Newport PLATINUM Series User manual

DasyLAB MODBUS Interface Manual

Additional products from

Counters

Frequency Meters

PID Controllers

Clock/Timers

Printers

Process Meters

On/Off

Controllers

Recorders

Relative

Humidity

Transmitters

Thermocouples

Thermistors

Wire

Wireless

Rate Meters

Timers

Totalizers

Strain Gauge

Meters

Voltmeters

Multimeters

Soldering Iron

Testers

pH pens

pH Controllers

pH Electrodes

RTDs

Thermowells

Flow Sensors

For Immediate Assistance

In the U.S.A. and Canada: 1-800-NEWPORT

®

In Mexico: (95) 800-NEWPORT

SM

Or call your local NEWPORT Office.

The information contained in this document is believed to be correct but NEWPORT Electronics, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

TRADEMARk NOTICE: ®

,

®

NEWPORT, NEWPORT®,and newportUS.com are trademarks of NEWPORT

Electronics, Inc.

This device is marked with the international caution symbol. It is important to read the Setup Guide before

installing or commissioning this device as it contains important information relating to safety and EMC.

Newport Electronics, Inc.

2229 South Yale Street

Santa Ana, CA 92704

www.newportUS.com

DasyLab Platinum Modbus Interface

Revision 1.0 Page 1 of 11

Table of Contents

1Introduction........................................................................................................... 2

1.1 Purpose....................................................................................................................2

1.2 Definition of Terms and Acronyms ........................................................................2

1.3 Applicable Documents............................................................................................3

2Modbus Interface.................................................................................................. 4

2.1 Modbus Functions ..................................................................................................4

2.2 Data Formats ...........................................................................................................4

2.2.1 Multiple Register Reads........................................................................................................ 4

2.2.2 Multiple Register Writes ........................................................................................................5

2.2.3 Request Packet Sizes........................................................................................................... 5

2.2.4 Modbus USB Support ...........................................................................................................6

3Platinum Modbus Register Assignments........................................................... 7

3.1 DasyLab Platinum Modbus Registers....................................................................7

3.2 DasyLab Platinum Modbus Register Access ........................................................8

3.3 Example ...................................................................................................................9

3.3.1 Serial inteface........................................................................................................................9

3.3.2 TCP/IP Interface..................................................................................................................11

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 2 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

1 Introduction

1.1 Purpose

The following document defines the Modbus protocol support and register mapping used by the

Platinum product allowing interfacing to the DasyLab Modbus interface software.

The Modbus interface is available on all communication channels and support is provided for

MODBUS/ASCII, MODBUS/RTU and MODBUS/TCP/IP transactions.

1.2 Definition of Terms and Acronyms

I2C 2 wire serial interface

Base Device Device connected to slave device

Smart Input Device supporting 1 or more Input sensors

Smart Output Device supporting 1 or more Output Elements

Sensor Element One of the physical sensing elements on a Smart Output

AC Alternating Current

DC Direct Current

CS Chip Select

ADC Analog to Digital Converter

DAC Digital to Analog Converter

RS485 Electrical signals used for serial communications

RS232 Electrical signals used for serial communications

CSV Comma Separated Values

COTS Commercially-Off-The-Shelf

ESD Electo Static Discharge

FW Firmware

HW Hardware

I/O Input/Output

LED Light Emitting Diode

Hexadecimal Values expressed using base 16 (24)

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 3 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

1.3 Applicable Documents

Doc. # Name / Description Rev. #

Platinum Modbus Interface Reference 1.0

Platinum Load and Save File Format 0.0.1

Platinum Ramp and Soak Processing

0.0.1

MODBUS APPLICATION PROTOCOL SPECIFICATION

V1.1b3

Device Serialization and Version Information Rev 0.1

Omega Engineering Coding Standard Rev 1.2.0

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 4 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

2 Modbus Interface

The Modbus interface is fully described in MODBUS APPLICATION PROTOCOL SPECIFICATION

(V1.1b3).

The Modbus specification allows accessing to up 65535 internal ‘holding’ registers using register

READ, register WRITE and WRITE MULTIPLE commands. Each Modbus holding register is defined

as a 16 bit entity structured as BIG ENDIAN values (most significant byte always presented first).

The Platinum Modbus interface provides access to the internal database of the Platinum product

family by internally mapping Modbus holding registers to specific database items.

Modbus is structured using a MASTER-SLAVE topology, in which there is one MASTER device and

up to 255 slave devices. All transactions are initiated by the MASTER device.

Modbus slave devices are individually accessed using a one byte SLAVE address. The MASTER

device initiates a transaction by sending a request packet to a specific slave. The SLAVE device

processes the transaction and returns either response packet indicating success or failure.

Address 0 is reserved as a ‘broadcast’ address, in which all slave devices will accept and process the

transaction but will not send a response.

2.1 Modbus Functions

The Platinum Modbus interface supports the following Modbus FUNCTION requests.

