRATIONS

FIGURE TITLE PAGE

1 Direction of Rotation……………………...................................................2

2 T100-VE with Exhaust Closure Plate ......................................................9

3 T100-VE with Exhaust Deflector……………..........................................10

4 T100-VE Installation Drawing……………..............................................11

5 T100-VE Installation Drawing (Multiple Starters)………........................12

T112-VE Performance Curve – 12 nozzles (air)....................................13

T121-VE Performance Curve – 21 nozzles (air)....................................13

T112-VE Performance Curve – 12 nozzles (gas)..................................14

T121-VE Performance Curve – 21 nozzles (gas)..................................14

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 1

Issued May 20, 2016

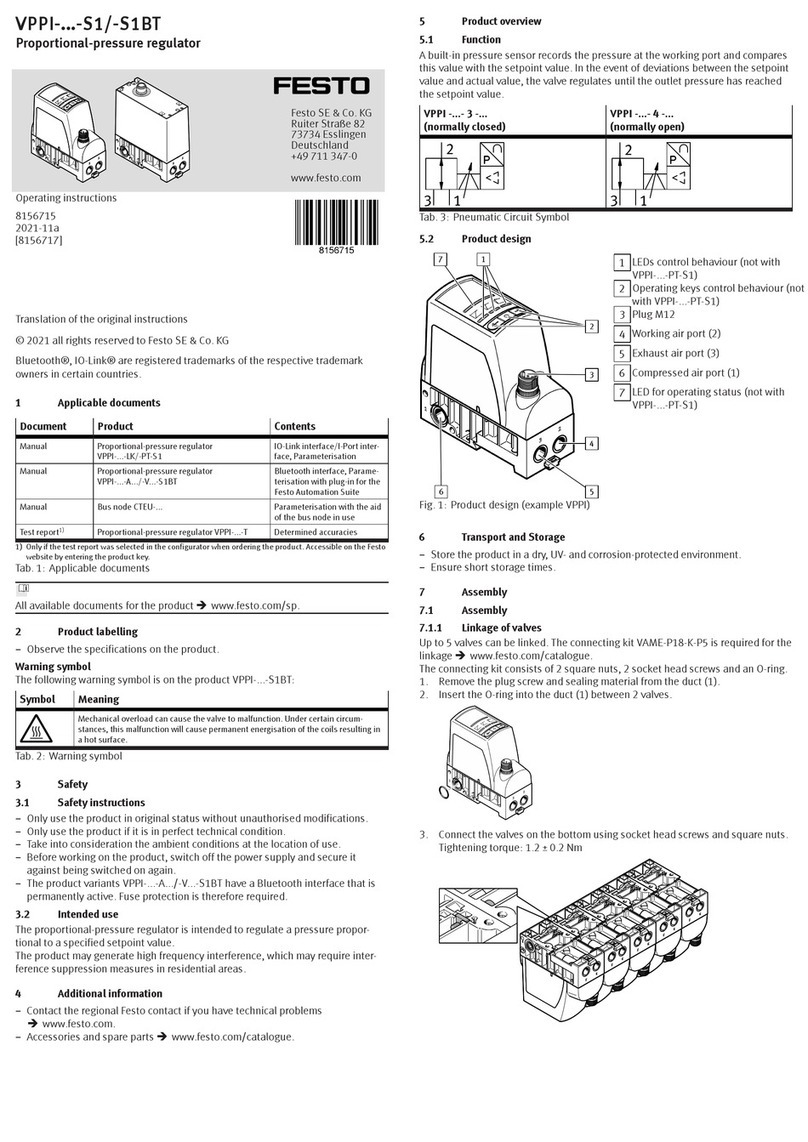

1.0 GENERAL INFORMATION

This manual provides instructions for the installation and

operation of the TDI T100-VE TURBOTWIN Air Starters. If

there are questions not answered in this manual, please

contact your TDI TURBOTWIN distributor or dealer for

assistance.

The T100-VE starters are turbine driven starters with a

pre-engaged starter drive. The T100-VE starters have

applications ranging from 1800 CID (30 Liters) on diesel

engines and up to 18000 CID (300 Liters) on gas

engines. The T100-VE models are suited to operate

within a wide range of inlet pressures and ambient

temperatures. The engine size and parasitic loading will

determine the exact minimum pressure that will assure

reliable cranking.

