Newtech SF Series User manual

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected]

SF SERIES CNG COMPRESSOR

MODEL HF-5MH

5 Nm3/Hour Displacement

OPERATION MANUAL

Email: synew[email protected] Website: www.synewtech.com www.chinagascompressor.cn 1

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 2

Content

1.General Description...................................................................................................................................... 3

2.Main technical parameters........................................................................................................................... 3

3.Structural principle....................................................................................................................................... 4

3.1 Main structure............................................................................................................................................ 4

3.2 Compressor set........................................................................................................................................... 4

3.3 Pressure gauge and safety valve ............................................................................................................... 4

4.Installation and operation............................................................................................................................ 4

4.1 Installation.................................................................................................................................................. 4

4.2 Preparation before startup........................................................................................................................ 4

4.3 Trial run...................................................................................................................................................... 5

4.4 Bottle-filling operation .............................................................................................................................. 5

5.Daily maintenance and service .................................................................................................................... 5

5.1 Oil level inspection and oil change ........................................................................................................... 5

5.2 Discharge filtration.................................................................................................................................... 5

5.3 Exhaust emission........................................................................................................................................ 5

6.Trouble shooting............................................................................................................................................ 6

7. Electric wiring and diagram....................................................................................................................... 7

8. Operating instructions................................................................................................................................. 8

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 3

1.General Description

CNG Compressor Model HF-5MH is a natural gas pressuring device and is mainly used to compress and fill the

family-use natural gas to cars, i.e. pressuring the family-use micro-pressured natural gas to

200bar(2900PSI)/250bar(3600PSI) with the gas-filling time for 2 hours each time. It is small in dimensions, light in

weight, superior in performance, safe and reliable in operation, durable and economic in application.

Model explanation

Compressor model Sector, one phase

Cooling model Air-cooled by fan

Displacement 5Nm3/h

Intake pressure 0.017-0.035 bar (0.25-0.5PSI)

Discharge pressure 200bar(2900PSI)/250bar(3600PSI)

2.Main technical parameters

1 Volumetric

displacement 5Nm3/h

2 Intake pressure 0.017-0.035bar (0.25-0.5PSI)

3 Discharge pressure 200bar(2900PSI)/250bar(3600PSI)

4 Compression medium natural gas

(Not containing sulfur, water and solid particles of more than 20μm)

5 Compression stage NO. 4

6 Gas feeding

temperature ambient temperature+10℃

7 Cooling model air-cooled by fan

8 Motor power 4 KW

9 Voltage 220V/240V,50Hz/60Hz ,three phase

10 Frequency 50/60 HZ

11 Noise level 55 db

12 Weight 125 Kg

13 Recommend oil SLG150(ESSO)、GCS150(BP)、P125(Elf)

14 Overall dimensions 900 x 600 x600

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 4

3.Structural principle

3.1 Main structure

This compressor is mainly composed of compressor set, explosion-proof motor, control box, cooling fan, oil/gas separator,

pipeline, safety components and frame, etc. At first, the gas runs into the 1st stage cylinder through the gas intake pipe. After

the 1st stage compression, the gas runs to the 1st stage cooler and after cooling runs to the 2nd stage cylinder. Thus, after

passing through the 3rd stage cylinder and 4th stage cylinder, the pressure of natural gas will be raised to 20MPa. Finally,

the compressed natural gas is discharged through the high pressure de-oil filter where the excessive residual oil will be

filtered out and fed through the high-pressure hose to fill cars. The compressor is integrally explosion-proof and has the

discharge pressure protection. If filling to the setting pressure, the compressor will automatically stop filling. In addition, it

fits a safety valve to prevent overpressure.

3.2 Compressor set

The compressor set is mainly composed of crankcase, crankshaft, cylinder, piston, gas intake and discharge valves, etc. The

crankcase is made of aluminum alloy. The needle roller bearings are installed both on the front and rear end covers of the

crankcase so as to support the rotation of the crankshaft. Meanwhile, the front and rear end covers of the crankcase are

sealed with the O-rings. The movement of the crankshaft and connecting rod fully depends on the operation of the needle

bearing with the protective support. All the connecting rods are installed on the crankshaft with the special angles. The 1st

stage and 2nd stage pistons are all made from aluminum and equipped with piston rings. The 3rd stage piston is made from

ferroalloy and with the special piston rings. The 4th stage piston is made from reliable neutral steel without elastic rings. The

cylinder with radiator plates is provided in each stage.

