Newport MM2000 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Newport / Klinger MM2000 at our website: Click HERE

O

PERATOR

’

S

M

ANUAL

DC Interface Box

for use with

MM2000 Motion Controller/Driver

ESP6000 Motion Controller/Driver

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

DC Interface Box

for use with

MM2000 Motion Controller/Driver

ESP6000 Motion Controller/Driver

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

Warranty

Newport Corporation warrants this product to be free from defects in

material and workmanship for a period of one year from the date of ship-

ment. If found to be defective during the warranty period, the product will

either be repaired or replaced at Newport’s option.

To exercise this warranty, write or call your local Newport office or repre-

sentative, or contact Newport headquarters in Irvine, California. You will

be given prompt assistance and return instructions. Send the instrument,

transportation prepaid, to the indicated service facility. Repairs will be

made and the instrument returned, transportation prepaid. Repaired

products are warranted for the balance of the original warranty period, or

at least 90 days.

Limitation of Warranty

This warranty does not apply to defects resulting from modification or

misuse of any product or part. This warranty also does not apply to fuses,

batteries, or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied,

including any implied warranty of merchantability or fitness for a particular

use. Newport Corporation shall not be liable for any indirect, special, or

consequential damages.

First Printing May, 1998

Copyright 1998 by Newport Corporation, Irvine, CA. All rights reserved.

No part of this manual may be reproduced or copied without the prior

written approval of Newport Corporation.

This manual has been provided for information only and product specifi-

cations are subject to change without notice. Any changes will be reflected

in future printings.

© 1998 Newport Corporation

1791 Deere Avenue

Irvine, CA 92606

(949) 863-3144

P/N 25564-01, Rev.E

IN-04981(01-00)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

Table of Contents

Section Title Page

Warranty ............................................................................................................ii

List of Figures ..................................................................................................iv

List of Tables....................................................................................................iv

Section 1 — Introduction and Overview ......................................1-1

1.1 Description Summary - DC Interface Box ..........................................1-1

1.2 Motor Power Requirements ................................................................1-3

1.3 Description of Panel Functions on DCIB ............................................1-4

1.4 DCIB DC Module Specifications ..........................................................1-6

1.5 Application for MM2000 and ESP6000 Motion Controllers..............1-6

1.6 General Safety Considerations ............................................................1-8

Section 2 — Installation ..........................................................................2-1

2.1 Connecting the DCIB to MM2000 or ESP6000 Motion Controllers..2-1

2.2 Installing the DCIB DC Module inside the DCIB ................................2-2

Section 3 — Connector PIN Assignments ......................................3-1

3.1 Connector Pin Assignments for DCIB ................................................3-1

3.2 Connector Pin Assignments for MM2000 Motion Controller ..........3-2

3.3 Connector Pin Assignments for ESP6000 Motion Controller ..........3-5

Section 4 — Maintenance and Repair ............................................4-1

4.1 Maintenance ..........................................................................................4-1

4.2 Obtaining Service ..................................................................................4-3

4.3 Recommended Long-Term Maintenance (Service Contract) ..........4-3

4.4 Service Form ..........................................................................................4-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

List of Figures

Figure No. Title Page

1-1 DCIB Configuration with MM2000 Controller Card................................1-1

1-2 DCIB Configuration with ESP6000 Controller Card................................1-1

1-3 PWR2 - AC Powered ..................................................................................1-5

1-4 PWR2 - DC Powered ..................................................................................1-5

2-1 View inside the DC Interface Box ............................................................2-1

2-2 Installation View of Jumpers inside the DCIB ........................................2-3

2-3 View of DCIB DC Module ..........................................................................2-5

List of Tables

Table No. Title Page

1-1 Settings for an eight-position rotary switch ..........................................1-6

2-1 Jumper and Switch Settings......................................................................2-4

3-1 AUX Connector Pin Outs (15-pin connector) ........................................3-1