The T100-VE starters are designed for operation with

compressed air or natural gas; materials used are

compatible with “sour” natural gas and marine

environments. Small amounts of foreign matter or liquid

in the air supply will not adversely affect T100-VE

starters. As with all TDI starters, no lubrication is

required in the air supply.

Please review the rest of this manual before installing

the T100-VE air starter.

WARNINGS, CAUTIONS, AND NOTES

Certain types of information are highlighted in this

manual for your attention:

WARNING - used where injury to personnel or

damage to the equipment is possible.

CAUTION - used where there is the possibility of

damage to the equipment.

NOTE - used to point out special interest

information.

NOTE

Throughout this manual, the term “air” is used to

designate the starter drive medium. Unless otherwise

stated, “air” means either compressed air or natural gas.

1.1 DESCRIPTION

The T100-VE features three basic subassemblies: a

unique two stage turbine motor section, an offset/spur

gear assembly and a pre-engage drive assembly.

The two stage motor section features greater stall torque

than a single stage turbine plus aerodynamic speed

control. This aerodynamic speed control helps protect

the T100-VE starter from damage caused by starter

motor over speed. In addition, a specially designed

motor housing module and low-mass rotors provide fail-

safe operation.

The T100-VE employs 9.25:1 ratio spur gearbox. This

low gear ratio allows the turbine motor to spin at low

speeds for long bearing life. At a typical 3000 rpm pinion

speed, the turbine is rotating at a low 27750 rpm.

A reliable pre-engaged drive delivers the torque to the

pinion. The pinion is translated out to engage the

engine's ring gear via the starter’s engagement piston.

Compressed air or natural gas is used to power the

T100-VE through the inlet port. The air or gas is

expanded through the first nozzle or stators. The high

velocity gas impinges on the first stage rotor to yield

torque to the gearbox through momentum exchange.

The gas is further directed through the second stage

stators which impart additional torque to the second

stage rotor.

1.2 PRODUCT IDENTIFICATION

The starter nameplate which is attached to the turbine

housing contains the following information: model

number, serial number, part number, direction of rotation

and the maximum rated operating pressure.

The directions of rotation are either right hand or left

hand rotation as shown in Figure 1. Right Hand rotation

is defined as clockwise rotation as viewed from the

pinion end of the starter, and Left Hand rotation is

counter clockwise rotation viewed from the pinion end of

the starter.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 2 Publication T1-932

Issued May 20, 2016

Figure 1. Direction of Rotation viewed from Pinion End.

The maximum operating pressure identified on the

nameplate is measured at the check port on the starter

inlet with the starter in operation.

CAUTION

Exceeding the maximum pressure shown on the

nameplate may result in drive failure, damage to the

starter, or damage to the engine.

The housing proof pressure is 600 psig and is also

shown on the nameplate. This means that the turbine

housing will not burst when subjected to a static

pressure of 600 psig.

1.3 PHYSICAL CHARACTERISTICS

Figure 2 shows the standard configuration for the T100-

VE with exhaust screen. This model weighs

approximately 54 lbs. and is 16.8 inches in length. The

turbine housing diameter is 6.8 inches, which is common

to all T100 TURBOTWIN air starters.

1.4 PERFORMANCE

The performance curve for the T100-VE illustrates the

pinion torque versus pinion speed (rpm) at a constant

drive air pressure, and horsepower versus pinion

speed at a constant drive air pressure. The pinion

speed is shown on the horizontal axis while the pinion

torque is shown on the left edge of the vertical axis. Air

consumption rates are given for the various drive

pressures. The drive gas used for the performance

curve is air.

2.0 ORIENTATION OF THE STARTER

If the factory orientation of the starter turbine housing

assembly does not fit your engine installation, this

component can be re-oriented.

Determine the required orientation of the turbine housing

assembly and gearbox housing assembly. The turbine

housing assembly can be rotated to six different

positions relative to the gearbox housing assembly. The

drive assembly can be rotated to twenty four positions

relative to the inlet port.

Orientation of the starter should be accomplished prior to

installing the starter on the engine.

CAUTION

All screw threads are treated at the factory with a

fastener retention compound. Every screw and

tapped hole must be clean and have a drop of

Loctite 242 applied to the threads before being

installed.

3.0 INSTALLING THE STARTER

A turbine air starter does not require lubrication in the

supply air. Therefore, if a vane type starter motor is

being replaced, TDI recommends that all lubrication

devices and lines be removed to minimize flow

restrictions.