Function

Code Mnemonic Description

0x03 Read Holding Register Reads one or more consecutive 16 bit holding registers

0x06 Write Single Register Writes a specific 16 bit holding register

0x07 Read Exception status Reads structured status information

0x08 Diagnostic Read/Write diagnostic information

0x10 Write Multiple Registers Write one or more consecutive 16 bit holding registers

0x0b Get Comm events Read communication event counters

2.2 Data Formats

Modbus holding registers are represented as 16 bit entities. The following encoding is used for

extended data items. Note that ‘byte 0’ will be the first byte received/transmitted.

For data types that can be represented in 16 bit (Boolean, byte, char, int16 and uint16) a single

register is used.

For data types that require 32 bits two consecutive registers are used. The lower number register will

represent the most significant data. The 2nd register represents the leas significant data.

2.2.1 Multiple Register Reads

When reading a dual register entity the lower order register should be used as the requested ‘holdiing

register’, with a request for a minimum of 2 registers. Internally the entire entity is read and data is

then built into a response packet.

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 5 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

The access can be split into 2 consecutive single register reads. When the lower (base) register is

accessed the entire 32 bit entity is read and the two most significant bytes are returned. The following

single register read must specify the next consecutive register address. The two least significant

bytes of the internally buffered data used in the response.

Attempts to access the two least significant bytes without first reading the two most significant bytes

will result in an error response.

2.2.2 Multiple Register Writes

When writing a dual register entity the lower order register should be used as the requested ‘holdiing

register’, with a request for minimum of 2 registers. The write data is internally buffered and

transferred to the database entry as a 32 bit value.

The access can be split into 2 consecutive single register writes. When the lower (base) register is

written the 16 bit entity is internally buffered BUT NO DATA TRANSFER IS MADE TO THE

DATABASE. The following single register write must specify the next consecutive register address.

The two least significant bytes of the write request are combined with the previous write data and the

entire 32 bit entity is written to the database.

Attempts to write the two least significant bytes without first writing the two most significant bytes will

result in an error response.