3-2 Pinouts for DCIB (J1 - 25-Pin Connector Pinouts) ................................3-1

3-3 Pinouts for MM2000 Motion Controller (J3 - 68-Pin

Connector Pinouts)....................................................................................3-2

3-4 Motor/Driver Interface (100-to-68 Pin) Cable to Connector Pinouts

(ESP6000 Motion Controller)....................................................................3-5

4-1 Trouble-Shooting Guide ............................................................................4-2

4-2 Technical Customer Support Contacts ..................................................4-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 1 — Introduction and Overview

1.1 Description Summary — DC Interface Box

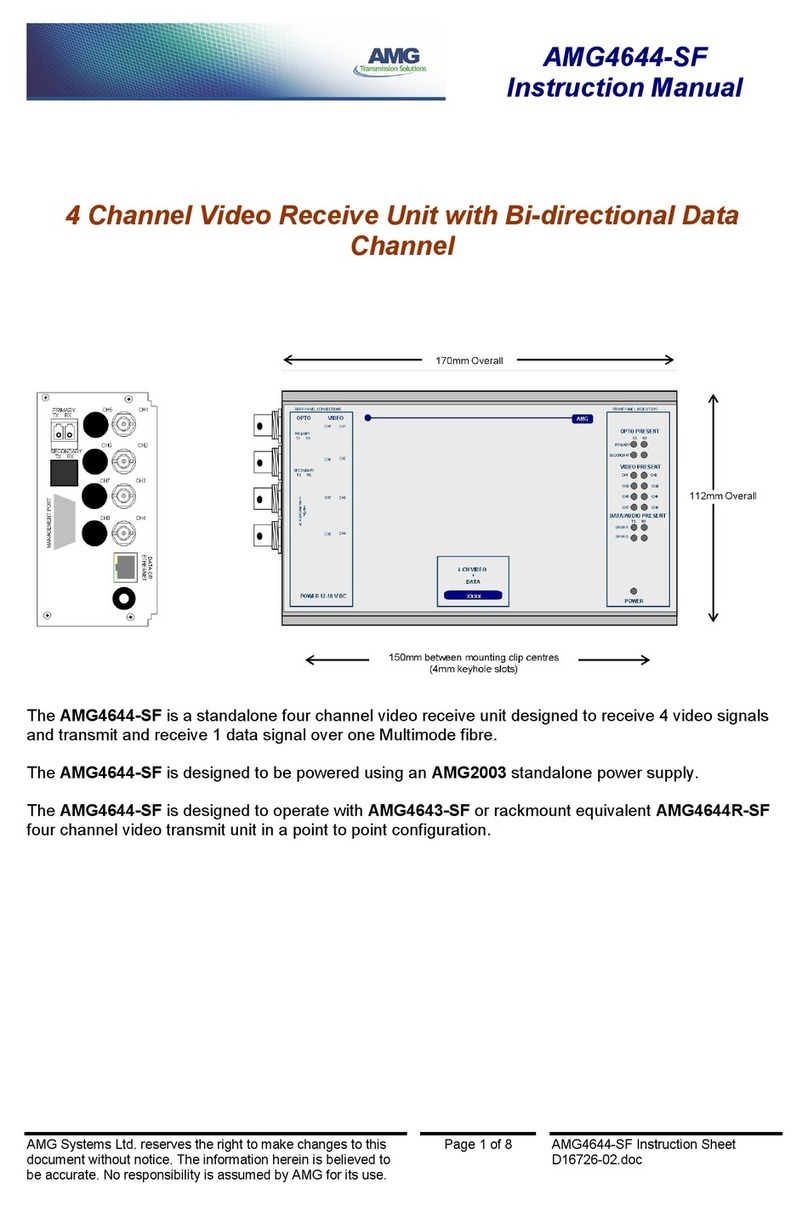

Figure 1-1: DCIB Configuration with MM2000 Controller Card

Figure 1-2: DCIB Configuration with ESP6000 Controller Card

Section 1 — Introduction and Overview 1-1

DC Interface Box68-pin Connector

68-pin Connector

MM2000 Controller Card

DC Interface Box

68-pin Connector

100-pin Connector

ESP6000 Controller Card

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-2

1. Used with small DC Motors

In the current configuration, the DC Interface Box is intended to be used

primarily with small DC motors. The motors could be driven directly by

the modules of the MM2000 Motion Controller, or by the DC Module of the

DC Interface Box. Due to the power supply constrains of the typical PC,

the applications with the MM2000, are limited to only two actuators mov-

ing at a time. With the DCIB DC Module(s), four actuators can be moving

at a time.

Motor OFF Feature

An important feature of the DC Interface Box is the support for the manual

position-adjusting knob. This knob, present on the 850F actuator, needs an

open motor circuitry in order to operate with the minimum resistance.

The function is implemented with one relay for each axis, controlled by

the MM2000 board through the user I/O lines, or ESP6000 board through

the Amplifier Enable Output lines.

For MM2000 Only:

Due to the limited number of I/O lines, three modes of relay control are

available to allow the user to select the configuration that best fits his

application. A bank of four jumpers selects which I/O line, if any, will be

used to activate the open-motor relay.

Each axis jumper could set one of the following modes:

• jumpers on the right (as shown in the chart above) : The same I/O line

controls all relays, number 7. (factory default setting)

• jumpers on the left: Each relay is controlled by a different I/O line; in