WARNING

If a fuel (pulse) lubricator has previously been

installed in the system, disconnect and plug the line

to eliminate spraying diesel fuel on the engine.

The starter should be installed with the inlet valve in a

position between horizontal and straight down. Any

condensation will be restricted to the air lines and not in

the starter.

WARNING

Do not operate this starter unless it is properly

connected to an engine.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 3

Issued May 20, 2016

3.1 SUPPLY LINE INSTALLATION

WARNING

Be sure to either bleed the pressurized air reservoir

and/or safety the system such as closing all valves

prior to installing any starter supply line.

T100-VE starters come standard with a 2" NPT female

pipe thread for the inlet connection port.The supply line

consists of the line from the air source, a pressure

regulator (when necessary), a manual or relay valve,

and the connection to the starter inlet. Hard piping may

be used, but a section of flexible tubing should be

installed at the starter to prevent leaks due to engine

vibration.

Care must be taken to ensure that all inlet supply line

piping is no less than 1.5” and that all components used

are capable of passing the required air flow.

NOTE

Valves with a Cv of 40 or higher is recommended.

If the supply line must be longer than 20 feet, the inlet

supply line piping should be increased to 2" in diameter

to ensure proper performance by your TURBOTWIN.

Because turbine starters such as the T100-VE are

sensitive to flow restrictions, care must be taken to use

uniform hose or tubing and fittings for connection of the

supply line. Tees, elbows and line length must be kept

to a minimum. TDI recommends that hose or flex

couplings be installed to eliminate possible leakage

caused by strain on the supply line.

Normally, an air strainer is not required. In dirty

environments, use of a #40 mesh Y-strainer is

recommended. The T100-VE is highly tolerant of dirt in

the air line, however, starter life can be increased with

the use of an air strainer.

A pressure regulator is required when the air supply

pressure is great enough to exceed the starter operating

pressure (at the inlet port) and/or the maximum torque.

A manual ball valve may be used to admit drive air/gas

to the starter. The manual valve should be located in a

safe position away from the engine.

A preferred valve is pilot-operated, which can be

pneumatically or electrically actuated. The valve should

be located close to or even on the starter inlet for best

performance. Pneumatic or electrical control lines may

be routed virtually anywhere for the customer's preferred

operating station. This type of valve actuates from a fully

closed to a fully open position very rapidly. TDI offers a

variety of relay valves such as P/N RLVA-25683-001-2-

01, which is a 1-1/2" port, pneumatically actuated valve.

The supply line should be dry-fitted for proper

alignment/location prior to final assembly. All pipe-

threaded joints should be sealed with Loctite Pipe

Thread Sealant (TDI P/N 9-94085) or equivalent for leak

tight joints prior to final assembly. Be sure to tighten all

joints to proper torque after final assembly.

CAUTION

In cold weather climates, care should be taken while

designing your installation to prevent condensation

from developing in the starter system. In systems

with a regulator valve or relay valve, there is the

possibility of freeze-ups.

A tee connection with a quick disconnect can be added

to the inlet. This will allow an external air source to be

used to accomplish a “blow start” if the system freezes.

Once the engine has been started, the other system

components may be thawed.

CAUTION

On new installations, it is strongly recommended to

blow out the supply line with air to remove possible

dirt and welding slag prior to final connection to the

TURBOTWIN starter. Be sure to secure the free end

of the supply line prior to blowing out the line.

3.2 INLET PRESSURE PORT

A 1/4" NPT port is located on the air inlet. This port may

be used to check the supply pressure at the starter when

the starter is operating. Remove the 1/4" NPT pipe plug

and save for later use. Install 1/4" minimum size tubing

to the port. Route the tubing away from the starter to a

safe location away from the engine. Install a pressure

gauge on the tubing. This pressure monitoring

line/gauge may be permanently installed. Use Loctite

Pipe Thread Sealant or equivalent. Alternately, a

pressure transducer may be installed at the pressure

check port and electrical lines routed to a digital display

at the operator's station.

This pressure port is invaluable in diagnosing air starter

and/or installation problems.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 4 Publication T1-932

Issued May 20, 2016

3.3 EXHAUST PIPING

The turbine exhaust may be plumbed away from the

starter area. All starters using natural gas must be piped

according to industry codes and local regulations.

The performance of a turbine starter will be decreased

because of back pressure when smaller than

recommended exhaust piping is installed. If back

pressure hampers starter performance, compensation

can be made by increasing the supply pressure. Consult

your TDI distributor for advice.