3.3 Pressure gauge and safety valve

Each stage of pressure gauge installs on the compressor in order to check whether there is a trouble in compressor, according

to whether pressure readings of each stage are in setting values or not. The safety valve installs at the rear of each stage

cylinder to take the overpressure protection. The preset opening pressure of safety valve is 1.1times to rated pressure. The

safety valve should be installed on the compressor in advance to avoid overpressure due to any compressor troubles. As soon

as the safety valve’s pressure reaches to the preset value, the valve will open automatically. Please don’t adjust the safety

valve, otherwise, the serious damage or danger will be resulted from, and if so, our warranty for maintenance will be

cancelled. Caution: (the opening pressure of the safety valve can’t be adjusted higher at random).

4.Installation and operation

4.1 Installation

The compressor should be placed at clean and good ventilation site where also supplies the qualified power. The gradient

between compressor and ground should no more than 5°. There must be enough space around the compressor so that it will

be convenient to thermal radiation and operation.

4.2 Preparation before startup

Fill the crankcase with the recommend compressor lubricant and check that the oil level should be above the upper line of

oil leveler. Note: it will be unfavorable if the oil level is too high or too low. If the oil level is too high, the oil consumption

will be larger and the carbon will be accumulated in the gas valve. If the oil is too low, the lubrication must be poor, even the

compressor will be damaged.

In accordance with the requirements in the electrical wiring diagram, the wire should be connected correctly with reliable

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 5

grounding. Check the tension of the V-belt and the connection of all parts. Rotate the host fan manually to check whether it

is normal or not. Start the compressor to check the rotating direction. If the cooling airflow from the fan blows toward the

cylinder, it indicates the rotating direction is right.

4.3 Trial run

Before starting the compressor, the drainage valve should be opened to carry out the no-load start. After startup, it needs a

short-time no-load running. At the same time, the gas-filling bottle and compressor should be connected by the high-pressure

hose. After the stable operation, the drainage valve should be closed and the compressor will begin to supercharge. After

reaching the rated pressure value, the pressure controller will activate so that the compressor will be stopped automatically.

The compressor can also be stopped manually. When the compressor is stopped manually, the drainage valve should be

opened at first, then press the red button to cut off power supply. Each gas-filling time should be controlled within 3-6 hours.

If such time is too long, the compressor maybe shutdown due to high temperature. After finishing the each gas-filling

operation, all the drainage valves should be opened to keep all the readings on pressure gauges of each stage at zero.

4.4 Bottle-filling operation

The verified and qualified high-pressure steel bottles should be selected and their max gas-filling pressure shouldn’t be

larger than the safety working pressure of the steel bottle. Check and make sure that there is no scratch or damage in the

high-pressure gas-filling hose. The high-pressure gas-filing hose should be installed on the bottle needed fill gas. Open the

drainage valve and start the compressor at no-load. After the running is stable, close the drainage valve and begin to fill the

bottle. When the gas-filling pressure reaches the preset value, the drainage valve should be opened to keep the compressor at

an unloading run. The pressure within all the pipelines should be also relieved. (After the bottle filling each time, opened

drainage valve once to discharge high pressure gas and water in the pipeline)

5.Daily maintenance and service

5.1 Oil level inspection and oil change

Before starting the compressor every time, check the oil level in the crankcase to make sure the oil level between the two

marks of the oil leveler. Oil in compressor should be renewed once after 2000 hours running per. If the compressor is

stopped for more than 6 months, the oil should also be renewed in time before using it again. The recommend oil for the

compressor is SLG150 (ESSO), GCS150 (BP), and P125 (Elf). Don’t mix different brands of lube oils.