this case the relays for axis number 1, 2, 3 and 4 are controlled by the

I/O bits number 4, 5, 6 and 7, respectively.

• jumpers missing: The relays are always closed and the I/O lines are

available for general-purpose interface.

NOTE

The three different modes of operation can be mixed on the four axes.

I/O 7

I/O 6

I/O 5

I/O 4

I/O 7

…………Axis #4

…………Axis #3

…………Axis #2

…………Axis #1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 1 — Introduction and Overview 1-3

NOTE

Once an I/O line is selected to control an open-motor relay, it cannot be

used for general-purpose interface.

NOTE

If the interface box is used with MM2000 firmware version 1.4 or earli-

er, the I/O bits must be toggled manually through the use of the BO, CB

and SB commands. A high bit turns the motors off.

For ESP6000 Only:

This information is the same as MM2000, with the following exceptions:

• I/O’s 4, 5, 6, and 7 are performed by Amplifier Enable Output lines of

their respective axes. Jumpers have the same function of enabling and

disabling the operation of the Amplifier.

2. Used as a Pass-Through Box

When used as a pass-through box with a driver unit (MD4 or similar), the

DC Interface Box fans out the command and feedback signals to one auxil-

iary and four axis interface connectors. To eliminate the possibility of

unwanted motor movement during the controller’s power ON/OFF cycles,

special circuitry monitors all voltages and disables the command signals

to the driver during all power transactions.

1.2 Motor Power Requirements

DC Module of the MM2000 has a built-in amplifier capable of driving small

DC motors up to 200 mA.

Due to power supply constraints of the typical PC, the applications with

the MM2000, are limited to only two actuators moving at a time. The DCIB

DC Module is capable of driving small DC motors up to 400 mA.

If increased power requirements are needed by the user, or to avoid draw-

ing power from the PC power supply, the user can drive the system using

the Universal Interface Box with plug-in DC Modules.

When DC Modules are used, an external power source is always required.

The DCIB has a built-in low voltage power supply, which has advanced

voltage monitoring capabilities.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-4

If voltage is between 12 -19V, the relay will close and NORMAL (Green) LED

will illuminate.

If voltage is under 12 volts, relay will open and LOW (Red) LED will illuminate.

If voltage is over 19 volts, relay will open and HIGH (Red) LED will illuminate.

