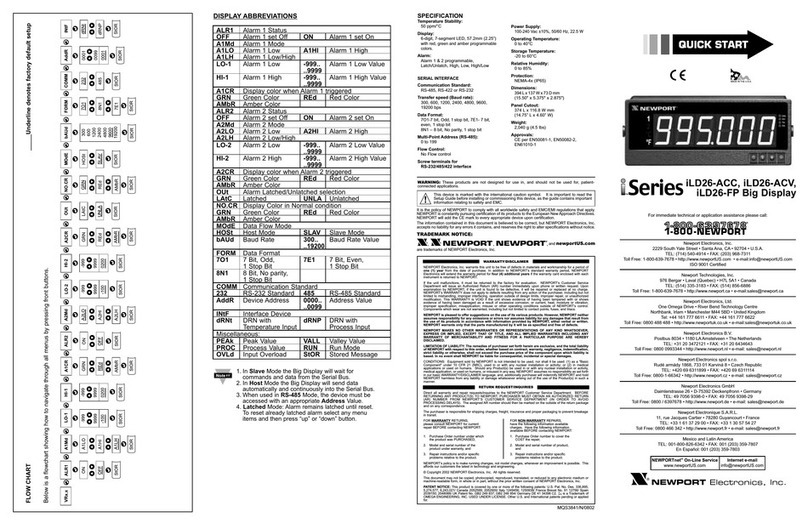

Newport i Series User manual

http://www.newportUS.com/i

®

NEWPORT

Electronics, Inc.

iLD Big Display

Universal Temperature & Process

Monitor

Operator’s Manual

Counters

Frequency Meters

PID Controllers

Clock/Timers

Printers

Process Meters

On/Off

Controllers

Recorders

Relative

Humidity

Transmitters

Thermocou les

Thermistors

Wire

Rate Meters

Timers

Totalizers

Strain Gauge

Meters

Voltmeters

Multimeters

Soldering Iron

Testers

H ens

H Controllers

H Electrodes

RTDs

Thermowells

Flow Sensors

For Immediate Assistance

In the U.S.A. and Canada: 1-800-NEWPORT

®

In Mexico: (95) 800-NEWPORT

SM

Or call your local NEWPORT Office.

Internet e-mail

info@new ortUS.com

Additional roducts from

NEWPORTnetSM On-Line Service

www.new ortUS.com

®

NEWPORT

Electronics, Inc.

It is the olicy of NEWPORT to com ly with all worldwide safety and EMC/EMI regulations that a ly. NEWPORT is constantly

ursuing certification of its roducts to the Euro ean New A roach Directives. NEWPORT will add the CE mark to every

a ro riate device u on certification.

The information contained in this document is believed to be correct but NEWPORT Electronics, Inc. acce ts no liability for any

errors it contains, and reserves the right to alter s ecifications without notice.

WARNING: These roducts are not designed for use in, and should not be used for, atient connected a lications.

TRADEMARK NOTICE:

, NEWPORT,new ortUS.com, and NEWPORT

®

are trademarks of NEWPORT

Electronics, Inc.

PATENT NOTICE: This roduct is covered by one or more of the following atents: U.S. Pat. No. Des. 336,895; 5,274,577;

6,243,021 / CANADA 2052599; 2052600/ ITALY 1249456; 1250938 / FRANCE BREVET No. 91 12756 / SPAIN 2039150;

2048066 / UK PATENT No. GB2 249 837; GB2 248 954 / GERMANY DE 41 34398 C2. The ™is a trademark of OMEGA

Engineering, Inc. Used Under License. Other US and International Patents ending or a lied for.

!This device is marked with the international caution symbol. It is im ortant to read the Setu Guide before installing or

commissioning this device as it contains im ortant information relating to safety and EMC.