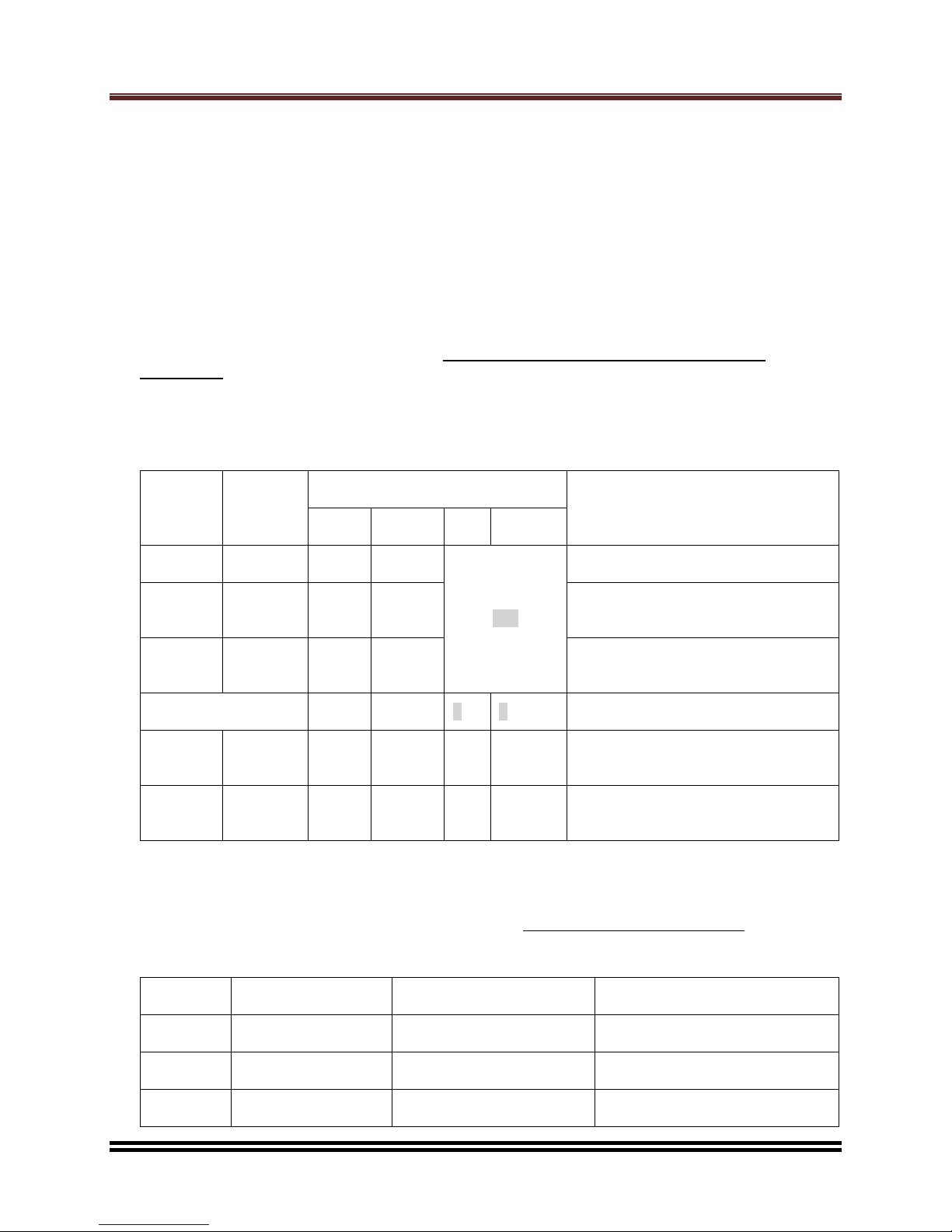

Data

Types Number

of

Registers

Byte Description

0 1 2 3

Boolean 1 -- LSB

N/A

Zero = OFF, non-zero = ON

Byte,

Char 1 -- LSB Entity contained in LSB of register,

Byte 0 ignored.

Int16,

uint16 1 MSB LSB Entity contained in MSB/LSB of

register.

0 1 2 3 (dual register data)

Int32,

uint32 2 MSB B-1 B-2 LSB Requires 2 consecutive registers,

MSB transferred first

float 2 Sign+

Exp Mantisa

MSB B-1 Mantisa

LSB IEEE formatted value contained in 2

consecutive register

2.2.3 Request Packet Sizes

Multiple consecutive registers may be accessed in a single transaction.

The Platinum Modbus interface imposes a maximum of 64 bytes for the total transaction. Allowing for

the required framing, addressing and integrity checks results in the following data size restrictions

using the READ and WRITE MULTIPLE functions.

Format Protocol Overhead Maximum Read data Maximum Write data

ASCII 16 12 Registers 12 Registers

RTU 8 23 Registers 23 Registers

TCP/IP 8 23 Registers 23 Registers

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 6 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

2.2.4 Modbus USB Support

The Modbus specification supports RS232 and RS485 serial data. For ASCII formatted packets a

USB virtual comm channel provides full support since the framing information is specified by unique

characters (SOF = ‘:’, EOF = CR/LF).

For RTU formatted packets the Modbus requires specific inter-frame character timing to determine

the framing of each transaction. This information is not available using a generic virtual comm

channel across USB, which will typically collect ‘serial’ data into 64 byte packets for transmission, as

determined by the USB end-point buffer size. The USB Modbus RTU interface relies on the USB

channel collecting data into 64 byte packets.

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 7 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

3 Platinum Modbus Register Assignments

All accesses to the Platinum database information are made through the Modbus registers.

Mnemonic entries marked with ‘*’ are identical to those used by the Platinum LOAD and SAVE file

formats.

Mnemonic entries marked with ‘**’ are identical to those used by the Platinum LOAD and SAVE file

formats but are referenced in LOAD and FILE data are made using meta characters (%).

Data types are:

R – single 16 bit register (may be Boolean, byte, char, int16 or uint16 data)

L – dual (32 bit) register (may be int32 or uint32 data)

F – IEEE Floating point value

All data is transferred using BIG ENDIAN formatting, where the most significant byte is transmitted

first.