5.2 Discharge filtration

In order to remove out the oil content in natural gas resulted from the lubrication, the de-oil filter is equipped in the 4th

stage, and the filter element should be replaced after 8000 working hours or 1 year working.

5.3 Exhaust emission

After the compressor stops, the drainage valve should be opened in time to relief the high-pressure gas and exhaust the

oily dirty filtered out.

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 6

6.Trouble shooting

Trouble Possible cause Solution

The compressor cannot be started Power cutoff 1.Check the power supply

2.Replace the fuse in circuit-breaker

The motor works but the compressor set

doesn’t work Too high load or belt loose 1.Make sure that the discharge gas should be emptied in starting without pressure

2.Tight the bell

Too high discharge pressure in 1st stage The 2nd stage gas valve damaged Check the 2nd stage gas valve

Too low discharge pressure in 1st stage No natural gas enters

The 1st stage gas valve damaged

The 1st stage discharge pipe leaked

1.Without any intake pressure

2.Check the 1st stage gas valve

3.Check and fasten it

Too high discharge pressure in 2nd stage The 3rd stage gas valve damaged Check the 3rd gas valve

Too low discharge pressure in 2nd stage Low discharge pressure in the 1st stage

The 2nd stage gas valve damaged

The 2nd stage discharge pipe leaked

1.Check to find the reason caused low discharge pressure in the 1st stage

2.Check the 2nd stage gas valve

3.Check and fasten it

Too high discharge pressure in 3rd stage The 4th stage gas valve damaged Check the 4th stage gas valve

Too low discharge pressure in 3rd stage Low stage discharge pressure in the 2nd

The 3rd stage gas valve damaged

The 3rd stage discharge pipe leaked

1.Check to find the reason caused the low discharge pressure in the 2nd stage

2.Check the 3rd stage gas valve

3. Check and fasten it

Too high discharge pressure in 4th stage Too high setting value in pressure controller

The safety valve doesn’t work 1.Reset it

2.Check the safety valve

The shutdown pressure is reached but the

compressor can not stop automatically. Failure in the circuit of pressure controller

The pressure controller damaged 1.Check the controlling circuit

2.Replace the pressure controller

The compressor is overheated High ambient temperature

Too much dust on the surface of compressor 1.Improve environment

2.Clean and remove the dust

Descent in discharge capacity

The pipeline leaked

Low pressure in gas intake

The gas valve damaged

The piston ring abraded

1.Check to find the leakage point

2.Increase the gas intake pressure

3.Replace the gas valve

4.Replace the piston ring

Too much oil in discharge Too much oil in CNG gas 1.Drain it in time

2.Replace the filter element

Abnormal noise appears in the compressor The gas valve damaged

The moving parts abraded 1.Check and replace the gas valve if necessary

2.Replace the damaged moving parts

The piston doesn’t move in the cylinder The crankcase is short of oil

Brand of compressor oil is wrong

High ambient temperature

1.Fill the oil

2.Change the oil

3.Improve environment

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected]