Summary: The DCIB DC Module is NOT operating if the Green LED is not

illuminated!

1.3 Description of Panel Functions on DCIB

Front Panel:

The Front Panel of the DCIB includes the following items, reading left to

right:

AUX This is a 15-Pin Connector that gives access to the I/O bits

or, with simple modifications on the board, to the encoder

or pulse train signals. (See Pinouts in Section 3 of this

manual).

Main This is a 68-Pin Connector used for an Interconnect Cable

Connector link, from the MotionMaster2000 or ESP6000 motherboard

to the DCIB (See Pinouts in Section 3 of this manual).

LED’s External Power Voltage status is indicated by three Light

Emitting Diodes (LED): LOW, NORMAL, and HIGH.

• LOW (Red) - This LED is for LOW Power Voltage, and is

illuminated when DCIB power is on.

• NORMAL (Green) - This LED is for NORMAL Power

Voltage.

• HIGH (Red) - This LED is for HIGH Power Voltage.

PWR 1 This is an external power supply connector to be used

when a DC driver module is present.

Transformer

(Power Source)

A

Rectifier

DC

AC

PWR Relay

UIB

Amplifier

A = Electronic circuitry is monitoring this point.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 1 — Introduction and Overview 1-5

PWR 2 This secondary power connector can be powered by a

transformer with a center tap, or by an external dual volt-

age power supply (See Figure 1-3).

Figure 1-3: PWR2 AC Powered

Figure 1-4: PWR2 - DC Powered

NOTE

Polarity Orientation not important!

Recommended transformer to be used with the DCIB:

• AC-AC Wall Mount Adapter with the following specifications:

12VAC at 2 amps (To be connected to PWR1 on the front panel of the

DCIB). An AC – AC wall mount adapter (P/N 22588-01 for 110V line) is

included if at least one driver module is installed.

Rear Panel:

The four (4) connectors on the rear panel are labeled: AXIS 1, AXIS 2, AXIS

3, and AXIS 4. These connectors are used for connections to DC Servo

Motors, or MD4 Driver.

Line

Safety

Fused

DC

Power

Supply

+15V

0V

–15V

PWR2

Line

Safety

Fused

12V

PWR2

12V

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-6

1.4 DCIB DC Module Specifications

The DCIB DC Module is a low power DC motor driver designed to work

with the DC Interface Box. Its main specifications are:

• Drives both 12V and 24V DC motors. Voltage is selectable via a jumper.

• Drives DC motors up to 400mA.

• Capable to generate limit switch signals or limits the motor current

when motor current exceeds a preset value. Mode of operation is selec-

table with a jumper. When the jumper is missing, both functions are

disabled.

• The current setting for both modes of operation is done with an eight

position rotary switch, having the following settings:

Table 1-1: Settings for an eight position rotary switch

Position Current Limit/Trigger

0 Disabled

1 400 mA

2 200 mA

3 133 mA

4 100 mA

5 80 mA

6 66 mA

7 57 mA

1.5 Application for MM2000 and ESP6000 Motion Controllers

Introduction - MM2000 Motion Controller

The MotionMaster 2000 is an advanced motion controller which plugs

directly into any IBM PC / XT / AT and compatible computers. This

includes computers with 8088, 80286, 80386, and 80486 microprocessors,

and which are not PS/2 model types. In addition to the PC-bus interface,

the unit includes a full duplex RS-232-C serial interface and supports an

optional IEEE-488 interface. Using “piggy-back” plug-in modules, one (1)

MotionMaster 2000 main-board supports up to four (4) axes of motion

consisting of any combination of stepping, or brush DC servo motors.

The hardware that comprises the MotionMaster 2000 system is:

1. A motherboard that plugs into an expansion slot of an IBM PC / XT /

AT and compatible computers.