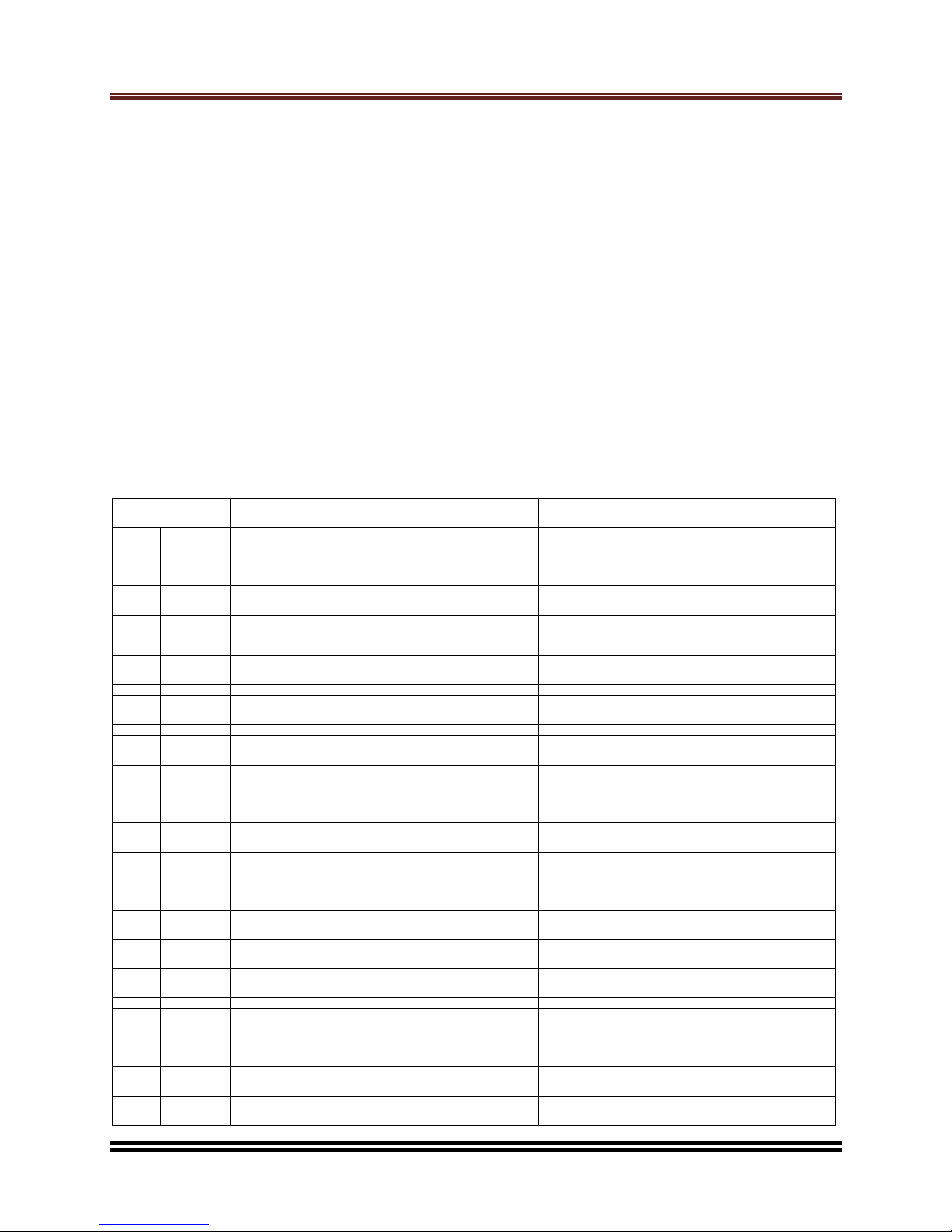

3.1 DasyLab Platinum Modbus Registers

The following is an abbreviated list of the more common registers within a Platinum controller. Refer

to the Platinum Modbus Interface document for a complete list.

Index

Mnemonic

Type

Description

512

0x0200

DEVICE_ID**

L

Device Identifier

514

0x0202

VERSION_NUMBER**

L

Device Version number (Hex Value)

516

0x0204

SYSTEM_STATUS

L

Enumerated Status value

528

0x0210

CURRENT_INPUT_VALUE

F

Measured process input value

532

0x0214

REMOTE_SETPOINT_VALUE

F

Measured auxiliary input value

542

0x021e

INPUT_DIGITAL

R

State of digital input pin

544

0x0220

CURRENT_SETPOINT_1

F

Current value of Setpoint 1

546

0x0222

CURRENT_SETPOINT_2

F

Current value of Setpoint 2

548

0x0224

CONTROL_SETPOINT

F

Setpoint used in PID calculations

550

0x0226

PEAK_VALUE

F

Maximum Value processed

552

0x0228

VALLEY_VALUE

F

Minimum Value processed

554

0x022a

PID_OUTPUT

F

PID Output level (0..100%)

556

0x022c

CURRENT_INPUT_VALID

R

Flag indicating process value is valid

557

0x022d

ALARM_STATE

R

558

0x022e

RAMP_SOAK_STATE

R

Enumerated value - R&S state

560

0x0230

OUTPUT_1_STATE

R

Flag indicating state of Output (0/1)

561

0x0231

OUTPUT_2_STATE

R

Flag indicating state of Output (0/1)

562

0x0232

OUTPUT_3_STATE

R

Flag indicating state of Output (0/1)

563

0x0233

OUTPUT_4_STATE

R

Flag indicating state of Output (0/1)

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 8 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

564

0x0234

OUTPUT_5_STATE

R

Flag indicating state of Output (0/1)

565

0x0235

OUTPUT_6_STATE

R

Flag indicating state of Output (0/1)

566

0x0236

OUTPUT_7_STATE

R

Flag indicating state of Output (0/1)

567

0x0237

OUTPUT_8_STATE

R

Flag indicating state of Output (0/1)

Control Functions

576

0x0240

RUN_MODE

R

Enumerated value – system running state

578

0x0242

LATCH_RESET

R

Write 1 to reset latched alarms

Alarm Configuration

1280

0x0500

ALARM_1_STATE

R

Alarm state (Bit 0)