Exhaust piping should be routed downward to help

prevent any accumulation of condensation in the starter

motor.

If the overhung section of the starter is not otherwise

supported, TDI recommends that the exhaust piping be

supported with a suitable bracket(s).

3.4 SOFT START VALVE & FILTER FITTING

The soft starter fitting P/N: 2-28243 and filter P/N: 2-

28270 originally provided with the model T100-VE air

starters are no longer required. The two fittings will not

be supplied in the red envelope attached to the starter

flange or installed on starters with the relay valve

integrated into the package.

The air starter packages using hard piping now utilize a

flow-thru adapter fitting P/N: 3-30560 installed directly in

the relay valve “APP” port and in the starter “IN” port to

replace the soft start and filter fittings. The flow-thru

adapter fitting is configured with a large internal cavity;

therefore, no cleaning or maintenance of this part is

required.

Note that installations using flexible tubing can pipe

directly to the relay valve “APP” port and starter “IN” port

without the use of the flow-thru adapter fitting.

See service bulletin # 108 for additional information

regarding obsoleting of the soft start P/N: 2-28243 and

filter fitting P/N: 2-28270.

CAUTION

For maximum pinion life and full warranty coverage,

the soft start valve (P/N: 2-28243) MUST be

installed in the applied pressure port (APP) of the

relay valve.

3.5 NATURAL GAS INSTALLATION

The installation of the starter using natural gas is similar

to the air installation except all fittings, piping, valves and

regulators must be compatible with natural gas.

Proper control of natural gas is a major consideration

when used in the starter system. All starters using

natural gas must pipe the exhaust according to industry

codes and local regulations.

There is a natural gas vent port in the turbine housing

that is plugged for compressed air use. This vent is used

to remove any natural gas that could leak past the

primary turbine shaft seal. Remove this 3/8"NPT plug

and install a line to carry gas away from the starter area.

WARNING

Do not connect the turbine housing vent line to the

turbine exhaust line. Exhaust gas can pressurize the

turbine housing.

3.6 PIPING SYSTEM

Only type approved metallic hose assemblies are

approved in permanently pressurized compressed air

lines of starters. Non-metallic hose assemblies are

allowed only in case the piping system will be emptied

after the starting procedure.

Pipe unions must be type approved by GL. Downstream

of the pressure regulator a pressure relief valve should

be provided.

3.7 ATEX APPLICATIONS

This ATEX designation applies to the use of the starter

on reciprocating internal combustion engines only. For

use in other applications please consult Tech

Development.

NOTE

T100-VE starters conforming to ATEX requirements will

be equipped with a copper beryllium (non-sparking)

pinion.

WARNING

Non-compliance with any of these special conditions

could result in ignition of potentially explosive

atmospheres.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 5

Issued May 20, 2016

Sparks will result from the engagement / disengagement

of the pinion with the flywheel gear. Users of this product

are hereby warned of this possibility, and advised to take

appropriate precaution.

The end user is responsible for taking appropriate action

to prevent ignition source from becoming effective.

Rubbing and friction can cause sparks or elevated

temperatures that may be a source of ignition of an

explosive atmosphere.

Starter Installation and Application

The air starter shall not be operated when an explosive

atmosphere is present.

Never use the starter on any application where there is a

possibility that a may be present. These gases cause a

high probability of explosion.

A work permit should be used that ensures that

explosive atmospheres are not present in the zone of

operation during starter operation.

Do not install, maintain, or remove starter from engine in

the presence of a potentially explosive atmosphere.

Due to the possibility of accumulation of static discharge,

care must be taken to ensure the motor is properly

grounded at all times to prevent ignition hazards from

electrostatic discharge.

Air pressure above the maximum rated pressure on

starter nameplate, located on the starter housing may

result in a source of ignition caused by premature failure

of bearings or other components due to excessive

speed, output torque, or force.

Starter Maintenance

Removal from the engine is mandatory prior to any

maintenance being performed on the starter.

Do not perform maintenance or repairs when hazardous

atmospheres are present.

Take proper precaution and use protective equipment

when servicing/cleaning the engine flywheel housing.

WARNING

These special conditions must be followed for the

starter to conform to the ATEX Directive and for the

ATEX Declaration of Incorporation to be valid.

3.8 BEST INSTALLATION PRACTICES

Wear protective gloves and steel toe shoes when

installing air starter.