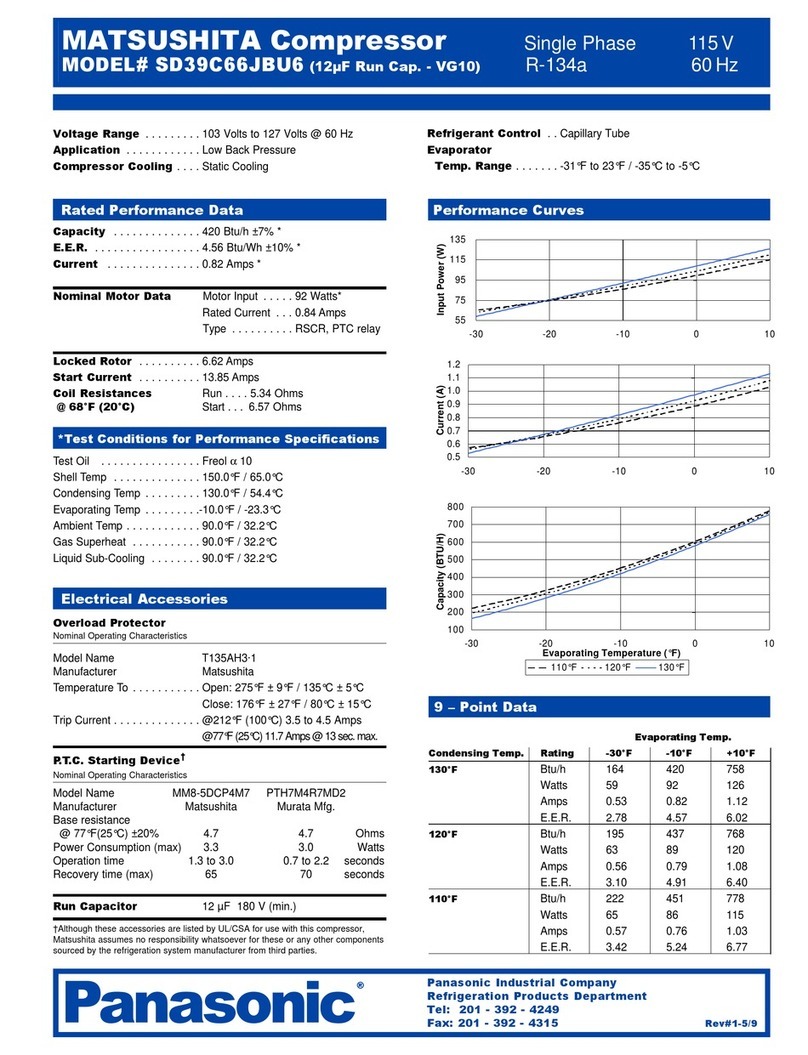

7. Electric wiring and diagram

Email: synew[email protected] Website: www.synewtech.com www.chinagascompressor.cn 7

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected] Email: [email protected] Website: www.synewtech.com www.chinagascompressor.cn 8

8. Operating instructions

8.1 Before starting, check the oil level in the crankcase, and the oil level is between the upper and lower marks of the oil

leveler.

8.2 The power wire should be connected correctly.

8.3 Before starting the compressor, open the drainage valve to deliver the high-pressure gas so as to start the compressor at

light load.

8.4 Connect the intake hose.

8.5 Connect the gas-filled hose

8.6 Press the green button to start the compressor.

8.7 When the gas-filling operation stops automatically, press down the red button to cut off power supply.

8.8 Open the drainage valve to empty the high pressure gas in the system to keep the readings of pressure gauges in each

stage at zero.

8.9 Dismantle the gas-filling hose.

8.10 When stopping the compressor manually: press down the red button to cut off the power supply. Open the drainage

valve to empty the high pressure gas in the system to keep the readings of pressure gauges in each stage at zero.

Notes!

A. When dismantling the hose or maintenance the compressor, it is necessary to keep

the readings of pressure gauges in every stage at zero.

B. When the compressor is stopped, the user’s intake valve should be closed.

C. The electrical voltage is 220V/240V,frequency is 50Hz/60Hz, one phase

D. Intake pressure is 0.017-0.035bar (0.25-0.5PSI)

E. Recommend oil is SLG150(ESSO)、GCS150(BP)、P125(Elf)

F. Fix the grounding tightly.

G. When carrying the operation and maintenance, make sure that there isn’t any

possible spark or high temperature on the site.

Shenyang Newtech International Co., Ltd.

ADD.: Rm C-8-2 No.168 Shifu Road, Shenyang 110014, China

Adam'mobile No.: 0086 13804042544 TEL: 0086 24 22532086 FAX: 0086 24 22532084 Skype: adamhuang08

MSN: [email protected]

HOSTAPPEARANCE

Email: synew[email protected] Website: www.synewtech.com www.chinagascompressor.cn 9

This manual suits for next models

1

Table of contents

Popular Air Compressor manuals by other brands

California Air Tools

California Air Tools 10020SPCAD owner's manual

Draper

Draper 59085 instructions

Craftsman

Craftsman 921.164780 owner's manual

Scheppach

Scheppach HC26 Translation of original instruction manual

Sealey

Sealey RE230UK instructions

California Air Tools

California Air Tools CR20300 owner's manual