1312

0x0520

ALARM_2_STATE

R

Excitation Voltage

1472

0x05c0

EXCITATION_VOLTAGE*

R

Enumerated Excitation Voltage

Annunciators

1504

0x05e0

DB_ANNUNCIATOR_1_STATE

R

Enumerated Annunciator State

1508

0x05e4

DB_ANNUNCIATOR_2_STATE

R

Enumerated Annunciator State

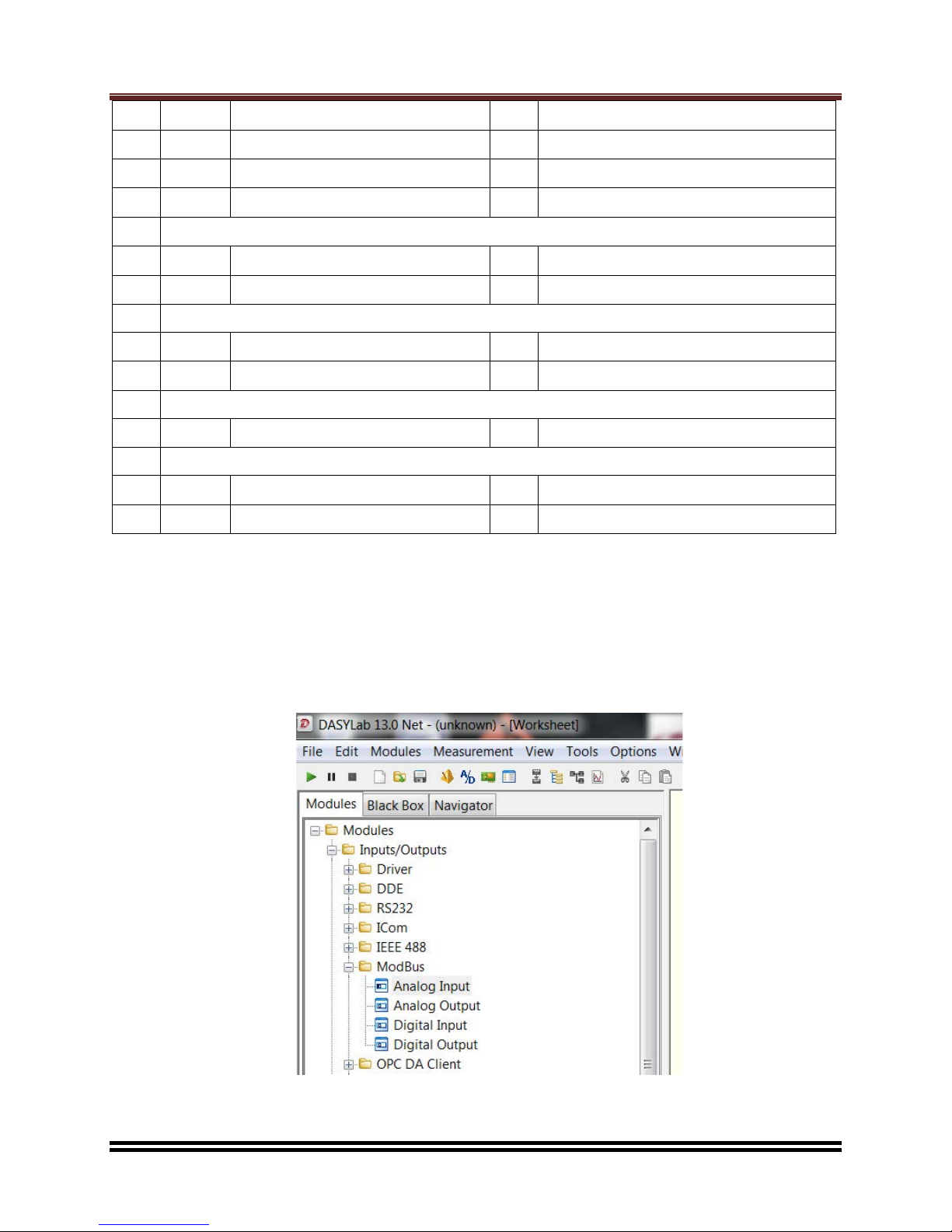

3.2 DasyLab Platinum Modbus Register Access

The following specifications have been verified with DasyLab version 13. Refer to DasyLab specific

documentation for further details.

The DasyLab software package allows the integration of Modbus compatible equipment through the

Modbus Input/Output Module. All Platinum registers are treated as Analog INPUT or Analog OUTPUT

values. Use Modbus Analog Input module to request data from Platinum and use Modbus Analog

Output module to send data to Platinum.

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 9 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

DasyLab supports Modbus RTU (serial) and Modbus TCP/IP (Ethernet). The Platinum controller

supports Modbus RTU on the USB interface, the RS232/RS485 interface (if installed) and Modbus

TCP/IP on the Ethernet interface (if installed). For the serial channel and USB connections the correct

COM channel must be selected and for serial channels the appropriate INTERFACE parameters

must be chosen. The Platinum unit must have its corresponding COM parameters set accordingly.

If using serial interface, DASYLab assumes the function of the master which sends commands to the

measurement devices or slaves. If using TCP/IP interface, DASYLab assumes the function of the

client which requests data from the server.