TABLE OF CONTENTS

Part 1: Introduction............................................................................................2

1.1 Descri tion .................................................................................2

1.2 Safety Considerations ...............................................................3

1.3 Before You Begin .......................................................................4

Part 2: Setu .......................................................................................................5

2.1 Mounting .....................................................................................5

2.2 Rear Panel Connections............................................................7

2.3 Electrical Installation .................................................................8

2.3.1 Power Connections........................................................8

2.3.2 Thermocou le - In ut Connection................................9

2.3.3 Two / Three / Four Wire RTD-Hooku s.......................10

2.3.4 Process Current - Wiring Hooku ...............................11

2.3.5 Process Voltage - Wiring Hooku ...............................11

2.3.6 Communication Out ut - Wiring Hooku ...................12

Part 3: O eration: Configuration Mode .........................................................13

3.1 Introduction ..............................................................................13

Turning your Instrument On for the First Time

Buttons Functions in Configuration Mode

3.2 Menu Configuration ................................................................14

3.2.1 ID Number .....................................................................15

3.2.2 Set oints .......................................................................16

3.2.3 Configuration Menu ....................................................17

3.2.4 In ut Ty e Menu ...........................................................17

In ut Ty e (Thermocou le) ........................................18

In ut Ty e (RTD)...........................................................19

In ut Ty e (Process) ...................................................20

3.2.5 Reading Configuration Menu .....................................20

3.2.6 Alarm 1 Menu ...............................................................24

3.2.7 Alarm 2 Menu................................................................28

3.2.8 Reading Adjust Menu...................................................29

3.2.9 Set oint Deviation Menu / Field Calibration ..............30

3.2.10 ID Code Menu ...............................................................31

3.2.11 Communication (O tions) Menu.................................33

3.2.12 Dis lay Color Selection Menu.....................................39

Part 4: S ecifications ......................................................................................42

Part 5: Factory Preset Values .........................................................................45

CE APPROVAL INFORMATION .......................................................................46

i

LIST OF FIGURES:

Figure 2.1 Mounting ...............................................................................................5

Figure 2.2 Rear Panel Power Connector Labels..................................................7

Figure 2.3 Rear Panel In ut Connector Labels....................................................7

Figure 2.4 Main Power Connections.....................................................................8

Figure 2.5 Inside Cover Rear View........................................................................8

Figure 2.6 Thermocou le Wiring Hooku ............................................................9

Figure 2.7 Two/Three/Four-wire RTD

a) RTD-1000 ohm and 500 ohm Wiring Hooku ............................10

b) RTD-100 ohm Wiring Hooku .....................................................10

Figure 2.8 Process Current Wiring Hooku

(Internal and External Excitation)......................................................11

Figure 2.9 Process Voltage Wiring Hooku

a) Without Sensor Excitation ..........................................................11

b) With Sensor Excitation ................................................................11

Figure 2.10 Communication Out ut:

a) RS-232 Out ut – Wiring Hooku ................................................12

b) RS-485 Out ut – Wiring Hooku ................................................12

Figure 3.1 Flow Chart for ID and Set oints........................................................14

Figure 3.2 Flow Chart for Configuration Menu ..................................................17

Figure 3.3 Flow Chart for In ut Ty e Menu........................................................17

Figure 3.4 Flow Chart for Reading Configuration .............................................20

Figure 3.5 Flow Chart for Alarm 1 .......................................................................24

Figure 3.6 Flow Chart for Alarm 2 .......................................................................28

Figure 3.7 Flow Chart for Reading Adjust Menu ...............................................29

Figure 3.8 Flow Chart for Set oint Deviation Menu / Field Calibration...........30

Figure 3.9 Flow Chart for ID Code.......................................................................31

Figure 3.10 Flow Chart for Communication O tion ............................................33

Figure 3.11 Flow Chart for Dis lay Color Selection............................................39

LIST OF TABLES:

Table 2.1 Front Panel Annunciators....................................................................6

Table 2.2 Rear Panel Connector..........................................................................7

Table 2.3 TC Wire Color Chart .............................................................................9

Table 3.1 Button Function in Configuration Mode...........................................13

Table 3.2 Conversion Table................................................................................23

Table 4.1 In ut Pro erties..................................................................................44

Table 5.1 Factory Preset Values ........................................................................45

ii

NOTES, WARNINGS and CAUTIONS

Information that is es ecially im ortant to note is identified by following labels:

• NOTE

• WARNING or CAUTION

• IMPORTANT

• TIP

NOTE: Provides you with information that is im ortant to successfully

setu and use the Programmable Digital Meter.