Follow engine manufacturer’s torque requirements

for all starter attachment screws.

For new installations or where new piping or

receiver tanks are installed, always purge the

starter supply line of debris before installing or

operating the air starter.

Install and maintain a 40-mesh (400 micron) Y-

strainer in the starter supply line to reduce the

level of contamination entering air starter.

To insure maximum performance and starter life,

use the recommended starter inlet and exhaust

piping sizes.

Limit the number of elbows installed in starting

system supply/exhaust lines and minimize to the

extent possible, the length of these lines to

prevent excessive flow losses and/or back

pressure.

Use a quick-opening starter relay valve to operate

air starter, and install within 10 feet of the air

starter inlet.

To properly control the starter, use a control valve

configured with 3 ports (IN, OUT, VENT). Use a

3-way valve only. Never use a 2-way or manual

ball valve to operate a pre-engaged starter

model or within the pre-engagement controls

piping.)

When a pressure regulator is required, locate this

at a minimum distance of 10 feet away from the

starter relay valve.

Utilize pressure regulator(s) with flow

characteristics that meet or exceed the selected

air starter’s flow requirements (Cu factor).

Regulators located far from the starter may

require sensing downstream pressure closer to

the starter inlet to deliver the desired dynamic

pressure to the starter while operating.

Do not use any mist or injection type

lubricators/devices in supply line to a TDI air

starter.

Where used in sub-freezing ambient

temperatures, install air starter with inlet and

exhaust in 6 o-clock position to allow drainage

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 6 Publication T1-932

Issued May 20, 2016

preventing freezing of trapped moisture in the

starter inlet.

4.0 STARTER OPERATION

Prior to operation, check that all connections are tight

and free from leaks. Check the 1/4" NPT pipe plug or a

pressure gauge/transducer that may be connected to the

pressure port on the starter inlet.

WARNING

Do not operate the TDI TURBOTWIN starter with air

pressure greater than the pressure rating on the

nameplate. This pressure is measured at the starter

inlet while the starter is running.

The maximum operating pressure limit is the inlet

pressure measured at the starter’s inlet pressure check

port. To check the pressure, a 1/4"NPT pipe tap

connection is provided in the inlet housing to attach a

pressure gauge. The maximum pressure assumes an

open exhaust (the standard turbine exhaust guard). The

standard exhaust guard causes no back pressure.

The static non-flowing supply pressure will always be

higher than the operating (dynamic) pressure. The

maximum pressure limit (proof pressure) that the T100-

VE starter housings may be subjected to is 600 PSIG

(42 BAR). System pressure that exceeds the maximum

operating limit must use a pressure reducing device to

ensure that the operating pressure limit to the T100-VE

starter is maintained.

System static pressure that exceeds the 600 PSIG (42

BAR) limit must, in addition to pressure reducer devices,

incorporate a pressure relief valve set below 600 PSIG

(42 BAR) in the supply air line.

NOTE

For maximum life of the starter pinion and for the

protection of the engine ring gear, limit the operating

pressure to that necessary to start the engine at its most

difficult starting conditions.

All appropriate local pressure codes and pressure

limitations on other system components must be

adhered to and supersede the guidelines given in this

manual.

Consult your TDI distributor if you have exhaust

plumbing that creates back pressure and reduces starter

performance. You may be able to increase the supply

pressure to restore the lost power.

Follow the engine manufacturer’s instructions for starting

the engine.

CAUTION

The grease used in the planetary system has a shelf

life of 2 years. Therefore, if the starter is NOT

installed and operated on the engine for 2 years

after the starter is manufactured, the grease should

be replaced prior to starter operation. The

manufactured date is reflected in the starter serial

number. (Ex: 0602-0567 has a manufactured date

of February 2006.

4.1 BASIC OPERATION

The basic operation of the starter follows:

Pressurized air or natural gas is admitted to the starter’s

engagement piston chamber via the “in” control port by

opening the manual or solenoid valve. The air then

translates the starter’s piston forward allowing the pinion

to engage the engine’s ring gear.

NOTE

40 psi minimum pressure applied to the pre-engaged

piston is required to engage the pinion into the ring.

The forward movement of the piston causes the starter’s

“out” control port to open. Air is then transmitted to the

automatic pilot port (APP) on the relay valve causing the

relay valve to open.