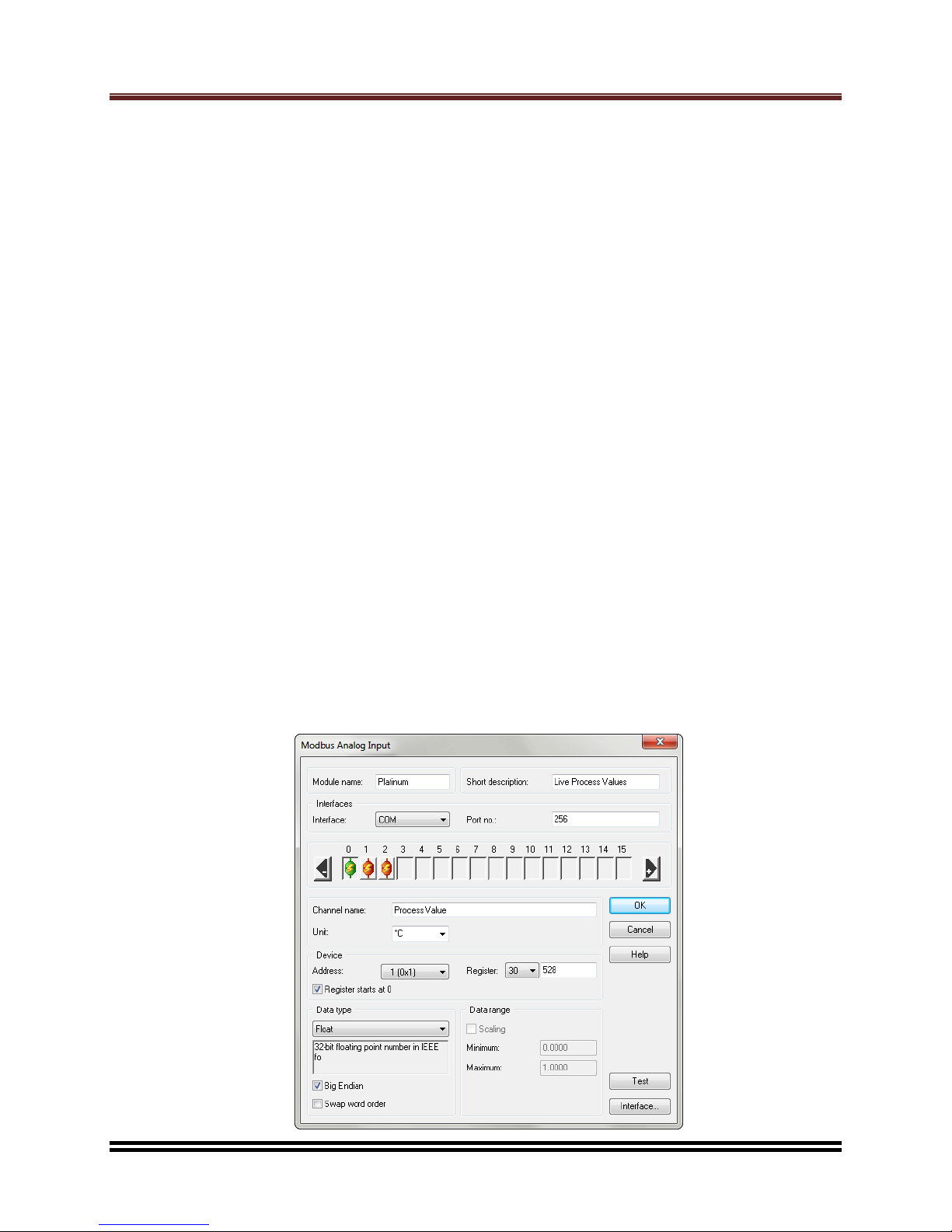

3.3 Example

3.3.1 Serial interface

In the example shown, the Platinum controller has been connected using a USB cable and appears

as ‘Virtual COM Port’ 256 within the Windows environment. For USB connections the serial interface

parameters are ignored. The Platinum /INIT/COMM/USB/PROT (front panel access menu) has been

set to MODBUS/RTU.

The Register Starts at 0 option should be checked. The ‘30’ Pull Down option may be ignored. All

values are accessed using BIG ENDIAN format and the ‘swap word order’ option should remain

unchecked.

When a Modbus Input/Output module is placed it is necessary to link the associated values with the

correct Platinum Modbus registers. DasyLab requires that register values are entered as decimal

values.

The following example shows how Modbus Analog Input module can be configured.

On Analog Input Channel 0, the channel is named as Process Value with Celsius temperature unit.

The register index is 528 (Register starts at 0) and the Register data type is Float (32 bit). The Device

Address is 0x01.

On Analog Input Channel 1 and 2 (not shown), Peak Value and Valley Value are configured with the

matching Register index and Data type that can be found in Platinum Series User Manual -

Modbus Interface document.

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 10 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