CAUTION or WARNING: Tells you about the risk of electrical shock.

CAUTION, WARNING or IMPORTANT: Tells you of circumstances or

ractices that can effect the instrument’s functionality and must refer

to accom anying documents.

TIP: Provides you hel ful hints.

1

PART 1

INTRODUCTION

1.1 Descri tion

This device can be urchased as monitor (read rocess value only) or as

a controller.

• The iLD Big Dis lay monitor offers un aralleled flexibility in rocess

measurement. Each unit allows the user to select the in ut ty e, from

10 thermocou le ty es (J, K, T, E, R, S, B, C, N and J DIN), Pt RTDs (100,

500 or 1000 Ω, with either 385 or 392 curve), DC voltage, or DC current.

The voltage/current in uts are fully scalable to virtually all engineering units,

with selectable decimal oint, erfect for use with ressure, flow or other

rocess in ut.

• The iLD Big Dis lay device features a large, three color rogrammable

dis lay with ca ability to change a color every time the Alarm is triggered.

O tions include rogrammable RS-232 or RS-485 serial communication and

excitation. Universal ower su ly acce ts 100 to 240 Vac.

2

1.2 Safety Considerations

This device is marked with the international caution symbol. It is im ortant

to read this manual before installing or commissioning this device as it

contains im ortant information relating to Safety and EMC

(Electromagnetic Com atibility).

This instrument is a anel mount device rotected in accordance with

EN 61010-1:2001, electrical safety requirements for electrical equi ment

for measurement, control and laboratory. Installation of this instrument

should be done by qualified ersonnel. In order to ensure safe o eration,

the following instructions should be followed.

This instrument has no ower-on switch. An external switch or circuit-

breaker shall be included in the building installation as a disconnecting

device. It shall be marked to indicate this function, and it shall be in close

roximity to the equi ment within easy reach of the o erator. The switch or

circuit-breaker shall meet the relevant requirements of IEC 947–1 and

IEC 947-3 (International Electrotechnical Commission). The switch shall

not be incor orated in the main su ly cord.

Furthermore, to rovide rotection against excessive energy being drawn

from the main su ly in case of a fault in the equi ment, an overcurrent

rotection device shall be installed.

• Do not exceed voltage rating on the label located on the to of the

instrument housing.

• Always disconnect ower before changing signal and ower

connections.

• Do not use this instrument on a work bench without its case for safety

reasons.

• Do not o erate this instrument in flammable or ex losive atmos heres.

• Do not ex ose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure

instrument does not exceed o erating tem erature rating.

• Use electrical wires with adequate size to handle mechanical strain

and ower requirements. Install without ex osing bare wire outside the

connector to minimize electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and ower wires in the same conduit.

• Use signal wire connections with twisted- air cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC

roblems ersist.

Failure to follow all instructions and warnings may result in injury!

3

1.3 Before You Begin

Ins ecting Your Shi ment:

Remove the acking sli and verify that you have received everything

listed. Ins ect the container and equi ment for signs of damage as soon

as you receive the shi ment. Note any evidence of rough handling in

transit. Immediately re ort any damage to the shi ing agent. The carrier

will not honor damage claims unless all shi ing material is saved for

ins ection. After examining and removing the contents, save the acking

material and carton in the event reshi ment is necessary.

Customer Service:

If you need assistance, lease call the nearest Customer Service

De artment, listed in this manual.

Manuals, Software:

The latest O eration and Communication Manual as well as free

configuration software and ActiveX controls are available from the

website listed in this manual or on the CD-ROM enclosed with your

shi ment.

For first-time users: Refer to the QuickStart Manual for basic o eration

and set-u instructions.

If you have the Serial Communications/Ethernet O tion you can easily

configure the controller on your com uter or on-line.

To Disable Out uts:

Standby Mode is useful during setu of the instrument or when

maintenance of the system is necessary. When the instrument is in

standby, it remains in the ready condition but all out uts are disabled.

This allows the system to remain owered and ready to go.

When the instrument is in "RUN" Mode, ush dtwice to disable all

out uts and alarms. It is now in "STANDBY" Mode. Push donce more

to resume "RUN" Mode.

PUSH dTWICE to disable the system during an EMERGENCY.