Pressurized air or natural gas is admitted to the starter’s

turbine assembly by the opening of the relay valve. The

air expands through the turbine which produces shaft

rotation and torque. The starter motor torque causes the

engine to accelerate. The fuel and ignition systems now

fire the engine. Closing the relay valve stops the starter.

The operator may decrease starter life by the continual

operation of the starter after the engine has started. After

a successful engine start, turn the air off to the starter

immediately. Minimizing the time the starter is operating

unloaded will maximize starter life. If a start is aborted, a

restart may be attempted after the engine and the starter

has come to rest. CAUTION

Do not engage the starter while the engine is

running.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 7

Issued May 20, 2016

The drive air pressure is the primary starter control

parameter. It is important, especially on new

installations, to measure this pressure during several

engine starts. The secondary parameter is the starter

pinion speed. This speed is usually measured by

knowledge of the engine starting speed and the starter

cranking ratio. The cranking ratio is the number of ring

gear teeth divided by the number of pinion teeth. The

starter pinion speed is then found by multiplying the

engine speed by the cranking ratio. The pinion speed is

usually 2000-3500 rpm at typical engine starting speed.

4.2 AUTOMATED START PANEL

The starter drive pressure measured at the starter inlet

will need to be set. As noted above, for maximum life of

the starter pinion and for the protection of the engine ring

gear, limit the operating pressure to that necessary to

start the engine at its most difficult starting conditions.

The speed control parameter will then need to be set.

Engine starting speed along with the cranking ratio

number can be used to determine starter pinion speed.

The pinion speed is usually 2000-3500 rpm for a typical

engine starting speed. Once the start sequence has

begun, the air is admitted to the starter. The starter

begins to accelerate the engine. Once the firing speed of

the engine is reached, the automated start panel may

deliver fuel to the engine. The engine will begin to

accelerate under its own power. The starter should be

dropped out of the sequence at an rpm higher than the

firing speed, but less than the engine idle speed.

The automated start panel should monitor engine speed

to determine air on and air off. Do not simply use time

as a control parameter. Avoiding excessive operation of

the starter after the engine is firing will maximize the

starter life.

4.3 BEST OPERATING PRACTICES

To extend starter life, apply only the minimum

pressure required, to successfully crank & start

the engine.

Never exceed starter maximum operating

pressure identified on starter nameplate. This

pressure can be best measured dynamically

while starter is running.

For longer starter life, operate (or design controls)

to shut off supply pressure to the air starter

immediately after a successful engine start.

If engine fails to start or stalls, wait at least 15

seconds before attempting to re-start to allow

the starter to coast to a complete stop.

Never re-engage pinion into ring gear when

starter is coasting down as this may damage the

starter pinion gear and engine ring gear.

Never engage starter while engine is operating as

this may damage the starter, the pinion gear,

and engine ring gear.

5.0 WARRANTY

Tech Development (TDI) warrants to the original user of the TDI TURBOTWIN™air starters to be free from defects in

material and workmanship for a period of one year from the date of installation. The warranty period shall not extend

beyond two years from the date the unit was manufactured. (i.e.: a unit with a manufactured date of July 1999 (SN: 9907-

101) will not be covered under warranty after July 2001). The conditions of this warranty are: a) TDI is notified within this

period by return of such product to TDI or its authorized distributor/dealer, transportation prepaid by user; b) the starter

has been installed according to TDI's specifications; c) the starter has not been misused, abused, or improperly

maintained by user; d) the defect is not the result of normal wear and tear; e) the starter has been repaired with parts

manufactured or authorized by TDI; and f) TDI installation and repair procedures as outlined in the appropriate manual

were properly followed.

Tech Development will repair, or at its option, replace the unit during the warranty period at no charge to the customer,

provided it is returned to TDI with the proper return procedure.

Tech Development makes no other warranty, and implied warranties including any warranty or merchantability or fitness

for a particular purpose are hereby disclaimed.

This warranty constitutes the entire obligation of Tech Development relating to the sale and use of such product, and

TDI's maximum liability is limited to the purchase price of such product at the date of purchase. In no event shall TDI be

liable for incidental, indirect, consequential, or special damages of any nature arising from the sale or use of such engine

starter product.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 8 Publication T1-932

Issued May 20, 2016

6.0 OPERATOR’S TROUBLESHOOTING GUIDE

TROUBLE PROBABLE CAUSE SOLUTION

1. Air always flow through

exhaust A. Relay valve improperly

installed. A. Check typical installation

diagram and correct.