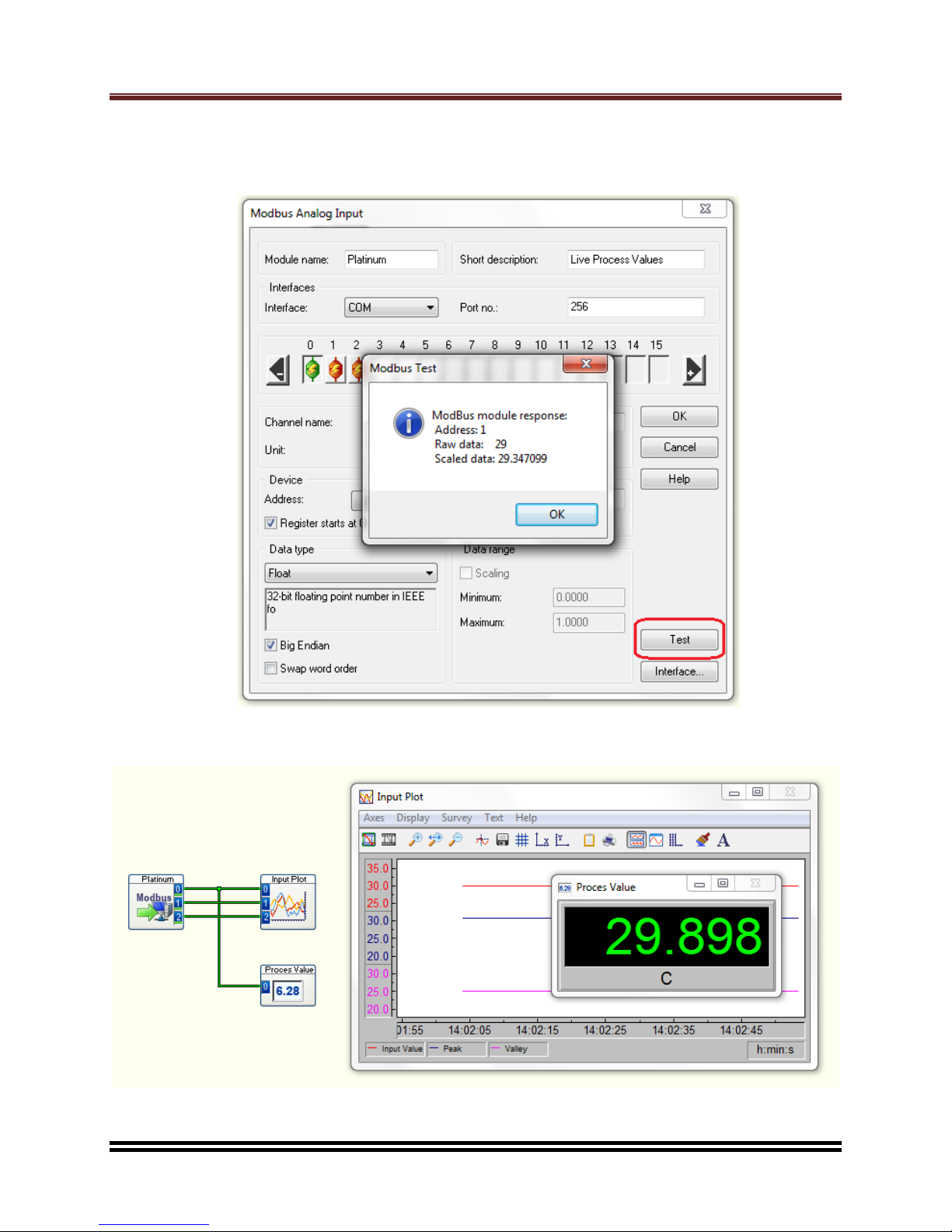

To quickly test communication to Platinum controller with Modbus Analog Input module, click on

“Test” and the data returned from the device is displayed in “Scaled data” as shown in the screenshot

below.

Once the Modbus Analog Input module is configured, it can then be connected to Display modules

such as Digital display or Chart Recorder module which can be found in Display category.

DasyLab Platinum Modbus Interface

Document Number Revision 1.0 Page 11 of 11

For Internal Use Only: This document contains confidential, proprietary information of Omega Engineering/Newport Electronics,

The Document may not be copied or reproduced without the prior, written permission of Omega Engineering/Newport Electronics