To Reset the Meter:

When the controller is in the "MENU" Mode, ush conce to direct

controller one ste backward of the to menu item.

Push ctwice to reset controller, rior to resuming "Run" Mode exce t

after "Alarms", that will go to the "Run" Mode without resetting the

controller.

4

PART 2

SETUP

2.1 Mounting

Figure 2.1 Mounting

5

Mounting iLD Big Dis lay Through Panel:

1. Using the anel cutout diagram shown in your Quick Start manual, cut

an o ening in the anel.

2. Remove six (or eight) screws at the back of iLD Big Dis lay to remove

back cover.

3. Insert the unit into the o ening from the front of the anel so the gasket

seals between the bezel and the front of the anel.

4. Pass all wiring through customer drilled holes in back cover and

connect wiring to terminal blocks.

5. Align back cover to iLD Big Dis lay and reinstall screws.

Mounting iLD Big Dis lay on Bail:

1. Remove six (or eight) screws at the back of iLD Big Dis lay to remove

back cover.

2. Pass all wiring through customer drilled holes in back cover and

connect wiring to terminal blocks.

3. Align back cover to iLD Big Dis lay and reinstall screws.

4. Mark the location of mounting screws on the flat surface.

5. Be sure to leave enough room around the bail to allow for removal and

rotation of the dis lay.

6. The dis lay can be rotated for the best viewing angle.

Table 2.1 Front Panel Annunciators

1Out ut 1/Set oint 1/ Alarm 1 indicator

2Out ut 2/Set oint 2/ Alarm 2 indicator

°C °C unit indicator

°F °F unit indicator

aChanges dis lay to Configuration Mode

and advances through menu items*

bUsed in Program Mode and Peak Recall*

cUsed in Program Mode and Valley Recall*

d

Accesses submenus in Configuration Mode

and stores selected values*

* See Part 3 O eration: Configuration Mode

6

7

2.2 Rear Panel Connections

The rear anel connections are shown in Figures 2.2 and 2.3.

Figure 2.2 Rear Panel Power Connections

Figure 2.3 Rear Panel In ut Connections

Table 2.2 Rear Panel Connector

POWER AC Power Connector: All models

INPUT In ut Connector: TB7 & TB8 for TC models

TB9 for PR (Process) & RTD models

OPTION Based on one of the following models:

RS-232C or RS-485

213

8

2.3 Electrical Installation

2.3.1 Power Connections

Caution: Do not connect ower to your device until you have com leted all

in ut and out ut connections. Failure to do so may result in injury!

Connect the main ower connections as shown in Figure 2.4.

Figure 2.4 Main Power Connections

Figure 2.5 Inside Cover Rear View

1 2 3 1 2 1 2 3 4 5

L N + -

1 2 31 2 3 4 5 6 1 2 3 4 5 6 7 8

1 2 3 4 5 6

1 3 5

2 4 6

+ -

OUTPUT2 OUTPUT1

RTN

Rx Tx

1 2

TB5A TB5CTB5B

3 4 5 6

iLD24 OUTPUTS

OUTPUT2 OUTPUT1

AC

PWR

TB1

DC

PWR

REMOTE

PROGRAMMER

TB2 TB3 TB4 TB9

TB7 TB8

PJ3

COMMUNICATION OUTPUTS T/C INPUT INPUTS

TB5

123

9

2.3.2 Thermocou le

The figure below shows the wiring hooku for any thermocou le ty e. For

exam le, for Ty e K hooku , connect the yellow wire to the TB7 terminal and the

red wire to the TB8 terminal.

When configuring your controller, select Thermocou le and Thermocou le

Ty e in the In ut Ty e menu (see Part 3).

Figure 2.6 Thermocou le Wiring Hooku

TYPE In ut Connector Jacket (external insulation)

Terminal 8 (-) Terminal 7 (+) Extension Grade

JRed White dark-Brown Black

KRed Yellow dark-Brown Yellow

TRed Blue dark-Brown Blue

ERed Pur le dark-Brown Pur le

NRed Orange dark-Brown Brown

RRed Black - Green

SRed Black - Green

BRed Gray - Black

Table 2.3 TC Wire Color Chart

10

2.3.3 Two/Three/Four-Wire RTD

The figures below show the in ut connections and in ut connector jum ers

(shown in bold lines) required to hooku a 2-, 3- or 4-wire RTD.