B. Relay valve not sealing

properly. B. Check for damaged sealing

ring, replace relay valve or

damaged parts.

C. Solenoid is not sealing,

pressure remains in APP port of

relay valve.

C. Check solenoid potential at the

lead to ground should be 0. If not,

fix ignition switch problem.

2. Starter engages but does not

run, A. Bad relay valve A. Replace relay valve.

3. Starter does not run, small air

flow from turbine exhaust or

drive housing.

A. Nozzle blockage. A. Remove blockage or obstruction

from nozzles.

4. Starter does not run. Normal

air flow from exhaust. A. Excessive bends in the

supply line. A. Shorten length or straighten

supply air line.

5. Pinion does not engage A. Air pressure is too low A. Increase air pressure to 40 -

150 psig.

B. Control lines to starter ports

reversed. B. Check installation diagram and

correct.

C. Solenoid valve not operating

or plugged. C. Check wiring and solenoid

operation. Correct wiring, remove

blockage, or replace solenoid

valve as needed.

D. Damaged pinion teeth. D. Replace pinion or starter drive

as necessary.

6. Starter runs but engine cranks

slowly or not at all. A. Air pressure too low A. Increase air pressure to 40 –

150 psig.

B. Excessive back pressure. B. Check Exhaust Closure Plate.

C. Nozzle blocked or damaged. C. Remove blockage or replace

damaged parts.

7. Starter continues to operate

after start button is released. A. Solenoid valve is not sealing

correctly. A. See 1C above

B. Relay valve is not sealing

correctly. B. See 1B above

8. Air tank pressure decays after

extended shut down. A. Air connections are not tight. A. Tighten loose fittings. Repair or

replace damaged fittings.

B. Damaged air lines: crushed,

frayed, and kinked. B. Replace damaged lines.

C. Relay valve is not sealing

correctly. C. See 1B above

D. Solenoid valve is stuck open. D. A. See 1C above

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 9

Issued May 20, 2016

Figure 2. T100-VE TURBOTWIN Air Starter with Exhaust Closure Plate

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 10 Publication T1-932

Issued May 20, 2016

Figure 3. T100-VE TURBOTWIN Air Starter with Exhaust Deflector

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 11

Issued May 20, 2016

Figure 4. T100-VE TURBOTWIN Air Starter Installation Drawing

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 12 Publication T1-932

Issued May 20, 2016

Figure 5. T100-VE TURBOTWIN Air Starter Installation Drawing (Multiple Starters)

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T1-932 Page 13

Issued May 20, 2016

0

50

100

150

200

250

300

350

400

0 1,000 2,000 3,000 4,000 5,000

Pinion Speed (rpm)

0

10

20

30

40

50

60

70

80

90 psig

60 psig

40 psig

Nm lb.ft Hp Kw

0

68

136

204

272

340

408

476

544

0

7.5

22.4

29.8

37.2

14.9

44.8

59.6

52.2

Model: T121-V Performance Curve

21 Nozzles, Compressed Air, 9.25:1 Ratio

Inlet Pressure SCFM Nm3/h

90 psig 1606 2730

60 psig 1158 1969

40 psig 848 1442

TORQUE POWER

0

10

20

30

40

50

60

70

0

50

100

150

200

250

300

350

0 1,000 2,000 3,000 4,000 5,000

Pinion Speed (rpm)

150 psig

90 psig

60 psig

120 psig

0

7.5

14.9

22.4

29.8

37.2

44.8

52.2

0

68

136

204

272

340

408

476 Hp Kw

Nm lb.ft.Model:T112-V Performance Curve

12 Nozzles, Compressed Air, 9.25:1 Ratio

Inlet Pressure SCFM

Nm3/h

150 psig 1472

2502

120 psig 1199

2038

TORQUE POWER

ModelT112‐VEPerformanceCurve

ModelT121‐VEPerformanceCurve

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 14 Publication T1-932

Issued May 20, 2016

ModelT112‐VEPerformanceCurve

ModelT121‐VEPerformanceCurve

Table of contents

Other TDI Controllers manuals

Popular Controllers manuals by other brands

Abelko

Abelko UltraBase30 quick start guide

Siemens

Siemens SINAMICS S120 manual

Nanda

Nanda NA300 Series User manual and technical specifications

alre

alre KTRRN-267.014 quick start guide

Festo

Festo VPPI S1BT Series operating instructions

Bernard Controls

Bernard Controls SQX Series INSTRUCTIONS FOR START-UP