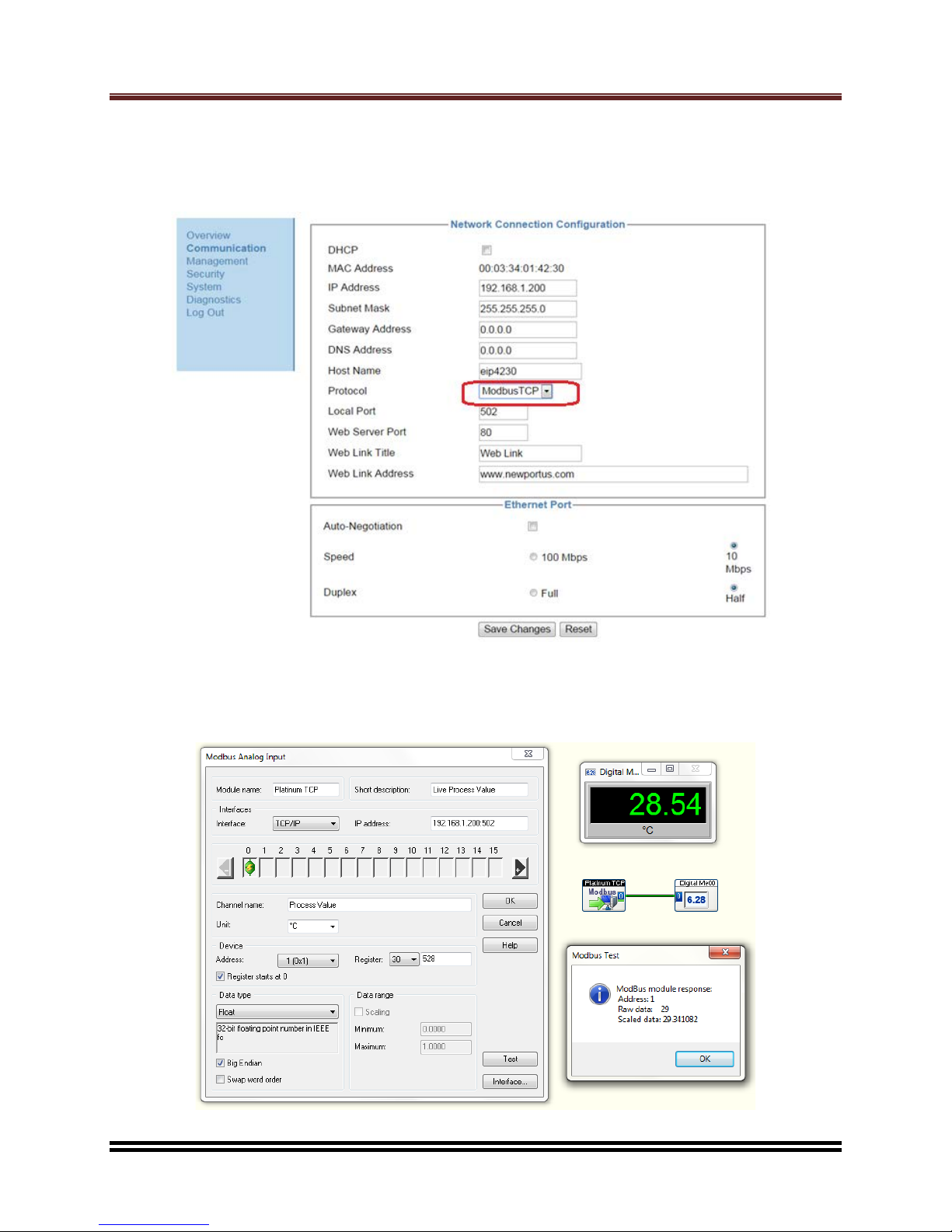

3.3.2 TCP/IP Interface

In this example, Modbus communication to Platinum is through TCP/IP interface. The TCP

communication protocol needs to be changed to ModbusTCP. This setting can be found on

Communication page/Network Connection Configuration section. The default device IP address of

Platinum’s TCP/IP interface is 192.168.1.200 and the default Modbus Local Port is 502.

Platinum Ethernet communication protocol also needs to be changed to Modbus/RTU. This setting is

accessible through the front panel menu /INIT/COMM/ETHN/PROT.

The setup procedure for DasyLab Modbus over TCP/TIP is similar to DasyLab Modbus Serial. The

following screenshot illustrates a typical configuration.

Warranty/Disclaimer

NEWPORT Electronics, Inc. warrants this unit to be free of defects in materials and workmanship for a period of one

(1) year from the date of purchase. In addition to NEWPORT’s standard warranty period, NEWPORT Electronics

will extend the warranty period for four (4) additional years if the warranty card enclosed with each instrument is

returned to NEWPORT.

If the unit should malfunction, it must be returned to the factory for evaluation. NEWPORT’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon

examination by NEWPORT, if the unit is found to be defective it will be repaired or replaced at no charge.

NEWPORT’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not

limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized

modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of being damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of NEWPORT’s control. Components which wear are

not warranted, including but not limited to contact points, fuses, and triacs.

NEWPORT is pleased to offer suggestions on the use of its various products. However, NEWPORT neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result from

the use of its products in accordance with information provided by NEWPORT, either verbal or written.

NEWPORT warrants only that the parts manufactured by it will be as specified and free of defects.

NEWPORT MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING

ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY

DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and

the total liability of NEWPORT with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon

which liability is based. In no event shall NEWPORT be liable for consequential, incidental or special

damages.

CONDITIONS: Equipment sold by NEWPORT is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical

application, or used on humans, or misused in any way,

NEWPORT assumes no responsibility as set forth in our basic

WARRANTY / DISCLAIMER language, and additionally purchaser will indemnify NEWPORT and hold NEWPORT

harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting NEWPORT:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS, consult NEWPORT

for current repair charges. Have the following

information available BEFORE contacting NEWPORT:

1. P.O. number to cover the COST of

the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems relative

to the product.

NEWPORT’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

NEWPORT is a registered trademark of NEWPORT Electronics, Inc. Patent pending.

© Copyright 2015 NEWPORT Electronics, Inc. All rights reserved. This document may not be copied, photo-

copied, reproduced, translated, or reduced to any electronic medium or machine-readable form,

in whole or in part, without prior written consent of NEWPORT Electronics, Inc.

Direct all warranty and repair requests/inquiries to the NEWPORT Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO NEWPORT, PURCHASER MUST OBTAIN AN AUTHORIZED

RETURN (AR) NUMBER FROM NEWPORT’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package

and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in

transit.

Return Requests/Inquiries

M5548/N/1215

Table of contents

Other Newport Recording Equipment manuals