Figure 2.7

a)

RTD-1000 ohm and 500 ohm b) RTD-100 ohm Wiring Hooku

Wiring Hooku

The two-wire connection is sim lest method, but does not com ensate for

lead-wire tem erature change and often requires calibration to cancel lead-wire

resistance offset.

The three-wire connection works best with RTD leads closely equal in

resistance. The device measures the RTD, lus u er and lower lead dro

voltage and the subtracts twice the measured dro in the lower su ly current

lead roducing excellent lead-resistance cancellation for balanced

measurements.

The four-wire RTD hooku is a licable to unbalanced lead resistance and

enables the device to measure and subtract the lead voltage, which roduces

the best lead-resistance cancellation.

When configuring your controller, select RTD ty e and RTD value in the

In ut Ty e menu (see Part 3).

If the in ut wires of the meter get disconnected or broken, it will dis lay

+OPN “In ut (+) O en” message exce t in case of 500/1000 Ω 2-wire

RTD. In this case the dis lay shows -OPN “In ut (-) O en” message. For

safety ur ose you may want to set u your alarm to be triggered when

in ut is o en. See Alarm 1 & 2 cha ters for details.

11

2.3.4 Process Current

The figure below shows the wiring hooku for Process Current 0 – 20 mA.

Figure 2.8 Process Current Wiring Hooku

(Internal and External Excitation)

When configuring your instrument, select Process Ty e in the In ut Ty e Menu (see Part 3).

2.3.5 Process Voltage

The figure below shows the wiring hooku for Process Voltage 0 – 100 mV,

0 – 1 V, 0 – 10 V.

Figure 2.9

a) Process Voltage Wiring Hooku b) Process Voltage Wiring Hooku

with Sensor Excitation without Sensor Excitation

RL- Voltage limiting resistor, which allows conversion of the 24 Vdc internal excitation voltage to

the a ro riate rocess in ut value. For instance: if the otentiometer value is equal to 10 kΩ, the

minimum RLis 14 kΩ for 10 V rocess in ut.

When configuring your instrument, select Process Ty e in the In ut Ty e Menu (see Part 3).

12

2.3.6 Communication Out ut

This device may have a rogrammable communication out ut. The RS-232 and

RS-485 Out ut Connection are shown below.

Figure 2.10

a) RS-232 Out ut Wiring Hooku b) RS-485 Out ut Wiring Hooku

11

13

PART 3

OPERATION: Configuration Mode

3.1 Introduction

The instrument has two different modes of o eration. The first, Run Mode, is

used to dis lay values for the Process Variable, and to dis lay or clear Peak

and Valley values. The other mode, Menu Configuration Mode, is used to

navigate through the menu o tions and configure the controller. Part 3 of this

manual will ex lain the Menu Configuration Mode. For your instrument to

o erate ro erly, the user must first " rogram" or configure the menu o tions.

Turning your Controller On for the First Time

The device becomes active as soon as it is connected to a ower source. It

has no On or Off switch. The device at first momentarily shows the software

version number, followed by reset RST, and then roceeds to the Run Mode.

Table 3.1 Button Function in Configuration Mode

• To enter the Menu, the user must first ress abutton.

• Use this button to advance/navigate to the next menu item. The user can

navigate through all the to level menus by ressing a.

• While a arameter is being modified, ress ato esca e without saving

the arameter.

• Press the u bbutton to scroll through “flashing” selections. When a

numerical value is dis layed ress this key to increase value of a

arameter that is currently being modified.

• Holding the bbutton down for a roximately 3 seconds will s eed u the

rate at which the set oint value increments.

• In the Run Mode ress bcauses the dis lay to flash the PEAK value –

ress again to return to the Run Mode.

• Press the down cbutton to go back to a revious To Level Menu item.

• Press this button twice to reset the controller to the Run Mode.

• When a numerical value is flashing (exce t set oint value) ress cto

scroll digits from left to right allowing the user to select the desired digit to

modify.