2. A stepping motor module that plugs onto the motherboard and/or...

3. A DC motor or stepper motor module that plugs onto the mother-

board.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 1 — Introduction and Overview 1-7

Description - MM2000 Motion Controller

The MotionMaster 2000 is “state-of-the-art” technology with two 16-bit

microcontrollers and sophisticated internal software to achieve high-

speed intelligent positioning. Its capabilities range from simple point to

point positioning to elaborate tasks which require multiaxis coordination

and velocity and position change ‘on the fly’.

The MM2000 is command driven. With a host computer, the user sends

commands that direct it to carry out typical operations in a motion con-

trol system. For example, included in its command set, there are com-

mands which tell the MM2000 the distance, the direction, the speed, and

the acceleration of the next move, and which direct it to send system sta-

tus information, typically the position as the move progresses, whether

the move is complete or in progress, and whether an error has occurred.

The MM2000 can be set up to interrupt the users host computer when a

move is complete or any error or unexpected event occurs. This will great-

ly improve the user’s execution speeds and processing power because

their host computer is free to execute other tasks during a typical move

and still know exactly when the move is complete...so that the next one

can be initiated, for example.

The MM2000 provides 25,000 bytes of non-volatile memory for

program/parameter storage. Sophisticated motions control programs with

“IF...THEN” and “WHILE ... WEND” statements, which test the logical levels

of 8 I/O bits, can be created. Also system configurations and options such

as velocity, acceleration, software limits, and PID compensation parame-

ters are retained during power off and automatically reloaded at power on.

The MM2000 features encoder counting circuitry and commands that

enable the user to read the position of the system at any instant of time.

The encoder required is an incremental encoder with TTL compatible

quadrature outputs.

The MM2000 can be directed to find a home position defined by either the

location of a switch or the position where its internal position counter is

zero. It also monitors plus and minus direction limits inputs to protect the

user’s system from damage.

The MM2000 features an elaborate command interpreter and system moni-

tor. Every command received is analyzed for the correct format. If the

command format is incorrect, the MM2000 will not execute the command

and will store a descriptive error message in its output buffer.

Description - ESP6000 Motion Controller

The Enhanced System Performance (ESP) architecture consists of the

ESP6000 controller card, UniDrive6000 universal motor driver, and ESP-

compatible stages. The ESP6000 controller card is designed for convenient

installation in the user’s own PC.

The ESP6000’s Windows-based setup utility provides a full range of func-

tions for configuring and operating from one to six axes.

The system is designed to operate with Newport Corporation’s ESP-com-

patible stages, but can be configured to function with other stages.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-8

The ESP6000 includes the following features:

• Combined data acquisition and motion control

• ‘Plug-and-play’ controller, driver, and stage setup

• Bench-top or rack-mount configuration for the UniDrive6000

• Configured for any combination of motor type (DC/stepper) or size

• Feed-forward servo algorithm for smooth and precise motion

• Multi-axis synchronization

• Powerful motion programming capabilities in Visual Basic/C, and

LabVIEW languages. Extensive set of Newport Corporation-provided

commands.

• User-selectable displacement units

1.6 General Safety Considerations

The following general safety precautions must be observed during all

phases of operation of this equipment. Failure to comply with these pre-

cautions violates safety standards of design, manufacture, and intended

use of equipment.

Disconnect or do not plug in the power cord in the following circum-

stances:

• If the power cord or any other attached cables are frayed or damaged.

• If the power plug or receptacle is damaged.

• If the unit is exposed to rain or excessive moisture, or liquids are

spilled on it.

• If the unit has been dropped or the case is damaged.

• If the user suspects service or repair is required.

To protect the equipment from damage and avoid hazardous situations,

follow these recommendations:

• Do NOT make modifications or parts substitutions.

• Return equipment to Newport Corporation for service and repair.

• Do not touch, directly or with other objects, live circuits inside the

unit.

• Do not operate the unit in an explosive atmosphere.

• Keep liquids away from unit.