• When a set oint value is dis layed ress cto decrease value of a

set oint that is currently being modified. Holding the cbutton down for

a roximately 3 seconds will s eed u the rate at which the set oint

value is decremented.

• In the Run Mode ress ccauses the dis lay to flash the VALLEY value –

ress again to return to the Run Mode.

• Press the enter dbutton to access the submenus from a To Level

Menu item.

• Press dto store a submenu selection or after entering a value — the

dis lay will flash a STRD message to confirm your selection.

• To reset flashing Peak or Valley ress d.

• In the Run Mode, ress dtwice to enable Standby Mode with

flashing STBY.

Reset: Exce t for Alarms, modifying any settings of the menu configuration

will reset the instrument rior to resuming Run Mode.

a

MENU

b

(UP)

c

(DOWN)

d

ENTER

14

3.2 Menu Configuration

It is recommended that you ut the controller in the Standby Mode for

any configuration change other than Set oints & Alarms.

Figure 3.1 Flow Chart for ID and Set oints

15

3.2.1 ID Number

SEE ID MENU SELECTION IN CONFIGURATION SECTION FOR

ENABLE/DISABLE OR CHANGE ID CODE.

If ID Code is Disabled or set as Default (0000) the menu will ski ID ste

to Set oint Menu.

If ID Code is set to Full Security Level and user attem ts to enter the

Main Menu, they will be rom ted for an ID Code.

If ID Code is set to Set oint/ID Security Level and user attem ts to enter

the Configuration Menu, they will be rom ted for an ID Code.

ENTERING YOUR NON-DEFAULT FULL SECURITY ID NUMBER.

Press a1) Dis lay shows ID.

Press d2) Dis lay advances to ____.

Press b& c3) Press bto increase digit 0-9. Press cto activate next digit

(flashing). Continue to use band cto enter your 4-digit ID

code.

Press d4) If the correct ID code is entered, the menu will advance to the

Set oint 1 Menu, otherwise an error message ERRo will be

dis layed and the instrument will return to the Run Mode.

To change ID Code, see ID Menu in the Configuration section.

ENTERING YOUR NON-DEFAULT SETPOINT/ID SECURITY ID NUMBER.

Press a5) Dis lay shows SP1 Set oint 1 Menu.

Press a6) Dis lay shows SP2 Set oint 2 Menu.

Press a7) Dis lay shows ID ID Code Menu.

Press d8) Dis lay advances to ____.

Press b& c9) Use band cto change your ID Code.

Press d10) If correct ID Code is entered, the dis lay will advance to the

INPT In ut Menu, otherwise the error message ERRo will be

dis layed and the controller will return to the Run Mode.

To revent unauthorized tam ering with the setu arameters, the

instrument rovides rotection by requiring the user to enter the ID Code

before allowing access to subsequent menus. If the ID Code entered

does not match the ID Code stored, the controller res onds with an error

message and access to subsequent menus will be denied.

Use numbers that are easy for you to remember. If the ID Code is

forgotten or lost, call customer service with your serial number to access

and reset the default to 0000.

16

3.2.2 Set Points

SETPOINT 1:

Press a1) Press a, if necessary until SP1 rom t a ears.

Press d2) Dis lay shows revious value of “Set oint 1”.

Press b& c3) Press band cto increase or decrease Set oint 1

res ectively.

Holding b& cbuttons down for a roximately 3 seconds will s eed u the

rate at which the Set oint value increments or decrements.

Press b& c4) Continue to use band cto enter your 4-digit Set oint 1 value.

Press d5) Dis lay shows STRD stored message momentarily and then

advances to SP2 only, if a change was made, otherwise ress

ato advance to SP2 Set oint 2 Menu.

SETPOINT 2:

Press d6) Dis lay shows revious value of “Set oint 2”.

Press b& c7) Press band cto increase or decrease Set oint 2

res ectively.

Holding b& cbuttons down for a roximately 3 seconds will s eed u

the rate at which the set oint value increments or decrements.

Press d8) Dis lay shows STRD stored message momentarily and then

advances to CNFG only, if a change was made, otherwise ress

ato advance to CNFG Configuration Menu.

Other manuals for i Series

3

This manual suits for next models

1

Table of contents

Other Newport Monitor manuals