• Do not expose equipment to excessive moisture (>90% humidity).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 2 — Installation 2-1

Section 2 — Installation

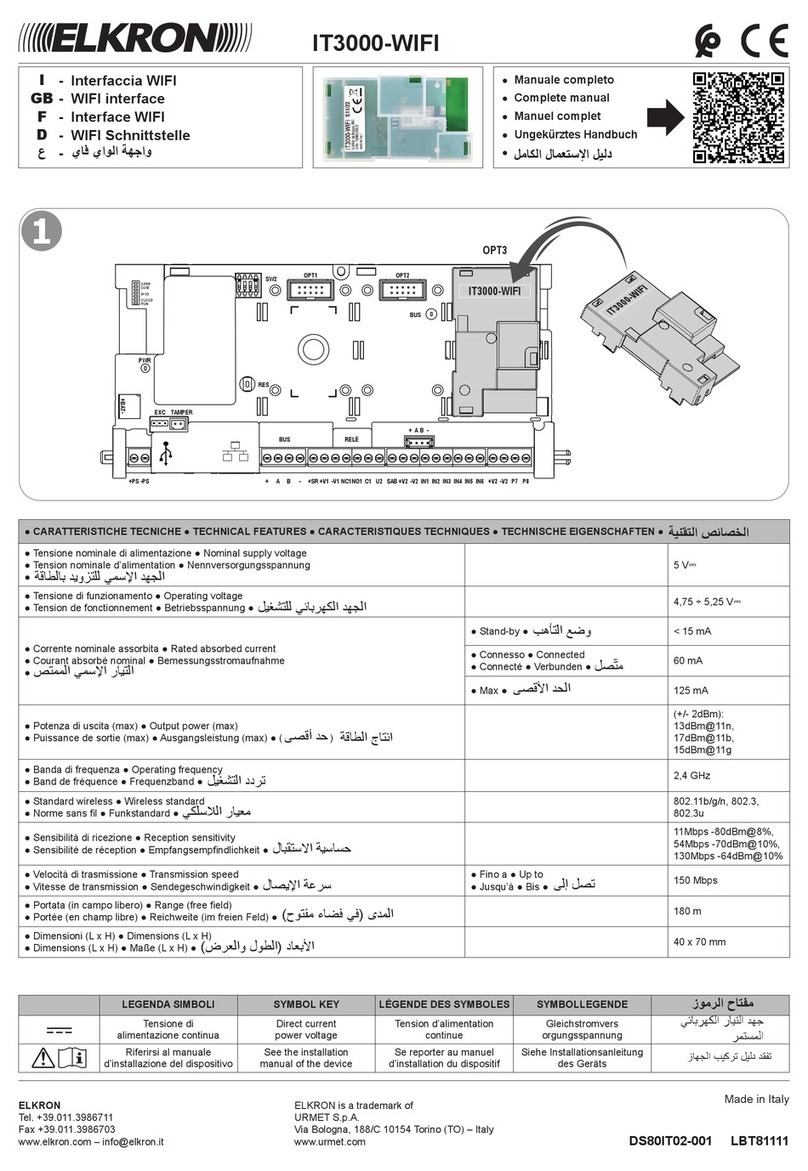

Figure 2-1: View inside the DC Interface Box

2.1 Connecting the DCIB to MM2000 or ESP6000 Motion Controllers

Connect MM2000 to Motors and/or Drivers:

The motor control signals generated by the MM2000 appear at the 68-pin

output connector at the back of the user’s computer. With the MM2000 the

user received a DC Interface Box, which divides the 68 signals into 4 axes

of motor control.

Locate the enclosed 68-pin shielded cable, connect one end to the

MM2000 output connector, and connect the other end to the DC Interface

Box.

The user should connect the motors and motor drivers to the 25 pin out-

put connectors on the rear panel of the DCIB. The connectors are labeled

AXIS 1, AXIS 2, AXIS 3, and AXIS 4.

NOTE

See Section 3 of the MM2000 Quick Installation and Start Up Guide,

Revision 3.2, for hook-up instructions.

AUX PWR1 PWR2

Main Connector

Location

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-2

NOTE

For Start-up of the MM2000, see Quick Installation and Start Up Guide,

Revision 3.2, section 5.

Connect DCIB to ESP6000:

The ESP6000 controller card comes with a 100-to-100 or 100-to-68 pin inter-

face cables which connect the UniDrive and DC Interface Box (DCIB),

respectively.

1. Driver Interface (100-100 pin) Cable

The driver interface cable connects the ESP6000 controller card to the

UniDrive6000. Connector Pin Assignments are shown in Section 3 of

this User Manual.

2. Motor/Driver (100-68 pin) Cable

The motor/driver cable connects the ESP6000 controller card to the

DCIB. Connector Pin Assignments are shown in Section 3 of this User

manual.

2.2 Installing The DCIB DC Module Inside The DCIB

To install a DC Module driver in a DC Interface Box, execute the following

steps:

1. Turn power off to the MM2000 or ESP6000 and the DC Interface Box.

2. Disconnect all cables from the DC Interface Box.

3. Remove the top cover of the DC Interface Box by removing the four

screws, two in each side.

4. Remove the three jumpers that belong to the axes receiving the mod-

ule (Figure 2-2). The jumpers are located inside the larger rectangle

identifying the location of each axis module, clearly marked in silk-

screen.

5. If limit switch signals need to be generated from the current sensing

circuit, cut the limit switch traces for the desired axes on the DC

Interface Box as indicated in Figure 2-2 (See Table 2-1, D).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 2 — Installation 2-3

Figure 2-2: Installation View of Jumpers inside the DCIB

6. Set the jumpers and current setting as needed (See Table 2-1, A, B, C,

and D) on the DC Module.

7. Insert the DC Module in the appropriate axis location. Observe the

three jumper headers on the DC Interface Box are also used as a key

for proper module location.

8. Place the DC Interface Box’s top cover back on the unit, and secure it

with the four screws.

9. The DC Interface Box is now ready to be reconnected and powered on.

NOTE

In order for a DC Module to be functional, an appropriate power supply

must be connected to the DC Interface Box.

Cut +LIMIT

and –LIMIT traces

between pads per

table D

Remove jumpers

Universal

Interface Board

Silk-screen

Axis #

+LIMIT

–LIMIT

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-4

Table 2-1: Jumper and Switch Settings

Table A: JP1 Settings

Setting Description

12V Driver set for 12V motors

24V Driver set for 24V motors

Missing Driver disabled

Table B: JP2 Settings

Setting Description

LD Current sensing enabled to emulate limit switches

CL Current sensing enabled to limit the motor current

Missing Current sensing disabled

Table C: SW1 Settings

Position Current limit/trigger

0 Current sensing disabled

1 400 mA

2 200 mA

3 133 mA

4 100 mA

5 80 mA

6 66 mA

7 57 mA

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 2 — Installation 2-5

Table D: Settings for Specific Motors

Motor Type SW1 JP1 JP2 Cuts on main board

UE16CC 5 12V CL None

UE30CC 2 24V CL None

UE31CC 5 24V CL None

UE32CC 1 24V CL None

850G-HS, 3 24V CL None

850F(-HS)

850G, 850G-LS, 5 12V CL None

850F-LS

850B 4 12V LD -LIMIT and +LIMIT

850B-HS 3 12V LD -LIMIT and +LIMIT

850B-LS 5 12V LD -LIMIT and +LIMIT

495 3 12V CL None

496 2 12V CL None

850F, 3 12V CL None

CMA-xxCCCL

Figure 2-3: View of DCIB DC Module

DC Module

PCB Assembly

mounted

inside DCIB

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-6

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents

Other Newport Recording Equipment manuals